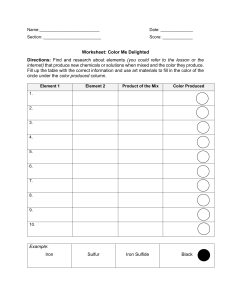

materials Article Preparation of Continuous Alumina Fiber with Nano Grains by the Addition of Iron Sol Luqun Liu, Juan Wang, Yunzhu Ma, Wensheng Liu and Shuwei Yao * National Key Laboratory of Science and Technology for National Defense on High-strength Structural Materials, Central South University, Changsha 410083, China; lluqun@csu.edu.cn (L.L.); wangjuan@csu.edu.cn (J.W.); zhuzipm@csu.edu.cn (Y.M.); liuwensheng@csu.edu.cn (W.L.) * Correspondence: shwyao@csu.edu.cn Received: 4 November 2020; Accepted: 26 November 2020; Published: 29 November 2020 Abstract: Continuous alumina fiber exhibits excellent mechanical properties owing to its dense microstructure with fine grains. In this study, alumina fiber was prepared by the sol–gel method using iron sol as a nucleating agent. It was proposed that the α-Al2 O3 grain size be adjusted based on the modification of colloidal particle size. The effect of holding temperature and reaction material ratio on the iron colloidal particle size was studied. The microstructure of alumina fiber was characterized by scanning electron microscopy (SEM). The experiment results indicated that iron colloidal particle size increases with the holding temperature and the NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratio. The alumina fiber with uniform nano α-Al2 O3 grains was obtained by calcination at 1400 ◦ C for 5 min. The mean grain size tends to rise with the mean colloidal particle size. Using the iron sol as a nucleating agent, the fiber with a mean grain size of 22.5 nm could be formed. The tensile strength of fibers increased with the decrease of grain size. Keywords: alumina fiber; iron sol; holding temperature; colloidal particle size; grain size 1. Introduction Continuous alumina fiber has been widely applied in various fields such as aerospace, military industry and automobile, owing to its high strength, high modulus and exceptional oxidation resistance [1–6]. The excellent mechanical properties of alumina fiber mainly depend on the dense nanocrystalline structure. For example, NextelTM 610 fiber and FP fiber are typical alumina fibers with high purity of α-Al2 O3 (>99 wt.%). The NextelTM 610 fiber, having a grain size of ~100 nm, exhibits high tensile strength of greater than 3.1 GPa [3], while the tensile strength of FP fiber is only about 1.4 GPa due to its larger grains (>500 nm) [5]. Hay et al. [6] found that the tensile strength of NextelTM 610 fiber was reduced with the growth of α-Al2 O3 grains. Thus, controlling the grain size is essentially important in order to prepare high performance alumina fiber. Generally, alumina fiber is prepared by the sol-gel method [7–12]. In this method, complex phase transformations of Al2 O3 take place. The fiber transfers from amorphous to metastable phases (η, δ, γ, etc.) and then transforms into α-Al2 O3 . Since the transformation temperature of metastable phases to α-Al2 O3 is about 1200 ◦ C, it is challenging to avoid α-Al2 O3 grain from coarsening during the transformation and densification processes. In order to obtain fiber with fine grains, nano α-Al2 O3 , α-Fe2 O3 and α-Cr2 O3 serving as seeds are added in alumina fiber, which induce the heterogeneous nucleation of α-Al2 O3 at a lower temperature [13–18]. Yamamura et al. [14] found that the alumina gel added with 5 wt.% α-Al2 O3 particles partially crystallized to α-Al2 O3 by annealing at temperature as low as 600 ◦ C. Li et al. [19] revealed that the addition of 3 wt.% α-Al2 O3 seeds lowered the γ-to-α transformation temperature by 175 ◦ C. As a result, the primary α-Al2 O3 grain size decreased from 56 to 30 nm. Kumagai et al. [20] found that the introduction of nano α-Al2 O3 seeds resulted in a Materials 2020, 13, 5442; doi:10.3390/ma13235442 www.mdpi.com/journal/materials Materials 2020, 13, 5442 2 of 14 dense microstructure with α-Al2 O3 grain size of 100–400 nm at 1200 ◦ C. In addition, NextelTM 610 fiber, the most representative alumina fiber, was also successfully produced by adding 0.7 wt.% Fe2 O3 . The addition of Fe2 O3 provided the benefits of forming fine α-Al2 O3 grains with the uniform size of 100 nm. In theory, increasing nucleation sites leads to the formation of more α-Al2 O3 grains, subsequently contributing to refine grains. Li et al. [19] found that the grain size of the alumina fiber sintered at 1100 ◦ C decreases from 86.7 to 74.3 nm, when the weight percent of α-Al2 O3 seeds rises from 1% to 3%. However, the content of nucleating agent cannot be added indefinitely in order to obtain continuous high purity alumina fiber. Theoretically, reducing the seed size is an effective way to increase the amount of nucleation sites when the content of the nucleating agent is constant. Xie et al. [21] compared the effect of α-Al2 O3 -seed size on the transformation from κ to α phase. Employing the same content of nucleating agent, the sample added with finer α-Al2 O3 powder exhibits a smaller average particle size with a narrow distribution. However, the size of α-Al2 O3 , Fe2 O3 and α-Cr2 O3 powders is limited by the production technologies, which is usually lager than 10 nm. Considering the agglomeration of nanoparticles, the nucleation seed size is almost larger than the particle size of powders. Thus, employing powders as nucleating agents, the seed size is difficult to further decrease. Wilson et al. [22] prepared a dense α-Al2 O3 fiber with finer grains (200–300 nm) through the addition of iron sol. It was confirmed that the iron sol could be transformed into α-Fe2 O3 before the formation of α-Al2 O3 and accelerating the transformation from metastable phases to α-Al2 O3 . Compared with powders, the size of colloidal particles can be controlled in the range of 1–100 nm. In addition, the iron colloidal particles can be uniformly distributed in the aluminum sol. However, these factors affecting iron colloidal particle size are unclear. The influence of iron colloidal particle sizes on the transformation of Al2 O3 and the morphology of α-Al2 O3 grains has not been reported. In this paper, it was proposed to prepare alumina fiber with ultra-fine grains by adjusting the iron colloidal particle size. Fe(NO3 )3 ·9H2 O and NH4 HCO3 were employed to prepare the iron sol. The effect of the material ratio and reaction temperature on the microstructure of iron colloidal particles was investigated. Alumina fiber with the nano grain size was prepared using iron sol as a nucleating agent. The relationship between the iron colloidal particle size and the grain size of α-Al2 O3 fiber was discovered. The effect of iron sol on the microstructure of alumina fiber was discussed. 2. Materials and Methods 2.1. Iron Sol Preparation Analytical pure Fe(NO3 )3 ·9H2 O and NH4 HCO3 provided by Aladdin (Shanghai, China) were used to prepare the iron sol. Firstly, Fe(NO3 )3 ·9H2 O and NH4 HCO3 were dissolved in a proper amount of water at room temperature. The weight ratios of Fe(NO3 )3 ·9H2 O/H2 O and NH4 HCO3 /H2 O were set to be at 1:23.5 and 1:10, respectively. Then, a certain amount of NH4 HCO3 solution was slowly added (3 drops/s) into the rapidly stirred Fe(NO3 )3 solution, which was placed in a 500 mL conical flask and stirred by a magnetic stirrer. The molar ratios of NH4 HCO3 to Fe(NO3 )3 ·9H2 O were set to be at 1.5, 1.75, 2.0, 2.25 and 2.5. Finally, the mixed solution was held at a certain temperature for 1 h. The holding temperature varied from 25 to 80 ◦ C. 2.2. Preparation of Alumina Fibers In this study, alumina fiber was prepared by the sol-gel method, which includes the preparation of alumina precursor sol, concentration of the precursor sol and the spinning and sintering processes [23,24]. In this study, alumina powder (>99.5 wt.%, 1–3 µm), formic acid (99 wt.%), acetic acid (99.5 wt.%), nitric acid (65 wt.%) and deionized water (lab made) were employed to prepare the alumina precursor sol. The alumina powder, formic acid, acetic acid and nitric acid were all provided by Aladdin (Shanghai, China). The molar ratio of starting materials was set to be at 1:0.67:0.6:0.36:28. The alumina precursor sol was prepared at 85 ◦ C in a single-layer glass reactor. The iron sol was added into the alumina Materials 2020, 13, 5442 3 of 14 precursor sol prior to the concentration process. The additional amount of iron sol was set in order to obtain a high-purity alumina fiber with 0.65 wt.% Fe2 O3 . The mixed solution was concentrated at 30–60 ◦ C using a rotary evaporator (Shanghai Xiande Experimental Instrument Co., LTD, Shanghai, China) to obtain sols with a suitable viscosity (50–200 Pa·s) for spinning. The precursor fiber was prepared using a lab-made dry spinning apparatus and collected by a bobbin winder. The precursor fiber was first preheated at 500 ◦ C and then calcined at 1400 ◦ C for 5 min using a tube furnace (BTF-1600C-IV-SL, BEQ, Hefei, China). 2.3. Characterization The morphology of iron colloidal particles was observed by a high-resolution transmission electron microscopy (TEM, JEM-2100F, JEOL, Tokyo, Japan). The colloidal particle size and Zeta potential of iron sol were measured by a particle size analyzer (Zetasizer Nano ZS, Malvern, Malvern, England). The thermal decomposition behavior of iron sol was analyzed using a simultaneous thermal analyzer (STA-449C, Netzsch, Selb, Germany). The microstructure of calcined alumina fiber was characterized by a scanning electron microscopy (SEM, Nova Nano, FEI, Hillsboro, Oregon, USA). The fiber mean grain size was calculated by measuring the grain sizes using the image analysis software Images J (V1.51, National Institutes of Health, Bethesda, Maryland, America). More than 800 grains were randomly selected from the cross-section image and measured for each fiber. The tensile strength of the fiber was measured by a fiber strength tester (XS(08)XT-3, XuSai, Shanghai, China) at room temperatures. The gauge length of the tested fiber was set to be at 15 mm. The cross-sectional area of the fiber was measured by SEM. In this study, thirty samples were tested for each kind of fiber in order to acquire its strength values. 3. Results and Discussion 3.1. Effect of Preparation Conditions on the Size of Iron Colloidal Particles In this study, iron sol was successfully prepared, which could be characterized by the color of dark red-brown. When a laser beam penetrated the sol, the Tyndall effect could be clearly observed. The morphology of iron colloidal particles obtained at different holding temperature is shown in Figure 1. In these cases, the molar ratio of NH4 HCO3 to Fe(NO3 )3 ·9H2 O was set to be at 2.5. In Figure 1, the black dots correspond to iron colloidal particles. It can be seen that the colloidal particles are approximately spherical with a particle size of less than 10 nm. When the holding temperature rises, the colloidal particles tend to be larger. The colloidal particle size of iron sol was measured by a particle size analyzer. As shown in Figure 2a, the colloidal particle size follows the lognormal distribution. The sol that was prepared at temperatures ranging from 25 to 70 ◦ C, its colloidal particle size mainly distributed in the range of 2–10 nm. With the increase of holding temperature, the distribution curve of colloidal particle size shifted to the right, which means that large colloidal particles tend to be formed at a higher temperature. When the holding temperature increased to 80 ◦ C, the colloidal particle size varied from 5 to 20 nm, which is much larger than others. Figure 2b shows the average size of iron colloidal particles. It was also found that the average size sharply increases from 7.06 to 10.16 nm, when the holding temperature rose from 70 to 80 ◦ C. Compared with the TEM results, the colloidal particle size obtained by the particle size analyzer is a little larger. This is because water in iron colloidal particles was lost during the preparation of the TEM sample. As a result, the size of iron colloidal particles decreased. Based on the above results, it is confirmed that increasing holding temperature contributes to larger iron colloidal particles being formed. Materials 2020, 13, 5442 4 of 14 Materials 2020, 13, x FOR PEER REVIEW 4 of 15 (a) (b) (c) (d) . (e) Figure 1. The morphology of iron colloidal particles prepared at different temperatures: (a) 40 ◦ C; ◦ C;iron ◦ C. Figure The colloidal particles prepared at different temperatures: (a) 40 °C; (b) (b) 501.◦ C; (c)morphology 60 ◦ C; (d) 70 of (e) 80 50 °C; (c) 60 °C; (d) 70 °C; (e) 80 °C. The colloidal particle size of iron sol was measured by a particle size analyzer. As shown in Figure 2a, the colloidal particle size follows the lognormal distribution. The sol that was prepared at temperatures ranging from 25 to 70 °C, its colloidal particle size mainly distributed in the range of 2– 10 nm. With the increase of holding temperature, the distribution curve of colloidal particle size shifted to the right, which means that large colloidal particles tend to be formed at a higher temperature. When the holding temperature increased to 80 °C, the colloidal particle size varied from 5 to 20 nm, which is much larger than others. Figure 2b shows the average size of iron colloidal particles. It was also found that the average size sharply increases from 7.06 to 10.16 nm, when the holding temperature rose from 70 to 80 °C. Compared with the TEM results, the colloidal particle size Materials 2020, 13, x FOR PEER REVIEW 5 of 15 obtained by the particle size analyzer is a little larger. This is because water in iron colloidal particles was lost during the preparation of theisTEM result, the water size ofiniron obtained by the particle size analyzer a littlesample. larger. As Thisa is because ironcolloidal colloidal particles particles decreased. Basedthe on the above results, it is confirmed holding contributes was lost during preparation of the TEM sample.that As increasing a result, the size oftemperature iron colloidal particles to larger iron colloidal being formed. decreased. Based on theparticles above results, it is confirmed that increasing holding temperature contributes Materials 2020, 13, 5442 5 of 14 to larger iron colloidal particles being formed. (a) (a) (b) (b) Figure 2. The size of iron colloidal particles prepared at different temperatures: (a) size distribution; Figure 2. The size of iron colloidal particles prepared at different temperatures: (a) size distribution; (b) average size. Figure 2. The size of iron colloidal particles prepared at different temperatures: (a) size distribution; (b) average size. (b) average size. Figure 3a 3/Fe(NO3)3·9H2O ratio on the size distribution of the iron Figure 3a presents presents the theeffect effectof ofNH NH4HCO 4 HCO3 /Fe(NO3 )3 ·9H2 O ratio on the size distribution of the ◦ colloidal particles prepared at 50 °C. As shown in in this figure, iron colloidal particle mainly Figure 3a presents the effect of NH 4 HCO 3/Fe(NO 3)3this ·9H 2figure, O ratio on the size distribution of the iron iron colloidal particles prepared at 50 C. As shown iron colloidal particle size size mainly distributes in the the range range of 2–10 2–10 nm. The distribution curves of colloidal colloidal particle size size are similar similar to the the colloidal particles prepared atnm. 50 °C. shown incurves this figure, iron colloidal particle size mainly distributes in of The As distribution of particle are to iron sols prepared under different conditions. When the ratio rises from 1.5 to 2.5, the distribution distributes in the range of 2–10 nm. The distribution curves of colloidal particle size are similar to the iron sols prepared under different conditions. When the ratio rises from 1.5 to 2.5, the distribution curve curve shifts to the right a little. Figure 3b shows the relationship between the average colloidal particle iron sols prepared under different conditions. When the ratio rises from 1.5 to 2.5, the distribution shifts to the right a little. Figure 3b shows the relationship between the average colloidal particle size size and the NH 4HCO 3/Fe(NO )3·9H2O3b molar ratio. can be seenbetween that the average sizecolloidal of iron colloidal curve shifts to the right a little.3Figure shows the It relationship the average particle and the NH 4 HCO3 /Fe(NO3 )3 ·9H2 O molar ratio. It can be seen that the average size of iron colloidal particles is only 3.61 nm when the NH 4HCO 3/Fe(NO 3)can 3·9H 2Oseen ratio is set to be at 1.5. With the increase size and the NH 4 HCO 3 /Fe(NO 3 ) 3 ·9H 2 O molar ratio. It be that the average size of iron colloidal particles is only 3.61 nm when the NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratio is set to be at 1.5. With the increase of the material material ratio, the average colloidal particle size slightly increases from 3.61 to 5.2nm. nm. particles is onlyratio, 3.61 the nm average when the NH4HCO 3/Fe(NO 3)3slightly ·9H 2O ratio is set to be at 1.5.to With the increase of the colloidal particle size increases from 3.61 5.2 of the material ratio, the average colloidal particle size slightly increases from 3.61 to 5.2 nm. (a) (a) (b) (b) Figure 3. The size of iron colloidal particles prepared with different NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratios at Figure 3. The size of iron colloidal particles prepared with different NH4HCO3/Fe(NO3)3·9H2O ratios 50 ◦ C: (a) size distribution; (b) average size. k in Figure 3a represents NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratio. at 50 °C:3. (a) (b) average k in Figure 3a represents NH43HCO 3/Fe(NO )3·9H 2O Figure Thesize sizedistribution; of iron colloidal particlessize. prepared with different NH4HCO /Fe(NO 3)3·9H23O ratios ratio. at 50 °C: (a) size distribution; (b) average size. k in Figure 3a represents NH 4 HCO 3 /Fe(NO 3 ) 3 ·9H 2O The stability of iron sol was studied by measuring the Zeta potential. As shown in Figure 4, ratio. the iron colloidal particles are positively charged, which is the same as alumina precursor colloidal The stability of iron sol was studied by measuring the Zeta potential. As shown in Figure 4, the particles. The zeta potential of iron sol ranges from 15 to 34 mV, indicating that all the sols are stable. iron colloidal particles charged, which is same as alumina precursor colloidal The stability of ironare solpositively was studied by measuring thethe Zeta potential. As shown in Figure 4, the Thus, the iron sol and alumina precursor sol can be mixed evenly without colloid coagulation. Among iron colloidal particles are positively charged, which is the same as alumina precursor colloidal all sols, the one prepared at 50 ◦ C with the NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratio of 1.5 has the smallest zeta potential. This is probably related to its small colloidal particle size. Materials 2020, 13, x FOR PEER REVIEW 6 of 15 particles. The zeta potential of iron sol ranges from 15 to 34 mV, indicating that all the sols are stable. Thus, the iron sol and alumina precursor sol can be mixed evenly without colloid coagulation. Among all sols, the one prepared at 50 °C with the NH 4HCO3/Fe(NO3)3·9H2O ratio of 1.5 has the Materials 2020, 13, 5442 6 of 14 smallest zeta potential. This is probably related to its small colloidal particle size. (a) (b) Figure 4. The Zeta potential of iron sols: (a) Zeta potential vs. holding temperature; (b) Zeta potential Figure 4. The Zeta potential of iron sols: (a) Zeta potential vs. holding temperature; (b) Zeta potential vs. vs. NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratio. NH4HCO3/Fe(NO3)3·9H2O ratio. During the preparation process of iron sol, many complicated chemical reactions took place, the preparation iron sol, manyreaction. complicated reactions took place, such During as the hydrolysis reactionprocess and theofpolymerization It waschemical discovered that hydrous iron such as the hydrolysis reaction and the polymerization reaction. It was discovered that hydrous iron polymers have the following formula [25], polymers have the following formula [25], [FeOq (OH)x (H2 O)p [3-(x + 2q)]+ ]n [counterions− ][3 − (x + 2q)]n/s [FeOq(OH)x(H2O)p[3-(x + 2q)]+]n[counterions−][3 − (x + 2q)]n/s (1) (1) where s is the charge of the counterion having a value of 1, 2 or 3 and n can be larger than where s is the charge of the counterion having a value of 1, 2 or 3 and−n can3− be larger than 500. The 500. The counterion can be any water-solubilizing anion, such as Cl , NO and COOH− . These counterion can be any water-solubilizing anion, such as Cl−, NO3− and COOH−. These complicated complicated reactions can be simply described in the following equations: reactions can be simply described in the following equations: Fe3+ + H2 O Fe(OH)2+ + H+ Fe3+ + H2O ⇌ Fe(OH)2+ + H+ )2+ +2+ +HH Fe(OH Fe(OH) + + H+ 2O Fe(OH) 2O ⇌ Fe(OH)22+ + H+ Fe OH )2 + + H2 O Fe(OH) + H+ Fe(OH) 2+ + H 2O ⇌ Fe(OH)33 + H+ (2) (2) + + NH4NH + OH) ++H+H+ 2O 4 +HH 2O ⇌ NH NH44((OH) (5) (5) – – – – HCO HO HCO 3 +H H 2O ⇌ H H22CO3 ++HO 3 + 2O (6) (6) – – ++ HCO HH O ++CO CO HCO 3 + ⇌ H22O 2 2 3 + h i x + 2q)]+ z)+ + H2O ⇌ [FeOq(OH)x(H2O)p[3-(x nFe(OH) z(3 –+ ]n nFe(OH )z (3 – z)+ H2 O FeOq (OH)x (H2 O)p [3−+(2q)]+ (7) (7) (3) (3) (4) (4) n (8) (8) In this this study, study,adding addingmore moreNH NH4 4HCO HCO33 solution solution in inthe theFe(NO Fe(NO33))33 solution solution will will consume consume more more H H++ In 3+ 3+ 3+ 3+ and accelerate accelerate the the hydrolysis hydrolysis reaction reactionof ofFe Fe .. Since Since the the Fe Fe hydrolysis reaction is an an endothermic endothermic and reaction, the increasing temperature also promotes the hydrolysis reaction. As a result, the value of of x reaction, the increasing temperature also promotes the hydrolysis reaction. As a result, the value increaseswith withthe theincrease increaseof ofholding holdingtemperature temperatureororNH NH 4HCO/Fe(NO ·9H22O ratio. ratio. In the hydrous hydrous increases 4 HCO 3 3/Fe(NO 3 )33)3·9H 3+ together. When the value of x increases, iron polymer, polymer,OH OH–– can can work work as as aa bridge bridge joining joining the the two twoFe Fe3+ iron the colloid colloid particles particles become larger. larger. Although the polymerization reaction is an exothermic reaction, the largeenergy energy barrier should be overcome during the polymerization [26]. Thus, large aa large barrier should be overcome during the polymerization processprocess [26]. Thus, large colloidal colloidaltend particles to be at highertemperatures. holding temperatures. particles to betend formed atformed higher holding 3.2. Thermal Analysis of Iron Sol Figure 5 shows the TG–DSC curves of iron sols prepared with different NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratios. It can be seen that these TG–DSC curves are similar for different samples. Thus, the iron sol prepared at 70 ◦ C with the NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratio of 2.5 was taken as an example to study Materials 2020, 13, 5442 7 of 14 its thermal decomposition behavior. These TG–DSC curves of iron sol obtained at a heating rate of 10 ◦ C/min in air atmosphere are presented in Figure 5. The TG curve reveals that the mass loss of iron sol occurs from room temperature to about 400 ◦ C, which can be divided into three stages. In the Materials 2020, 13, x FOR PEER REVIEW 7 of 13 first stage, from room temperature to about 190 ◦ C, the mass decreases slowly and the weight loss is ◦ C to 270 ◦ C. In this stage, the mass sharply declines from about 7%. slowly The second stage is from decreases and the weight loss190 is about 7%. The second stage is from 190 °C to 270 °C. In this ◦ 93% 64%. In the thirddeclines stage (270–400 C),tothe mass decreases gradually and°C), the the weight is only stage,tothe mass sharply from 93% 64%. In the third stage (270–400 massloss decreases 3%. After that, the mass of iron sol keeps in constant. During the thermal decomposition process, gradually and the weight loss is only 3%. After that, the mass of iron sol keeps in constant. During the weight loss is approximately 39%. shownloss in Figure 5, there are39%. threeAs small endothermic the total thermal decomposition process, the totalAsweight is approximately shown in Figure peaks andare twothree exothermic peaks in the DSC curve. endothermic distribute in thecurve. first stage. 5, there small endothermic peaks andAll two exothermicpeaks peaks in the DSC All ◦ C, respectively. Among all peaks, the one at 251 ◦ C The two exothermic peaks are at 251 and 380 endothermic peaks distribute in the first stage. The two exothermic peaks are at 251 and 380 °C, is the sharpest, whichall corresponds theatsharp decline mass. According to the TG–DSC respectively. Among peaks, the to one 251 °C is theinsharpest, which corresponds to thecurves, sharp it was inferred that the first stage of thermal decomposition is related to the removal of free water, decline in mass. According to the TG–DSC curves, it was inferred that the first stage of thermal bound water and ammonia gas.removal In the second dehydration and condensation hydroxyl decomposition is related to the of freestage, water,the bound water and ammonia gas. Inofthe second and the decomposition of Nitrate take place. In the third the weight lossofisNitrate probably stage, the dehydration and condensation of hydroxyl andstage, the decomposition takecaused place. by In the removal of residual hydroxyl and Nitrate. third stage, the weight loss is probably caused by the removal of residual hydroxyl and Nitrate. Figure 5. TG–DSC TG–DSC curves prepared with different NHNH at 70at◦70 C. curvesofofthe theiron ironsolsol prepared with different 4HCO 3/Fe(NO 3)3·9H O ratio 4 HCO 3 /Fe(NO 3 )3 ·9H 2 O 2ratio °C. The exothermic peak at 380 ◦ C is related to the transformation from iron sol to α-Fe2 O3 . It can ◦ C. Figure 6 shows the XRD patterns of the iron sols. be seen α-Fe2 O3 peak startsatto380 form Thethat exothermic °C at is about related350 to the transformation from iron sol to α-Fe2O3. It can be ◦ C for 12 h consists of orthorhombic NH NO (o-NH NO ), the amorphous The dried at 60 to 4 XRD 3 patterns 4 seeniron thatsol α-Fe 2O3 starts form at about 350 °C. Figure 6 shows the of3 the iron sols. The phase and a small amount of tetragonal NH NO (t-NH NO ). The amorphous phase corresponds to 4 3 4NH43NO3 (o-NH4NO3), the amorphous iron sol dried at 60 °C for 12 h consists of orthorhombic phase ◦ C for 1 h, the thermal decomposition the hydrous iron polymers. When the iron sol was annealed at 200 and a small amount of tetragonal NH4NO3 (t-NH4NO3). The amorphous phase corresponds to the of iron sol occurred. AsWhen a result, of these peaks t-NH4 NO3 4 NO3 and hydrous iron polymers. thethe ironintensity sol was annealed at 200related °C for 1toh,o-NH the thermal decomposition ◦ C for 1 h, the iron sol completely transformed into decreases. When the sol was calcined at 300 or 400 of iron sol occurred. As a result, the intensity of these peaks related to o-NH4NO3 and t-NH4NO3 α-Fe thethe formation of α-Fe is much lower than sol thatcompletely of α-Al2 O3transformed , the iron sol 2 O3 . Since 2 O3°C decreases. When sol was temperature calcined at 300 or 400 for 1 h, the iron can served as a nucleating agent for aluminaoffiber. intobe α-Fe 2O3. Since the formation temperature α-Fe2O3 is much lower than that of α-Al2O3, the iron sol can be served as a nucleating agent for alumina fiber. Figure 6. XRD patterns of the iron sol calcined at different temperatures for 1 h. hydrous iron polymers. When the iron sol was annealed at 200 °C for 1 h, the thermal decomposition of iron sol occurred. As a result, the intensity of these peaks related to o-NH4NO3 and t-NH4NO3 decreases. When the sol was calcined at 300 or 400 °C for 1 h, the iron sol completely transformed into α-Fe2O3. Since the formation temperature of α-Fe2O3 is much lower than that of α-Al2O3, the iron Materials 2020, 13, 5442 8 of 14 sol can be served as a nucleating agent for alumina fiber. Figure 6. XRD patterns of the iron sol calcined at different temperatures for 1 h. Figure 6. XRD patterns of the iron sol calcined at different temperatures for 1 h. 3.3. The Effect of Iron Sol on the Microstructure of Calcined Alumina Fibers In this study, the iron sols prepared with the NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratio of 1.5, 2.0 and 2.5 at 4 HCO3 /Fe(NO3 )3 ·9H2 O ratio of 2.5 at the temperature of 40, 50, 60, 70 and 80 ◦ C were chosen as nucleating agents to be added in alumina fibers. For simplicity, the iron sol was labeled as T-x and K-y, where T represents the one being prepared at different temperatures with the NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratio of 2.5, K corresponds to the sol obtained with different material ratio at 50 ◦ C and x and y are the holding temperature and the NH4 HCO3 /Fe(NO3 )3 ·9H2 O ratio, respectively. The Al2 O3 fibers prepared in this study are listed in Table 1. 50 ◦ C and the sols obtained with the NH Table 1. Samples prepared in this study. Iron Sol Preparation Condition Fiber Sample A1 A2 A3 A4 A5 B1 B2 Iron Sol T40 T50 T60 T70 T80 K1.5 K2.0 Holding Temperature ◦C 40 50 ◦ C 60 ◦ C 70 ◦ C 80 ◦ C 50 ◦ C 50 ◦ C NH4 HCO3 /Fe(NO3 )3 ·9H2 O Ratio 2.5 2.5 2.5 2.5 2.5 1.5 2.0 The Fe content in the calcined Al2 O3 fibers was measured by inductively coupled plasma optical emission spectrometer (ICP-OES). The calculated Fe2 O3 content based on the Fe content varied from 0.63% to 0.66%, which is in agreement with the setting value. The sample A4 was taken as an example to study the phase transformation of alumina fiber. Figure 7 shows the XRD patterns of this fiber. It can be seen that the amorphous phase exists only in the fiber preheated at 500 ◦ C. When the fiber was calcined at 1400 ◦ C for 1 min, the amorphous Al2 O3 partially crystallized to γ-Al2 O3 . With the holding time prolonged, α-Al2 O3 became the main phase. The fiber completely transformed into α-Al2 O3 phase, when it was calcined for 5 min. Thus, all the alumina fibers were calcined at 1400 ◦ C for 5 min. Materials 2020, 2020, 13, 13, x 5442 Materials FOR PEER REVIEW Materials 2020, 13, x FOR PEER REVIEW of 15 14 99of 9 of 15 Figure 7. XRD patterns of Al2O3 fibers calcined at 1400 °C. ◦ C. Figure Figure7.7.XRD XRDpatterns patternsof ofAl Al22O O33 fibers calcined at 1400 °C. The morphology and cross-section microstructure of calcined Al2O3 fibers are shown in Figure The morphology and cross-section microstructure ofofcalcined AlAl are shown inin Figure 8. 2 O2O 3 fibers Thebe morphology cross-section microstructure calcined 3from fibers15 are shown Figure 8. It can seen that alland the fibers are continuous with a diameter ranging to 18 µ m. The fiber It bebe seen that allall the fibers are continuous with ranging from µm. 8. can It can seen that the fibers are continuous withaother adiameter diameter ranging from15 15to to18 18microstructure µ m. The The fiber fiber surface is smooth without obvious cracks, pores and defects. The cross-section surface is smooth without obvious cracks, pores and other defects. The cross-section microstructure surface is smooth cracks,ofpores and other defects.grains. The cross-section microstructure of alumina fiber iswithout uniformobvious and consists nano-scale equiaxed For different fibers, these of alumina fiber is uniform and consists of nano-scale equiaxed grains. For different fibers, these of alumina fiber is uniform and consists of nano-scale equiaxed grains. For different these microsturctures are similar except for their grain size. Among all fibers, the sample A1,fibers, B1 and B2 microsturctures are similar except forfor their grain size. Among all fibers, the sample A1, B1 and B2 have microsturctures are similar except their grain size. Among all fibers, the sample A1, B1 and B2 have a significantly smaller grain size. From sample A1 to A5, the α-Al2O3 grain size increases ahave significantly smaller grain size. From sample A1 to A5, the α-Al O grain size increases gradually. 3 α-Al2O3 grain size increases a significantly smaller grain size. From sample A1 to A5,2 the gradually. gradually. (a) (a) (b) (b) (c) (c) (d) (d) Figure 8. Cont. Materials 2020, 13, 5442 10 of 14 Materials 2020, 13, x FOR PEER REVIEW 10 of 15 (e) (f) (g) (h) (i) (j) (k) (l) Figure 8. Cont. Materials 2020, 13, 5442 11 of 14 Materials 2020, 13, x FOR PEER REVIEW 11 of 15 (k) (l) (m) (n) (m) (n) Figure 8. The morphology and cross-section ofcalcined calcined Sample-A1; 3 fibers: Figure 8. The morphology and cross-sectionmicrostructure microstructure of AlAl 2O2 3O fibers: (a,b)(a,b) Sample-A1; Figure 8. The morphology and cross-section microstructure of calcined Al2O3 fibers: (a,b) Sample-A1; (c,d) Sample-A2; (e,f)(e,f) Sample-A3; (g,h) Sample-A4; (k,l) Sample-B1; (m,n)SampleSample-B2. (c,d) Sample-A2; Sample-A3; (g,h) Sample-A4;(i,j) (i,j)Sample-A5; Sample-A5; (k),l) Sample-B1; (m,n) (c,d) Sample-A2; (e,f) Sample-A3; (g,h) Sample-A4; (i,j) Sample-A5; (k),l) Sample-B1; (m,n) SampleB2. B2. The distribution of fiber grain size is shown in Figure 9. It can be seen that the grain size of each The follows distribution fiber grain size is shown in Figure 9. ItA1 can seen the value grain size of each from kind of fiber theof normal distribution. From sample tobe A5, thethat peak increases The distribution of fiber graindistribution. size is shown in Figure 9. Ittocan bethe seen that theincreases grain size of each kind of fiber follows the normal From sample A1 A5, peak value from 37.5 to 54.0 nm. The sample B1 and B2 exhibit finer grains, which distribute in the range of 14–35 nm kind 37.5 of fiber follows thesample normal distribution. From sample A1 to A5, theinpeak valueofincreases from to 54.0 nm. The B1 and B2 exhibit finer grains, which distribute the range 14–35 nm and 12–42 nm, respectively. The relationship between the fiber grain size and the iron colloidal particle and 12–42 The B2 relationship between thewhich fiber grain size and therange iron colloidal 37.5 to 54.0 nm.nm, Therespectively. sample B1 and exhibit finer grains, distribute in the of 14–35 nm size is shown in Figure 9h. It was revealed that the maximum mean grain size of fiber (sample A5) was particle size is shown in Figure 9h. It was revealed that the maximum mean grain size of fiber (sample and 12–42 nm, respectively. The relationship between the fiber grain size and the iron colloidal only 54.3 nm. When the mean colloidal particle size decreased from 10.16 to 5.65 nm, the mean grain A5)size wasisonly 54.3 in nm. When9h. theItmean colloidal that particle decreased fromgrain 10.16size to 5.65 nm, (sample the particle shown Figure was revealed thesize maximum mean of fiber size also gradually from 54.3 to 46.5 nm.54.3 With the further decrease of mean colloidal particle mean grain sizedeclined also gradually declined from to 46.5 nm. With the further decrease of mean A5) was only 54.3 nm. When the mean colloidal particle size decreased from 10.16 to 5.65 nm, the size from 5.65 particle to 3.61 nm, mean size quickly decreased to 22.5 nm. Generally, the22.5 grain size of colloidal size the from 5.65 grain to 3.61 nm, the mean grain size quickly decreased to nm. mean grain size also gradually declined from 54.3 to 46.5 nm. With the further decrease of mean alumina fiber isthe equal larger than 100 nm. In this the addition ofthis ironstudy, sol with small colloidal Generally, grainorsize of alumina fiber is equal orstudy, larger than 100 nm. In the addition of colloidal particlesmall size colloidal from 5.65 to 3.61 nm, the mean grain alumina size quickly decreased to 22.5 nm. ironsize sol with particle size contributed to nano forming fiber with nano grains. particle contributed to forming alumina fiber with grains. Generally, the grain size of alumina fiber is equal or larger than 100 nm. In this study, the addition of iron sol with small colloidal particle size contributed to forming alumina fiber with nano grains. (a) (b) Figure 9. Cont. (a) (b) Materials 2020, 13, 5442 12 of 14 Materials 2020, 13, x FOR PEER REVIEW 11 of 13 (c) (d) (e) (f) (g) (h) The grain distribution aluminafiber: fiber: (a) (a) Sample A2,A2, (c) Sample A3, A3, FigureFigure 9. The9. grain sizesize distribution ofof alumina SampleA1, A1,(b) (b)Sample Sample (c) Sample (d) Sample A4, (e) Sample A5, (f) Sample B1 and (g) Sample B2. (h) The relationship between mean (d) Sample A4, (e) Sample A5, (f) Sample B1 and (g) Sample B2. (h) The relationship between mean grain size and mean colloidal particle size. grain size and mean colloidal particle size. Figure 10 shows the tensile strength of alumina fibers. The sample B1 exhibits the highest tensile Figure 10 shows the tensile strength of alumina fibers. The sample B1 exhibits the highest tensile strength, up to ~1400 MPa, which is related to the smallest grain size. From sample A1 to A5, the strength, up to ~1400 MPa, which is related to the smallest grain size. From sample A1 to A5, the tensile tensile grain size decreases, corresponding to the increase of the grain size. Thus, decreasing fiber grain grain size decreases, corresponding to thestrength increase of the grain size. Thus, decreasing fiber grain size size contributes to higher tensile being acquired. contributes to higher tensile strength being acquired. The formation of α-Al2 O3 includes the nucleation and grain growth processes. Based on the above results, all the iron sols can be employed as nucleating agents to promote the formation of α-Al2 O3 . In the nucleation process, the nucleation density of α-Al2 O3 is proportional to the number of iron colloidal particles added in unit volume. When the additional amount is consistent, the reduction of colloidal particle size is effective to increase the colloidal particle number and the nucleation density. Thus, decreasing the colloidal particle size contributes to forming more α-Al2 O3 grains in smaller size. In theory, the initial grain size of α-Al2 O3 increases linearly with the colloidal particle size. Materials 2020, 13, 5442 13 of 14 However, the α-Al2 O3 grain size rises slightly when the colloidal particle size is larger than 5.65 nm. This probably results from the grain growth of α-Al2 O3 . As shown in Figure 7, most of α-Al2 O3 can be formed before 3 min, while the phase transformation completes at 5 min. During this process, the initial α-Al2 O3 grains will grow up and merge into lager grains. Since the growth rate decreases with the increase of Al2 O3 grain size, as a result, the grain size of the samples added with large iron colloidal particles tends be constant. Materials 2020, 13, x FOR PEERtoREVIEW 12 of 14 Figure 10. Tensile strength of alumina fibers. 4. Conclusions Figure 10. Tensile strength of alumina fibers. In this study, stable iron sols were prepared with NH4 HCO3 and Fe(NO3 )3 ·9H2 O. The mean The formation of α-Al2O3 includes the nucleation and grain growth processes. Based on the colloidal particle size ranges from 3.61 to 10.16 nm, which increases with the holding temperature above results, all the iron sols can be employed as nucleating agents to promote the formation of αand the NH4 HCO3 /Fe(NO3 )3 ·9H2 O molar ratio. Sintered at 300 ◦ C for 1 h, the iron sol completely Al2O3. In the nucleation process, the nucleation density of α-Al2O3 is proportional to the number of transformed into α-Fe2 O3 . Adding iron sol to alumina fiber contributes to forming alumina fiber with iron colloidal particles added in unit volume. When the additional amount is consistent, the reduction uniform nano-scale grains. The minimum mean grain size of fiber is only 22.5 nm, when the iron sol of colloidal particle size is effective to increase the colloidal particle number and the nucleation with the mean colloidal particle size of 3.61 nm was used as a nucleating agent. With the increase of density. Thus, decreasing the colloidal particle size contributes to forming more α-Al2O3 grains in colloidal particle size, the grain size tends to rise from 22.5 to 54.3 nm. The fiber with the smallest smaller size. In theory, the initial grain size of α-Al2O3 increases linearly with the colloidal particle grain size exhibits the highest tensile strength, up to ~1400 MPa. size. However, the α-Al2O3 grain size rises slightly when the colloidal particle size is larger than 5.65 nm. This probably results fromW.L., the grain growth of α-Al2O3. to Asthe shown in Figure 7, most of L.L., α-AlJ.W. 2O3 Author Contributions: L.L., J.W., Y.M. and S.Y. contributed investigation of the study. and preparedbefore and analyzed sol and and L.L. wrote completes the manuscript. and Y.M. can S.Y. be formed 3 min,the while thefibers. phaseS.Y. transformation at 5 J.W., min.W.L. During this reviewed process, the and gave comments. All authors have read and agreed to the published version of the manuscript. themanuscript initial α-Al 2O3 grains will grow up and merge into lager grains. Since the growth rate decreases Funding: research was by National Nature Science China, grant number with the This increase of Al 2O3funded grain size, as a result, the grainFoundation size of theofsamples added with 52001333. large iron colloidal particles tends to be constant. Conflicts of Interest: The authors declare no conflict of interest. 4. Conclusions References TM 6103 Fibers In this study, stable iron sols were prepared with NH4HCO and Fe(NO 3)3·9H O. The mean Schmucker, M.; Mechnich, P. Microstructural Coarsening of Nextel Embedded in2Alumina-Based colloidal particle size ranges to 10.16 nm, which increases with the holding temperature Matrices. J. Am. Ceram. Soc.from 2008, 3.61 91, 1306–1308. [CrossRef] and the NH4HCO 3/Fe(NO 3)3of ·9H 2O molar ratio. alumina Sinteredfibers at 300 for 1filament h, the iron sol completely 2. Cantonwine, P.E. Strength thermally exposed Part°C I Single behavior. J. Mater. Sci. transformed into α-Fe[CrossRef] 2O3. Adding iron sol to alumina fiber contributes to forming alumina fiber with 2003, 38, 461–470. TM 610 and NextelTM 720 fibres. J. Mater. Sci. 1997, 32, 3. Wilson, D.M. Statistical strength ofmean Nextel uniform nano-scale grains.tensile The minimum grain size of fiber is only 22.5 nm, when the iron sol [CrossRef]particle size of 3.61 nm was used as a nucleating agent. With the increase of with 2535–2542. the mean colloidal 4. Johnson, D.W.;size, Evans, A.G.; Goettler, R.W. Ceramic Coatings: Materials for thethe Twenty-First colloidal particle the grain size tends to riseFibers fromand 22.5 to 54.3Advanced nm. The fiber with smallest National DC, 1998. grainCentury; size exhibits theAcademy highest Press: tensileWashington, strength, up toUSA, ~1400 MPa. 5. Dhingra, A.K. Alumina Fibre FP. R. Soc. Lond. Philos. Trans. 1980, 294, 411–416. 6. Hay, R.S.; Fair, G.E.; Tidball, Fiber Strength After Grain Growth Nextel™ 610ofAlumina Fiber. Am. Author Contributions: L.L., J.W., T. W.L., Y.M. and S.Y. contributed to theininvestigation the study. L.L.,J. J.W. Ceram. Soc. 2015, 1907–1914. and S.Y. prepared and98, analyzed the [CrossRef] sol and fibers. S.Y. and L.L. wrote the manuscript. J.W., W.L. and Y.M. reviewed the manuscript and gave comments. All authors have read and agreed to the published version of the manuscript. 1. Funding: This research was funded by National Nature Science Foundation of China, grant number 52001333. Conflicts of Interest: The authors declare no conflict of interest. References Materials 2020, 13, 5442 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 14 of 14 Chen, Z.; Zhang, Z.; Tsai, C.C.; Kornev, K.; Luzinov, I.; Fang, M.; Peng, F. Electrospun mullite fibers from the sol-gel precursor. J. Sol-Gel Sci. Technol. 2015, 74, 208–219. [CrossRef] Roque-Ruiz, J.H.; Medellín-Castillo, N.A.; Reyes-López, S.Y. Fabrication of α-alumina fibers by sol-gel and electrospinning of aluminum nitrate precursor solutions. Results Phys. 2019, 12, 193–204. [CrossRef] Song, X.; Ma, Y.; Wang, J.; Liu, B.; Yao, S.; Cai, Q.; Liu, W. Homogeneous and flexible mullite nanofibers fabricated by electrospinning through diphasic mullite sol–gel route. J. Mater. Sci. 2018, 53, 14871–14883. [CrossRef] Li, X.; Su, X.; Xiao, H.; Chen, L.; Li, S.; Tang, M. Continuous alpha-Al2 O3 fibers grown by seeding with in-situ suspension. Ceram. Int. 2020, 46, 15638–15645. [CrossRef] Sakka, S. Current and Future Possibilities of Sol-Gel Process. Trans. Indian Ceram. Soc. 2005, 64, 13–19. [CrossRef] Tan, H.B.; Guo, C.S. Preparation of long alumina fibers by sol-gel method using malic acid. Int. J. Miner. Metall. Mater. 2011, 21, 1563–1567. [CrossRef] Xie, Z.P.; Lu, J.W.; Huang, Y.; Cheng, Y.B. Influence of α-alumina seed on the morphology of grain growth in alumina ceramics from Bayer aluminum hydroxide. Mater. Lett. 2003, 57, 2501–2508. [CrossRef] Yamamura, K.; Kobayashi, Y.; Yasuda, Y.; Morita, T. Fabrication of α-alumina by a combination of a hydrothermal process and a seeding technique. Funct. Mater. Lett. 2018, 11, 1850042.1–1850042.4. [CrossRef] Levin, I.; Brandon, D. Metastable Alumina Polymorphs: Crystal Structures and Transition Sequences. J. Am. Ceram. Soc. 1998, 81, 1995–2012. [CrossRef] Chang, P.L.; Yen, F.S.; Cheng, K.C.; Wen, H.L. Examinations on the Critical and Primary Crystallite Sizes during θ- to α-Phase Transformation of Ultrafine Alumina Powders. Nano Lett. 2001, 1, 253–261. [CrossRef] Bell, N.S.; Cho, S.B.; Adair, J.H. Size Control of α-Alumina Particles Synthesized in 1,4-Butanediol Solution by α-Alumina and α-Hematite Seeding. J. Am. Ceram. Soc. 2005, 81, 1411–1420. [CrossRef] Nordahl, C.S.; Messing, G.L. Thermal analysis of phase transformation kinetics in α-Al2 O3 seeded boehmite and γ-Al2 O3 . Thermochim. Acta 1998, 318, 187–199. [CrossRef] Li, X.; Xu, H.; Wang, Q.; Li, S.; Xiao, H.; Zhang, L.; Tang, M.; Chen, L. Control of continuous α-Al2 O3 fibers by self-seeding and SiO2 -Sol doping. Ceram. Int. 2019, 45, 12053–12059. [CrossRef] Kumagai, M.; Messing, G.L. Controlled, Transformation and Sintering of a Boehmite Sol-Gel by α-Alumina Seeding. J. Am. Ceram. Soc. 1985, 68, 500–505. [CrossRef] Xie, Z.; Lu, J.; Gao, L.; Li, W.; Xu, L.; Wang, X. Influence of different seeds on transformation of aluminum hydroxides and morphology of alumina grains by hot-pressing. Mater. Des. 2003, 24, 209–214. [CrossRef] Wilson, D.M.; Wood, T.E. Microcrystalline Alumina-Based Ceramic Articles. U.S. Patent 4,954,462, 4 September 1990. Liang, C.; Liu, W.; Liu, Q.; Gao, Y.; Liu, J.; Wang, J.; Yao, S.; Ma, Y. The formation of core-sheath structure and its effects on thermal decomposition and crystallization of alumina fibers. Ceramic Int. 2020, in press. [CrossRef] Liu, J.; Ma, Y.; Liu, W.; Song, X.; Yao, S.; Wang, J.; Cheng, M.; Li, C. Preparation of alumina precursor sols with a high solid content for alumina fibers. Mater. Res. Express 2019, 6, 045207. [CrossRef] Wood, T.E.; Wilson, D.M.; Sowman, H.G. Microcrystalline Alumina-Based Ceramic Articles. U.S. Patent 5,185,299, 9 February 1993. Li, C.; Liu, W.; Ma, Y. Influence of H3 O+ on the structure formation of oligomers in aluminium sols prepared from basic aluminium acetate: Experiments and computations. J. Mol. Liq. 2019, 289, 111052. [CrossRef] Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. © 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).