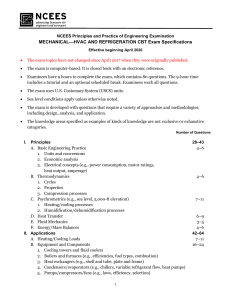

www.araner.com | info@araner.com Technical Reference eBook DISTRICT COOLING DC DISTRICT COOLING REFERENCE EBOOK 01 INTRODUCTION TO DISTRICT COOLING 01 INTRODUCTION TO DCP DISTRICT COOLING District Cooling refers to the centralized production and distribution of cooling energy. The cooling energy is produced in a central cooling plant as chilled water and is distributed to consumers in a closed piping circuit, also referred to as a reticulation system. The concept of District Cooling is being implemented more often worldwide by many different organizations, both private and public, due to the multiple benefits that brings to a high density demand area. More and more often it is incorporated just as another facility for a building, like electricity, fresh water or natural gas may be. Traditionally, DC Plants have been designed following residential standards and practices. However, the most recent Plants with a capacity of several tens of thousands of Tons of Refrigeration (TR) cannot be designed following this philosophy. The idea behind central cooling is applying economies of scale to the residential refrigeration. Traditionally, the building refrigeration systems have been designed following residential standards and practices. Summing up the refrigeration demand from several consumers enables a larger production of refrigeration energy. That implies the use of industrial-grade equipment and industrial practices in order to ensure the reliability and safety of the District Cooling Plant. Efficiency is a crucial parameter for these kinds of plants as the amounts of energy consumed throughout the year is very high. Any improvement in efficiency results in huge savings in any developer’s running costs. Reliability is also a must as so many residences, hotels, people and businesses depend on it. 2 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 01 INTRODUCTION TO DISTRICT COOLING 01 INTRODUCTION TO DCP BUILDING A DISTRICT COOLING Building a District Cooling is not always feasible. The main factor for the DC implementation is the consumer density. Having a high demand in a small area makes it a better solution compared with the traditional ones. If the consumers are too spread apart, the DC may not be possible due to high energy loses in the cooling energy transport. Just as any other utility, the construction of the District Cooling is more difficult to achieve in an already existing development. This is the reason why the developments of new construction are already implementing this technology, providing the necessary space for its elements. The concentration of heterogeneous consumers with different land uses will make necessary the study of the simultaneity of the cooling load profiles. Not all consumers have their peak cooling load at the same time; for example offices will have their maximum consumption during the working hours while the maximum consumption for the hotels will be in the afternoon. Therefore the cooling plant shall be designed according to this peak of the connected load. Regarding the rest of the factors surrounding the potential District Cooling, both the other utilities and the local legislation (such as water regulations, electricity regulations, etc.) should be compatible with the system implementation. ARANER studies the particular contour conditions in order to provide a tailor-made solution. 3 www.araner.com | info@araner.com www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 02 BENEFITS OF DISTRICT COOLING 02 BENEFITS OF DISTRICT COOLING STAKEHOLDERS PRODUCERS DC is a safe business with a quite stable demand and relatively low payback periods. As production takes place in an industrial environment, it is always subjected to optimization and improvement of efficiencies and installed cooling capacity. Reduction in Optimization peak Electricity of the installed Demand cooling capacity Possibility of Energy Storage CONSUMERS The capital cost and operation cost are reduced. In addition, the cooling equipment which can be noisy is usually placed outside the building, sometimes remotely, and the maintenance operations are often outsourced. SOCIETY The implantation of DC System for sustainable cities, since it is a more efficient solution than a stand-alone chiller. This means a reduction of the energy consumption and of the CO2 footprint. Also the city skyline benefits by eliminating the installation of individual cooling equipment systems. 4 Recognized Green Technology with carbon credit Operation and Maintenance Reduction in Services Provided CO2 Emissions by experts Higher Higher Reliability Efficiency www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 02 BENEFITS OF DISTRICT COOLING 02 BENEFITS OF DISTRICT COOLING TYPICAL POWER DEMAND TYPICAL PEAK POWER DEMAND FOR DIFFERENT COOLING SOLUTIONS When a DC is designed for several building with different usage, the demand can greatly differ among the different heating consumers. Building energy efficiency 2 legislation has traditionally focused on space cooling energy consumption. However, in the future when more renewable energy is used both on site and in energy systems, and energy security. If the network is well balanced, the production plant size can be optimized adding some thermal storage technology. This reduction in the plant production power will not only reduce the total amount of energy consumed, but also the primary energy needed to feed the District Cooling. P E AK P OWE R DE M AND ( KW / T R ) the peak energy demand becomes more important with respect to CO2 emissions 1.75 1.5 1.25 1 0.75 0.5 0.25 0 5 Air Cooled Building Systems District Cooling (Electric) District Cooling (Electric with TES) District Cooling (100% Gas-fired) DISTRICT COOLING REFERENCE EBOOK 03 EFFICIENT DISTRICT COOLING SYSTEMS 03 EFFICIENT DC SYSTEMS GREEN BUILDING Green building (also known as green construction or sustainable building) refers to a structure that is designed, constructed and operated using processes that are environmentally responsible and resource-efficient. Efficient District Cooling Systems contribute to the Green building as the total electrical consumption of the building is reduced. LEED Certification (Leadership in Energy & Efficient Design), which is recognized across the world as the premier standard for Green buildings, recognizes the use of DC systems as a significant contributor towards achieving a highly efficient building. This is a point based system that categorizes Green buildings into four different levels – Certified, Silver, Gold and Platinum. Selecting an environmentally friendly refrigerant is also important in order to receive a higher quantity of LEED points to achieve a higher certification level. The refrigerant used must have a very low Global Warming Potential and Ozone Depletion Potential. CFC and HCFC refrigerants have been already phased out in most of the countries around the world and R-134 will be phased out in the very near future (phase out is already planned in USA and Europe); given its favorable properties R-717 remains a preferred refrigerant for efficiency and environmental reasons and is expected to remain so indefinitely. 6 LEED CERTIFICATIONS www.araner.com | info@araner.com USGBC www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 04 DESIGN CRITERIA & SIMULATIONS 04 DESIGN CRITERIA DC SIMULATION The first stage is to design the DC Plant as efficient as possible, in this regards studying the simultaneity of the cooling demand of the different buildings/consumers can result in a great optimization of the system. Not all consumers have their peak cooling load at the same time. As an example, offices will have their maximum consumption during the working hours while the maximum consumption for the hotels will be in the afternoon. Studying the simultaneity of the different buildings/consumers will determine the peak of the connected cooling load of the entire DC system. The cooling plant in order to be efficient shall be designed according to this peak of the connected cooling load and maximize energy production. A simulation of the District Cooling for a complete year will be very useful in order 100% to evaluate the different technologies and select the optimum solution for every 90% 80% factors: • • • The ambient temperature The building occupancy depending on the hour and the building type (office, residential, hotel, retail…) The seasonal occupancy (in case of resorts, universities or any other special cases which have very low occupancy during certain months of the year) Loads % of Peak case. The simulation will estimate the Hourly Cooling Demand based on the following 70% 60% 50% 40% 30% Residential 20% Offices Hotel Retail 10% 0% 0 2 4 6 8 10 12 Hours of the Day 7 14 16 18 20 22 24 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 04 DESIGN CRITERIA & SIMULATIONS 04 DESIGN CRITERIA For this third stage, it is recommended to involve a DC Designer with parameters in order to achieve an optimum design. The natural following important point is to wonder whether it is advisable to install a Thermal Energy Storage (TES) system in our plant. Then, how can we reject the heat from our refrigeration process? Here we have three main options: • • • Air cooled Water cooled Chiller Consumption (kW·h) extensive experience and the capability to evaluate the relevant 16,000,000 16,000,000 14,000,000 14,000,000 12,000,000 12,000,000 10,000,000 10,000,000 8,000,000 8,000,000 6,000,000 6,000,000 4,000,000 4,000,000 2,000,000 2,000,000 Sea water / river water cooled Water Cooled Chillers Consumption (kW·h) After the preliminary configuration of the plant is selected, it is advisable to run a simulation for a complete year in order to check the overall benefit of the system. Once the cooling demand is simulated, the cooling plant consumption will be also evaluated using local costs for energy and water. The optimum solution will depend on the Owner’s criteria: • • • 8 0 0 Reduce the yearly operation cost Reduce the yearly electrical consumption Reduce the yearly water consumption Air Cooled Chillers Consumption (kW·h) Cooling Demand (TR·h) Cooling Demand DC SIMULATION www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 05 DISTRICT COOLING PLANT COMPONENTS 05 DISTRICT COOLING PLANTS COMPONENTS > HEAT REJECTION TECHNOLOGIES THERMAL ENERGY STORAGE TANK < CONSUMPTION PUMPS HIGH - EFFICIENT INDUSTRIAL CHILLERS 9 > < PRODUCTION PUMPS > DISTRICT COOLING REFERENCE EBOOK 05 DISTRICT COOLING PLANT COMPONENTS www.araner.com | info@araner.com The chillers are one of the most important elements of the plant, since they have the mission of producing the cooling energy, performing the 05 DCP COMPONENTS MECHANICAL ROOM > HIGH- INDUSTRIAL EFFICIENCY CHILLERS When designing the cooling plant the chillers selection play an important role for lowering the energy consumption. These are one of the most important elements of the plant, since they have the mission of producing the cooling energy, performing the refrigeration cycle. The common practice is to use vapor compression chillers, but other technologies can be applied depending on the project conditions and cooling requirements. ARANER´s chillers are robust industrial grade machines designed and manufactured to improve the District Cooling plant efficiency, reducing the total water and electrical consumption in the plant. Energy consumption is one of the major concerns worldwide in these days. Lowering energy consumption not only results in big savings in operation cost but also contributes to the environment by reducing the CO2 footprint. Furthermore, the tailor-made chillers developed by ARANER are very flexible and will be suitable despite the project specifications and site conditions: • • • • • • 10 Different refrigerant types (R717, R134a, R504a) Electrical, diesel or gas driven motors Dry cooled or water cooled solutions and sea water cooled Absorption chillers Integration with Thermal Energy Storage Technologies Centrifugal or Screw type refrigeration cycle DISTRICT COOLING REFERENCE EBOOK 05 DISTRICT COOLING PLANT COMPONENTS 05 DCP COMPONENTS MECHANICAL ROOM CENTRIFUGAL VS. SCREW These are one of the most important elements of the plant, since they have the mission of producing the cooling energy, performing the refrigeration cycle. The common practice is to use vapor compression chillers, but other technologies can be applied depending on the project conditions and cooling requirements. These vapor compressors could be: • CENTRIFUGAL: They are a non-positive displacement type and therefore more sensible to a pressure differential lift between evaporation pressure and condensing pressure. The main advantage of centrifugal compressors is their high flow rates capability and good efficiency characteristics • SCREW: They are positive displacement compressors encase a quantity of refrigerant in a decreasing volume during the compression process. They provide excellent lift characteristics. ARANER screw machines have an extra improved efficiency for the oil injection system. A key factor when designing a District Cooling is the proper chiller selection. The selection shall come together with the District Cooling plant design, in order to ensure the smooth integration of the system. 11 www.araner.com | info@araner.com www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 05 DISTRICT COOLING PLANT COMPONENTS 05 DCP COMPONENTS MECHANICAL ROOM CENTRIFUGAL CHILLER SCREW CHILLER Centrifugal compressors are a non-positive displacement type and therefore more Screw compressor or positive displacement compressors encase a quantity of sensible to a pressure differential lift between evaporation pressure and condensing refrigerant in a decreasing volume during the compression process. They provide pressure. excellent lift characteristics • Centrifugal chillers are designed with fewer moving parts and straightforward with efficient engineering, and have proven durability records in hospitals, district cooling systems, and in other applications where minimal downtime is a crucial concern • High strength aluminum-alloy compressor impellers feature backward curved vanes for high efficiency. Airfoil shaped pre-rotation vanes minimize flow disruption for the most efficient partial load performance • The advantage of centrifugal compressors is their high flow rates capability and good efficiency characteristics. 12 • They are low speed machines with less wear and so, long trouble free life with less maintenance. • Screw compressors are able to accommodates the pressure lift increasing performance for different conditions (day/night, Summer/winter) • ARANER screw machines have an extra improved efficiency for the oil injection system DISTRICT COOLING REFERENCE EBOOK 05 DISTRICT COOLING PLANT COMPONENTS 05 DCP COMPONENTS MECHANICAL ROOM ABSORPTION CHILLER Absorption chillers, instead of using electricity, use ‘heat’ as the energy source, a low grade energy. The energy source may be steam or hot water, or it may even be waste heat like in exhaust gases from an engine (gas or oil based). ARANER offers a wide range of solutions for each of these energy sources, all of which represent a major advance in Absorption Refrigeration Technology. ARANER absorption heat pump uses tested components and procedures for industrial refrigeration applications. Their main characteristics are: • • • • • • • Minimum maintenance due to few moving parts Ready for dry condensation with ZERO water consumption Modular solution, factory assembled LiBr-water technology as the most proven for heating Lower electrical energy consumption compared with compression heat pumps Higher CAPEX than compression heat pumps Extra investment is recovered on mid/long-term basis Our absorption heat pumps can be installed in a co-generation plant as a heat recovery system, in order to reduce steam consumption. It can be also used on the flue gas condensation for improving the system efficiency. 13 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 05 DISTRICT COOLING PLANT COMPONENTS 05 DCP COMPONENTS MECHANICAL ROOM > HEAT REJECTION Due to the nature of the cooling process, the heat extracted from one system should be transferred to another one, thus rejected from the District Cooling plant. Learn the main advantages and disadvantages in our White-paper and discover the technology that best suits your project. In the following chapters you can find out how to improve the District Cooling plant performance, taking into account the most important factors. Other than that, heat rejection is closely bounded to the chiller design and chiller selection. > PUMPING SYSTEMS Usually there are two pumping groups for the chilled water and one for the condenser water (if they are required). Regarding the chilled water pumps, they are usually divided into production pumps, pumping into the chillers the necessary return of chilled water, and consumption pumps, responsible of moving the water along the Distribution Piping Network (DPN) and the Energy Transfer Stations (ETS). Nevertheless, the pumping strategy may vary depending on the DPN & ETS of each particular project. 14 www.araner.com | info@araner.com www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 05 DISTRICT COOLING PLANT COMPONENTS 05 DCP COMPONENTS ELECTRICAL & CONTROL ROOM > ELECTRICAL ROOM > CONTROL ROOM Electrical rooms are very important for projects successfully operation, providing a hub The diverse components of each project need to operate and perform all together as to supply electrical power for equipment and other components of the DCP. The main a single and fully integrated system in order to achieve the optimum performance of advantage of a well-designed electrical room is providing a central location where the plant, up to client satisfaction. technical staff members can manage and service building power systems and ensure an optimized operating work space day after day, even in blackouts or emergency situations. ARANER designs, implements and develops a Safety and Redundant Systems with the highest specifications from the industry according to the project requirement, including since the most basic devices up to the highest performance equipment. Our control Our Electrical Department is formed by highly skilled engineers with relevant experience systems are based on latest PAC (Programmable Automation Controller) technology in most electrical engineering fields, such as; high and low voltage substations, for highest performance and durability and are equipped with a suite of tools that Overhead lines, Variable Frequency Drives and Soft Starters...Our engineers design the allow the creation of full customizable features, such as HMI alarms, historical and real- electrical facilities as per the most recent industry standards from IEC, IEEE, NEC, BS, time trending, built in reporting. With a very intuitive and easy-to-use Human Machine and other Electrical Engineering institutions. Interfaces (HMI) and SCADA’s, full control and plant integration are achieved 15 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 05 DISTRICT COOLING PLANT COMPONENTS 05 DC COMPONENTS DISTRIBUTION PIPING NETWORK (DPN) As the principle behind District Cooling lies in the production of cooling energy in a Depending on the particular conditions of the area where the District Cooling will be centralized location, this cooling energy should be delivered to the costumers. Chilled deployed, the distribution network can be above ground or underground. Regarding water is conducted then to the consumption points by means of a Distribution Piping the underground piping, it could be directly buried, laying on a gallery or trench, or Network (DPN). The routing of the distribution pipe implies two different conductions: traveling along a basement. Any of those arrangements should provide an access one for chilled water supply and another one for chilled water return. The temperatures to the piping every few meters, in case maintenance is required. In order to do that, of the supply and return water will vary depending on the cooling energy deliver: isolating cutting points shall also be foreseen. • • DIRECT CHILLED WATER UTILIZATION: the water from the DPN is pumped directly The deployment area, together with the chilled water network analysis, conditions the through the end user heat exchangers. It is used for small installations where piping material selection. Suitable materials could be for example PCV or carbon steel. any failure on the end user side can be easily solved (usually they have the In any case, the pipe should be thermally isolated, so that energy losses are minimized same owner). The typical temperatures for this method are 7 ºC for the supply It is usual that there are several District Cooling plants supplying energy to the network and 12 ºC for the return. from different locations. Therefore, the selection of an appropriate topology is a key ENERGY TRANSFER STATION (ETS): the energy is transferred in a heat exchanger to another water circuit. It is extensively used, as it allows a normal performance of the network in case of a failure on the end user side. The typical temperatures for this method are 4.4 ºC for the supply and 13.3 ºC for the return. 16 aspect for the supply of critical loads. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 05 DISTRICT COOLING PLANT COMPONENTS 05 DCP COMPONENTS ENERGY TRANSFER STATION (ETS) An Energy Transfer Station (ETS) takes cold energy from the network by means of a This valve ensures a determined flow rate, which will vary according to the ETS heat exchanger for delivering it to the end user. On one side of the heat exchanger demand. The demand flow rate is usually calculated measuring the chilled water consequently the chilled water supply will be heated up to the return temperature. return temperature from the ETS: if the demand rises, the return temperature will be On the other side, an independent water circuit is cooled – this circuit is called tertiary lower and it will require a higher flow rate in order to maintain a constant temperature. system. The ETS, composed by the heat exchanger and the pumping group, has usually a The tertiary system delivers the cooling energy direct to the end user heat exchangers, dedicated space inside the building, most often in the basement. It distributes the cold as it takes it from the network. It has its own pumping group, since it is not hydraulically water to the different end users just as another building utility. In that sense, each ETS connected to the network. This means they can be individually designed according to has their own metering equipment and the building owner can decide if having also the building characteristics, with no influence on the rest of the District Cooling design. partial metering devices in his tertiary system for the different end users. A common practice is the installation of partial redundancy in the ETS heat exchanger. That means As the supply and return temperature in the DPN are constant, the energy transferred installing two heat exchanger with 75% each of the total capacity required. The two to the ETS depends on the flow rate that passes through it. The flow rate adapts to the heat exchangers should work together for achieving the peak capacity, but one of demand by partially opening or closing a Pressure Independent Control Valve (PICV). them can be stopped for maintenance while the other is running during low demand periods, avoiding service interruption. 17 DISTRICT COOLING REFERENCE EBOOK www.araner.com | info@araner.com 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION COOLING TOWERS The District Cooling plant may reject the heat derived from the cooling process with The water quality is an important factor in the cooling tower design. Depending on this a cooling tower. Cooling towers are available in different types and sizes depending parameter, the cooling water will have a different number of cycles of concentration on the load configuration: an important reason to outline the options available. Note (CoC). A good water quality would imply a high CoC, typically around 10 or 11, so less that despite the different designs, the basic function remains the same as that of blow-down water would be required and consequently less make-up consumption. dissipating heat from the process to the air through evaporation. Defining the design On the other hand, with a bad water quality the CoC would be low, around 3-5. The wet bulb temperature is a key aspect for a proper cooling water dimensioning. The latter is usual when direct TSE water is used as make-up water. wet bulb temperature is the minimum theoretical temperature that can be achieved at the cooling tower outlet, as heat is rejected by evaporation. The fact is that the outlet temperature is higher: the difference between this two temperatures is called approach. Selecting a smaller approach will result in a bigger cooling tower, which may be not feasible in economical or technical terms. The approach selected is usually higher than 3 ºC. The placement of the cooling towers is also very important, as the air should be allowed to flow inside and outside the tower, with less obstructions as possible. If several cooling towers are arranged in the immediate vicinity, the outlet wet air of one cooling tower could enter in another cooling tower (which will reduce drastically its performance), if they are not carefully located depending on the direction of the prevailing wind. The same phenomenon could occur with one cooling tower itself. This recirculation depends on the relation between the plume discharge velocity and the ambient wind velocity. In order to ensure a suitable cooling tower performance, ARANER can develop a CFD model simulating the interaction between the wind and the cooling tower air current. 18 The air current that flows through the cooling tower can drag away water droplets due to its speed. For avoid water losses, a drift eliminator is installed. This also helps to prevent the formation of a plume, as the moist outlet air meets the ambient. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION AIR CONDENSATION With this technology, heat is rejected to the ambient air by means of a fin and tubes temperature approach between the refrigerant and the cooling water and heat exchanger. A current of ambient air is forced through the heat exchanger by another one between the cooling water and the dry bulb temperature. a fan installed on top of it. This air current flows between the heat exchanger tubes, arranged in coils. The tubes have fins attached to them, so that the surface of thermal exchange is enhanced. Therefore, heat is transferred from the fluid inside the tubes to the air current. The tubes are normally made of copper and the fins material is usually aluminum, nevertheless different treatments such as protective coating and different alloys with good thermal transmission properties can be selected. The minimum theoretical temperature that can be achieved with this technology will be the ambient dry bulb temperature. This is not feasible as the size of the heat exchanger would be infinite, therefore the fluid outlet temperature will be higher than the dry bulb temperature. The difference between the minimum theoretical temperature (in this case the dry bulb) and the fluid outlet temperature is called approach. The dry bulb temperature is always higher than the wet bulb temperature, and this difference is even higher in dry climates. This temperature conditions the condensation temperature of the refrigeration machine (the condensation temperature must be higher than the dry bulb temperature, so that heat exchange takes place), and consequently the plant efficiency: the lower the condensation temperature is, the better efficiency can be accomplished. Depending on the type of air condensation used, the efficiency can vary: • INDIRECT CONDENSATION. The fluid sent to the fin and tubes heat exchanger is water. This water is circulated in a closed circuit, rejecting the heat from the condenser of the refrigeration machine. There would exist hence a 19 • DIRECT CONDENSATION. The refrigerant is sent directly to the fin and tubes heat exchanger. Compared with the indirect condensation, one temperature approach will be avoided, so that the condensation temperature will be able to be lower, leading to a higher plant efficiency. The problem with direct condensation is the fact that the fin and tubes heat exchanger should be integrated into the refrigeration machine, as the exchanger is now the condenser, substituting the usual shell and tubes heat exchanger. This is not a solution proposed by centrifugal chiller manufacturers because it requires a complex calculation of the refrigeration cycle for each particular scenario instead of a packaged solution. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION SEA WATER CONDENSATION A good alternative for condensation technologies is rejecting the heat to the sea. Around 70 % of the Earth’s surface is covered by water, making it an unlimited, constant and low-cost resource. Moreover, the water mass has a lower temperature than the ambient temperature and it also suffers less temperature variations. There is no contact between sea water and other fluids (such as refrigerant, oils, etc.) During the process, so water can be released back into the sea with no changes but a slight increase of temperature. However, this resource is not always available depending on the project location (obviously it is not available everywhere) and its particular constrains. The local regulations protect as well the environment from the uncontrolled used, such as limiting the temperature rise and the sea water interfaces (intake and discharge), preserving the zones with high submarine value. Water is taken from the sea with a sufficient height from the sea bed in order to avoid Even if most solid particles entrance is avoided with a good sea water intake design, a sand to come inside the system, and deep enough to prevent the entrance of lower filtration system is necessary for protecting the pumping system and the heat exchanger. density debris. Furthermore, the intake water speed should be low enough for fish to The filtration system selected should adequate to the sea water characteristics and to be able to swim away when they get the feeling that they are dragged by the current. the project specific conditions. The sea water quality usually has more influence in The stability of the submerged system should be also carefully studied, as it is subject the number of filtration stages and the free span of the mesh, whether the contour to mechanical stresses caused by the tides and the geotechnical conditions. Without conditions usually influence more in the technology selected (screen coarse, rotating a proper structural dimensioning the system components could flip, turn, fall or even filters, disk filters, etc.). In order to avoid the growth of marine life inside the system, break, causing important malfunctions downstream. which could deposit and result of great efficiency losses, antibiofouling measures must be installed. 20 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION SEA WATER CONDENSATION The materials of the sea water system should be selected according to the water • SUBMERGED DISCHARGE: similar considerations as for the sea water intake must characteristics. As a clear example, the salinity of the Dead Sea, which is around 337 be taken into account. Additionally, some nozzles at the end of the discharge g/kg, has nothing to do with the World Ocean salinity, which has a mean of 34.7 g/ pipe shall be placed. The nozzles will just allow the flow of water to the sea, not kg. The presence of sodium chloride makes the water corrosive against some usual letting marine life to enter the pipe when the system is not working construction materials like SEA copper. Organic materials are normally inert to this water, just like PE or PVC, making them often suitable for water conduction. In addition to water corrosion resistance, the material selected for each component should meet their own requirements. Pumps material should guarantee their mechanical performance, and the heat exchangers material should have a good heat transmission coefficient. Regarding the sea water discharge, the determination of the water outlet point is essential. Recirculation must be avoided so that the system can work properly, therefore a careful study of the currents and the project particularities must be held. The discharge point shall comply with the local regulation and with this regard it could be differently performed: 21 • ABOVE WATER DISCHARGE: it causes more visual impact as the previous one. Nevertheless, the discharge could be used with aesthetically purposes, and the complex developer may take advantage of the DC plant discharge for applying it to a decorative space. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION RIVER WATER CONDENSATION River water cooling is a system very similar to the sea water condensation, also with no water consumption and low visual impact. In addition to the advantages of the sea water systems, river water condensation implies the following: • Less corrosive water, which benefits the system components • Constant direction of the river flow prevents the recirculation of water, ensuring a good performance of the plant • Alternative to sea water condensation in locations further away from the sea side As always when designing a cooling solution that uses water from the environment, special attention should be paid to the particularities of the project. A river water current study, an environmental impact study, a water quality study, etc. should be elaborated, which are required in order to comply with the environmental legislation. Not all the rivers are suitable to be used in this application. Water is taken from the river with a sufficient height from the river bed in order to avoid sand to coming inside the system, and deep enough to prevent the entrance of lower density debris. Moreover, the intake water speed should be low enough for fish to be able to swim away when they get the feeling that they are dragged by the current. The water is also filtrated, so that suspension solids are removed from the cooling water. 22 After that, water should be treated to avoid the growth of water life inside the system, which could deposit and result of great efficiency losses (great pressure losses, lower heat transmission, etc.). Therefore an antibiofouling system may be used. Water is then pumped into the chiller condenser by means of a pumping group. Both pumps and condenser materials in contact with water should be adequate in order to not present corrosion. Finally, water is returned to the river with a slight increase of temperature, as per environmental legislation. As stated before, the discharge point should be carefully placed with the support of studies. It is also important to diffuse the discharge along the river and not in a single point, since depending on the particular conditions it could have an impact over the river life. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION REFRIGERANT SELECTION No refrigerant fits the requirements 100 % for all cooling plants. An ideal refrigerant would need to have it all in terms of material compatibility, chemical stability, performance, non-toxicity, non-flammability, boiling point among other criterion industrial refrigeration engineers, our designs, manufactures and installations are suitable for the most popular refrigerants. > HFC HFC is the third generation of fluorinated refrigerants. These are manmade organic > AMMONIA R717 Ammonia, a member of the so-called halogen-free chemicals, it’s perhaps the most common refrigerant in industrial cooling plants and among the oldest ones. Its heat absorption per volume is unrivaled. This alone allows its application in smaller components- no need for huge cooling plants. Other attractive features include high critical point, high coefficient of performance and low molecular weight. Highly energy-efficient refrigerant with minimal environmental problems, for that, ammonia should be always selected, when possible, for industrial refrigeration installations. compounds having fluorine and hydrogen atoms. The main difference in comparison with HCFC refrigerants is that HFC do not contain chlorine. Chlorine can cause harm to the ozone layer, whereas HFC is free of chlorine so they do not harm the ozone layer. Therefore HFC are considered more environmentally friendly than HCFC. The most common HFC refrigerant is R134a. R407A, R410a, R507A, etc. are also part of the HFC group.. > HFOS (HYDROFLUORO-OLEFINS) HFOs are the fourth generation of fluorinated refrigerants. HFOs are composed of the same atoms like HFCs: carbon (C), hydrogen (H) and fluorine (F), but are unsaturated organic compounds – hence the suffix “olefin”. They are based on alkenes like propene and butane. Their Global Warming Potential (GWP) is very low, much lower than HFC’s GWP; however when HFOs decompose in the atmosphere, trifluoroacetic acid (TFA(A)) is formed which produce trifluoroacetate (TFA), a salt very difficult to remove from drinking water. The most utilized HFOs refrigerants are HFO-1234yf, HFO1234ze, HFO-1233zd. 23 > CO2 R744 CO2 scores highly because of its minimal environmental impact. The refrigerant is also non-flammable and non-toxic. However, despite these pleasant attributes, the refrigerant needs careful handling. First, the chemical is heavier meaning that in case of leakage, it would displace oxygen from the room. Combining that with the fact that it is odorless forms a very dangerous scenario. It mainly revolves around efficiency, size and cost of system. A pressure of about 4,000 psi presents a huge cost and technical challenge for heat exchangers and compressors. DISTRICT COOLING REFERENCE EBOOK www.araner.com | info@araner.com 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION REFRIGERANT SELECTION > WATER Water has been used as a refrigerant for many decades and it never ceases to impress. Apart from being readily available, this substance has impeccable chemical and thermodynamic properties. It cannot be considered as a refrigerant itself, but The debate over what is “the best” commercial refrigerant has been around and is unlikely to end anytime soon. Intensity on this matter is even increasing as leakage studies reveal the adverse effects of HFC emissions. The only way out for centralized systems is emissions reduction, which while possible, is costly. it is chilled in cooling plants and introduced into the circuit to lower temperatures. It presents several technical challenges though. These include high-pressure ratios and The industry is committed to reducing environmental impact even as it promotes safety outlet temperatures at the compressor. and efficiency. Governments are continually requiring equipment manufacturers to shift to chemicals that are safer to the environment. In the cooling/ refrigeration > HCFC-HYDROCHLOROFLUOROCARBONS These compounds are slowly being phased out because of their high GWP. Some places have already banned the use of this refrigerant in new equipment. If you are looking to recover, maintain or replace your HCFC refrigeration equipment, ARANER qualified personnel can help. Specifically, they will help you handle the dangerous refrigerant with expert guidance and suggest better options for you. Some examples of specific refrigerants under this group are R2, R22, R123 and R124. Others include R133 and R151. > HYDROCARBONS (HCS) HCs are usually available as either R600a (isobutene) or R290 (propane). You will find these chemicals in domestic refrigeration systems, commercial refrigeration systems and air conditioning systems. The flammability of these substances requires special safety installations, but some plants are willing to take the extra precaution. Propane has zero ODP making it suitable for industrial cooling. As a natural refrigerant, the chemical does not make any effect on global warming either. 24 market, the result is that dangerous chemical refrigerants such as chlorofluorocarbons (CFCs), hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs) are being replaced with environmental friendly ones. The industry is committed to reducing environmental impact even as it promotes safety and efficiency www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION THERMAL ENERGY STORAGE IMPLEMENTATION DISTRICT COOLING LOAD PROFILE AND TES TANK OPERATION TES Tank is a thermal accumulator that allows the storage of chilled water or ice 60,000 200,000 Cooling Demand, TR produced during off-peak time. This energy is later used during on-peak time. A TES Chiller Output, TR • • • • • Maximum efficiency in simultaneous chilled water production and consumption, usage of what you need, storage of excess average loads and not for peaks Energy production and storage during electricity low-cost periods. Ice storage option available where site space constraints would not allow for 120,000 30,000 100,000 80,000 20,000 60,000 40,000 10,000 20,000 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 0 Hour of the Day a chilled water TES tank lower due to the cooling energy already accumulated in the tank during the previous 25 140,000 40,000 Smaller refrigeration equipment sizes and costs as they are designed for In District cooling plants with TES Tank, the refrigeration capacity of the chillers will be hours. Refrigeration Load, TR temperature is low and chillers have better performance. 160,000 Stored Energy, TR·h tank reduces refrigerant plant capacity and operational cost, producing chilled water when demand is low, which usually coincides with the night, when ambient 180,000 TES Charge, TR·h 50,000 In other words, a smaller refrigeration system can be used to satisfy an specified peak demand. Therefore, ARANER engineers put a great effort to design the most efficient Thermal Energy Storage Tanks for District Cooling Plants. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION THERMAL ENERGY STORAGE IMPLEMENTATION > OPERATING PHASES Thermal Energy Storage (TES) has two operational phases: charging and discharging. During the discharge phase, the warmer, less dense returning water floats on top of the stored chilled water. The water from storage is supplied and withdrawn in low velocity, in essentially horizontal flow, so that buoyancy forces dominate inertial effects. When the stratified storage tank is charging, chilled supply water, enters through the diffuser at the bottom of the tank, and return water exits to the chiller unit through the diffuser at the top of the tank. CFD (Computational Fluid Dynamics) uses numerical algorithms and computational software to simulate how a fluid flows within a certain boundary domain. The numerical model must be accurate and truthful to ensure the proper performance of the prototype. The CFD techniques offer the capacity of studying a fluid system under conditions over its limits and understanding the features of the result. Through the use of CFD analysis ARANER provides a real conditions-tested design that fulfills specifications and assures thermal stratification of water inside the TES Tank. The use of CFD software ensures authenticity and quick turnaround time, reducing cost and adding significant value to the final plant and thus, to the customers. > DESIGN CRITERIA - CFD In District cooling plants with TES Tank, the refrigeration capacity of the chillers will be lower due to the cooling energy already accumulated in the tank during the previous hours. In other words, a smaller refrigeration system can be used to satisfy an specified peak demand. In Thermal Energy Storage Tanks, a proper diffuser geometry helps the water volumes to stratify uniformly inside the tank, via water velocities and densities, and thus provide the District Cooling System with the required cooling capacity. ARANER sets a great effort to design the most efficient Thermal Energy Storage Tanks for its cooling plants. To ensure that the cooling needs of the plants are absolutely fulfilled, it is extremely important to test the performance of the designed TES in real conditions before erection. 26 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION THERMAL ENERGY STORAGE IMPLEMENTATION > BENEFITS AND ADVANTAGES 1 2 The overall cost of the installation is lower due to the reduction of the refrigeration plant installed capacity. The refrigeration equipment size is smaller because it is designed for average loads and not for peaks The operational cost is reduced in comparison with an online cooling system because peak consumption can be avoided during high electrical tariff periods TYPICAL CONFIGURATION FOR COOLING PLANT WITH TES • • • 3 Stores the thermal energy and transforms it later on electrical energy Maximum net electricity production during the most profitable moments The plant dimension of the refrigeration system could be reduced. This is given by the fact that the refrigeration capacity of energy to be produced by the plant will be lower due to the energy already accumulated in the tank. TYPICAL CONFIGURATION FOR ONLINE COOLING • • • Deferred cooling production 4 The environmental impact is reduced because of the reduction of CO2 storing the energy and improving operating efficiency with TES tank helps to reduce even more the CO2 emissions of a district cooling system Coinciding cooling production/use Heating cost varies with energy cost Net electricity production reduction during the most profitable PRODUCTION PUMPS LOAD T T 27 CHILLER 2 CHILLER 1 CHILLER 1 CONSUMPTION PUMPS LOAD LOAD T T T P T CHILLER 2 T P PUMPING GROUP LOAD T www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION ENERGY TRANSFER STATION · ETS Normally, every District Cooling System is supplying chilled water to its consumers CHILLED WATER DISTRICT SIDE (NETWORK) through a sub-station, which we will call Energy Transfer Station (ETS). The Energy Transfer Station can be located in some machinery room inside the building to be serviced. Every building residential towers, hotels, hospital, shopping boulevard, etc.) which is serviced by the District Cooling will require an Energy Transfer Station. This ETS will consist of pumps (for controlling the building side), heat exchangers (the heart of the ETS; they transfer the cooling energy from the DC Network), control valves (PICV’s), strainers, instrumentation and PLC. In order to identify the parts of the ETS, we can identify two side: 28 The chilled water district side shall tie directly into the district’s main chilled water distribution header. The standard chilled water district side shall be comprised of the following equipment that directly ties into the automation system: • • • • • • Energy quantifiers: Energy meter, Flow meter, Supply temperature & Return temperature Chilled Water supply strainer differential pressure transmitter Chilled Water supply/return differential pressure transmitter Modulating temperature control valve Pressure Independent Control Valve Network to Building System Plate Heat Exchangers www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION ENERGY TRANSFER STATION · ETS CHILLED WATER CUSTOMER SIDE (BUILDING) The chilled water customer side shall tie directly into the customer’s equipment. Cooling energy shall be transferred from the CHW district loop to the CHW customer side through the use of the CHW to CHW heat exchangers listed above. The CHW As a possibility for good design and improvement in the capabilities of control for efficiency enhancement, the PLC’s central processing unit (CPU) can communicate with the local operator interface terminal via a local ETS Ethernet network and shall communicate with the SCADA system via Fiber. customer side shall be comprised of the following equipment that directly ties into the Going through the operation philosophy of the ETS, the control can be done in several automation system: ways and even it is possible to have configured different modes to act depending on • • • • • • • different conditions (weather, season, demand, etc.). The purpose of the control in the Supply temperature transmitter in Building side Return temperature transmitter in Building side In case there is more than one PHE, supply and return temperature off each CHW heat exchanger Return strainer differential pressure transmitter Differential pressure transmitter Circulation pumps to supply water to the building Network to Building System Plate Heat Exchangers ETS pay attention to 2 factors mainly: • • The supply water temperature in the Building (consumer side) The delta T in the Network (district side) In order to have a proper performance in the District Cooling System, it is necessary that the consumers allows the ETS to have the chilled water return temperature as per design. In addition, the supply water temperature in the Building is usually guaranteed by the DC Services Provider to the consumers by contract. 29 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION SPECIAL & TAILORED SOLUTIONS > ENGINE DRIVEN CHILLERS The refrigeration machines require a work input in order to have the capability of performing the refrigeration cycle. In compression chillers, mechanical energy is transmitted to the chiller compressor by an engine. Generally the use of an electrical motor as the compressor mover is the most extended solution, due to its versatility and cost. However, in some cases the access to electricity is limited and there is no power available for the chiller. In such occasions the motor may use some of the following technologies: Diesel piston engine, Natural gas piston engine & Natural gas turbine engine The heat rejection in these cases would be greater than in the case of an electrical chiller. Also different requirements and standards should be met, often more restrictive in comparison with electrical chillers. The use of this technologies would be bound to the particular constrain conditions of each particular project. > ABSORPTION CHILLERS The working principle of the absorption chillers is similar to the compression chillers, as they both perform the refrigeration cycle. Nevertheless, the compression chillers perform the refrigerant pressurization over a gas, while the absorption chillers do it over a liquid by means of a pump. As the refrigerant exits the evaporator in its gas phase, it is absorbed by a liquid absorbent. After the pressurization, the absorption process is reversed and solely the refrigerant enters in the condenser in the form of gas. In order to reverse the absorption of the refrigerant, the absorbent solution shall be 30 heated, therefore the machine requires a heat input. These machines demand more energy that the compression chillers. However, pressurizing a liquid instead of a gas requires less energy and produces less noise. That makes the absorption chiller to have a very low electrical consumption. The electrical consumption of an absorption chiller is often despicable when compared with the heat input that requires; consequently it is often referred to the heat consumption of the absorption chiller as the only energy consumption that it has. The absorption technology is mainly used when a suitable heat source is available. When this heat source is a waste product of another industrial process, the system is highly energy-efficient, and the operation costs can be greatly reduced. If there is no heat available, the use of absorption technology is not preferred over compression due to its higher cost and higher energy consumption. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 06 DISTRICT COOLING DESIGN OPTIMIZATION 06 DESIGN OPTIMIZATION SPECIAL & TAILORED SOLUTIONS > SOLAR COOLING The sun is normally associated with heating applications but, what about cooling? Solar energy is a renewable energy that is normally available during the peak cooling demand hours, so it could be used to produce cold energy. Traditionally there are two ways of exploiting solar energy. • • PHOTOVOLTAIC SOLAR COOLING. It consists on obtaining electricity out of the sun. This electricity would be used to feed the compression chiller. THERMAL SOLAR COOLING. It consists on the use of the heating capacity of the sun for feeding an absorption chiller. As seen before, the absorption chiller needs a heat supply for the cold production. > COMPLEMENTARY HEATING : HEAT PUMPS Most often the consumers of the District Cooling network also have a heat demand (e.g. heating, sanitary water). Depending on the nature of the project, this demand could be satisfied locally or with centralized heat production. The latter would use its own District Heating network, often next to the DC one. The combination of District Cooling and Heating is regularly referred to as District Energy. In order to provide central heating, a heat pump solution may be used. A heat pump is a machine that performs the refrigeration cycle just as a chiller does, transferring heat from a cold environment into a hot one, opposite to the natural heat flow. The difference is that in this case the heat produced in the condenser is used for heating purposes, while the cold energy produced in the evaporator is rejected. 31 Both heat pump and chiller may work together if both the heating and cooling demand profile are suitable, so that one can use part of the energy that the other rejects. Also depending on this load profile difference, the use of a Thermal Energy Storage may enhance the efficiency of the system. In case of marked seasonal environments, the chiller can be designed as a reversible machine. That would mean that the machine will work as a chiller during the summer season, delivering cold to the network, and as a heat pump during the winter season, delivering heat to the network. This would imply a deep study of the project conditions and technologies selected. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 07 DCP’S PERFORMANCE 07 DCP’S PERFORMANCE COOLING LOADS CALCULATIONS When sizing a District Cooling plant, cooling load calculations play a critical role. This It is clear, therefore, that this profile simulation leans towards a clearer picture of a is a complex process; calculate the cooling demand and the plant performance for complete cooling plant performance. For the best results in District Cooling design and thousands of different ambient conditions involves great efforts and resources. With decision-making process, a detailed cooling load profile simulation is essential. Only ARANER’s conscientious and experienced, clients can be sure of getting a District Detailed Cooling Load Profile calculations can guarantee that the resulting District Cooling system that will serve perfectly for many years. ARANER opts to use the more Cooling system is optimally energy efficient, comfortable and satisfactory. strenuous and reliable complex simulation method because its high accuracy helps predict the energy performance of a District Cooling system with minimal errors. 60,000 We recognize that the cooling equipment may not operate at maximum capacity 180,000 means that the cooling demand and the cooling plant performance is calculated for 8,760 different points. Our collection of data is straightforward, but thorough at the same time. The most important thing about our detailed cooling load profile is that it describes the variation of the load within time. Some issues may affect this profile and they include: • • • 32 Refrigeration load (TR) hour per day, we consider real weather data hour-by-hour for a complete year. This 50,000 Base loads- computer rooms, telecom closets, etc. 140,000 40,000 120,000 30,000 100,000 80,000 20,000 60,000 40,000 10,000 20,000 0 0:00 Hours of operation of a facility Climate of plant’s location 160,000 Time 0:00 2:00 4:00 4:48 6:00 8:00 9:36 Demand: (TR) 10:00 12:00 14:00 16:00 18:00 20:00 22:00 14:24 Chiller: (TR) 19:12 0:00 TES Status: (TR·h) 0 4:48 Stored energy (TR·h) throughout the day, leave alone the month or year. That is why we use powerful computer software to determine the ideal cooling load profile. Instead of picking one 200,000 DISTRICT COOLING REFERENCE EBOOK 07 DCP’S PERFORMANCE 07 DCP’S PERFORMANCE STUDY OF CHILLED WATER NETWORK The recently constructed District Cooling plants, especially in Middle East, have a total cooling capacity of several dozen thousands of Refrigeration Tons. These high capacities result in large chilled water flows which require a thorough analysis of the water pipe network: • Pressure Drop. This is the difference of pressure between two points of a fluid in the piping network due to frictional forces. This calculation is necessary to • select the correct size of the pumps for the system Pipe Stress Calculation. It is necessary to determine if the pipes accomplish with the stress code, determine the forces that will act in the nozzles of the equipment and in the pipe supports, etc. This analysis ensures the mechanical • life cycle of the pipe system Water Analysis. The water is studied to prevent corrosion in pipes and equipment. With this data we make a properly selection of equipment materials, required • chemical products and water treatments Water Hammer Analysis. Water hammer is a pressure surge or wave caused when a fluid in motion is forced to stop or change direction suddenly. This pressure wave can cause major problems, from noise and vibration to pipe collapse. We make simulations in the design phase to avoid these problems • during operation Hydraulic Balance. We do studies of hydraulic balance to avoid shortage of service in any point of the network and to have the equipment in its optimal working point, which is translated in energy efficiency, saving costs and client satisfaction 33 www.araner.com | info@araner.com www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 08 POTENTIAL DC FAILURES & PROBLEMS 08 POTENTIAL DC FAILURES & PROBLEMS LOW DELTA-T SYNDROME Low Delta T Syndrome is a common problem in chilled water cooling plants in general, Both reasons produce that the opening percentage of the PICV is higher than actually which occurs more often than expected when the system is not properly designed needed, increasing the water flow and reducing the Delta T. In order to fight against and/or operated. For different reasons, the Delta T of the actual chilled water flow this problem, the chilled water supply and return temperatures must be monitored for (supply water temperature minus return water temperature) is lower than the Design both the Cooling Plant side and Developers/Buildings side. If low Delta T is detected, value. As the water flow needed is inversely proportional to the Delta T, low Delta T and Alarm must inform the District Cooling Plant operator in order to proceed with the results in higher required water flow and increase in the required pumping energy, required counter-measures. which adversely affects system efficiency. The Low Delta T phenomenon can be found on both the Cooling Plant side and Developers/Buildings (consumers) side of the water The consequence of the low Delta T is an increase in the electrical consumption of the circuit. The most common causes of low Delta T are: DC plant and reduction in the efficiency. In addition, more wear of the main equipment • • • occurs, due to longer operation running status of the water pumps and compressors. Non-proper functioning of the control system of the Energy Transfer Station Non-proper interface between the control system of the ETS and the control system of the DC Plant. Normally, due to an improper or lack of communication between them Incorrect selection of the Pressure Independent Control valve (PICV) ARANER DCPs are much less susceptible to suffer the Low Delta T Syndrome due to: • • • • 34 Real-time monitoring and control of the ETS from the DC Plant Control Room. Different modes for ETS control depending on several factors like demand or season conditions Proper selection of PICV in the ETS’s and deep design of the equipment of the ETS’s Proper operation guidelines are provided and followed www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 08 POTENTIAL DC FAILURES & PROBLEMS 08 POTENTIAL DC FAILURES & PROBLEMS FOULING Heat exchangers are totally necessary in the refrigeration cycle of a District Cooling However, in this post we will focus on shell & tube and plate heat exchangers. These Plant. As it has mentioned before, they are the interface equipment between are two of the most used types of heat exchangers in District Cooling Plants. refrigerant system and chilled water system, as well as between the refrigerant system and ambient to dissipate (either by mean of dry condensation or via cooling towers or In both of them, the efficiency is related directly to fouling. Fouling could be defined any other fluid that can absorb the heat rejected by the refrigeration cycle. Two out as the accumulation of deposits in the heat exchanger surfaces. There are many of the four basic steps in the refrigerant cycle are heat exchangers. Their operation causes of this: scaling, biological, suspended particles in the fluids… This accumulation affects greatly to the overall plant efficiency, so their maintenance is very important. produces a loss of heat transfer, reducing its efficiency and, in the case of a District Cooling Plant, reducing the overall plant efficiency. Also fouling can increase the Heat exchangers, like pressure vessels, are classified as static equipment as they don’t head loss due to the reduction of the water section pass. Proper operation guidelines have any moving parts. They don’t require too much maintenance, but it is important are provided and followed to make visual inspections to detect leaks or corrosion and control its efficiency as it can decrease with time due to fouling. An ideal refrigerant system consists on one compressor, one condenser, one expansion valve and one evaporator. Condenser and evaporator are both of them heat exchangers. In the evaporator the refrigerant absorbs the heat of the water so it is chilled. In the condenser the refrigerant rejects that heat and the compressor heat to other media, usually air or water. There are many types of heat exchangers. 35 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 08 POTENTIAL DC FAILURES & PROBLEMS 08 POTENTIAL DC FAILURES & PROBLEMS FOULING This process is unavoidable. With time every heat transfer system will see a reduction An overstated fouling factor increases the heat exchanger initial cost and substated on his efficiency, but cleaning the surfaces will revert the heat exchanger to its original fouling factor increases the maintenance and operation costs during its life, so it is efficiency. The velocity of the fouling process depends mainly on the characteristics of important to set the correct fouling factor during design. the fluid used: fouling will not be the same using treated water than using sea-water: the second one will carry more particles and biological contamination. Depending on the type of fouling there are different methods to solve it. All of them have the same purpose: to clean the surfaces of the heat exchangers. Heat exchanger During design of the heat exchanger a fouling factor is provided to ensure that the cleaning supposes a costly maintenance time and depending on the installations also heat exchanger can work during certain time at design conditions, but after some means the shutdown of the plant. So every investment in the reduction of the number time fouling will increase and a cleaning operation will be required. The fouling factor of these maintenance operations along the time will be profitable. There are many used in design will increase the initial cost of the equipment as this fouling factor is ways to reduce the fouling problem that can be divided in two types: translated in an increase of the heat transfer area. ONLINE METHODS 36 OFFLINE METHODS Consist on stopping the heat exchanger Online methods don’t require the stop service and dismount and clean the surfaces of the plant. These methods are applied directly. There are many methods used: during operation and we can find upstream manual cleaning, jet cleaning, blasting… filtration, back flushing, flow excursion… These methods are simple but require These methods increase the initial cost of the stopping the plant. They suppose a cost plant but avoid plant shutdowns and reduce during the operation of the plant. the maintenance costs of the plant.. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 08 POTENTIAL DC FAILURES & PROBLEMS 08 POTENTIAL DC FAILURES & PROBLEMS CORROSION There are many causes that can lead to corrosion in a water piping system like the one existing in district cooling networks. Sometimes the corrosion is due to one or more factors. The following are the main causes that may be related: • • Water temperature: The hotter the water, the more pronounced the corrosion. Water’s chemical make-up: Minerals in water can either mitigate or increase corrosive levels. For instance, if there are high levels of calcium in water, it may • • cause harm the corrosion levels. Water velocity: Excessive velocity and/or sudden changes in direction (turns, elbows) can lead to erosion corrosion because of water turbulence. The pH of the water: In copper piping systems, if the pH is under a certain level, it harms the protective barrier of the pipe and leads to corrosion. This fact is especially important in case there is any copper coil or braze plate heat • exchanger in the piping system. Oxygen in the water: Oxygen degrades metals, gradually converting the metal to rust. As this happens, impurities are deposited into water lines or collected on the piping wall, creating restrictions and blockages. These water issues are some of the things that can lead to corrosion in the piping system and DC network. Careful attention needs to be paid to these facts, as the effects of that corrosion may lead to several health problems as well as wasting the DC operator’s money in many ways. 37 THE EFFECTS OF CORROSION It is essential to mention that corrosion effects can be very expensive to repair and it can be a waste of money in many ways: • • • • Corroded water can hurt the efficiency of heat exchangers in cooling and heating systems, and cause premature failure. It can cause premature failure of plumbing systems and fixtures (facility of the DC building) It can result in stained fixtures and potential odors. Proper operation guidelines are provided and followed www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 08 POTENTIAL DC FAILURES & PROBLEMS 08 POTENTIAL DC FAILURES & PROBLEMS CORROSION PREVENTION METHODS > PROTECTIVE COATINGS > METAL TYPE The application of a paint coating is a cost-effective way of preventing corrosion. One simple way to prevent corrosion is to use a corrosion resistant metal such as aluminum or stainless steel. Depending on the application, these metals can be used to reduce the need for additional corrosion protection. These metals are usually used in heat exchangers in order to improve the exchange efficiency. However, these materials are very expensive in order to use it in large water systems like DC Plants > ENVIRONMENTAL MEASURES Corrosion is caused by a chemical reaction between the metal and gases in the surrounding environment. By taking measures to control the environment, these unwanted reactions can be minimized. This can be as simple as reducing exposure to rain or seawater, or more complex measures, such as controlling the amounts of sulfur, chlorine, or oxygen in the surrounding environment. > CATHODIC PROTECTION The most common example of cathodic protection is the coating of iron alloy steel with zinc, a process known as galvanizing. Zinc is a more active metal than steel, and when it starts to corrode it oxides which inhibits the corrosion of the steel. This method is known as cathodic protection because it works by making the steel the cathode of an electrochemical cell. Cathodic protection is used for steel pipelines carrying water or fuel, water heater tanks, ship hulls, and offshore oil platforms. However it is not commonly used in District Cooling water system network, due to its high cost. 38 Paint coatings act as a barrier to prevent the transfer of electrochemical charge from the corrosive solution to the metal underneath. > ANODIC PROTECTION Anodic protection involves coating the iron alloy steel with a less active metal, such as tin. Tin will not corrode, so the steel will be protected as long as the tin coating is in place. This method is known as anodic protection because it makes the steel the anode of an electrochemical cell. Anodic protection is often applied to carbon steel storage tanks used to store sulfuric acid and 50% caustic soda. > CORROSION INHIBITORS Corrosion inhibitors are chemicals that react with the surface of the metal or the surrounding gases to suppress the electrochemical reactions leading to corrosion. They work by being applied to the surface of a metal where they form a protective film. Inhibitors can be applied as a solution or as a protective coating using dispersion techniques. Corrosion inhibitors are commonly applied via a process known as passivation In passivation, a light coat of a protective material, such as metal oxide, creates a protective layer over the metal which acts as a barrier against corrosion. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 08 POTENTIAL DC FAILURES & PROBLEMS 08 POTENTIAL DC FAILURES & PROBLEMS LEGIONELLA Legionella bacteria can infect humans and cause legionellosis and Legionnaires’ For this reason, all cooling towers should be treated with a dual biocide program that disease. The bacteria can grow on the wet surfaces of cooling towers, evaporative uses both an oxidizing and non-oxidizing biocide whenever possible. condensers (cooling plant) and scrubbers. Poorly positioned air intakes for air conditioning units can also capture the bacterial plume and draw it into buildings. In According to OSHA, cooling towers and evaporative condensers should be District Cooling Plants, a disinfection system should always be installed in cooling water inspected and thoroughly cleaned at least twice a year. Algae and accumulated system as cooling towers are often subject to microbacterial growth. scale should be removed. All metal surfaces should be treated with a biocide. Corroded parts, such as drift eliminators, should be replaced. Because of the Cooling towers and evaporative condensers are used to dissipate unwanted heat to potential dangers associated with them, all cooling tower cleanings should be the atmosphere through water evaporation. Water is sprayed into the cooling tower done under the supervision of a technician trained in legionella remediation. through spray nozzles and tiny airborne droplets are formed. While falling through the At Clarity Water Technologies, we take legionella prevention and legionella tower, some of the water evaporates but some droplets, known as drift, are carried out remediation very seriously. of the tower by the air stream produced by the fans. The presence of drift has been detected as far as 6 km away from the cooling tower. Legionella bacteria grow often in the water and are easily dispersed together with the drift. This water mist can be breathed into the respiratory system, causing risk of Legionella disease and Pontiac fever. The likelihood of legionella infection can be significantly reduced by good engineering and water treatment practices in the installation, operation and maintenance of air and water handling systems. 39 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 09 INTEGRATED CONTROL SYSTEMS 09 INTEGRATED CONTROL SYSTEMS ARANER PERFORMANCE OPTIMIZATION Different components of the District Cooling system need to operate and perform all ARANER designs, implements and develops a Safety and Redundant Systems with the together as a single and fully integrated system. The best practice is to integrate into highest specifications from the Industry according to the project requirement, including one single Control System all the information regarding the main equipment (chillers, since the most basic devices up to the highest performance equipment. Our control pumps, heat rejection devices) and the Energy Transfer Stations (ETSs). Even Preventive systems are based on latest PAC (Programmable Automation Controller) technology maintenance management system and ETSs Consumption billing system can be for highest performance and durability. Our Control Systems are equipped with a suite integrated in the same Control System of tools that allow the creation of full customizable features, such as HMI alarms, color schemes, historical and real-time trending, built in reporting. ARANER designs and integrates our own control systems. With a very intuitive and easy-to-use Human Machine Interfaces (HMI) and SCADA’s, full control and plant Control solutions used by ARANER allows our customers to improve their process and integration are achieved. ARANER built a manage control system architecture utilizing become agiler by simplifying integration, streamlining commissioning and providing redundant EtherNet/IP as their communication backbone, as well as other common increased operational flexibility and performance. industrial communication protocols such Modbus, Profinet or BacNet. As a result, they can seamlessly integrate with other automation systems and software platforms. 40 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 09 INTEGRATED CONTROL SYSTEMS 09 INTEGRATED CONTROL SYSTEMS ARANER PERFORMANCE OPTIMIZATION Nowadays, industrial plants are full of sensors providing massive data. • ARTIFICIAL INTELLIGENCE: According to performance optimization, predictive Data without control is unavailing information. behaviors are developed by ARANER AI. Learning capabilities is one the Collect, save, sort and analyze data represents a complex process that has challenges of the new era: knowing how the cooling load is going to be in the to be developed fast and efficient in order to provide valuable information: following hours or predict the electricity cost in the following days is a money • saver. ARANER AI learns with trends and tendencies during District Cooling BILLING SYSTEM: All the Energy Transfer Stations (ETS) of each client are under ARANER control system, enabling data collection and analyzation. This feature allows to detect any abnormal condition in a remote area in real time, at the • CLOUDING, IOT: Cybersecurity is one of the basics in ARANER Control Systems. Cybersecurity is not at odds with accessibility. ARANER DCP provide the owner ARANER Billing System provides the owner the capability to extend weekly safety access to his plant from any place in the world if it is required. Supervise or monthly invoices to each client with a fix cooling water price or variable KPIs or check the plant performance during a meeting is now a real possibility. one, depending on the electricity cost or the time scheduled consumption. Receive emails in case of important alarms, or start a pump from a tablet in front of it to monitor the pressures are others of the smart features. REPORTING SERVICES: The DC plant maintenance team has a deep knowledge and performing maintenance activities. ARANER Reporting Services allows the maintenance team to receive a daily report of the maintenance activities to be done as well as it advises if any equipment is having an unusual performance. PERFORMANCE OPTIMIZATION: The target of a District Cooling plant is to reduce the client’s cooling costs with a larger centralized plant that provides a better performance than small individual ones. ARANER Performance Optimization System checks several parameters such as the weather forecast, the weekday, the electricity price, etc. and selects how many chillers and when have to be running, in order to reduce energy costs. 41 • same time that the system is recording the client consumption in every instant. of the complete plant and they are capable of managing technical mishaps • Plant life in order to predict future behaviors and optimize the performances. www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 10 OPERATION AND MAINTENANCE 10 OPERATION AND MAINTENANCE ACTIVITIES TO BE PERFORMED Depending on the topology, technology of the plant, and the refrigerant used, the The other important element in the chilled water system are the evaporators (these operation and maintenance activities may vary in a slight way. Below, it is briefly are part of the refrigerant system too) and heat exchangers in general. When the heat explained the maintenance activities to be performed in the 3 main systems of a exchangers are plates type, if gasketed, these would be opened after 4-5 years of District Cooling Plant: operation in order to clean the plates and re-gasket the plate heat exchanger. There > CHILLED WATER SYSTEM may be other plate heat exchangers without gaskets (brazed or welded). These will The most important equipment in this system are the circulating pumps. In case exchangers used in a District Cooling Plant are the shell and tube heat exchanger. the District Cooling Plant has a TES Tank, there will be also production pumps. The Some of them may be inspected due to an access point. Those which cannot, a CIP water pumps used by Araner are always cutting-edge technology from renowned shall be done after 4-5 years of operation. manufacturers. Thus, the maintenance activities need to be programmed less often. The main maintenance activities required for the water pumps are the following: • • • • • • • Inspection for leaks (monthly) Monitor vibrations and temperature (monthly) Re-greasing bearings (yearly) Check alignment (yearly) Replace gasket kit (every 2 years) Replace mechanical seal (every 3 years or when damaged) Impeller and shaft (only if it is required) Another important element are the butterfly valves or ball valves. These valves need to be serviced from time to time. Thus, gaskets, O-rings and seals shall be replaced after 3 years of operation. In addition, gear-boxes for these valves shall be greased annually. 42 be cleaned by mean of a CIP (clean-in-place). Last but not least, other type of heat www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK 10 OPERATION AND MAINTENANCE 10 OPERATION AND MAINTENANCE ACTIVITIES TO BE PERFORMED > CONDENSATION SYSTEM > REFRIGERANT SYSTEM The condensation of the refrigerant can generally be done by means of air (dry The heart of the refrigerant system in a District Cooling Plant are the compressors. condensation) or water in a District Cooling Plant. If it is done by means of air, air- Compressor usually used in ARANER District Cooling Plant are twin screw compressors condensers have to be installed in our District Cooling Plant, and these are the main or centrifugal compressors. For the compressors, an overhaul shall be done every 5 maintenance activities to be performed: years. However, there is an annual service kit to be replaced every year in order to • • • • • • Inspection for noises (daily) Monitor vibrations and temperature (weekly) Re-greasing motor bearings (yearly) Re-greasing fan bearings (yearly) Check alignment (monthly) Check belt tension (monthly) When the refrigerant is condensed by water, a heat exchanger is necessary. Thus, it applies what has been explained before about the heat exchangers (plate type and shell and tube type). Furthermore, additional information will be provided in another section related to fouling in heat exchangers. When condensed by water, these water may come from a cooling tower. There are some activities to be done in order to prevent legionella and to have the system clean. assure the proper performance of the seal, gaskets, O-rings and mechanical seals. The main activities for the compressor and compressor unit/chiller are: • • • • • • • • • • Inspection for leaks (daily) Monitor vibrations and temperature (weekly) Inspect lube oil strainers (monthly) Replace oil super-filters (yearly) Inspection of refrigerant strainers (yearly) Check alignment of the compressor (yearly) Replace gasket kit (every 1 years) Replace mechanical seal (every 3 years or when damaged) Impeller or screws and shaft (only if it is required) Major overhaul (every 4 years) Another important equipment of the refrigeration system are the refrigerant valves, which shall be serviced after some years of operation. In addition, the heat exchangers are part of the refrigerant cycle. 2 out of 4 steps implies the use of heat exchangers: evaporation and condensation. For evaporation applies what has been explained in the sub-epigraph of chilled water system. 43 www.araner.com | info@araner.com DISTRICT COOLING REFERENCE EBOOK ABOUT ARANER ARANER Group of Companies constitutes an innovative and multi-disciplinary ARANER’s main strength lies in its manpower, with the team committed to EPC engineering, aim and accept challenges that bring value in any of the fields where we procurement and construction activities. ARANER gets the know-how and are present. ARANER faces each project with the utmost professionalism. This experience of several pioneering and innovative companies from different allows our clients to be confident with our engineering and to be satisfied with areas of the world. our solutions. business group, involving design, manufacturing, The company provides a wide range of products, solutions and professional services to clients all across the world, where its leading-edge capabilities cover several disciplines, mostly linked to Energy systems and Cooling and Heating plants. Our goal is to create value for our stakeholders by meeting the stated and implied needs of our customers, employees and the communities where we exist and do business. We provide the best people working on the most advanced engineering systems. The company’s international structure, incorporated around ARANER Global DMCC, as a Holding Company, and with subsidiaries in the most relevant areas, allows the group to provide its solutions to all the markets where they are required. ARANER guarantees success in each project implementation. The company develops pioneering and innovative solutions tailored to customer needs that go beyond the usual requirements of the industry, focused on high efficiency and reliability. 44 Contact ARANER > DISTRICT COOLING REFERENCE EBOOK www.araner.com | info@araner.com www.araner.com | info@araner.com For continual development, ARANER reserves the right to change specifications or designs without notice. 45 ©2020 ARANER