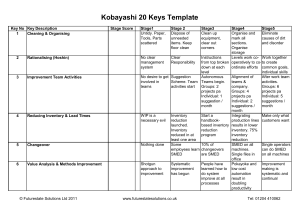

Kobayashi 20 Keys Table Key No Key Description 1 Cleaning & Organising 2 Rationalising (Hoshin) 3 Improvement Team Activities 4 Reducing Inventory & Lead Times 5 Changeover 6 Value Analysis & Methods Improvement © Vajna VSM Kft. Stage Score Stage1 Untidy. Paper, Tools, Parts scattered Stage4 Stage5 Organise and Eliminate mark all causes of dirt sections. and disorder Organise storage No clear Clear Instructions Levels work co- Work together management Responsibility from top broken operatively to co- to create system ordinate efforts common goals, down at each individual skills level No desire to get Suggestion Alignment of After work team Autonomous Scheme. Team Teams begin. teams & activities. involved in Groups: 2 company. Groups: 6 activities start teams projects pa projects pa Groups: 4 Individual: 1 projects pa Individual: 5 suggestions / suggestion / Individual: 2 month suggestions / month month WIP is a Inventory Start a Integrating Make only what necessary evil reduction handbookproduction lines customers want launched. based inventory results in lower Inventory reduction inventory. 75% reduced in at program inventory least one area reduction Nothing done 10% of SMED on all Single operators Some employees learn changeovers machines. can do SMED SMED are SMED on all machines Single files in office Shotgun Systematic People have Pokayoke and Improvement learned how to low cost making is approach to improvement do system automation systematic and improvement has begun improve at all result in continual processes doubling productivity www.vajna.hu Stage 2 Dispose of unneeded items. Keep floor clean Stage3 Clean up equipment, clear out corners Tel: +36-30-9829879 Kobayashi 20 Keys Template 7 Zero Monitoring Manufacturing Low recognition that monitoring (watching machines) is waste 8 Coupled/Synchronised Manufacturing Each workplace Emphasis on functions connections independently between processes Factory employees set up kanban stores 9 Maintenance 10 Time Control & Commitment Work & break times left to operators discretion Morning meetings are held. Safety equipment is worn at all times 11 Quality Quality left to inspectors Operators inspect their own products Supervisors meet to establish time control issues. Work starts promptly. Tools returned Defect info passed along immediately. Prevention takes place immediately © Vajna VSM Kft. Everyone recognises that monitoring is waste 10% process have unmanned operation during breaks All machines can operate during breaks; operators handle > 1 machine Clearly visible kanban established throughout. Fishbowl offices All machines are running on one-cycle automation zero monitoring Workers are conscientious about time. No early stops. Next day assignments known Pokayoke's are being built Rhythm is established. Value adding work performed for full shift All interdepartment walls are demolished. Goods and info flow freely Run machines Everyone Operator Full commitment A focused into the ground understands the responsible for to focused improvement need for TPM. elimination of 3 improvement. programme is in OEE is evils Zero breakdown place OEE is measured. (contamination, goal. Downtime 95% inadequate reduced by 75% lubrication, disoperation) www.vajna.hu Full pokayoke. Zero customer complaints Tel: +36-30-9829879 Kobayashi 20 Keys Template 12 Supplier Development Manufacturer / Supplier relationship limited to purchasing, acceptance, price negotiation 13 Waste Elimination Little understanding of waste 14 Worker Empowerment 15 Skill Versatility © Vajna VSM Kft. Suppliers and manufacturers work together on implementing all 20 keys Suppliers have reached a score of at least 70 on the 20 keys Everyone knows Waste what waste elimination really is begins by operators Improvement is Improvement Workers someone else's corners set up. participate in Teams make making their job their own own tools. shelves, tables, SMED has etc begun Actual work ratio is 85% (Value Add v Waste) Low cost automation devices are designed and made in house Actual work ratio is at least 95% No one is intersested in skill versatility Everyone embraced the goal of the adaptable factory. Cross training across classifications The factory is fully able to adapt to change by re-assigning trained employees. Most on 'Master' level www.vajna.hu Technical assistance is given in response to supplier queries. Support for upstream process Cross training begins. Willingness to learn Send technical assistance to suppliers. Provide QC and IE support Complete cross training being implemented. Everyone's core skills have doubled Factory makes and uses its own automation devices such as detectors, sensors, sorters Tel: +36-30-9829879 Kobayashi 20 Keys Template 16 Scheduling Deliveries rarely Some late on schedule delivery. Non uniform production still exists Work operations levelled throughout the month. Clear visible schedules 100% on time delivery, level schedules, plus level 3 on all keys Level schedules, with pull, plus level 4 on all other keys 17 Efficiency Control Indirect efficiency control reporting used Standard and actual times set and reviewed. Graph's kept Efficiency control monitored and graphed daily Everyone motivated to achieve suitably challenging goals 18 Shop Floor Information Systems Low awareness Used in limited of CIM, OA, areas POP information A factory wide automation policy developed CIM system fine- CIM and POP tuned after level systems fully 3 in other keys. implemented POP system implement 19 Energy & Materials Conservation not considered Company wide conservation policy begun Comprehensive Full pursuit of programme in conservation place 20 Leading Technology & Benchmarking No monitoring of competitors Position with respect to competitors established savings on existing equipment begun Keeping pace with average for the industry © Vajna VSM Kft. www.vajna.hu Labour content reported by family. Efficiency charts established One step ahead of industry average. Easy incorporation of new technologies Site technology amongst the best in the industry. Monitors leading edge technology Tel: +36-30-9829879