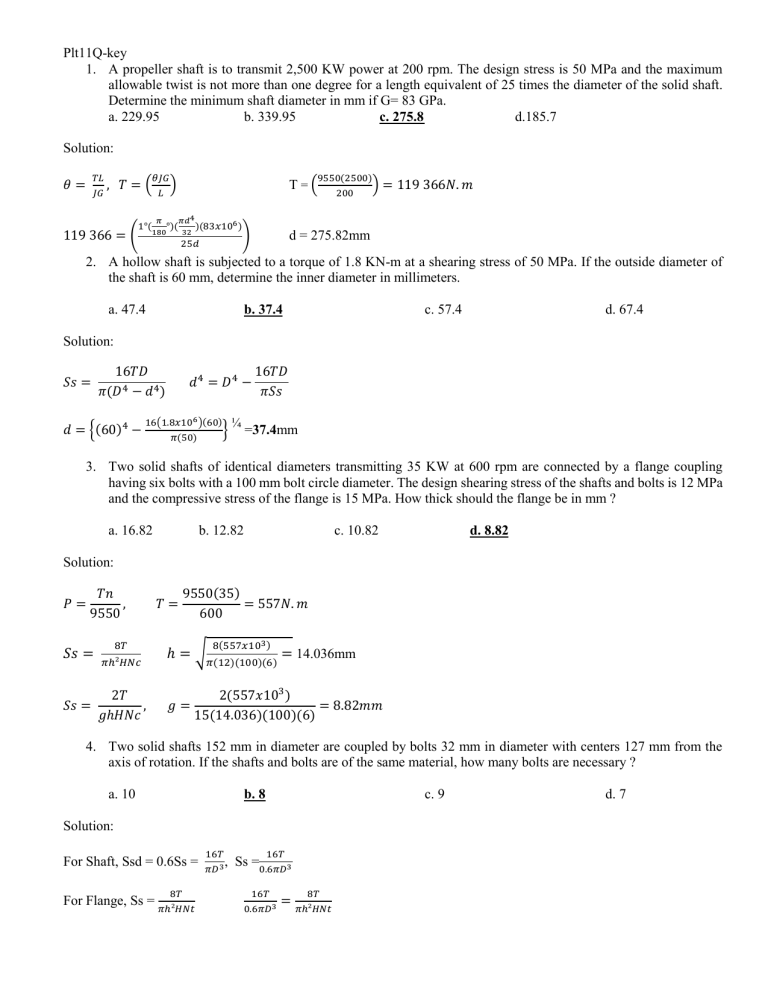

Plt11Q-key

1. A propeller shaft is to transmit 2,500 KW power at 200 rpm. The design stress is 50 MPa and the maximum

allowable twist is not more than one degree for a length equivalent of 25 times the diameter of the solid shaft.

Determine the minimum shaft diameter in mm if G= 83 GPa.

a. 229.95

b. 339.95

c. 275.8

d.185.7

Solution:

𝑇𝐿

,

𝐽𝐺

𝜃=

𝜃𝐽𝐺

)

𝐿

9550(2500)

)

200

𝑇=(

119 366 = (

1°(

T=(

𝜋

𝜋𝑑4

°)(

)(83𝑥106 )

180

32

)

25𝑑

= 119 366𝑁. 𝑚

d = 275.82mm

2. A hollow shaft is subjected to a torque of 1.8 KN-m at a shearing stress of 50 MPa. If the outside diameter of

the shaft is 60 mm, determine the inner diameter in millimeters.

a. 47.4

b. 37.4

c. 57.4

d. 67.4

Solution:

𝑆𝑠 =

16𝑇𝐷

𝜋(𝐷 4 − 𝑑4 )

𝑑 = {(60)4 −

𝑑4 = 𝐷4 −

16(1.8𝑥106 )(60)

𝜋(50)

}

¼

16𝑇𝐷

𝜋𝑆𝑠

=37.4mm

3. Two solid shafts of identical diameters transmitting 35 KW at 600 rpm are connected by a flange coupling

having six bolts with a 100 mm bolt circle diameter. The design shearing stress of the shafts and bolts is 12 MPa

and the compressive stress of the flange is 15 MPa. How thick should the flange be in mm ?

a. 16.82

b. 12.82

c. 10.82

d. 8.82

Solution:

𝑃=

𝑇𝑛

,

9550

𝑆𝑠 =

𝑆𝑠 =

8𝑇

𝜋ℎ²𝐻𝑁𝑐

2𝑇

,

𝑔ℎ𝐻𝑁𝑐

𝑇=

9550(35)

= 557𝑁. 𝑚

600

8(557𝑥103 )

ℎ = √𝜋(12)(100)(6) = 14.036mm

𝑔=

2(557𝑥103 )

= 8.82𝑚𝑚

15(14.036)(100)(6)

4. Two solid shafts 152 mm in diameter are coupled by bolts 32 mm in diameter with centers 127 mm from the

axis of rotation. If the shafts and bolts are of the same material, how many bolts are necessary ?

a. 10

b. 8

c. 9

Solution:

For Shaft, Ssd = 0.6Ss =

For Flange, Ss =

8𝑇

𝜋ℎ²𝐻𝑁𝑡

16𝑇

,

𝜋𝐷 3

16𝑇

Ss =0.6𝜋𝐷3

16𝑇

0.6𝜋𝐷 3

=

8𝑇

𝜋ℎ²𝐻𝑁𝑡

d. 7

0.6𝑑³

0.6(152)³

=

= 8𝑏𝑜𝑙𝑡𝑠

2ℎ²𝐻 2(32)²(127)

5. A flange coupling consist of eight 12 mm diameter steel bolts on a 300 mm bolt circle diameter and four 12 mm

diameter steel bolts on a concentric bolt circle 200 mm in diameter. If the shearing stress on the bolts is 72 MPa,

determine the maximum power in KW it can transmit at 1200 rpm.

𝑁𝑡 =

a. 1200

b. 1300

c. 1400

d. 1500

Solution:

T = T 1 + T2

T1 =F1r1Nt1

2 𝑟

𝑑

2

T2 = F2r2Nt2

12 2 100 2

F2 =(𝑑2 ) (𝑟2 ) 𝐹₁ = (12) (150) 𝐹₁

1

1

𝜋

F1 = SA1 = 4 (12)2 (72) = 8143.01𝑁

F2 =0.667F1

F2 = 0.667(8 143.01) = 5431.386N

300

200

T = 8143.01( 2 ) + 5431.386 ( 2 ) = 11 944.164𝑁. 𝑚

11 944.164(1200)

𝑃=

= 1500𝑘𝑊

9550

6. A Feroza jeep’s engine develops 50 KW at 1200 rpm with a single plate clutch with two pairs of friction surfaces

transmitting the power. Consider the coefficient of friction and the mean diameter to be 0.30 and 250mm,

respectively. Determine the axial force required to engage the clutch and transmit the power.

a. 4306.67 N

b. 3306.67 N

c. 5306.67 N

d. 6306.67 N

Solution:

𝑇 = 𝑛𝑓𝐹𝑎𝑟𝑓

𝐹𝑎 =

𝑇=

9550(50)

= 397.92𝑁. 𝑚

1200

𝑇

397𝑥103

=

= 5305.6𝑁

𝑛𝑓𝑟𝑓 2(0.30) (250)

2

7. A multidisc clutch transmit 20 KW at 500 rpm. It has 17 disks, 8 disks mounted on one shaft and 9 disks on the

other shaft. The disks are 140 mm outside diameter and 64 mm inside diameter. If the coefficient of friction is

0.20, calculate the axial force required to engage the clutch and transmit the torque.

a. 2137.16 N

b. 2237.16 N

c. 2337.16 N

Solution:

𝑇 = 𝑛𝑓𝐹𝑎𝑟𝑓

2 𝑟ₒ3 −rᵢ3

𝑇=

2

9550(20)

= 382 𝑁. 𝑚

500

(

rf = 3 (r02 −rᵢ2) = [(3) (

3

140

64mm 3

914.4 2

mm) +(

) −2(64Mpa)(

)

2

2

2

2

2

140mm

64mm

(

) −(

)

2

2

382 x 10³ = (17-1)(020)Fa(53.36)

Fa = 2 237.16 N

)] = 53.36Mpa

d. 2437.16 N

8. It requires 152 kg-m of energy for a shearing machine to shear a steel sheet. The normal speed of the shearing

machine is 3.33 m/s and it slow down to 3 m/s during the shearing process. The flywheel of the machine has a

mean diameter of 76.20 cm and weighs 7750 kg per cubic meter. The width of the rim is 40.48 cm. If the hub

and arms of the flywheel accounts to 15% of its total weight, find the thickness of the rim in cm.

a. 16.15

b. 18.15

c. 20.15

Solution:

120

𝑉1 = 2(0.762) ( 60 ) = 12.566 𝑟𝑎𝑑⁄𝑠𝑒𝑐

𝐾𝐸 =

𝑊𝑓

2𝑔

(𝑉ᵢ2 − 𝑉2 ²)

𝑊𝑓 =

60

𝜔2 = 2𝜋 (60) = 6.283 𝑟𝑎𝑑⁄𝑠𝑒𝑐

𝐾𝐸2𝑔

=

𝑉ᵢ2 − 𝑉2 ²

152(2)(9.81)

= 1 427.66 𝐾𝑔

(3.33)² − (3)²

𝑊𝑟𝑖𝑚 = (1 − .015)𝑊𝑓

𝑊𝑓 = 𝑊𝑟𝑖𝑚 + 0.15𝑊𝑓

𝑡=

d. 14.15

𝑊𝑟𝑖𝑚 = 0.85(1427.66) = 1213.51 𝐾𝑔

𝑊𝑟𝑖𝑚

1213.51

=

= 𝟏𝟔. 𝟏𝟔 𝒄𝒎

𝜋𝐷𝑚𝑏𝜌 𝜋(0.762)(0.4048)(7750)

9. A 122 cm diameter spoked flywheel having 30 cm width and 25 cm thickness rotates at 200 rpm. The hub and

the spokes accounts for 12% of the rim weight. The flywheel material has a density of 7750 kg/m3. During

stamping, the force exerted by the stamp varies from maximum at the point of contact to zero when the stamp

emerges from the metal. How long a cut can be stamped in a 2.5 cm thick aluminum plate if its ultimate shearing

strength is 275 MPa ?

a. 78.4 cm

b. 64.8 cm

Solution:

c. 54.8 cm

d. 48.4 cm

Concentration is at Di

𝑊𝑟𝑖𝑚 = 𝜋𝐷𝑖𝑏𝑡𝜌 = 𝜋{1.22 − (2 𝑥 0.25)}(0.30)(0.25)(7750) = 1314.756 𝐾𝑔

200

𝑉 = 𝜋(0.72) ( 60 ) = 7.54 𝑚⁄𝑠𝑒𝑐

𝑊𝑓 = 1.12(1314.756) = 1472.527𝐾𝑔

𝐾𝐸 =

1

2

(1472.527) (7.542 − 02 ) = 41857.76 𝑁. 𝑚

2(1472.527)

𝐹=[

] = 3 348 620.6 𝑁

0.025

𝐿=[

𝐾𝐸 = 𝑊 =

1

2

𝐹𝑡

𝐹

𝐹

𝑆𝑢 = [ ] = [ ]

𝐴

𝐿𝑡

3 348 620.6

] = 0.487𝑚 = 48.7𝑐𝑚

275 𝑥 10⁶(0.25)

10. The flywheel of a punching machine has a mean diameter of 36 inches and a rim 10 inches wide by 4 inches

deep. The operating speed is 600 rpm. What is the maximum diameter of a hole that can be punched through an

aluminum plate 1 inch thick if the ultimate shearing stress of the aluminum plate is 36,000 PSI? Assume

coefficient of fluctuation of 0.10 and density of the flywheel material of 0.28 lb/ in 3 and neglect the weight of

the spokes and hub.

a. 3.726 inches

Solution:

36

600

𝑉 = (12) ( 60 ) = 30𝜋

𝑓𝑡⁄

𝑠𝑒𝑐

b. 4.726 inches

c. 5.726 inches

d. 6.726 inches

𝑊𝑓 = 𝜋𝐷𝑚𝑏𝑡𝜌 = 𝜋(36)(10)(4)(0.28) = 1 266.69 𝑙𝑏

𝐸=

𝑊 2

1266.69

𝑉 𝐶𝑓 = (

) (30𝜋)2 (0.1) = 17471.36𝑓𝑡 − 𝑙𝑏

2𝑔

2(32.2)

1

𝐸 = 𝐹𝑡

2

2𝐸

2(17471.36)

=(

) = 419312.66 𝑙𝑏

1

𝑡

12

𝐹

2(419312.66)

𝑆𝑢 =

𝑑=

= 3.707 𝑖𝑛.

𝜋𝑑𝑡

36000(𝜋)(1)

11. A loaded carriage weighing 200 kg is moving at a velocity of 5 KPH. It was brought to rest by a bumper

𝐹=

consisting of two special steel spring ( spring index = 6 ). The springs are compressed by 20 cm. If the allowable

stress is 600 MPa, determine the mean diameter of the coils in mm.

a. 105.23

b. 106.23

c. 108.23

d. 101.23

Solution:

𝐹=

𝑚𝑉²

2𝑦

𝑆𝑠 =

=(

2000(

5000

)

3600

2(0.2)

) = 9.645𝐾𝑁

4𝐶−1

𝑘 = 4𝐶−4 +

C=6

0.615

𝐶

𝑘 = 1.2525

𝑘8𝐹𝐷𝑚 𝑘8𝐹𝐷𝑚 𝑘8𝐹𝐶³

=

=

𝜋𝑑³

𝐷𝑚³

𝜋𝐷𝑚²

𝜋

𝐶³

(1.2525)8(9.645)(6)³

𝐷𝑚 = √

= 0.105325𝑚 = 𝟏𝟎𝟓. 𝟑𝟐𝟓𝒎𝒎

𝜋(600 𝑥 103 )

12. A helical compression spring has a scale of 80 KN per meter. The spring mean diameter is 8 times the wire

diameter. The spring carries a load of 3500 N and the permissible working shear stress is 434,250 Kpa. Find

the effective number of coils. Use G = 74,442.86 Mpa.

a. 3.16

b. 4.16

c. 5.16

d. 6.16

Solution:

8𝐹𝐶 3 𝑁𝑐

𝐺𝑑

𝑆𝑠 =

𝑘8𝐹𝐷𝑚

𝜋𝑑 3

𝑆𝑠 =

𝑘8𝐹𝐶𝑑 1.184(8)(3.5)(8)

=

= 434 250 𝐾𝑁⁄

𝑚²

𝜋𝑑3

𝜋𝑑²

𝑑=√

𝑁𝑐 =

y=

𝐶=

8𝑑

𝑑

=8

4(8)−1

𝑘 = 4(8)−4 +

0.615

8

= 1.184

1.184(8)(3.5)(8)

= 0.1394𝑚 = 13.94𝑐𝑚

𝜋(434250)

𝐺𝑑

74442.86(123.94)

=

= 𝟑. 𝟏𝟔𝟕 𝑐𝑜𝑖𝑙𝑠

𝐹

8(80)(8)³

8 𝐶³

𝑦

13. A coiled squared and ground end compression spring of oil-tempered steel wire has seven active coils of 7/16

– inch wire wound in a coil of 3.5-inch outside diameter. The spring is used to produce axial pressure on a clutch.

The free length is 7.5 inches. With the clutch engaged, the length is 5and 5/8 inches. .Use G = 11,600,000 PSI.

Calculate the spring constant.

a. 218.2 lb/in

b. 264.2 lb/in

c. 294.2 lb/ in

d. 314.2 lb/in

Solution:

7

𝐷𝑚 (3.5 − 16)

𝐶=

=

=7

7

𝑑

16

y=

8𝐹𝐶 3 𝑁𝑐

,

𝐺𝑑

𝐹

𝑦

=

𝐺𝑑

8𝐶 3 𝑁𝑐

=

7

16

11.5 𝑥 10²( )

8(7)³(7)

= 𝟐𝟔𝟒. 𝟐𝟏𝟑 𝑙𝑏⁄𝑖𝑛.

14. A ground coil spring is made of 8 effective coils with an outside diameter of 2.5 inches. The permissible stress

is 50,000 PSI. Determine the maximum load that can be supported by the spring if the wire diameter is 7/16

inch.

a. 398.32 lb

b. 498.32 lb

c. 598.32 lb

d. 698.32 lb

Solution:

𝐷𝑚 = 𝐷𝑜 − 𝑑 = 2.5 −

7

16

= 2.0625𝑖𝑛.

𝐶=

𝐷𝑚

𝑑

=

2.0625

7

16

= 4.714

𝑘=

4(4.714)−1

0.615

+

4(4.714)−4

4.714

= 1.3324

7

(16)³(50000)

𝜋𝑑³𝑆𝑠

𝐹=

=

= 598.32𝑙𝑏

𝑘8𝐷𝑚 (1.2324)(8)(2.0625)

𝑘8𝐹𝐷𝑚

𝑆𝑠 =

,

𝜋𝑑³

15. A squared end coil spring has 8.5 active coils of 10 mm steel wire diameter and an outside diameter of 90 mm.

The pitch of the spring is 30 mm. If the spring constant is 80 KN per meter, determine the stress at solid length

in MPa.

a. 3280.35

b. 2830.35

c. 2380.35

d. 3820.35

Solution:

(Squared end)

𝑆𝐿 = (𝑛 + 3)𝑑 = (8.5 + 3)(10) = 115𝑚𝑚

𝐹𝐿 = 𝑛𝑝 + 3𝑑 = 8.45(30) + 3(10) = 285𝑚𝑚

𝑦𝑚𝑎𝑥 = 𝐹𝑙 − 𝑆𝐿 = 285 − 115 = 170𝑚𝑚 = 0.17𝑚

𝐶=

𝐷𝑚

𝑑

𝑆𝑠 =

=

90−10

10

=8

𝑘=

4(8)−1

0.615

+

4(8)−4

8

𝐹 = 80(0.17) = 13.6𝐾𝑁

= 1.184

1.184(8)(13.6)(80)

= 𝟑𝟐𝟖𝟎. 𝟑𝟓𝑀𝑃𝑎

𝜋(10)³

16. Chuck used on turret lathe is

A. collet chuck B. four jaw self centering chuck

Answer: D

C. Magnetic Chuck

D. Three jaw independent chuck

17. Angle plate is used for

A. cutting gears in a shaper B. cutting gears in a milling

Answer: A

C. cutting tapers in a lathe

D. fixing job cut angles is grinder

18. For machining the flange of 90 elbow on a lathe, which of the following device is used?

A. Angle plate B. Catch Plate

C. Face Plate

D. Lathe plate

Answer: C

19. A sine bar can not be used without a/an

A. angle gage

Answer: A

B. micrometer

C. slip gage

D. vernier caliper

20. Safety features that must be placed and maintained at machine, black smith welding and foundry shops called

A. safety goggles

Answer: C

B. safety notices

C. safety notices in markers / boards

D. walkway shops

21. In cutting tool the cutting end can also be generally called

A. back rake

Answers: C

B. end cutting edge

C. nose

D. side rake

22. A machine shop equipment that can flatter horizontally, vertically or angular plane called

A. drill machine

Answer: C

B. power saw

C. shaper machine

D. welding machine

23. Which of the following is an unsafe condition in operating a lathe machine?

A. operating with safety gloves

B. wearing a canvass apron

Answer: B

C. wearing denim pants / safety shoes

D. wearing safety goggles / hearing aid

24. The instrument used to remove old packing from packing glands and stuffing boxes are called:

A. packing tools

Answer: A

B. packing bits

C. gland box cleaners

D. packing screws

25. The type and number of bearings to be used for spindles of machine tool depend on

A. type of spindle

Answer: D

B. type of machine tool

C. load on the ring

D. load on the bearing

26. Which of the following has its angle 30 and is used for dotting after marking the lines on general works?

A. center punch

Answer: D

B. dot punch

C. hollow punch

D. prick punch

27. Which of the following has its angle 60 and is used for dotting after marking the lines on general works?

A. center punch

Answer: B

B. dot punch

C. hollow punch

D. prick punch

28. Which of the following has its angle 90 and is used to give deep marks for the location of drill?

A. center punch

Answer: A

B. dot punch

C. hollow punch

D. prick punch

29. It is used on soft metals and non-metals for making holes.

A. center punch

Answer: C

B. dot punch

C. hollow punch

D. prick punch

30. Which of the following is a property of wrought iron?

A. brittle

Answer: D

B. can not be forged

C. can be easily cast into different shapes

31. A piece of stock 8’’ long is 4” diameter on one end and 1” diameter on the other end. The

D. ductile

taper per foot is:

A. 4”

B. 4 -1/2”

Answer: B

C. 4 -1/4”

D. 4 -1/16”

32. A piece of stock 8” long is 3” diameter at ine end and 1 – ½” diameter at the other end. The taper per inch is:

A. ½”

Answer: C

B. ¼”

C 3/16”

D. 5/16”

33. A piece of stock 6” long is 2” diameter at one end and is cut with a taper of ½” to the foot. The diameter of the smaller end

will be:

A. 1–½’

Answer: B

B.1–¾

D. 2”

C.1-¼’

34. If a piston ring is to be made 1/64” larger in diameter per inch diameter of the cylinder which it is to fit, the required

diameter for a piston ring to fit an 8” cylinder will be:

A. 8–¼”

Answer: B

B. 8 - 1/8”

C. 8 – 3/16”

D. 8 – 5/32”

35. The good quality of a measuring tool

A. should be easy to handle

Answer: D

B. should be easy to read

C. should be wear resistance

D. all of the above

C. by using dial test indicator

D. all of the above

36. The flatness of surface can be checked

A. by using straight edge

Answer: D

B. by using surface plate

37. A holding device which is used to hold or grip work piece, while filling, chipping or any other bench work or while

machining or drilling them

A. clamp

Answer: D

B. grid

C. pressed

D. vise

38. A multi pointed hand anything tool used to removed material from metallic and non-metallic work pieces to match with

drawing, shape and size.

A. Cold chisel

Answer: B

B. File

C. Hacksaw

D. Hammer

39. A side-cutting tool used for accurately finishing the straight or tapered holes already drilled or bored.

A. Peering

Answer: B

B. Reamer

C. Swaging

D. Tapping

40. The lip clearance of a drill should be approximately:

A. 20 deg. – 25 deg.

Answer: C

B. 5 deg. – 10 deg.

C. 12 deg. – 15 deg

D. 15 deg. – 20 deg

41. If the cutting edges of a drill are cut at different angles:

A. the drill will not cut B. the hole will be larger than the drill C. the hole will be smaller than the drill

Answer: B

42. The correct cutting angle on a drill for ordinary work is:

A. 45 deg.

Answer: C

B. 50 deg.

C. 59 deg

D. 65 deg

D. none of the above

43. Which of the following gives greater hardness, cutting toughness and dine grain structure?

A. Chromium

Answer: A

B. Nickel

C. Tungsten

D. Vanadium

44. It is a process to impact maximum hardness to the steel part.

A. Annealing

Answer: B

B. Hardening

C. Normalizing

D. Tempering

45. In referring to threads, “pitch” is:

A. the distance of the full length of the thread

B. the distance from a point on one thread to a corresponding point on the next thread measured parallel to the axis

C. the distance from the top of one thread to the bottom of the next thread

D. the distance from the bottom of a head on a bolt to the first thread

Answer: B

46. A tool bit for cutting an American National thread should be ground with a:

A. 45 deg. Angle

Answer: C

B. 90 deg. Angle

C. 60 deg. Angle

D. 30 deg. angle

47. An approximate safe rule for cutting new piston rings for steam pumps is to make the ring:

A. .002” between piston and cylindrical for each inch diameter of piston

B. .001” between piston and cylinder for each inch diameter

C. .010 between piston and cylinder for each inch diameter of piston

D. .0001” between piston and cylinder for each inch diameter of piston

Answer: B

48. What does 3/8 – 16 mean to you?

A. 16 pieces, 3/8 “ long

B. gear with 16 teeth and a 3/8” arbor hole

Answer: D

C. 3/8” square, 16” long

D. 3/8” diameter. 16 threads per inch

49. When cutting. A drill will “squeal” due to:

A. drill being ground improperly

Answer: D

B. drill being too hot

C. insufficient lubrication

D. any of the above

50. Tapered shanks are used on large drill presses so that:

A. the drill can be centered more easily

B. the drill can be easily forced out of the sleeve with a drift

Answer: B

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

C

B

D

B

D

C

B

A

D

A

275.8

37.4

8.82

8

1500

5306.67

2237.16

16.15

48.4

3.726

C. the shank will not turn when cutting

D. the shank can be reground when worn

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

A

A

B

C

A

D

A

C

A

C

C

C

B

A

D

D

B

A

A

C

B

C

B

B

D

D

D

B

B

C

B

C

A

B

B

C

B

D

D

B

105.23

3.16

264.2

598.32

3280.35