Hazardous Area Guide-EN-GU-B-IND-20231005-00144579

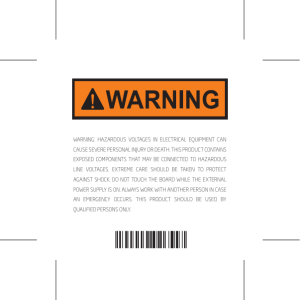

advertisement