ANSI C50.13-1989: Cylindrical-Rotor Synchronous Generators Standard

advertisement

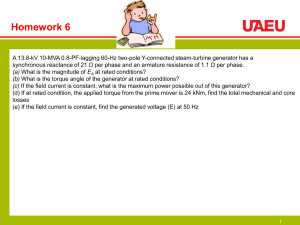

m m n -A American National Standards Institute 1430 Broadway New York, New York ~~ ~~~~ ~~ ~~~~ COPYRIGHT American National Standards Institute Licensed by Information Handling Services ~. 1O018 ANSI@ C50.13-1989 Revision of ANSI C50.13-1977 American National Standard for Rotating Electrical Machinery- Cylindrical-Rotor Synchronous Generators Secretariat National Electrical Manufacturers Association Approved January 23,1989 American National Standards Institute, Inc COPYRIGHT American National Standards Institute Licensed by Information Handling Services A N S I C50.13 87 0 7 2 i 1 5 0 OOOb1838 3 E ’ of an American National Standard requires verification by ANSI that the reAmerican Approval quirements for due process, consensus, and other criteria forapproval have been met by National the standards developer. Standard Consensus is established when, in the judgment of theANSI Board of Standards Review, substantial agreement has been reached by directly and materially affected interests. Substantial agreement means much more than asimple majority, but not necessarily unanimity. Consensus requires that all views and objections beconsidered, and that a concerted effort be made toward their resolution. The use of American National Standardsis completely voluntary; their existence does not in any respect preclude anyone, whether he hasapproved the standards or not, from manufacturing, marketing, purchasing, or using products, processes, or procedures not conforming to the standards. The American National Standards Institute does notdevelop standards and will in no circumstances give an interpretation of anyAmerican National Standard.Moreover, no person shall have theright or authority toissue an interpretation ofan American National Standard in the name-of theAmerican National Standards Institute. Requests for interpretations should be addressed to the secretariat or sponsorwhose name appears on the title page of this standard. CAUTION NOTICE: This American National Standard may be revised or withdrawn at any time. The proceduresof the American National Standards Institute require that action be taken periodically to reaffirm, revise, or withdraw this standard.Purchasers of American National Standardsmay receive current information on all standards by calling or writing the American National Standards Institute. Published by American National Standards Institute 1430 Broadway, New York, NewYork 10018 No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission of the publisher. Printed in the United Statesof America AlM889115 COPYRIGHT American National Standards Institute Licensed by Information Handling Services Foreword (This Foreword is not part of American National StandardC50.13-1989.) This standard is a revision of American National Standard Requirements for Cylindrical-Rotor Synchronous Generators,ANSI C50.13-1977. The major change in the 1989 version of this standard is the additionof a subsection dealing with the possible effects of system disturbances on generatorcomponents. It is the intent of the Accredited Standards Committee on RotatingElectrical Machinery, C50, to revise and update this standard at regular intervals. Suggestions for improvement of this standard will be welcome.They shouldbe sent to the National Electrical Manufacturers Association, 2101 L Street, NW, Suite 300, Washington, DC 20037. This standardwas processed and approved for submittal to ANSI by Accredited Standards Committee on Rotating Electrical Machinery, C50. Committee approval of the standarddoes not necessarily imply that all committee members voted for its approval. At the time it approved this standard, theC50 Committee had the following members: Paul I. Nippes, Chair James D. Raba, Secretary Organization Represented Name of Representative .............................. D. C. Azbill ....................... Stanley C. Houk ......................... C. James Erickson ................... Gerald Schmid ...................... David L. Gebhart (Chair) American Petroleum Institute Association of Iron and Steel Engineers Chemical Manufacturers Association Crane Manufacturers Association of America Electrical Apparatus Service Association Electric Light and Power Group ............................ ................................. ...................................... .......................................... FactoryMutualSystems Hydraulic Institute Institute of Electrical and Electronics Engineers National Electrical ContractorsAssociation National Electrical ManufacturersAssociation .................... ............... . ............................ .................................... .............................. Society of Automotive Engineers Technical Associationof the Pulp and Paper Industry U S . Department of the Navy Individual Members Lome W. Brotherton Joseph P. Fifzgerald Bjorn M. Kaupang Paul 1. Nippes Joseph E. Shea J. C. White Perry A. Weyant t COPYRIGHT American National Standards Institute Licensed by Information Handling Services Wilson A. Giles Preben Christensen (Alt) Joseph J. Wilkes (Chair) D. E. Loberg Arnold R. Roby John S. Swavel, J r Glen H. Griffin (Alt) J. L. Koepfinger (Alt) David E. Soffrin (Alt) Demitrious M. Karydas Robert G. Crawford S. B. Kuznefsov (Chair) Brian E. B. Gott M. H. Hesse Peter R. Landrieu William R. McCown James A. Oliver Nirmal K. Ghai (Alt) Charles J. Hart Sohn Keinz (Chair) Joseph E. Martin Dale Rawlings Walter G. Stiffler John Krueger Robert A. Richardson Harold J. Blakney Reagan Clark ~- " A N S I C 5 0 - L 3 87 072Lt350 0004bYO L Subcommittee C50.1 on Synchronous Machines, which developed this standard, had the following members: Joseph J. Wilkes, Chair James Raba, Secretary COPYRIGHT American National Standards Institute Licensed by Information Handling Services Charles J. Czech Joseph P. Fitzgerald Nirmal K. Ghai James J. Gibney, I11 Peter B. Goetz Brian E. B. Gott Glen H. Griffin Howard E. Jordan P. R. Landrieu J. M. Mayher William R. McCown James R. Michalec James A. Oliver Arnold R. Roby Perry A. Weyant =3 A N S I C50.33 8 9 W 072Ll350 0004643 3 Contents PAGE SECI'ION 1. scope ........................................................................................................................ . 3. 2 4 Referenced American National Standards ............................................................... 7 7 Classification ............................................................................................................ 3.1StatorTypes .................................................................................................... 3.2 RotorTypes .................................................................................................... 7 7 7 . Usual Service Conditions ......................................................................................... 4.1 VariationfromRatedVoltage 4.2VariationfromRatedHydrogenPressure ...................................................... 4.3VariationfromRatedFrequency .................................................................... 7 7 7 7 . Rating ....................................................................................................................... 5.1 Outputrating ................................................................................................... 5.2 Capability ....................................................................................................... 5.3 Voltage Ratings ............................................................................................. 7 7 8 8 . Temperature Rise ..................................................................................................... 6.1 Air-Cooled Machines ..................................................................................... 6.2Hydrogen-CooledMachines ........................................................................... 8 8 9 . Requirements for Abnormal Conditions .................................................................. 7.1 Armature Winding Short-Time Thermal Requirements ................................. 7.2 Field Winding Short-Time Thermal Requirements ........................................ 7.3 Rotor Short-Time Thermal Requirements for Unbalanced Faults 7.4MechanicalRequirementsforShortCircuits ................................................. 7.5ContinuousUnbalanceRequirements ............................................................ 7.6RequirementsforSystemDisturbances ......................................................... 11 11 Efficiency ................................................................................................................. 11 Overspeed ................................................................................................................ 11 5 6 7 . 9. 8 ........................................................................ 9 9 9 ................. 9 11 10. Telephone Influence Factor..................................................................................... 11 11 12 12 12 . 12. Direction of Rotation ............................................................................................... 12 13. Nameplate Marking.................................................................................................. 12 14. Performance Specification Forms............................................................................ 12 10.1Balanced ......................................................................................................... 10.2ResidualComponent ...................................................................................... 10.3SingleFrequency ............................................................................................ 10.4Other ............................................................................................................... 11 Test ........................................................................................................................... Tables Table 1 Limiting Observable Temperature Riseof Air.Cooled. Cylindrical-RotorGenerators Table 2 Limiting Observable Temperature and Temperature Rise of Hydrogen.Cooled. Cylindrical-Rotor Generators in Degrees Celsius.... Table 3 1960 Single-Frequency TF,Weighting Factors Table 4 Tests on Cylindrical-Rotor Synchronous Generators ............................. .................................................................. ..................................... COPYRIGHT American National Standards Institute Licensed by Information Handling Services 12 8 10 13 13 SECTION PAGE Figures Figure 1 Performance Specification Form for Steam-Turbine-Driven, HydraulicTurbine-Driven,and Motor-Driven, Air-Cooled, Cylindrical-Rotor SynchronousGenerators ......................................................................... 14 Figure 2 Performance Specification Form for Steam-Turbine-Driven, Hydrogen-Cooled, Cylindrical-Rotor Synchronous Generators............. 15 COPYRIGHT American National Standards Institute Licensed by Information Handling Services American National Standard for Rotating Electrical Machinery - Cylindrical-Rotor Synchronous Generators 1. Scope 4. Usual Service Conditions The requirements in this standard apply to 60-hertz cylindrical-rotor synchronous generators, except those covered in ANSI C50.14-1977. All requirements and definitions, except as specifically covered in this standard, shall bein accordance with ANSI C50.10-1977. The usual service conditions uponwhich the requirements for cylindrical-rotor synchronous generators are based are given in ANSI C50.101977. In addition to these usual service conditions, the following requirements shall be met. 2. Referenced American National Standards This standardis intended for use in conjunction with the following American National Standards. When these referenced standards aresuperseded by a revision approved by the American National Standards Institute, Inc, the revision shall apply: ANSI C50.10-1977, General Requirements for Synchronous Machines ANSI C50.14-1977 (R1989), Requirements for Combustion Gas Turbine Driven Synchronous Generators ANSIIIEEE 115-1983, Test Procedures for Synchronous Machines 4.1 Variation from Rated Voltage. Generators shall operate successfully at ratedkilovolt-amperes (kVA) frequency, and power factor at any voltage not more than 5 percent above or below rated voltage, but not necessarily in accordance with the standards of performance established for operation at rated voltage. 4.2 Variation from Rated Hydrogen Pressure. Capabilities at hydrogen pressures other than rated pressure shall be available from the manufacturer. The capabilities at hydrogen pressures other than rated pressure shall be determined such that the hottest-spot temperature of the winding that is limiting at the-specified capability is essentially the same as that at rating: 4.3 Variation from Rated Frequency. Capabilities at frequencies other than rated frequency shall be available from the manufacturer. 3. Classification A cylindrical-rotor synchronous generatoris classified by one of the stator and one of the rotor types. 3.1 Stator Types.' The typeof stator is defined by the method of armature winding cooling, either directly or indirectly. 3.2 Rotor Types.' The type of rotor is defined by the method of field winding cooling, either directly or indirectly. [Refer to ANSI C50.10-1977 for definitions. 5. Rating 5.1 Output Rating. The outputrating shall be expressed in kilovolt-amperes available at the terminals at a specified speed, frequency, voltage, and power factor. The outputrating of hydrogen-cooled generators shall be at the maximum hydrogen pressure imposed on the generator enclosure. The output rating, specified temperatures, and observable temperature rises shall be based only on rated hyd- 7 COPYRIGHT American National Standards Institute Licensed by Information Handling Services AMERICAN NATIONAL STANDARD C50.13-1989 Table 1 Limiting Observable Temperature Rise of &-Cooled, Cylindrical-Rotor Generators Item (1) Method of Temperature Temperature Rise Determination Machine Part Armature winding (a) below 10 O00 kVA 1563 (b) kVA and less (c) 1564 kVA to 10 O00 kVA ( 1 ) 7000 V and less (2) over 7000 V O00 kVA and above 10(d) ClassB resistance 125 105 embedded detector* 80 90 embedded 135detector* 110 embedded detector* embedded detector* 85 80 125 85 ("C) ClassH 140115 105 90t ll0t 90 110 (2) Field winding resistance 125 (3) Cores and mechanical parts in contact with or adjacent to insulation detector or thermometer 70 (4 1 Collector rings thermometer 85 85 85 (5) Miscellaneous parts (such as brushholders,brushes, etc) may attain such temperatures as will not injure the machine in any respect ~~ 105 70t ClassF ~ *Embedded detectors are located within the slot of the machine and can be either resistance elements or thermocouples. Embedded detector temperatures shall be used to demonstrate conformity with the standard for generators so equipped. +These values are f o r insulation systems with thermosetting materials. For thermoplastic materials the equivalent temperatures shall be 6OoC for Class B; Class F and Class H do not apply. rogen pressure. The preferred maximum hydrogen pressures are: ( I ) For indirectly cooled generators: 30 psig (pounds per square inch direct-connected with type gage) exciters. (2) For directly cooled generators: 30,45, 60, or 75 psig 5.2 Capability. The capability of a synchronous generator is the highest acceptable continuous loading (kVA) through the full range of power factor at a specified condition. 5.3 Voltage Ratings 5.3.1 Armature. Armature voltage ratings shall be: 240 * 480 600" 2 400* 4 160 4 goo* 6 900* 13 800 *These ratings are recognized for use on established systems, but not preferred for new undertakings. Generator voltages above 13 800 volts are desirable in large-capacity generators that usually are connected directly to their own step-up transformers, 5.3.2 Excitation System Voltage Ratings. The preferred excitation system voltage ratings for field 8 COPYRIGHT American National Standards Institute Licensed by Information Handling Services windings are 62.5,125,250,375, 500, 625, and 750 direct voltage. These excitation system voltages do not apply to generators of the brushless : ! 6. Temperature Rise I 6.1 Air-Cooled Machines. The observable tempera- ture rise of each of the various parts of the machine above the temperature of the cooling air, referred to as the cold air temperature, shall not exceed the values given in Table 1 when the machine is operated at output rating conditions. The temperature rises in Table 1 are based on a maximum cold air temperature of 40"C . For open machines and for parts of enclosed machines that are cooled by open ventilation passages, that is, collector rings, the cold air temperature is the average temperature of the external air as it enters the ventilating openings of the machine. For totally enclosed machines, the cold air temperature is the average temperature of the air leaving the cooler or coolers. The cold air temperature at rating, when the coolers are supplied with I o . i AMERICANNATIONALSTANDARD C50.13-1989 NOTES: water of the rated amount and temperature,is usu(1) The permissible armature currents attimes up to 120 ally specified as40°C. seconds, based upon the same incrementof heat storage as For machines that operate under prevailing defined in7.1, will be barometric pressure and are designed not to exceed 60 120 10 30 Time (seconds) standard temperature rise at altitudes from 3300 226 154 130 116 Armature current (percent) feet (1000 meters) to 13 O00 feet (4000 meters), the (2) It is recognized that armature temperatureswill exceed temperature rises, 2s checked by test at low altirated load values under these conditions and therefore, the tude, shall be less than those listed in Table 1 by 1 machine construction is based upon the assumption that the number of such operations at armature currents to the limits percent of the specified temperature rise for each specified in Note (1) will occur not more than times 2 per year. 330 feet (100 meters) of altitude inexcess of 3300 feet (1000 meters). 7.2 Field Winding Short-Time Thermal RequireWhen designing to meet the temperature rises of ments. The generator field winding shall be capable Table 1, it is intended that the hottest-spot temperof operating at a field voltage of 125 percent of ature should not exceed 130°C for Class B, 155OC rated-load field voltage for at least 1 minute startfor Class F, and 18OOC for Class H insulation ing from stabilized temperatures at rated systems. conditions. For machines of 10 O00 kVA and above, the relationship between hottest-spot temperature and NOTES: (I) The permissible field voltagesat times up to 120 seconds, the temperatures as specified in Table 1 for the based upon the sameincrement of heat storageas defined in armature and field windings shall be demonstrable 7.2, will be by direct measurement or recognized methods of Time 10 30 60 120 calculation correlated to special factory tests on a (seconds) Voltage Field (percent) 208 146 112125 basically similar machine. 6.2 Hydrogen-Cooled Machines. The observable temperature rise of each of the various parts of the machine above the average temperature of the cold coolant, when tested in accordance with the rating, shall not exceed the values given in Table 2. The temperature of the cold coolant shall be the average temperature of the coolant leaving the coolers when tested in accordance with the rating. The cold coolant temperatureshall not exceed the appropriate value for the rated hydrogen pressure as listed in Table 2. Temperatures shall be determined by the methods specified in Table 2. The hottest-spot temperature shall not exceed 130" C for Class B insulation systems. The relationship between hottest-spot temperature and the temperatures as specified in Table 2, for the armatureand field windings, shall be demonstrable by direct measurement or recognized methods of calculation correlated to special factory tests on a basically similar machine. (2) It is recognized that field winding temperatures under these conditions will exceed rated-load values and, therefore, the machine construction is based upon the assumption that the number of such operationsat fiekd voltages to the limits specified in Note(1) will occur not more than2 times per year. 7.3 Rotor Short-Time Thermal Requirements for Unbalanced Faults.The generator rotorshall be capable of withstanding, without injury, unbalanced short circuits or other unbalanced conditions on the system or at the armature terminals resulting in values of h 2 t as listed in the following table: Type of Cylindrical-Rotor Synchronous Generator Terms cooled Indirectly Directly cooled MVA up 800 800 MVA to 1600 MVA to Minimum Generator Short-Time Capability Expressed in of Z?r* 30 10 lO-(O.00625)(MVA-800) *See note in this subsection, 7. Requirements for Abnormal Conditions 7.1 Armature Winding Short-Time Thermal Requirements. The generator armatureshalI be capable of operating at 130 percent of rated armature current for atleast 1 minute starting from stabilized temperatures at rated conditions. h 2 t in the preceding table is the integrated product of the squareof the generatornegative-phasesequence current (Tz),expressed in per unit stator current at rated kilovolt-amperes and duration of the fault inseconds (t). The generator unbalanced fault capability expressed in terms of I2t applies for times up to 120 seconds, based on a constant increment of heat storage andnegligible heat dissipation. 9 ~~ COPYRIGHT American National Standards Institute Licensed by Information Handling Services ~ .~ AMERICAN NATIONAL STANDARDC50.13-1989 Table 2 Limiting Observable Temperature and Temperature Rise of Hydrogen-Cooled,Cylindrical-RotorGenerators in Degrees Celsius Item (11 Machine Part Indirectly Cooled Windings (rated a t 30 psig) Method of Type Temperature Class B*,$ Determination Temperature of detector cold coolant 46 (2) Temperature rise of armature winding embedded detector (3) Temperature rise of field winding (a) Generators below 100 O00 kVA (b) Generators 100 O00 kVA resistance and above resistance Directly Cooled Windings (rated at 30,45,60, 75 psig) Method of Class B**? of Coolant Determination Liquid Gas detector 45-50* 45-50* 54 5 ,** coolant** 55-50**§65-60*,§ 795 resistance 65-60*,§ 745 resistance 65-60*3§ detector 64 detector thermometer 85 thermometer Temperature rise of core and mechanical parts in contact with or adjacent to armature winding insulationt 85-80s 85-805 Temperature rise of collector rings brushes and brushholders (6) 85 Other metal parts such asshielding devices in the end region, structurai members, amortisseur windings, and the rotor surface may be operated a t temperatures that areconsidered safe for theparticular metals used, providing these parts do not appreciably influence the temperature of insulating material either by conduction or radiation *Because of the large thermal gradient between hottest spot and observed temperatures of large high-voltage generators and because of mechanical considerations of thermal expansion, it is often desirable t o design for lower temperatures than shown in Table 2 on large or high-voltage machines or machines intended for operation withhighly variable loads. tHydrogen-cooled generators that operate under controlled pressure do not require a correction for temperature rise a t altitude if the pressure of the cooling medium is maintained at the absolute pressure corresponding to the rated value. *Cold coolant temperatures may be provided within the range of46'C t o 5OoC, at themanufacturers' option, so long as compensating adjustments are madein the rise of the respective parts so that the sum of the cold coolant temperature andrespective part rise does not exceed (1) 100°C for liquid-cooled and llO°C for gas-cooled armature windings listed in Items (2) and (4) (2) ll0'C for gas-cooled field windings listed in Item (3) 0 Refer to 6.2. * * The temperaturerise of the coolant at theoutlet of the hottest coil shall beconsidered the observable temperature rise of conductor-cooledarmature winding. r t T h e values shown for Item 4 are limiting regardless of the operating power factor. **These values are for insulation systems with thermosetting materials. COPYRIGHT American National Standards Institute Licensed by Information Handling Services AMERICANNATIONAL STANDARD C50.13-1989 In the above criteria, the generator shall be capable of withstanding the thermal effect of unbalanced faults at themachine terminals, including the decaying effects of: (1) Field current, where protection is provided by causing field current reduction, such as with an exciter field breaker or equivalent (2) Direct-current component of the stator current N O T E Generators subjected to faults between the preceding values of Z;t and 200 percent of these values may suffer varying degrees of damage; for faults in excess of 200 percent of these limits, serious damage may be expected. 7.4 Mechanical Requirements for Short Circuits. The generatorshall be capable of withstanding, without mechanical injury, any type of short circuit at its terminals for times not exceeding short-time thermal requirements, when operating at rated kilovolt-amperes and power factor and 5 percent overvoltage, provided the maximum phase current is limited by external means to a value that does not exceed the maximum phase currentobtained from thethree-phase fault. NOTE: In the case of stator windings. the criteria for no injury is that the windings can satisfactorily withstand a normal m a h tenance high-potential test, There shall also be no visible abnormal deformation or damage to the winding coils and connections. 7.5 Continuous Unbalance Requirements.A generator shall be capable of withstanding, without injury, the effects of a continuous currentunbalance corresponding to a negative-phase-sequence current of the following values, providing the rated kVA is not exceeded and the maximum current does not exceed 105 percent of rated current in any phase. Negative-phase-sequence current is expressed in percent of rated stator current. Permissible 12 (percent) Generator Type of Cylindricalrotor indirectly cooled directly cooled to 960 MVA 961 to 1200 MVA 1201 to 1500MVA 10 8 6 5 These values also express the negative phase sequence current capability at reduced generator kilovolt-ampere capabilities, in percent of the stator current corresponding to thereduced capability. 7.6 Requirements forSystem Disturbances. System disturbances, such as electrical faults, network switching, faulty synchronizing, subsynchronous resonance, and other abnormalities, may have a detrimental effect o n turbine-generator shafts, end windings, and other components, Generator requirements that apply to these abnormalities, beyond those included in 7,l through 7.5, are not included in this standard due to themany combinations of circumstances possible. There areseveral IEEEWorking Group publications* that should assist the user to determine whether unique requirements should be established for a specific new equipment application or analyses made of an existing equipment application. 8. Efficiency The following losses shall be included in determining efficiency? (1) Z2R losses of armature and field winding. (2) Core loss. (3) Stray load loss. (4) Excitation system losses, if required by specifications, shall include the exciter, voltage regulator, and associated devices comprising the excitation for a particularsynchronous machine. Include motor loss if unit motor-generator exciter set is used; if a unit rectifier is used,include the loss of the rectifier and rectifier transformer. (5) Friction and windage loss. 9. Overspeed Cylindrical-rotor generators shall be so constructed that they will withstand, without injury, an overspeed of ,20 percent. 10. Telephone Influence Factor 10.1 Balanced. The balanced telephone influence factor (TIF) of synchronous generators, based on the weighting factors given in 10.3, shall not exceed the following values: RatinE kVA TIF of Machine Balanced 62.5to 300 to 700 to 5000 to 20000 to 100000 and 299 699 4 999 19 999 99 999 350 250 150 above 40 100 70 2For example, refer to IEEE Screening Guide for Planned Steady-State Switching Operationsto Minimize Harmful Effects on Steam Turbine-Generators (IEEEF80 202-2) and IEEE Working Group Interim Report on the Effects of Switching Network Disturbances on Turbine-Generator Shaft Systems (IEEE 82WM081-8). 'Refer to ANSI C50.10-1977for definifion of losses. 11 COPYRIGHT American National Standards Institute Licensed by Information Handling Services AMERICAN NATIONAL STANDARD C50.13-1989 10.2 Residual Component. The residualcomponent TIF of synchronous generators having voltage ratings 2000 volts and higher, based on the weighting factors given in 10.3, shall not exceed the following: kVA Rating of Machine l o o o t o4 9 9 9 5 o00 to 19 999 20 o00 to 99 999 100 o00 and above 12. Direction of Rotation The direction of rotation of the generator shall suit the prime mover requirements. Residual TIF 100 75 50 30 10.3 Single Frequency. The single-frequency telephone influence weighting factors (TIFF ) according to the 1960 single-frequency weightingare shown in Table 3. Methods of measurement for TIF shall be in accordance with ANSI/IEEE 115-1983. 10.4 Other. Special consideration may be necessary where trouble exists or may be anticipated from difficult exposure conditions. NOTES: (1) Although TIF is designed basically as a measure of the influence of current or voltage in a power circuit on parallel telephone circuits, the TIF of open-circuit generator voltage has been used for many years as an approximate index of the influence of generator waveshape. 'here has been no experience to indicate that generators designed in accordance with ANSI C50.1-1955' have caused inductive coordination problems, However, accuwlated measurements by manufacturers indicate that generator open-circuit TIF measured in accordance with the 1960 weighting averaged higher than with the 1935 weighting. Accordingly, in adopting the 1960 weighting in this revision of ANSI C50.1-1955, the limiting TIF values of lowercapacity machines were increased. At the same time, the greatly improved waveshape of modem highcapacity generators is recognized in setting a lower limit of balanced TIF for the larger units. (2) For information on TIF, see "Supplement to Engineering Report 33, The Telephone M u e n c e Factor of Supply System Voltages and Currents," Engineering Reports of the Joint Subcommittee on Development and Research, Edison Electric Institute. and Bell System, Edison Electric Institute Publication 6068. For further information on methods of measurement of TIF, see W.C. Ball and C.K. Poarch, "Telephone Influence Factor (TIF) and Its Measurement," AIEE Transactions, Pt I, vol 79, Jan 1961, pp 659-664. 11. Tests The tests specified in Table 4 shall be conducted in accordance with ANSIDEEE 115-1983 and ANSI C50.10-1977. COPYRIGHT American National Standards Institute Licensed by Information Handling Services 13. Nameplate Marking A nameplate having the following minimum information shall be provided: manufacturers's name, serial number, or other suitable identification. The following information at rating shall be supplied: (1) Voltage (2) Output kilovolt-amperes (3) Revolutions per minute (4) Armature amperes (5) Frequency (6) Temperature rise of armature (7) Temperature rise of field (8) Number of phases (9) Power factor (10) Excitation voltage (1 1) Excitation amperes (12) Hydrogen pressure (if hydrogen cooled) NOTES: (I) Direction of rotation should be shown on machine when necessary for correct operation. (2) For hydrogen-cooled machines, the values shall be given for maximum hydrogen pressures. 14. Performance Specification Forms Figure 1 shows the forms that shall be used for specifying the performance of steam-turbine-driven, hydraulic-turbine-driven, and motor-driven, aircooled synchronous generators. Figure 2 shows the form that shall be used for specifying the performance of steam-turbinedriven, hydrogen-cooled synchronous generators. ~~ ~ 4Later superseded by ANSIINEMA MGI-1978 and NEMA MGI-1987. ANSI C 5 0 - 3 3 87 W 0 7 2 4 3 5 0 bOb4647 8 AMERICANNATIONAL STANDARD C50.13-1989 Table 3 1960 Single-FrequencyTIFf Weighting Factors ~ 60 1980 180 2100 300 360 420 2340 540 2460 660 2580 720 7 282080 2940 900 1000 3000 3180 1020 3300 1080 1140 3540 3660 1260 3900 1380 1440 4020 4260 1500 4380 1620 5000 1740 1800 ~~ ~~~ TIFf FrequencyFrequency TIFf 1860 O.5 30 225 400 650 1320 2260 2760 3360 4350 5000 5100 5400 5630 6050 6370 6650 6680 6970 7320 7570 2160 2220 7820 8330 8830 9080 9330 9840 10 340 10 600 10 210 9820 9670 8740 8090 6730 61 30 4400 3700 27 50 2190 840 Table 4 Tests on Cylindrical-Rotor Synchronous Generators c Generators Completely Assembled for Test in Factory Factory Tests TesC Resistance of armature and field windings Dielectric tests of armature andfield windings Voltage balance Phase sequence Mechanical balance Open-circuit saturation curve Overspeed Short-circuit saturationcurve 1 Harmonic analysis and measurement of TIF Heat runs Short-circuit tests atreduced voltage to determine reactance and time constants Measurement of segregated losses Measurement of rotor impedance Measurement of insulation resistance of armature and field windings Measurement of bearing insulation resistance Generators Not Completely Assembled in Factory Field Tests X* X X X Xt X X -0 -0 -0 -0 -P X+* X -* * *An X indicates that testshall be made on each unit. tA field check of mechanical balance of all generatorsis recommended after installation. o *On brushless generatots, readingsof exciter field currentinstead of generator field currentmay be obtained. $This test, orcopies of a certified test report covering test made on an essentially duplicate generator, may be specified. **On all generators furnished with one or more insulated bearings, a field measurement of the bearing insulation resistance is recommended. WFor units less than 10 O 0 0 kVA and l e s than 7000 V. measwement of rotor impedance is not required. 13 COPYRIGHT American National Standards Institute Licensed by Information Handling Services 0724350 0004k50 4 W A N S I C50.33 87 AMERICAN NATIONAL STANDARD C50.13-1989 Figure 1 Performance Specification Form for Steam-Turbine-Driven, Hydraulic-Turbine-Driven, and Motor-Driven, Air-Cooled, Cylindrical-Rotor Synchronous Generators (The following data shall be given in accordance with ANSI C50.13-1989.) Date Output Rating Power Factor kVA No of Poles Spe? kW rlmm No of Phases Freq Hertz Volts Amperes Type or Frame Description -Type of excitation system - Maximum speed of generator (and exciter if shaft-driven) is rlminwithout mechanicalinjury. - Amortisseur winding is (closed) (open) (not supplied) -Generator cooling (shall) (shall not) include aclosed-circuit air system. . Armature Connections - Insulation Classes: Armature Winding - Direction of rotation viewing theendoppositethe I I Temoerature Rise Guarantees Rise C Not to Exceed Power kVA Max Excitation Requirements Gen Excitation Exciter Input Slip-Ring Type Brushless Wdg by I I . if of unidirectional design orconstruction. Volts Amp I Field Winding drive Volts Amp Excit Svstem Nominal Response Ceiling Rafio Volts I Exciter (1 ) (1) At “Maximum Excitation Requirements” operating level. Rating and temperature rises are based on an ambient temperatureof 40°C at an altitude notexceeding 3300 ft (1000 m). Minimum Efficiencies Power Factor kVA kW Load Load Load Efficiencies are determined by including Z losses of armature and field windings at -’C, core loss and strayload loss. Friction and windage loss (are) (are not) included; exciter and field rheostat losses (are) (are not) included. Approx Weights in Pounds Heaviest Part Total Total for Rotor Net Net Crane Shipping Reactances (Calc per Unit) X”dv Svnchtrans Transient Sub xd x‘di I 1 Circuit Ratio Ib-ft2 I I I I I I I - Approximate Operating Data for Cooling System with generator at rated load: Totally enclosed with water coolers Temperature of inlet water to coolers. “F Volume of cooling water. gallons per minute (gpm) bearing oil. when required) Enclosed. self-ventilated (no external blower) Volume of cfmcooling air. Pressure drop available for external ducts. filters. etc 14 ” 7. COPYRIGHT American National Standards Institute Licensed by Information Handling Services I - (for ventilating air and inch of water. l A N S I C50.13 B9 I0 7 2 4 3 5 0 0 0 0 4 b 5 3 b I AMERICAN NATIONAL STANDARD C50.13-1989 Figure 2 Performance Specification Form for Steam-Turbine-Driven, Hydrogen-Cooled, Cylindrical-Rotor Synchronous Generators (The following data shall be given in'accordance with ANSI C50.13-1989.) Output Rating Po wer Factor kVA kW Speed rlmin No of No of Poles Phases Freq Volts Hertz Amperes Type or Frame Description -Type of excitation system - Amortisseur winding is (closed) (open) (not supplied) -Insulation Classes: Armature Winding Field Winding -Direction , Armature Connections of rotation viewing the endoppositethedrive Temperature Rise Guarantees C Rise Not to Exceed Excitation Gen Winding Arm Power Embedded by Resistance I I if of unidirectional design or construction. Max Excitation Requirements Exciter Input Excit System Slip-Ring Type Brushless I Exciter (1) (1)At "MaximumExcitation Requirements" operating level. ' C Rating and temperature rises shall bein accordance with Table 2 of ANSI (30.13-1989and arebased on a temperature of of the cooling gas at theexit from the coolers, at psig pressure and at an altitude not exceeding 3300 fi (1000m). Efficiencies: Efficienciesof the generator are included in theover-all turbine-generator set efficiencies. Reactances Approx Unit) (Calc per Operating Data (at rated load and hydrogen pressure): (a) Temperature of inlet water to coolers. (b) Volume of cooling water^. gpm Weights in Pounds Heaviest OF 15 COPYRIGHT American National Standards Institute Licensed by Information Handling Services I