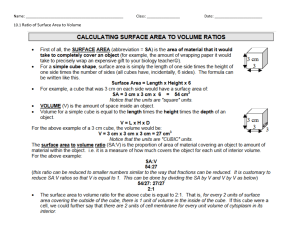

Anand Jain, Govt. Polytechnic Hanumangarh TRANSFORMER DES IGN EXAMPLES-3 TRANSFORMER DES IGN EXAMPLES-3 Anand Jain, Govt. Polytechnic Hanumangarh Design magnetic frame and winding for a 50 KVA, 11000/400 V, 50Hz, three phase delta/star core type distribution transformer. Assume flux density 1.2 T, current density (aluminum conductor) 1.5 A/mm2, window space factor=0.2, having window area 10 times net iron area. Use three stepped cores. Given Data : kVA=50, f = 50 Hz, VHV=11000 V delta VLV=400 V star Bm=1.2 T d=1.5 A/mm2 Kw=0.2 Aw/Ai =10 Output equation of transformer is given as 𝑸 = 𝟑. 𝟑𝟑 𝒇 𝑩𝒎 𝑨𝑰 𝑲𝑾 𝑨𝑾 𝜹 × 𝟏𝟎−𝟑 here So 𝑨𝒊 × 𝑨𝑾 = 𝟏𝟎𝑨𝒊 𝟐 = 𝑨𝑾 = 𝟏𝟎 𝑨𝑰 𝑸×𝟏𝟎𝟑 𝟑.𝟑𝟑 𝒇 𝑩𝒎 𝑲𝑾 𝜹 = 𝟓𝟎𝟎𝟎𝟎 𝟑.𝟑𝟑 ×𝟓𝟎×𝟏.𝟐×𝟎.𝟐×𝟏.𝟓×𝟏𝟎𝟔 Check 𝟏𝟎𝟔 figure in current density value 𝑨𝒊 𝟐 = 𝟖𝟑. 𝟑𝟑𝟑 × 𝟏𝟎−𝟔 or 𝑨𝒊 =. 𝟎𝟎𝟗𝟏𝟐𝟖𝟓 𝒎𝟐 = 𝟗𝟏. 𝟐𝟖 𝒄𝒎𝟐 Hence emf per turn 𝐸𝑡 = 4.44 𝑓𝑩𝒎 𝑨𝒊 = 4.44 × 50 × 1.2 ×. 𝟎𝟎𝟗𝟏𝟐𝟖𝟓 = 𝟐. 𝟒𝟑𝟐 volt/turn With such medium size 50KVA transformers three stepped or more stepped cores are used. When we use higher number of steps in core, we utilize the iron space better. By increasing the number of steps, the area of circumscribing circle is more effectively utilized for iron part. The relation between circumscribe circle diameter “d” and core cross section “Ai” can be expressed as follows 𝑨𝒊 = 𝒌 𝒅𝟐 The value of constant k depends upon the number of steps of core of the transformer, given as Core type Square Cruciform 3 stepped 4 stepped 5 stepped 6 stepped Constant k 0.45 0.56 0.6 0.62 0.64 0.65 for three stepped core circumscribing circle diameter 𝒅 = The most economical dimensions of various steps for a three-stepped core can be calculated. The results are 𝒂 = 𝟎. 𝟗𝟏 𝒅 = 𝟎. 𝟗𝟏 × 𝟏𝟐. 𝟑𝟑 = 𝟏𝟏. 𝟐𝟐 ≈ 𝟏𝟏. 𝟐 𝒄𝒎 𝒃 = 𝟎. 𝟕𝟎𝟕𝒅 = 𝟎. 𝟕𝟎𝟕 × 𝟏𝟐. 𝟑𝟑 = 𝟖. 𝟕𝟏𝟕 ≈ 𝟖. 𝟕 𝒄𝒎 𝒂𝒏𝒅 𝒄 = 𝟎. 𝟒𝟐 𝒅 = 𝟎. 𝟒𝟐 × 𝟏𝟐. 𝟑𝟑 = 𝟓. 𝟏𝟕𝟖 ≈ 𝟓. 𝟐 𝒄𝒎 𝑨𝒊 𝒌 = 𝟗𝟏.𝟐𝟖 𝟎.𝟔 = 𝟏𝟐. 𝟑𝟑 𝒄𝒎 It is given that window area is 10 times of net iron area so 𝑨𝒘 = 𝟏𝟎 𝑨𝒊 = 𝟏𝟎 × 𝟎. 𝟎𝟎𝟗𝟏𝟐𝟖𝟓 = 𝟎. 𝟎𝟗𝟏𝟐𝟖𝟓 𝒎𝟐 = 𝟗𝟏𝟐. 𝟖𝟓 𝒄𝒎𝟐 Window area is determined as product of width and height of the window. The height of the window, is usually taken 2 to 4 times of width of window. 𝐻𝑊 𝑊𝑊 = 2 𝑡𝑜 4 When height of window is taken high the mean turn length will decrease but leakage flux will increase. Similarly, less height and more width of window will increase the mean turn length but decrease leakage flux by some amount. Let us take height of window 2.5 times of width of window. 𝑨𝑾 = 𝟗𝟏𝟐. 𝟖𝟓 𝒄𝒎𝟐 = 𝐻𝑊 × 𝑊𝑊 = 2.5 𝑊𝑊 × 𝑊𝑊 or 𝑊𝑊 = 𝑨𝑾 2.5 = so height of window 912.85 2.5 = 19.11 ≈ 19.1 𝑐𝑚 𝐻𝑊 = 2.5 𝑊𝑊 = 2.5 × 19.11 = 47.8 𝑐𝑚 or 𝑊𝑊 = 19.1 𝑐𝑚 so height of window 𝐻𝑊 = 2.5 𝑊𝑊 = 2.5 × 19.11 = 47.8 𝑐𝑚 One significant dimension in core is center to center limb distance 𝐷 = 𝑊𝑤 + 𝑑 = 19.1 + 12.3 = 31.4 𝑐𝑚 Overall width of core 𝑊 = 2𝐷 + 𝑎 = 2 × 31.4 + 11.2 = 74 𝑐𝑚 Overall height of core 𝐻 = 𝐻𝑊 + 2 𝑎 = 47.8 + 2 × 11.2 = 70.2 𝑐𝑚 Winding design 𝑉𝑃ℎ = 𝑉𝐿 3 = 400 3 Low voltage winding 400 V star connection 𝑸 = 𝟑. 𝟑𝟑 𝒇 𝑩𝒎 𝑨𝑰 𝑲𝑾 𝑨𝑾 𝜹 × 𝟏𝟎−𝟑 here = 231.2 𝑉 No of turns 𝑁𝐿𝑉 = Current in LV 𝐼𝐿𝑉 = 𝑉 𝐸𝑡 = 𝑄 3𝑉𝑃ℎ 231.2 2.432 = = 95.06 ≈ 95 𝑡𝑢𝑟𝑛𝑠 50000 3×231.2 Cross section area of conductor 𝑎𝐿𝑉 = 𝑨𝑾 = 𝟏𝟎 𝑨𝑰 𝐸𝑡 = 4.44 𝑓𝑩𝒎 𝑨𝒊 = 𝟐. 𝟒𝟑𝟐 volt/turn = 72.088 𝐴 𝐼𝐿𝑉 𝛿 = 72.088 1.5 = 48.05867 𝑚𝑚2 We will select rectangle conductor of next higher standard size from conductor table, one can also use foil winding. High voltage winding 11KV Delta 𝑉𝑃ℎ = 𝑉𝐿 = 11000 𝑉 𝑉 No of turns 𝑁𝐻𝑉 = 𝑁𝐿𝑉 𝑉𝐻𝑉 = 95 × Current in HV 𝐼𝐻𝑉 = 𝐿𝑉 𝑄 3𝑉𝑃ℎ = 50000 3×11000 Cross section area of conductor 𝑎𝐻𝑉 = 11000 231.2 = 4519.89 ≈ 4520 𝑡𝑢𝑟𝑛𝑠 = 1.5151 𝐴 𝐼𝐻𝑉 𝛿 = 1.5151 1.5 = 1.01 𝑚𝑚2 We will select round conductor of next higher standard size from conductor table. Design magnetic frame and winding for a 10 KVA 11000/230 V, 50Hz, single phase core type transformer. Assume flux density 1.1 T, current density 2.2 A/mm2, window space factor=0.25, constant K=0.8 for single phase core type transformer. Use cruciform two stepped core. Given Data : Hence emf per turn kVA=10, VHV=11000 V f = 50 Hz, VLV=230 V Bm=1.1 T d=2.2 A/mm2 Kw=0.25 K=0.8 𝐸𝑡 = 𝐾 𝑄 = 0.8 10= 2.53 volt/turn 𝑬 The net core cross section area Ai is given as 𝑨𝒊 = 𝟒.𝟒𝟒 𝒇𝒕 𝑩 𝒎 Bm – maximum flux density in the core of the transformer in Wb/ m2 f – Frequency of the power supply in Hz With very small size transformers, rectangular core can be used with either circular or rectangular coils. With small size transformers less than 5KVA, square core can be used, with circular coils. With medium and large transformers, cruciform (two stepped) or more stepped cores are used. Stepped core utilizes the iron space better. 𝑨𝒊 = 𝑬𝒕 𝟐. 𝟓𝟑 = = 𝟎. 𝟎𝟏𝟎𝟑𝟔𝟏𝟑𝟒 𝒎𝟐 = 𝟏𝟎𝟑. 𝟔 𝒄𝒎𝟐 𝟒. 𝟒𝟒 𝒇 𝑩𝒎 𝟒. 𝟒𝟒 × 𝟓𝟎 × 𝟏. 𝟏 The relation between circumscribe circle diameter “d” and core cross section “Ai” can be expressed as follows 𝑨𝒊 = 𝒌 𝒅𝟐 The value of constant k depends upon the number of steps in core of the transformer, it is given as Core type Square Cruciform 3 stepped 4 stepped 5 stepped 6 stepped Constant k 0.45 0.56 0.6 0.62 0.64 0.65 for cruciform core circumscribing circle diameter 𝒅= 𝑨𝒊 𝒌 = 𝟏𝟎𝟑.𝟔 𝟎.𝟓𝟔 = 𝟏𝟑. 𝟔 𝒄𝒎 By increasing the number of steps, the area of circumscribing circle is more effectively utilized. The most economical dimensions of various steps for a multi-stepped core can be calculated. for two step size of core : 𝒂 = 𝟎. 𝟖𝟓 𝒅 = 𝟎. 𝟖𝟓 × 𝟏𝟑. 𝟔 = 𝟏𝟏. 𝟓𝟔 ≈ 𝟏𝟏. 𝟔 𝒄𝒎 𝒂𝒏𝒅 𝒃 = 𝟎. 𝟓𝟑𝒅 = 𝟎. 𝟓𝟑 × 𝟏𝟑. 𝟔 = 𝟕. 𝟐 𝒄𝒎 We can find out window area from output equation given as 𝑸 = 𝟐. 𝟐𝟐 𝒇 𝑩𝒎 𝑨𝑰 𝑲𝑾 𝑨𝑾 𝜹 × 𝟏𝟎−𝟑 So 𝑸×𝟏𝟎𝟑 𝒎 𝑨𝑰 𝑲𝑾 𝜹 𝑨𝑾 = 𝟐.𝟐𝟐 𝒇 𝑩 𝟏𝟎𝟎𝟎𝟎 = 𝟐.𝟐𝟐×𝟓𝟎×𝟏.𝟏×𝟎.𝟎𝟏𝟎𝟑𝟔×𝟎.𝟐𝟓×𝟐.𝟐×𝟏𝟎𝟔 = 𝟎. 𝟎𝟏𝟒𝟑𝟖 𝒎𝟐 = 𝟏𝟒𝟒 𝒄𝒎𝟐 Check 𝟏𝟎𝟔 figure in current density value Window area is determined as product of width and height of the window. The height of the window, is usually taken 2.5 to 4 times of width of window. 𝑯𝑾 𝑾𝑾 = 𝟐. 𝟓 𝒕𝒐 𝟒 When height of window is taken high the mean turn length will decrease but leakage flux will increase. Similarly, less height and more width of window will increase the mean turn length but decrease leakage flux by some amount. Let us take height of window three times of width of window. Thus, from the above equations, the height of the window & the width of the window can be calculated. 𝑨𝑾 = 𝟏𝟒𝟒 𝒄𝒎𝟐 = 𝐻𝑊 × 𝑊𝑊 = 3 𝑊𝑊 × 𝑊𝑊 or 𝑊𝑊 = 𝑨𝑾 3 = 144 3 = 6.93 ≈ 6.9 𝑐𝑚 so height of window 𝐻𝑊 = 3 𝑊𝑊 = 3 × 6.93 = 20.8 𝑐𝑚 One significant dimension in core is center to center limb distance 𝐷 = 𝑊𝑤 + 𝑑 = 6.9 + 13.6 = 20.5 𝑐𝑚 Overall width of core 𝑊 = 𝐷 + 𝑎 = 20.5 + 11.6 = 32.1 𝑐𝑚 Overall height of core 𝐻 = 𝐻𝑊 + 2 𝑎 = 20.8 + 2 × 11.6 = 44 𝑐𝑚 The transformer core frame with dimensions is as Winding design Low voltage winding No of turns 𝑁𝐿𝑉 = Current in LV 𝐼𝐿𝑉 = 𝑉 𝐸𝑡 𝑄 𝑉 = = 230 2.53 = 90.9 ≈ 91 𝑡𝑢𝑟𝑛𝑠 10000 230 = 43.48 𝐴 𝐼𝐿𝑉 𝛿 Cross section area of conductor 𝑎𝐿𝑉 = = 43.48 2.2 = 19.763 𝑚𝑚2 We will select rectangle conductor of next higher standard size from conductor table, one can also use foil winding. High voltage winding No of turns 𝑁𝐻𝑉 = 𝑁𝐿𝑉 4352 𝑡𝑢𝑟𝑛𝑠 Current in LV 𝐼𝐻𝑉 = 𝑄 𝑉 = 𝑉𝐻𝑉 𝑉𝐿𝑉 = 91 × 10000 11000 11000 230 = 4352.17 ≈ = 0.909 𝐴 Cross section area of conductor 𝑎𝐻𝑉 = 𝐼𝐻𝑉 𝛿 = 0.909 2.2 = 0.4132 𝑚𝑚2 We will select round conductor of next higher standard size from conductor table. Design magnetic frame and winding for a 250 KVA, 11000/230 V, 50Hz, three phase delta/star core type distribution transformer. Assume flux density 1.2 T, current density 2.5 A/mm2, window space factor=0.28, constant K=0.45 for three phase core type distribution transformers. Use three or four stepped cores. Given Data : kVA=250, Bm=1.2 T d=2.5 A/mm2 f = 50 Hz, VHV=11000 V delta VLV=230 V star Hence emf per turn 𝑬𝒕 = 𝑲 𝑸 = 𝟎. 𝟒𝟓 The net core cross section area Ai is given as 𝑨𝒊 = 𝟐𝟓𝟎 𝟑 Kw=0.28 K=0.45 = 𝟒. 𝟏 volt/turn 𝑬𝒕 𝟒.𝟒𝟒 𝒇 𝑩𝒎 Bm – maximum flux density in the core of the transformer in Wb/ m2 f – Frequency of the power supply in Hz With very small size transformers, rectangular core can be used with either circular or rectangular coils. With small size transformers less than 5KVA, square core can be used, with circular coils. With medium and large transformers, cruciform (two stepped) or more stepped cores are used. Stepped core utilizes the iron space better. 𝑨𝒊 = 𝑬𝒕 𝟒. 𝟏 = = 𝟎. 𝟎𝟏𝟓𝟒 𝒎𝟐 = 𝟏𝟓𝟒 𝒄𝒎𝟐 𝟒. 𝟒𝟒 𝒇 𝑩𝒎 𝟒. 𝟒𝟒 × 𝟓𝟎 × 𝟏. 𝟐 The relation between circumscribe circle diameter “d” and core cross section “Ai” can be expressed as follows 𝑨𝒊 = 𝒌 𝒅𝟐 The value of constant k depends upon the number of steps of core of the transformer, given as Square 0.45 Core type Constant k Cruciform 0.56 3 stepped 0.6 4 stepped 0.62 for four stepped core circumscribing circle diameter 𝒅= 𝑨𝒊 𝒌 = 𝟏𝟓𝟒 𝟎.𝟔𝟐 = 𝟏𝟓. 𝟕𝟔 𝒄𝒎 By increasing the number of steps, the area of circumscribing circle is more effectively utilized. The most economical dimensions of various steps for a four-stepped core can be calculated. The results are a = 𝟎. 𝟗𝟑 𝒅 = 𝟎. 𝟗𝟑 × 𝟏𝟓. 𝟕𝟔 = 𝟏𝟒. 𝟔𝟔 ≈ 𝟏𝟒. 𝟕 𝒄𝒎 𝒃 = 𝟎. 𝟖 𝒅 = 𝟎. 𝟖 × 𝟏𝟓. 𝟕𝟔 = 𝟏𝟐. 𝟔 𝒄𝒎 𝒄 = 𝟎. 𝟔 𝒅 = 𝟎. 𝟔 × 𝟏𝟓. 𝟕𝟔 = 𝟗. 𝟒 𝒄𝒎 𝒂𝒏𝒅 𝒅 = 𝟎. 𝟑𝟔 𝒅 = 𝟎. 𝟑𝟔 × 𝟏𝟓. 𝟕𝟔 = 𝟓. 𝟕 𝒄𝒎 5 stepped 0.64 6 stepped 0.65 We can find out window area from output equation given as 𝑸 = 𝟑. 𝟑𝟑 𝒇 𝑩𝒎 𝑨𝑰 𝑲𝑾 𝑨𝑾 𝜹 × 𝟏𝟎−𝟑 So 𝑸×𝟏𝟎𝟑 𝒎 𝑨𝑰 𝑲𝑾 𝜹 𝑨𝑾 = 𝟑.𝟑𝟑 𝒇 𝑩 𝟐𝟓𝟎𝟎𝟎𝟎 = 𝟑.𝟑𝟑 ×𝟓𝟎×𝟏.𝟐×𝟎.𝟎𝟏𝟓𝟒×𝟎.𝟐𝟖×𝟐.𝟓×𝟏𝟎𝟔 = 𝟎. 𝟏𝟏𝟔𝟏 𝒎𝟐 = 𝟏𝟏𝟔𝟏 𝒄𝒎𝟐 Check 𝟏𝟎𝟔 figure in current density value Window area is determined as product of width and height of the window. The height of the window, is usually taken 2 to 4 times of width of window. 𝐻𝑊 𝑊𝑊 = 2 𝑡𝑜 4 When height of window is taken high the mean turn length will decrease but leakage flux will increase. Similarly, less height and more width of window will increase the mean turn length but decrease leakage flux by some amount. Let us take height of window 2.5 times of width of window. Thus, from the above equations, the height of the window & the width of the window can be calculated. 𝑨𝑾 = 𝟏𝟏𝟔𝟏 𝒄𝒎𝟐 = 𝐻𝑊 × 𝑊𝑊 = 2.5 𝑊𝑊 × 𝑊𝑊 or 𝑊𝑊 = 𝑨𝑾 2.5 so height of window = 1161 2.5 = 21.55 ≈ 21.6 𝑐𝑚 𝐻𝑊 = 2.5 𝑊𝑊 = 2.5 × 21.55 = 53.9 𝑐𝑚 One significant dimension in core is center to center limb distance 𝐷 = 𝑊𝑤 + 𝑑 = 21.6 + 15.8 = 37.4 𝑐𝑚 Overall width of core 𝑊 = 2𝐷 + 𝑎 = 2 × 37.4 + 14.7 = 89.5 𝑐𝑚 Overall height of core 𝐻 = 𝐻𝑊 + 2 𝑎 = 53.9 + 2 × 14.7 = 83.3 𝑐𝑚 The transformer core frame with dimensions is as Winding design: Low voltage winding 400 V star connection 𝑽𝑷𝒉 = 𝑽𝑳 𝟑 = No of turns 𝑁𝐿𝑉 = Current in LV 𝐼𝐿𝑉 = 𝟒𝟎𝟎 𝟑 𝑉 𝐸𝑡 = 𝟐𝟑𝟏. 𝟐 𝑽 = 𝑄 3𝑉𝑃ℎ 231.2 4.1 = = 56.39 ≈ 56 𝑡𝑢𝑟𝑛𝑠 250000 = 360.44 𝐴 3×231.2 Cross section area of conductor 𝑎𝐿𝑉 = 𝐼𝐿𝑉 𝛿 = 360.44 2.5 = 144.176 𝑚𝑚2 We will select rectangle conductor of next higher standard size from conductor table, one can also use foil winding. High voltage winding 11KV Delta 𝑉𝑃ℎ = 𝑉𝐿 = 11000 𝑉 No of turns 𝑵𝑯𝑽 = 𝑵𝑳𝑽 Current in LV 𝑽𝑯𝑽 𝑽𝑳𝑽 𝐼𝐻𝑉 = = 𝟓𝟔 × 𝑄 3𝑉𝑃ℎ = 𝟏𝟏𝟎𝟎𝟎 𝟐𝟑𝟏.𝟐 250000 3×11000 Cross section area of conductor 𝑎𝐻𝑉 = = 𝟐𝟔𝟔𝟒. 𝟑𝟓 ≈ 𝟐𝟔𝟔𝟒 𝒕𝒖𝒓𝒏𝒔 = 7.5757 𝐴 𝐼𝐻𝑉 𝛿 = 7.5757 2.5 = 3.03 𝑚𝑚2 We will select round conductor of next higher standard size from conductor table.