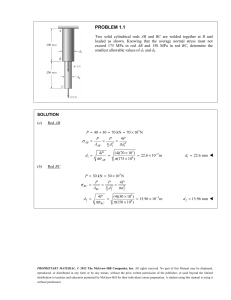

STRENGTH OF MATERIALS CHAPTER ONE INTRODUCTION CONCEPT OF STRESS Prepared by : Eng. Ahmad Bani Yaseen 1 1.1 REVIEW OF THE METHODS OF STATICS ❑ The main objective of the mechanics of materials is to analyse and design a given structure involving determination of stress and deformation. 2 ❑ Review of Statics • The structure is designed to support a 30 kN load • The structure consists of a links and rod joined by pins at the junctions and support. • Perform a static analysis to determine the internal force in each structural member and the reaction forces at the supports. 3 ❑ Structure Free-Body Diagram • The structure is detached from supports and the loads and reaction forces are indicated • Conditions for static equilibrium: • Ay and Cy can not be determined from these equations 4 ❑ Component Free-Body Diagram • In addition to the complete structure, each component must satisfy the conditions for static equilibrium • Consider a free-body diagram for the boom: • substitute into the structure equilibrium equation • Results: • Reaction forces are directed along link (AB) and rod (CD). 5 ❑ Method of Joints • The link (AB) and rod (BC) are 2-force members, i.e., the members are subjected to only two forces which are applied at member ends • For equilibrium, the forces must be parallel to an axis between the force application points, equal in magnitude, and in opposite directions • Joints must satisfy the conditions for static equilibrium which may be expressed in the form of a force triangle: 6 1.2 STRESS IN THE MEMBERS OF A STRUCTURE ▪ Can the system withstand the force? ▪ Will the system break down? ▪ Its ability to withstand the depends on 1- Its material (Steel is stronger than Aluminum) 2- The cross-section of the rod A Stress is the intensity of the internal forces distributed over a given area stress (N/m 2 = Pa) P = A Internal force (N) Cross-section area ( m2) 7 STRESS UNITS 8 ❑ Analysis and design • Assume rod BC is made of steel with maximum allowable stress all = 165 MPa FBC = 50kN = FBC 50 kN = = 159 MPa 2 −3 2 r (10 10 ) all *Thus, rod BC can withstand the load without breaking down 9 • Design of new structures requires selection of appropriate materials and component dimensions to meet performance requirements Example: What will be the suitable diameter for rod BC without exceeding all = 100 MPa. Solution: P all = A A= d2 A= 4 d= 4A = ( P all = 4 500 10 50 103 N 100 106 Pa −6 m 2 = 500 10− 6 m 2 ) = 2.52 10−2 m = 25.2 mm * The rod 26 mm or more in diameter will be suitable 10 ❑ Axial loading, Normal stress 𝐏 The stress 𝜎 = is the average stress on the cross−section. 𝐴 The stress at point 𝑄 is Δ𝐅 𝜎 = lim 𝐴→0 Δ𝐴 𝑃 = න𝑑𝐹 = න 𝜎𝑑𝐴 𝐴 11 ❑ The stress is considered uniformly distributed if: I. The line of action of the concentrated load passes through the centroid of the cross-section. 12 II. The cross-section is far from the edges where the load is applied. 13 SHEARING STRESS ❑ Transverse load is acting perpendicular to the rod (not in the normal direction). ❑ The load cause shear stress. ave P F = = A A 14 EXAMPLE ON SHEAR FORCE ave V F/2 = = A A 15 MORE EXAMPLES ON SHEAR ave P F/4 = = A A 16 Example: given width w = 150 mm. Find the average shear stress along sections a-a and b-b. Solution: a−a Va − a 3 103 = = = 200 kPa Aa − a 0.1 0.15 b −b Vb −b 3 103 = = = 160 kPa Ab −b 0.125 0.15 17 𝐄𝐱𝐚𝐦𝐩𝐥𝐞: Find 𝑑 and 𝑡 in order to support the 20kN, given 𝜎𝑎𝑙𝑙 = 60 MPa 𝜏𝑎𝑙𝑙 = 35 MPa 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧: 𝐏 𝐴= 𝜎𝑎𝑙𝑙 𝜋 2 20 × 103 𝑑 = 4 60 × 106 Then, we get =≫ 𝑑 = 20.6 mm 𝐕 𝐴= 𝜏𝑎𝑙𝑙 20 × 103 2𝜋 × 0.02 × 𝑡 = 35 × 106 𝑡 = 4.55 mm 18 𝐄𝐱𝐚𝐦𝐩𝐥𝐞: 𝑑 = 6 mm 𝑃 = 9 kN Find 𝜏𝑎𝑣𝑒 in pins 𝜏𝑎𝑣𝑒 in the shadow planes (tear out) 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧: 9 × 103 /4 𝜏𝑎𝑣𝑒 (𝑝𝑖𝑛𝑠) = 𝜋 = 79.6 MPa −3 2 (6 × 10 ) 4 9 × 103 /4 𝜏𝑎𝑣𝑒 (𝑝𝑙𝑎𝑛𝑒𝑠) = = 225 kPa 0.1 × 0.1 19 BEARING STRESS IN CONNECTIONS • Bolts, rivets, and pins create stresses on the points of contact or bearing surfaces of the members they connect. • The resultant of the force distribution on the surface is equal and opposite to the force exerted on the pin. P b = td 20 APPLICATION TO THE ANALYSIS AND DESIGN OF SIMPLE STRUCTURES We will determine the normal stresses, shearing stresses, and bearing stresses Normal Stress in Link AB and Rod BC 1- Normal stress on rod (BC) 𝐅𝐁𝐂 50 × 103 𝜎𝐵𝐶_𝑚𝑖𝑑 = 𝜎𝑎𝑣𝑔 = 2 = = 159 MPa 𝜋𝑟 314 × 10−6 𝐴BC_end = 𝐴BC_C = (20 )(40−25) × 10−6 = 300 × 10−6 m2 𝜎𝐵𝐶−𝐵 𝐅𝐁𝐂 50 × 103 = = = 167 MPa 𝐴𝐵𝐶−𝐵 300 × 10−6 𝜎𝐵𝐶−𝐶 = 𝜎𝐵𝐶−𝐵 = 167 MPa 21 2- Normal stress on link (AB) 𝜎𝐴𝐵 𝐅𝐀𝐁 −40 × 103 = = = −26.7 MPa 𝐴𝐴𝐵 30 × 50 × 10−6 ❖ Note that there is no stress on the joints A and B as the rod is under compression. Shearing Stress in Various Connections. 1- Shearing stress (Pin A) A = r 2 = (12.5 10−3 ) 2 = 49110−6 m 2 FAB P= = 20 kN 2 P A = = 40.7 MPa A 22 2- Shearing stress (Pin C) 𝐴 = 𝜋𝑟 2 = 𝜋(12.5 × 10−3 )2 = 491 × 10−6 m2 𝐏 = 𝐅𝐁𝐂 = 50 kN 𝐏 𝜏𝐶 = = 102 MPa 𝐴 23 3- Shearing stress (Pin B) PG 25 103 B = 2 = = 50.9 MPa −6 r 49110 Bearing stress 1- Bearing stress at point A 1− on the link 𝐏 40 × 103 𝜎𝑏 = = = 53.3 MPa 𝑡𝑑 30 × 25 × 10−6 2 − on the brackets 𝐏 40 × 103 𝜎𝑏 = = = 32.0 MPa 𝑡𝑑 2 × 25 × 25 × 10−6 24 2- Bearing stress at point C 1− on the link 𝐏 50 × 103 𝜎𝑏 = = = 100.0 MPa 𝑡𝑑 20 × 25 × 10−6 2 − on the brackets 𝐏 50 × 103 𝜎𝑏 = = = 100.0 MPa 𝑡𝑑 20 × 25 × 10−6 25 1.3 STRESS ON AN OBLIQUE PLANE UNDER AXIAL LOADING = F A = V A A0 A = cos 𝑃 cos 𝜃 𝜎= 𝐴0 / cos 𝜃 𝑃 𝜎= cos 2 𝜃 𝐴0 𝑃 sin 𝜃 𝜏= 𝐴0 / cos 𝜃 𝑃 𝜏= sin 𝜃 cos 𝜃 𝐴0 26 Problem 5.0 cm 5.0 cm The 15 kN load P is supported by two wooden members of uniform cross section that are joined by the simple glued scarf splice shown. Determine the normal and shearing stresses in the glued splice. Solution : F P V 30 60 o o 𝑃 𝜎= cos 2 𝜃 𝐴0 𝑃 𝜏= sin 𝜃 cos 𝜃 𝐴0 15 × 103 2 30 = 4.5 𝑀𝑃𝑎 𝜎= cos 25 × 10−4 15 × 103 𝜏= cos 30 sin 30 = 2.59 𝑀𝑃𝑎 25 × 10−4 27 1.5 DESIGN CONSIDERATION ❑ Allowable Load and Allowable Stress: Factor of Safety Structural members or machines must be designed such that the working stresses are less than the ultimate strength of the material. 1- Determination of the ultimate strength of a material. PU U = A 2- Allowable stress; factor of safety Factor of safety = F.S = Ultimate stress Allowable stress Factor of safety considerations: • uncertainty in material properties • uncertainty of loadings • uncertainty of analyses • number of loading cycles • types of failure • maintenance requirements and deterioration effects • importance of member to integrity of whole structure • risk to life and property • influence on machine function 28 COMMON SUPPORT REACTIONS 29 𝐄𝐱𝐚𝐦𝐩𝐥𝐞: Determine the required diameter of the bolts if the failure shear stress is 𝜏𝐹𝑎𝑖𝑙 = 350 MPa. Use a factor of safety F. S = 2.5. Solution : A= V all 20 103 2 = = d 6 350 10 / 2.5 4 then, we get d = 13.5 mm 30 𝐄𝐱𝐚𝐦𝐩𝐥𝐞: Given (𝜎𝐴𝐵 )𝑎𝑙𝑙 = 175 MPa (𝜎𝐵𝐶 )𝑎𝑙𝑙 = 150 MPa Find 𝒅𝑨𝑩 and 𝒅𝑩𝑪 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧: dAB 𝐅𝐀𝐁 = 70 kN, and 𝐅𝐁𝐂 = 30 kN 𝐅𝐀𝐁 (𝜎𝐴𝐵 )𝑎𝑙𝑙 = 𝜋 2 𝑑 𝐴𝐵 4 𝐅𝐁𝐂 (𝜎𝐵𝐶 )𝑎𝑙𝑙 = 𝜋 2 4 𝑑𝐵𝐶 dBC 𝑑𝐴𝐵 = 22.6 mm 𝑑𝐵𝐶 = 16 mm. 31 Problem 1.55 In the structure shown, an 8-mm-diameter pin is used at A, and 12-mm diameter pins are used at B and D. Knowing that the ultimate shearing stress is 100 MPa at all connections and that the ultimate normal stress is 250 MPa in each of the two links joining B and D, determine the allowable load P if an overall factor of safety of 3.0 is desired. 32 33