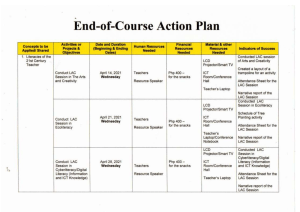

Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 Petroleum Development Oman L.L.C. SP-1101 Specification for Installation of Overhead Transmission Lines Document ID SP-1101 Document Type Specification Security Unrestricted Discipline Owner Issue Date Version Electrical UEE – CFDH-Electrical August-20 5.0 Keywords: This document is the property of Petroleum Development Oman, LLC. Neither the whole nor any part of this document may be disclosed to others or reproduced, stored in a retrieval system, or transmitted in any form by any means (electronic, mechanical, reprographic recording or otherwise) without prior written consent of the owner. Page 1 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 This page was intentionally left blank Page 2 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC ii Document Authorisation Authorised For Issue Document Authorisation Document Owner Document Custodian Document Author (CFDH) Haddabi, Salim UEE Kindi, Nabil UEE3 Saifi, Abdul Rahim UEE31 Date : 31-08-2020 Date : 31-08-2020 Date : 31-08-2020 User Note: The requirements of this document are mandatory. Non-compliance shall only be authorised by the Document Owner or his Delegate through Variance Tracking Tool approval. A controlled copy of the current version of this document is on PDO's EDMS. Before making reference to this document, it is the user's responsibility to ensure that any hard copy, or electronic copy, is current. For assistance, contact the Document Custodian or the Document Author. Users are encouraged to participate in the ongoing improvement of this document by providing constructive feedback. Page 3 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC iii Revision History The following is a brief summary of the 4 most recent revisions to this document. Details of all revisions prior to these are held on file by the issuing department. Version No. Version 5.0 Version 4.0 Version 3.0 Version 2.0 Version 1.0 Version 0 Date Author Scope / Remarks August .20 Dec.19 Generally updated. June 99 Saifi, Abdul Rahim UEE31 Saifi, Abdul Rahim UEE31 UIE44, Noora Naamani Said Al Shuley, UIE/6 Ali Al Raisi, OIE/23 Nov 86 BEB/4 Dec.16 May 08 Format changed and minor corrections and update made Format changed and minor corrections made Generally updated. Converted to Specification as per PDO Policy Cascade & minor changes to the text. Original issued as ERD-63-04 iv Related Business Processes Code Business Process (EPBM 4.0) v Related Corporate Management Frame Work (CMF) Documents The related CMF Documents can be retrieved from the Corporate Business Control Documentation Register CMF. Code CP-117 Page 4 Corporate Management Frame Work (CMF) Document Project Engineering Code of Practice Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 TABLE OF CONTENTS II DOCUMENT AUTHORISATION ................................................................................... 3 III REVISION HISTORY ..................................................................................................... 4 IV RELATED BUSINESS PROCESSES ........................................................................... 4 V RELATED CORPORATE MANAGEMENT FRAME WORK (CMF) DOCUMENTS ..... 4 1 INTRODUCTION ............................................................................................................ 6 1.1 PURPOSE ................................................................................................................................... 6 1.2 APPLICABLE STANDARDS, SPECIFICATION AND CODES .................................................... 6 1.2.1 PDO Standards .......................................................................................................... 6 1.2.2 International Standards .............................................................................................. 7 1.3 COMPLIANCE WITH STANDARDS .......................................................................................... 12 1.4 ENGINEERING DOCUMENTS TO BE SUBMITTED ................................................................ 12 2 SCOPE ......................................................................................................................... 14 2.1 GENERAL .................................................................................................................................. 14 2.1.1 2.2 Access to Site ........................................................................................................... 14 SITE PRELIMINARIES AND PREPARATORY WORKS ........................................................... 15 2.2.1 Soil Investigations..................................................................................................... 15 2.2.2 Line Route Survey .................................................................................................... 15 2.2.3 Route Clearance....................................................................................................... 17 2.2.4 Pegging Out.............................................................................................................. 18 2.2.5 Crossings.................................................................................................................. 18 2.3 LINE ERECTION ....................................................................................................................... 19 2.3.1 Safety ....................................................................................................................... 19 2.3.2 Erection of Lines with Lattice Steel Towers .............................................................. 19 Page 5 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 1 INTRODUCTION 1.1 PURPOSE Revision:5.0 Effective: August. 20 This Specification is applicable to 132 kV and 33 kV overhead lines constructed using concrete poles and steel lattice towers. Specifications SP-1114B,SP-1114C,SP-1114D and SP-1102B specify the design basis for 132 kV and 33 kV overhead lines and include detailed general arrangement drawings for all types of structures. It shall be the responsibility of the Contractor to ensure that lines are profiled and the structures are spotted in such a way that the standard design limits are not exceeded. 1.2 APPLICABLE STANDARDS, SPECIFICATION AND CODES The following Standards, specifications and codes should be consulted when applying the requirement of this Standard. All listed documents shall be latest issue except those documents prescribed by date. 1.2.1 1 PDO Standards HSESM Health Safety and Environmental Protection Standards Manual 2 SP-1131 3 PR-1282 Specification for Reinforced concrete 4 PR-1666 Project drawing Procedures. 5 SP-1274 6 SP-1131 7 SP-1011 Specification for Installation of Overhead Transmission Lines. 8 GU-920 Electrical Installation guideline. 9 SP-1102B Specification for Design of 33 kV Overhead Power Lines. 10 SP-1103 11 GU-946 Specification for Electrical Engineering Guidelines Electrical Safety Rules Guidance. 12 SP-1279 Specification for civil construction works. 13 SP-1106 Handover and As built Documentation. specification for civil & building construction materials Testing Civil & Building Guide to Concrete 14 SP-1107 Specification for Coding and Identification of Overhead Line Systems Electrical Protection Systems. 15 GU-861 Electrical safety Operating Guidance. 16 SP-1109 Specification for Earthing and Bonding. 17 SP-1111 18 SP-1114B 19 SP-1127 Specification for Temporary Electrical Supplies for Construction & Maintenance Work. Specification for Design of 132/220kV Overhead Power Lines on Steel Towers. Layout of Onshore Facilities 20 SP-1275 Specification and Criteria for Design of Civil & Building Works Page 6 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 21 GU-756 Survey Engineering Work Execution. 22 SP-2177 Survey Methods and Techniques 23 PR-1817 1.2.2 Revision:5.0 Effective: August. 20 Right of way Inspection procedure International Standards 1. Design of Overhead Lines 1 IEEE ANSI C2 - 2002 National Electrical Safety Code 2 ASCE No. 74 Guidelines for Electrical Transmission Line Structural Loading 3 DIN VDE 0210 Planning and Design of OHTL with Rated Voltage above 1 kV 4 EN 50341 Overhead Electrical Lines Exceeding AC 45kV 5 IEEE:524:1992 Guide to Installation of Overhead Transmission Line Conductors. 2. Steel Lattice Towers for Overhead Lines 1 ASCE 10-97 Design of Latticed Steel Transmission Structures 2 ASCE Manual No. 52 Design of lattice steel towers - Code of practice for Strength assessment of 3 ASTM A 36 Standard Specifications for Structural Steel 4 ASTM A 394 Standard Specification for zinc coated steel transmission tower bolts. 5 ASTM A 572 High Strength Structural Steel, Grade 50 6 ASTM A588/588M-94 Standard Specification for High-Strength Low-Alloy Structural Steel with 50ksi (345 Minimum members of lattice towers and masts Yield Point 7 BS 4:Part 11993 Structural Steel Sections. Specification for Hot-Rolled Sections 8 BS 729:1971(1986) Specification for Hot Dip Galvanised Coatings on Iron and Steel Articles. 9 BS 3436 Specification for ingot zinc 10 BS 3643:Part 2-1998 ISO Metric Screw Threads BS 4102-1998 Page 7 Specification for Installation of Overhead Transmission Lines Barbed Wire Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC 11 BS 4190 : 2001 ISO Metric Black Hexagon Bolts, Screws and Nuts-Specification 12 BS 4360 Specification for Weldable Structural Steel 13 BS 4464-1998 Specification for Spring Washers for general Engineering and automobile purposes-Metric Series 14 BS 4848:Part 4 Specification for Hot – Rolled Structural Steel Section. Equal and unequal angles 15 BS 4872:Part 1:1999 Specification for approval testing of welders When welding procedure approval is 16 BS 5135:1984 Specification for arc welding of carbon and carbon manganese steels 17 BS 5493:197 Code of practice for protective coating of iron and steel structures against corrosion 18 BS 59501:2000 Structural Use of Steelwork in Building 19 BS 7361-6 Coatings on Metal Fasteners - PART 6: Specification for Hot Dipped Galvanized Coatings 20 BS DD133 Code of Practice for Strength Assessment of Members of Lattice Towers and Masts 21 BS EN 1990:2002 Eurocode – Basis of structural design 22 BS EN 10025:1993 Specification for hot-rolled products of non-alloy structural steels and BS EN 10029:1991 Specification for tolerances on dimensions, shape and 24 BS EN 100562-1993 Specification for structural steel equal and unequal leg angle. Tolerances on shape and dimensions 25 BS EN 101131993 Hot-rolled products in weldable fine grain structural steels 26 BS EN 10155:1993 Structural steels with improved atmospheric corrosion resistance.Technical delivery conditions 27 BS EN 101631991 Specification for Delivery Requirements for Surface Conditions of HotRolled Steel Plate, Wide Flats and Sections 28 BS-EN-ISO1461-1999 Specification for Hot Dip Galvanising of Structural Steel 29 IEC 60652/2002 Testing of Towers 30 IEC 60826 Loading and strength of overhead transmission lines 31 ISO 1459:197 Metallic coatings – Protection against corrosion by hot-dip galvanizing – Guiding principles 32 IEEE Std. 9511988 Guide to the Assembly and Erection of Metal Transmission Structures. 23 not required Fusion welding of steel. their technical delivery conditions mass for hot-rolled steel plates 3 mm thick or above. . 3. Page 8 Foundations Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC 1 BS 8004:1986 Code of practice for foundations 2 BS 8081-1989 Ground anchorage 3 BS 8110-P11997 4 DIN 1045 Concrete, reinforced and prestressed concrete structures 5 DIN 4014 Bored piles, construction procedure, design and bearing behaviour 6 IEC 1277 Full scale test on foundations 7 IEC 61773/1996 Overhead lines - Testing of foundations for structures 8 IEEE Std. 9771991 Guide to installation of Foundations for Transmission Line Structures. 4. Code of practice for design and construction Phase Conductors & ACS Sheildwire 1 ASTM A 123-89a Standard Specifications for Zinc (Hot- Dip Galvanized) Coatings on Iron and Steel Products. 2 ASTM 399-82 Concentric lay stranded aluminium alloy 6201-T81 3 ASTM 399-90 Standard specification for aluminium alloy 6201-T81 wire for electrical purposes 4 ASTM B415:1992 Standard Specification for Hard-Drawn Aluminum- Clad Steel Wire 5 ASTM B416:1988 Specification for Concentric-Lay-Stranded Aluminum Clad-Steel Conductors 6 BS 443:1982(1990) Specification for testing zinc coatings on steel wire and for quality requirements 7 BS 1490:1988 Specification for aluminium and aluminium alloy ingots and castings for general engineering purposes 8 BS 3242-1970 Specification for Aluminium Alloy stranded Conductor for Overhead Power Transmission 9 BS EN 50182:2001 Conductors for overhead lines - Round wire concentric lay stranded conductors 10 CIGRE-Electra No. 75 Permanent Elongation of Conductors - Predictor Equation and Evaluation Methods 11 DIN 46391 Delivery Drums for Conductors 12 IEC 60104 Aluminium-magnesium-silicon alloy wire for OHTL 13 IEC 60888 IEC 60888 14 IEC 61089:1997 Amdt.1 1997 Round wire concentric lay overhead electrical stranded conductors 15 IEC 61089:199 Round wire Concentric Lay Overhead Electrical Stranded Conductors. IEC 61232:1993 Aluminum Clad-Steel Wire for Electrical Purposes 16 IEEE 738 IEEE Standard for the calculation of Current Temperature Relationship of Bare Overhead Conductors. Page 9 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC 5. Optical Fibre Ground Wire ( OPGW) 1 BS EN 1870001994 Generic specification for optical fibre cables 2 BS EN 1880001994 Generic specification for optical fibre cables 3 EIA 492A Generic Specification for Optical Waveguide Fibers 4 EIA 472A Sectional Specification for Fiber Optic Communication Cables for Outside Aerial Use 5 EIA/TIA-455 Standard Test Procedures for Fiber Optic Fibers Cables, Transducers, Sensors, Connecting and Terminating Devices and other Fiber Optic Components 6 IEC 60304 Colour coding of fibers 7 IEC 60793 Optical Fibers 8 IEC 60794 Optical Fiber Cables. Generic and production specifications 9 IEEE 1138 Standard Construction of Composite Fiber Optic Overhead Ground Wire (OPGW) for use on Electric Utility Power Lines 10 IEEE:P1138 Specification for optical fibre ground wire (OPGW) 11 ITU-T G.650 Definition and test methods for the relative parameters of single mode fibres 12 ITU-T G.652 Characteristics of a Single-Mode Optical Fiber Cable 13 ITU-T G.655 Characteristics of Non-Zero Dispersion-Shifted Single-Mode Optical Fibers 6. 1 Insulator Strings & Conductor Fittings ANSI C29.11 Composite Suspension Insulators for Overhead Transmission Lines - Tests 2 ASTM 153/153M95 Standard Specification for Zinc (Hot- Dip 3 ASTM A 563 Nuts for Bolted Connections 4 BS 3100:1991 Specification for steel castings for general engineering purposes 5 BS 3288 Part 1:1997 Insulator and conductor fittings for Overhead Power Lines. Performance and general requirements 6 Galvanized) on Iron and Steel Hardware Specification for a range of fittings. BS 3288 Part 2:1990 7 BS 3288 Part 3:1989 8 BS 3288 Part 4:1989 9 BS EN 60383- Page 10 Dimensions of ball and socket couplings of string insulator units. Locking devices for ball and socking couplings of string insulator units: dimensions and tests. Insulator strings & insulator sets for a.c. systems. Definitions, test method Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC 2:1995 and acceptance criteria 10 CISPR 18-2:1986: Part 2 Radio interference characteristics of overhead power lines and high- voltage equipment. Methods of measurement and procedure for determining limits 11 DIN/VDE 0212 Fittings for overhead lines and switchgear, Part 50 to 12 53 DIN 48006 Insulators of overhead lines: long rod insulators 13 DIN 48062-2 Overhead Lines, clevis caps for insulators 14 DIN 48069-1 Double eyes; without protective fitting attachment; for overhead power lines 15 DIN 48069-2 Double eyes; with protective fitting attachment; for overhead power lines 16 DIN 48070-1 Triangular yokes for overhead power lines 17 DIN 48073 Clevis-tongue couplings – Safety devices 18 DIN 48074 Eyes and clevises; connecting dimensions 19 DIN 48075 Parallel groove clamps for aluminium stranded conductors and for aluminium conductors steel-reinforced for overhead power lines 20 DIN 48078-1 Clevis straps for overhead lines; for coupling to connecting bolts on the strap side 21 DIN 48215 Clamps and Connectors for Overhead Power Lines DIN 48334 for overhead power lines 22 IEC 60060-1 High voltage test techniques 23 IEC 60120 Dimension of Ball and Socket couplings of String Insulator Units 24 Turnbuckles Insulators for overhead lines with nominal voltage above 1000 V IEC 60383 25 IEC 60433:1998 Characteristics of String Insulator Units of the Long Rod type. 26 IEC 60437:1997 Radio interference test on high voltage insulators 27 IEC 60471:1977 Dimensions of clevis and tongue coupling of string insulator units 28 IEC 60507:1991 Artificial pollution tests on high-voltage insulators to be used on a.c. systems 29 C 60587:1984 Test method for evaluating resistance to tracking and erosion of electrical insulating materials under severe ambient conditions 30 IEC 60707:1999 Method of test for the determination of the flammability of solid electrical insulating materials when exposed to an igniting source 31 IEC 60815:1986 Guide for selection of Insulators in respect of Polluted Conditions. 32 IEC 61109:1992 Composite Insulators for a.c. Overhead Lines with a nominal voltage greater than 1000 V – Definitions, test methods and acceptable tests. (& Amendment 1) 33 IEC 61854 Requirements and Tests for Spacers 34 IEC 61284 Overhead lines, Requirements and tests for fittings 35 IEC 61466 Composite string insulator units for overhead lines with a nominal voltage greater than 1000 V, parts 1 and 2 36 IEEE 4 Standard Techniques for High Voltage Testing 37 IEEE Report PAS- Standardisation of conductor vibration measurements Page 11 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC 85 38 IEEE:PAS-85 :l966 Vibration intensity of conductors. 39 ISO 1460:1992 Metallic coatings – Hot dip galvanised coatings on ferrous materials – Gravimetric 40 ISO 1461:1973 Metallic coatings – Hot dip galvanized coatings on fabricated ferrous products – Requirements 7. Earthing 1 BS 7430-1998 Code of Practice for Earthing. 2 BS EN 1654:1998 Copper and copper alloys. Strip for springs and connectors 3 DIN/VDE 0141 VDE-specification for earthing in installations of rated voltages above 1 kV a.c 4 DIN 48088 Earth Clamping Bolts 5 IEEE 1048 IEEE Guide for Protective Grounding of Power Lines. 6 IEEE Std. 52411993 Guide to Grounding During the Installation of Overhead Transmission Line Conductors 1.3 COMPLIANCE WITH STANDARDS All requirements of this Specification shall apply except where Manufacturer's standards are more stringent, then the latter shall apply. equipment For any deviations from this Specification, the Contractor shall obtain the written agreement of PDO prior to execution of the related engineering work. In all cases the Company shall determine the adequacy of design carried out and Works executed by the Contractor in accordance with this Specification. 1.4 ENGINEERING DOCUMENTS TO BE SUBMITTED 6. Page 12 1. 2. 3. OHL Plan and Profile OHL route plan SAGTension chart/report 4. Method statement for soil investigations 5. Method statement for erection of the Concrete pole structures foundations Method statement for erection of the concrete poles structures, include with list Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 of stringing chart and other construction and measurement tool. 7. Method statement for erection of the lattice steel towers foundations 8. Method statement for erection of the lattice steel towers 9. Method statement for stringing of phase conductors 10. Method statement for painting of lattice steel towers Method statement for installation of OPGW and/or Fiber Optic Cables (ADSS) and splicing in joint boxes 11. 12. Method statement for galvanization reparations Method statement for protection of the foundations (including protective painting, gabions protection etc.) 13. 14. 15. 16. Method statement for tests on piles/foundations Design calculation for 132kv OHL tower design Pile foundation calculation for 132kV tower. Installation criteria for structures foundations (including tower diagonal profiles, tower platforms, foundation/chimney extensions etc.) 17. Page 13 18. Site test programs 19. 20. 21. Site test details and site test procedures Final MTO. Final OHL accessories material list , include origin of manufacture 22. Final route records for overhead transmission line 23. Final result of earthing measurement 24. Site check lists and test packs as per CCMS. 25. Project completion report. Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 2 SCOPE 2.1 GENERAL This standard defines the requirements for the installation of overhead transmission lines with concrete pole supports as well as the lattice steel towers as applied to PDO installations. Concrete poles are to be used for 33kV system and for 132kV Only lattice steel towers are to be used unless stated by the CFDH-E for specific project. The following sections define in brief the basic requirements. 2.1.1 Access to Site The Company shall provide facilities for: • Such right of access along the route of the line as the Company agrees is necessary to enable the Contractor to proceed with erection. • The right to construct and make use of a reasonable width of access road along the route for the transport of materials and installation works, except at places where the Company considers that construction of access roads are not practically feasible. • The right to transport material from adjacent road on to each continuous length of the route at agreed points of access. Access road construction shall be in accordance with SP-1279 Specification for civil construction works After obtaining preliminary approval of the Company, the Contractor shall at an early stage of the Contract prepare access road drawings/maps indicating the access roads both along the line route and from the existing roads. The Contractor shall obtain route approvals from all the concerned local authorities (where required) and from the Company. For longer OHL length requirement for mobile camp should be in place. Once the Company approves the access roads, the Contractor shall not use any other access without the specific approval of the Company. The access roads shall be suitable for patrol and maintenance to all parts of the finished line except in the areas where the Company considers provision of access roads are not practical. The Contractor shall regularly liase with the Company Public Relations Department at all times throughout the construction to ensure minimal disruption of the local population. Page 14 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 2.2 Revision:5.0 Effective: August. 20 SITE PRELIMINARIES AND PREPARATORY WORKS 2.2.1 Soil Investigations The Contractor shall be responsible for conducting his own soil investigations, to the satisfaction of the Company, to determine the nature of ground conditions for the design of foundations (refer to SP-1274). The Contractor shall also carry out & obtain soil resistivity data during the soil investigations to determine the type and extent of earthing required at to determine the support-footing resistance and the requirement of counterpoise earthing. 2.2.2 Line Route Survey 2.2.2.1 Centre Line Survey Centre line survey is a preliminary survey, which fixes the proposed line route, angle and terminal points. Normally the Company carries out preliminary survey and issues preliminary line route drawings with the tender. The Contractor shall check the line route with reference to preliminary route drawings and shall follow the route shown in the drawings. If a change in route is required for any practical reason, approval should be obtained from the Company. Need to address the route survey for OHL extension and well hook up. Suggest reference to typical route survey shall be referred to it. 2.2.2.2 Detail Survey, line profiles and structure spotting The Contractor shall carryout a detailed precision survey for plotting ground and line profiles. While carrying out this work the following points shall be adhered to: Page 15 • The survey shall be carried out using instruments with accuracy within the permissible limits. Theodolite may be used for carrying out the survey although Total Station is preferred. The distance shall be accurately measured either by using tape/chain or tacheometry or by triangulation method depending on the territory. Electronic distance measurement (EDM) is preferred. • The ground profile shall be plotted on a 1: 2000 m scale (horizontal) and the line profile on a 1: 200 m scale (vertical). All angle and terminal points shall be fixed and their UTM co- ordinates shown on the drawings. • Bench marks shall be fixed along the line route based on the datum approved by the Company. Levels shall be taken at every 20 m along the line route and at each structure location, obstructions, cuttings and shallow portions. In addition, levels shall be taken for any sudden change in slopes more than 30 cm in height. • Where the line passes through slopes across the line, levels shall be taken on the transverse sides at an off-set distance of 20 m, in addition to the Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC • • Page 16 Revision:5.0 Effective: August. 20 centre line, to confirm that the ground clearance for the end conductors are within the specified limits. The offset levels shall be indicated on the profile and parallel lines drawn on either side of the centre line indicating the beginning and end of such terrain. Ground levels shall also be taken at the point of road, track, wadi, pipe line and overhead line crossing the proposed line. • All details upto 50 m on either side of the line shall be indicated on the ground profile drawing. These include any existing or planned infrastructure trees, obstructions, structures, sand dunes, mounds and ditches. • The location and width of roads, tracks, wadis, overhead lines, underground pipes/cables crossing the proposed overhead lines together with the angle of crossing shall be clearly indicated in the profile drawings. • It is necessary to note the following details in the profile drawings for any overhead line crossing the proposed line: - The height of the top most and bottom-most overhead line conductor crossing the proposed line route, at the point of crossing and at the point of supports. This information is required to determine the type (either above the existing line or below that or by underground cable) of proposed line crossing. The temperature at the time of measurement of conductor heights at the point of crossing shall be noted. - The voltage rating and type of construction. - Distance from the crossing point to the support structures on the existing line to be crossed. - Existing line structure identification numbers on either side of proposed line crossing. • The profile drawings shall indicate the visual nature of the ground, the line is traversing, such as clay, sand, rock, marsh, water logged, soft ground, cultivated land, wadi bed, normal ground etc. and their boundaries, along the line route, shall be clearly indicated. • The survey data shall be plotted on to a drawing sheet with the Company standard details and title blocks, to give ground and line profiles. The drawing material shall be A1 size polyester reproducible with printed grid lines of increasing thickness in 1, 5, 10 and 50 mm squares and drawn on the reverse side of the material. Individual profile sheets shall not exceed the size of A1 drawing sheet length-wise. • Profiles generated by approved overhead line software packages are preferred. • The line profile (vertical) shall be plotted in accordance with the design parameters obtained from the Company SPs for the design of 33 and 132 kV overhead lines respectively. While drawing the profile, a sinkage of 300 mm shall be considered for the structures. The line profile drawings shall contain proposed location and type of each support, values of wind, weight and equivalent spans, and section lengths. late based on the design data shall be prepared and used to draw profile curves for the bottom most conductor. Two curves shall be drawn, one curve based on the specified maximum temperature of the conductor (hot curve) and other curve based on the minimum ground clearance (clearance curve) and location of each structure spotted on the drawings. Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC • • Perspex templates shall be prepared by the Contractor to check the hot curve and the ground clearance curves. After the approval of the profile drawings, the Contractor shall spot the structures in the field and shall peg the location of each structure as indicated below. 2.2.2.3 Clearances The Contractor shall ensure that clearances are maintained from the live line to any part of the line or surroundings as per the following SP’s. • SP-1102B - • SP-1114B - • SP-1114C - • SP-1127 • PR-1817 - Specification for Design of 33kV Overhead Power Lines Specification of Design of 132 & 220kV Overhead Power Lines on Steel Towers Specification for Design of Twin ELM 132 kV Overhead Lines on Concrete Poles Layout OF onshore facilities and Facilities. Right of way Inspection procedure All graded roads, including well access roads, shall be taken as public roads within the terms of SP-1127 . The Contractor shall ensure that clearance to the existing and future pipeline and wells shall be allowed for as per the requirement of the Company. Pipeline clearance distance shall be measured from the edge of the pipeline. . (Reference to other SP SP-1208 ) 2.2.2.4 Structure Schedule The Contractor shall prepare a Structure Schedule consisting of structure location, type, height, span, section length, horizontal deflection (angle of deviation), type of foundation and number of stay wires. The schedule shall also contain special remarks such as whether ground has to be filled or levelled or platform or any foundation protection required. This schedule shall be submitted together with the profile drawings for the review of the Company. 2.2.3 Route Clearance 2.2.3.1 Vegetation The following requirements shall be considered while clearing the ground: Page 17 • Trees and tall shrub shall be cleared to a distance of 15 m on either side of the centre-line of the route. Trees and bushes shall be cut down to a height of not more than 1.25 m above ground level, after prior approval of the Company. • Whenever possible, felling of trees shall be avoided and should be executed only with the express permission of the Company. Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC • 2.2.4 Revision:5.0 Effective: August. 20 Felled trees and shrub together with the roots shall be removed from underneath the proposed overhead line and also on the access road running along the line route and access roads from existing roads to the line route. The access road shall be graded road suitable for traversing by a 4-wheel drive vehicle for line patrol and maintenance by the Company. Pegging Out The location of each structure shall be pegged out onsite. For angle and terminal locations, the peg shall consist of a steel angle stake painted with bands of red and white to avoid corrosion and for easy identification. Each peg shall be stencilled with the UTM co-ordinates, angle of deviation and structure number. For intermediate structure locations, either wooden or steel stakes can be used. These stakes shall be painted with bands of red and white paint and structure number shall be stencilled on the stake. All stakes shall be provided with a triangular red and white flag as a mark of caution. The pegs shall have a pointed edge on one side, which should be driven into the ground for at least 0.5 m to keep them firm and steady. Pegs shall be installed to mark the centre of the structure. Pegs shall also be installed in transverse direction for angle structure locations if required by the Company. After pegging all structure locations, before commencing construction, the Contractor shall give seven days notice to the Company for inspection of all structure locations/peg points. If required by the Company any or all locations shall be resurveyed and repegged. If structures are located in poor ground or if there are any obstructions the Contractor may relocate the structure subject to the satisfaction and agreement of the Company. 2.2.5 Crossings 2.2.5.1 Road and Service Crossings When the Contractor is ready to commence stringing of conductors along or across power lines, roads, or the like, he shall give a minimum 7 days notice to the Company for approval of the date and time at which he proposes to execute the Work. The Contractor shall provide diversions to the existing roads where it is necessary to avoid interference with the traffic as required by the Company or local authorities. Where the Company or any authority requires it, the Contractor shall Page 18 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC schedule the erection and stringing work at any timings of day or night as per the convenience of the Company or authorities. The Contractor shall ensure that sufficient resources are provided to complete the work during the allocated period. During any such works the Contractor shall provide appropriate warning notices, flashing lights, flag-men etc. as required by the Company or the local authorities, to ensure the safety of the public. 2.2.5.2 Other Crossings The Contractor shall at his own expense make the necessary arrangements and take any necessary precautions where the line route traverses ground over which erection cannot be executed in the normal manner. 2.3 LINE ERECTION Before commencement of the Works, the Contractor shall submit a written Work Method Statement covering all aspects of the overhead line erection work as indicated in this document. The Company shall have the right to require alterations to the proposed working method to ensure safe practice and high quality of the finished line. 2.3.1 Safety The Contractor shall obey the entire content of GU 861 ‘Electrical Safety Rules Guideline'. Once conductor stringing has been completed, temporary earths shall be applied to the line at the place of work (Worksite) before performing any further high level Works. Lifting procedure must be prepared and approved as per the company procedures such as lifting procedures for concrete poles illustrated in SP1102B, SP-1114C & SP-1114D. 2.3.2 Erection of Lines with Lattice Steel Towers 2.3.2.1 Foundation for Lattice Steel Towers General The foundation installation shall include site preparation, excavation, foundation placement measurements, stub angles, backfilling, foundation cap protection and clean up of the site. Page 19 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 The Contractor shall select the suitable type of foundation to be submitted for approval based on soil investigation data as well as information concerning flooding or other considerations affecting the foundation erection and maintenance. The foundation type for each tower location shall be selected by the Contractor to suit the particular site condition and the list for selected types shall be submitted for approval. Where the line route is on subkha, aggressive soils, sand dune areas or wadis the piled foundations with or without permanent casings, shall be considered. The foundation types to be installed shall cover all range of ground conditions occurring along the line route; among these may be included: normal ground, soft rock, hard rock, wadis conditions, sand dunes, subkha. Where actual soil conditions encountered show that the foundation required cannot be of standard range, then a special foundation shall be installed. The type of foundation to be used at each tower position shall be the most suitable practical solution. Wadis are watercourse beds, which can be dry for most of the year but are subject to occasional flash flooding. The structures in a wadi shall resist to water flow and shall be protected against pressure of water and debris. In sand dune areas the movement of the dunes can affect the overhead line structural integrity and electrical clearances. Subkha shall be considered the coastal flats of salty sands, but can be also of gravely, silty clay strata, of weak strength or some compact cemented layers. The water table frequently reach the ground level and above. 2.3.3.1.1 Site Preparation The Contractor shall make all measurements on site in order to establish the excavations limits or drilling positions, stub angle, template location data. All measurements shall be within the specified tolerances for steel lattice tower foundations. The centre peg shall not depart from the line axis by more than 50mm (except where approved offset is required). The centre peg of a foundation of intermediate support shall not depart from the longitudinal position by more than 500mm. The Contractor shall clear site area after installation, removing all debris or rubbish. 2.3.3.1.2 Concrete The concrete work shall comply SP 1282 “ Specification for Reinforced Concrete” For approval of concrete mix, the Contractor shall submit the following details: cement type, cement content, grading of aggregates, water/cement ratio. For each concrete mix, the Contractor shall provide a representative trial mix and make cubes to be tested for compressive strength at 7 and 28 days. Testing shall be in accordance to requirements of BS 1881. The Page 20 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC proposed concrete mix shall provide necessary characteristic strength, durability, density, resistance to sulphate and chloride attack. 2.3.3.1.1 Cement Unless specified otherwise in the Contract documents, Cement used for Concrete Works should be Ordinary Portland Cement in accordance with BS EN 197 or ASTM C150. If soil conditions, ground water, seawater or effluent water, are harmful to Ordinary Portland Cement, the most appropriate of the following types of cement shall be used after getting approval from the Company. - Sulphate Resisting Portland Cement Type-V in accordance with ASTM C150 - Portland Blast-Furnace Cement in accordance with BS EN 197 or Portland Cement Type-II in accordance with ASTM C150 - Ordinary Portland cement with micro silica conforming to ASTM C1240 or BS EN 13263-1. The quantity of micro silica to be used shall be determined based on trial mix design. 2.3.3.1.2 Reinforcing Steel The Contractor shall have the approval of PDO for the reinforcing steel to be used. Steel reinforcement in Concrete Works shall be ribbed round hot-rolled high-yield highbond bars complying with BS 4449. Cold-worked bars shall not be used. The Contractor shall provide samples and mill certificates showing the grade and quality and shall test the samples. All reinforcement shall be clean and free from dust, mill scale, loose rust, paint, oil etc. Dimensions of hooks, bends, etc, not specifically dimensioned on the bending schedule or elsewhere shall comply with BS 8666 and BS EN ISO 3766. Bars incorrectly bent shall not be straightened and re-bent. Heat shall not be used for bending reinforcement Reinforcement shall be stored on site in protected racks above ground to avoid any damage 2.3.3.1.3 Excavation and Backfilling The Contractor shall make excavations as specified on foundation drawings.All excavation and backfilling shall be in accordance with SP -1279 “Specification for Civil Construction Works”. 2.3.3.1.4 Installation of Foundations Stubs for tower foundations shall be installed by the use of approved templates. The foundation setting tolerances are: (a) The difference in elevation of foundation stubs: 5mm on tower face and 10mm between diagonally opposite legs. (b) The face dimensions (at the top of stub): 5mm from the approved tower drawings. The diagonal distance between any two stubs (at top of stubs): 10mm from dimensions specified on approved tower drawings. (c) The slope of stubs: shall not differ by more than 5mm/metre of the Page 21 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 stub length. The production, transporting, placing, compacting, concreting in hot weather and curing of concrete, the procedures for formwork requirements, construction joints and inspection shall be in accordance with specifications of BS 8110:1997. The towers will be erected when the backfilling is complete and the concrete has achieved its required designed strength 2.3.3.1.3 Bored Piles Installation The reinforcement shall be maintained in correct position during concreting. The cages shall be sufficiently rigid as to be handled without deformations. The bored piles installation shall comply to BS EN 1536:2000. On completion of boring, loose or disturbed soil shall be removed from the base of the pile. Lining tubes shall be provided for sufficient depth to ensure the stability of the pile excavation during boring and concreting operations. The temporary casings shall be withdrawn, during or immediately after completion of the concreting and before concrete is starting to harden. The use of conventional vibrators, for bored piles, is not permitted. 2.3.3.1.4 Protection of Foundations The Contractor shall provide anticorrosion paint treatment on tower stubs, steel piling casing and pile caps. The painting of the stubs with two layers of an epoxy type paint shall be applied on 300mm above concrete level. After concreting the foundation caps, the joint with the stub angle shall be sealed with an acrylic type seal material on 10cm thickness around the stub angle. The foundation cap shall be painted with a coal tar paint on 150mm over the concrete level and 300mm under ground level. Where instructed by PDO, the Contractor shall install gabion walls to protect tower locations against flooding waters. Gabions shall be filled in double-twisted hexagonal mesh of PVC coated galvanised steel wire of at least 2.5mm (steel) diameter. They shall be rectangular boxes of 2m long, 1m wide and 1m high with two compartments separated by a diaphragm, filled with approved broken rock of a minimum size greater than the mesh eye. Where required by PDO, the location shall be protected against erosion or floods by gatch platforms compacted to 150mm thick and extending 5m from the tower foundations. In low-lying areas and on subkha areas of the line, gatch platforms of 500mm thick minimum shall be considered upon instructions from PDO. 2.3.3.2 2.3.3.2.1 Erection of Lattice Steel Towers General Page 22 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC The Contractor shall ascertain that all concrete foundations or rock anchor grouting are cured and that all back-filled material is compacted to its approved level before placing or erecting tower steel on the foundations. Concrete in tower foundations shall be allowed to set a minimum of 7 days before erection of the tower and a minimum of 28 days before conductor and earth wire installation on the tower. The Contractor shall erect the types of towers specified at the locations indicated on the Contract Drawings. Towers shall be assembled in accordance with the approved drawings and erected by a suitable method, which will not overstrain structural members or their foundations, subject to PDO’s approval. 2.3.3.2.2 Handling and Storage of Steel Towers Steel shall be stored on wooden supports of sufficient height to avoid any ground contact or other contamination. Storage conditions shall be well ventilated, preventing the formation of wet storage stain from accumulation of humidity and sand. It shall be clearly understood, that white rust formation will lead to rejection of the affected material. All necessary measures shall be taken to prevent structural injury to members, or damage to galvanized coatings. Members shall not be dragged on the ground, nor will the practice of throwing tower steel into piles on conveyances, or from conveyances onto the ground, and of skidding steel members over each other, be permitted. Lifting of tower steel shall not be done with steel slings, being in direct contact with galvanized surfaces. Instead, fabric belts, or other suitable protection shall be applied. Tower material damaged shall be replaced by the Contractor at no cost to PDO. Small accidental damages to galvanized surfaces may be repaired by application of an approved repair paint. Minor damages to galvanized steel members could be repaired by application of a special paint as follows: • Brush cleaning of the damaged area of any trace of dust, rust and degreasing (if necessary); • Coating of the damaged area with two layers of zinc rich paint containing at least 95% Zn in the dry film. The painting shall be done according to manufacturer’s instructions. The final dry fill of paint shall be at least 150 microns. Larger damages to, or systematic defects of the galvanizing shall be repaired by hot-dip galvanizing, only. The attempt to repair shall not bind PDO to accept the repaired part when this is reoffered for inspection. Acceptance by PDO of any repaired galvanized steel does not absolve the Contractor from his responsibility of supplying galvanized steel to give satisfactory service in the prevailing corrosive atmosphere. PDO reserve the right to reject any galvanized steel found rusty, damaged, bent or other-wise defective, before final acceptance. Page 23 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 2.3.3.2.3 Revision:5.0 Effective: August. 20 Erection of Steel Towers Prior to the commencement of any tower erection activity the Contractor shall submit for approval a Method Statement detailing the proposed erection methods and safety precautions to be taken during the erection. The Contractor shall erect towers for the transmission line in accordance with the erection diagrams, construction lists and other drawings and instructions. The method of assembling and erecting a tower shall be such that during erection no member shall be subjected to any stress in excess of that for which it was designed. Misalignment or misfit of adjacent sections or members attributable to the adopted method of erection shall be corrected by changing erection methods as necessary to eliminate trouble. Straining of members shall not be permitted for bringing them into position. It may, however, be necessary to match hole positions at joints and to facilitate this, tommy bars not more than 450mm long may be used. For ease of checking bolts and nuts shall be generally fitted in such a way that the nuts are placed outside for horizontal bolts and downside for vertical bolts. Before starting erection of an upper section, the lower section shall be completely braced and all bolts provided tightened adequately in accordance with approved drawings to prevent any mishap during erection. All plan diagonals relevant to a section of tower shall be placed in position before assembly of upper section is taken up. All members shall have their joints cleaned when bolted up. If erected by assembling in sections, the initial tightening of bolts shall be adequate for dead load, live load and direction stresses, but shall not be so strong as to prevent aligning and fitting adjacent sections or members. The assembled sections shall be adequately supported during erection. All blank holes, if any left, after complete erection of the tower, are to be filled up by bolts and nuts of the correct size. During the erection, no tools shall be taken up to the towers, except structure wrenches and drift pins. Only such wrenches will be allowed, which do neither deform nor injure the galvanized coating of the bolts/nuts. Use of drift pins is limited to guiding the different tower members into position, without enlarging holes or distorting tower members. Each bolt shall be securely tightened with adequate but non-excessive torque. Proper tightness shall be spot checked by the Contractor, to PDO’s satisfaction, with an accurately calibrated torque wrench. The tightening torque to be applied on bolts is the following: – Page 24 6,0 daN×m for 12mm dia bolts Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC – – – – – – Revision:5.0 Effective: August. 20 7,0 daN×m for 14mm dia bolts 9,7 daN×m for 16mm dia bolts 17.2 daN×m for 20mm dia bolts 20.3 daN×m for 22mm dia bolts. 22.0 daN×m for 24mm dia bolts. 25.0 daN×m for 30mm dia bolts. All tower bolts shall be completely tightened, immediately after a tower is erected. After erection, towers shall be left in workmanlike condition, complete and safe in every respect. In order to prevent pilfering, all bolts and nuts below a minimum height of 3 m above the foundation cap shall be secured by suitable means, to be proposed by the Contractor, for PDO’s approval. During assembly punching, reaming or drilling for correction of mismatched holes shall not be permitted without the authorisation of PDO in writing. If any shop errors are discovered in the steel, the Contractor shall notify PDO who will decide on site whether the error shall be corrected on site or the members shall be replaced. All exposed steel surfaces around the holes or on cuts on which corrective work is permitted shall be given sufficient coats of an authorised zinc rich paint to provide sufficient protection to the steel and shall be to the approval of PDO. Towers must be completely erected with all members in place and bolts securely tightened before any stringing of conductors or earth wires may be started. All towers shall be inspected by PDO accompanied by the Contractor before the stringing operation. Prior to the erection of towers or parts of towers, which had completely been assembled on ground, the approval of PDO is required. In aviation-marking areas, immediately after erection above foundation level, the towers shall be illuminated, either by the permanent lighting system or by a temporary lighting system, to be approved by PACA (Public of Civil Aviation) 2.3.3.2.4 Tolerances for Installation of Steel Towers Members deformed in excess of the allowed limits shall not be erected Compression elements shall not have lateral deformation exceeding 1/600 of the member length. Tension members shall not have lateral deformation exceeding 1/300 of the member length. All towers shall be vertical after erection and shall remain substantially vertical under the stresses set up by the overhead line when complete. The self supporting tower shall not be out of plumb from transverse or longitudinal centreline by more than 1/480 of its height. 2.3.3.3 Aircraft Warning Painting 2.3.3.3.1 General All towers shall be red and white bands painted in accordance to Annex 14, Aerodromes, Chapter 6, paragraph 6.2.5 of the International Standards and Recommended Page 25 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC Practices issued by the International Civil Aviation Organization, and is subject to the PDO's approval .The towers fouling within a radius of 4.6km from runway shall be painted. This specification is to define surface preparation, protective coatings and paint systems to be applied on equipment and structures unless otherwise specified. The general guides for the work shall be: a) This specification British Standard Code of Practice CP.2008; 1966, B.S.: 4232, 2015, 729, 3083, 381 C, 4479, 4360, 3294 and 4604 (a) 2.3.3.3.2 (b) Swedish Standard SIS 05 59 00 - 1967 or equivalent standard (c) German Standards DIN 55 928 and DIN 4115 or equivalent standards (d) the paint manufacturer’s Technical Data Sheet and Instructions. Surface Preparation Prior to chemical treatment / surface preparation, the galvanised surfaces shall be carefully cleaned by brushing with fresh water to remove all foreign substances such as salt, white rust and zinc corrosion products, dust sand and dirt. If the galvanised steel surfaces shall be chemically treated it has to be subject to the approval of the PDO. Prior to painting, the galvanised surfaces shall be carefully checked for damages, defects and impurities. In case of persistent white rust and corrosion products it is necessary to remove these by sweep-blasting or mechanical brushes. However, tarnishing of surfaces must be avoided. In specific cases where damages are severe, re-galvanising shall be required. Such prepared surfaces must be approved by the PDO prior to paint application. 2.3.3.3.3 Preparation of coating materials Primers and paints which have liveried, gelled or are otherwise deteriorated shall not be used. All ingredients in any container shall be thoroughly mixed before use and shall be agitated frequently during application to keep the primer in suspension. Primer or paint mixed in the original container shall not be transferred until all settled pigment is incorporated into the body of liquid. Primer or paint shall be mixed in a manner ensuring the breakdown of all lumps, complete dispersion of pigment and uniform composition. Thinners shall not be added to primers or paints unless necessary for proper application according to the manufacturer’s instructions. Page 26 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 The type of thinners used shall comply with the manufacturer’s ‘instructions. When use of thinners is permitted, it shall be added to the primer or paint during mixing in a good ventilated area. 2.3.3.3.4 Painting of Steel Towers For better adhesion and corrosion protection priming coats shall be applied by brush or by airless spray only. The other coats of paint are to be applied by brush roller or spray and in accordance with the paint manufacturer’s recommendations. - first layer of primer - second layer of intermediate coat - the final layer of red or white colour. Type of paint to be applied on lattice steel towers and minimum thickness shall be: - Zinc-rich primer (two pack epoxy zinc rich primer, e.g. polyamide cured) with a grey dry film minimum thickness of 40 microns. - Intermediate coat (two- p a c k epoxy micaceous iron oxide, e.g. polyamide cured) with a dark grey film thickness of minimum 60 microns. - Final coat of aliphatic polyurethane or acrylic epoxy with a white (RAL 9010) and red (RAL 2002) dry film thickness of minimum 60 microns. - All surfaces to be painted must be moisture-free and paintings shall not take place when: the surface temperature is above 50°C - the relative humidity is above 85% or the surface temperature is closer than 3°C or below the dew point - - It is raining - sandstorms occur to such extent that the wet painting might be affected. To ensure the suitability of paints the Contractor shall execute sample tests at site. Such panels must be approved and shall be used as reference for quality control. These tests shall be carried out at a very early stage of the contract period and no paint shall be ordered beforehand. Final selection of the paint is subject to the approval of PDO, depending on the results of the above mentioned site tests. All finishes shall be clean and in good sound conditions. Each coat shall completely and uniformly cover the coat underneath it. There must be no delay between application of successive coats but each coat must by thoroughly dry or as directed in the paint instructions before next coat is applied. Before additional coats are applied to painted surfaces, the existing paint shall be cleaned of all foreign matters and suitably sanded if necessary. Page 27 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 Excessive coat thickness shall not exceed the maximum specified by the paint manufacturer. 2.3.3.3.5 Responsibilities and Guarantees Inspection of coatings by PDO shall neither relieve the paint manufacturer from his responsibility of providing good quality products nor the Contractor from his responsibility of acquiring the specified quality of material or the correct performance of the work. This is also applicable to shop-primed structural steel or other components. The Contractor shall bear the full responsibility for galvanizing and paint applied by him or by others. The complete painting system is guaranteed for a period of not less than 5 years after the Final Acceptance Certificate. The Contractor shall provide a Guarantee Performance Bond to assure the performance of extended guarantee obligations for PDO painting system. The Contractor shall carry out during the extended guarantee period any repair or replacement on the painting system executed under this specification at no additional cost after being intimated by PDO. If the repairs are not carried out to the satisfaction of PDO, these repairs shall be performed by others, who will be assigned by PDO, and the costs thereof shall be borne by activating the Performance Bond valid for the extended guarantee obligations. 2.3.4 Conductor Stringing 2.3.4.1 Preparation Before commencement of stringing, tower footing resistance tests shall be made at each tower and necessary earthing devices shall be installed and tested. Conductor and earthwire erection shall be carried out entirely by approved tension stringing methods, keeping conductor off the ground al all times when the conductor is in motion. Tenderers shall include with their Tenders details of the precise method of tension stringing they propose to use, together with details of their proposed stringing equipment. and qualified operators and linesmen . At least 3 months before stringing commences the Contractor shall submit to the Engineer for approval a fully detailed, comprehensive work proposal which shall include, but not limited to, the following: - Work sequence and methodology including creep compensation regime; - Locations of conductor drums and winch location;. - Temporary stay arrangements and temporary support strengthening; - Scaffold positions and types; - Positions of mid-span (tension) joints; Page 28 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 - Procedures and method for making joints and dead end clamps; - Schedule of conductor accessories to be fitted; - Erection (initial) sags and tensions. Particular attention shall be given in this work proposal to the procedure for stringing the OPGW where special care is required to guard against damage to the optical fibre cable. The supplier of the OPGW will be responsible for the supervision of installation by the Contractor, to ensure that the overall system reliability requirements met. To ensure that this is undertaken, the supplier will provide the services of a suitable qualified/experienced installation supervisor, who shall supervise the installation of the works throughout and shall advise PDO and the Contractor in matters of methods procedures and precautions to be followed and will be responsible for all matters pertaining to the quality of the installation. The Contractor shall provide PDO with a method statement giving sequential details of the stripping procedure and the optical fibre jointing (splicing) procedures. The method statements shall take full cognizance of the manufacturer's installation instructions. The method statements shall be submitted to PDO for acceptance the requisite period prior to stringing or optical fibre jointing commences. The Contractor shall ensure that the fibre optic cables are not strained or damaged either mechanically or optically during stringing and/or jointing. The Contractor shall demonstrate the suitability of his proposed method, including the choice of running blocks and stringing equipment, bull wheel diameters, fibre optic cable wrapping equipment and methods etc., prior to the commencement of stringing operations. Optical fibre joints either in the OPGW or between the OPGW and the nonmetallic underground fibre optic cable shall be housed in optical joint boxes. The joint boxes shall be located immediately above the anti-climbing device for convenient access by technical personnel. All joint boxes shall be earthed to the support steelwork using approved multi-wire/multi-strand flexible aluminium earthing bonds or copper earth fitted with bi-metallic lugs. 2.3.4.2 Equipment and Tools Conductors, joints, and clamps shall be erected using approved tools and in such a manner that no birdcaging and over-tensioning of individual wires or layers or other deformation or damage to the conductors occurs. Clamps or hauling devices used in erection shall be of approved design and shall not allow any relative movement of strands or layers of the conductors. The Contractor shall supply all the necessary drum-stands, drum-spindles, drum-brakes and jacks to ensure efficient paying-out of conductors. All winches, anchor sheaves and running lines shall be supplied by the Contractor and maintained in good order to the approval of the Company. Page 29 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC Connection of the steel running line (pilot wire) to the conductor shall be to the approval of the Company and shall be of a type capable of passing through the slinging snatch. Snatch blocks for slinging conductors shall be of an approved type and shall be robust. The conductor pulley shall be fabricated from aluminium or similar material. The Contractor shall provide sufficient snatch blocks to satisfactorily achieve the stringing of the longest continuous line section. Tensioning bull wheels shall have a minimum diameter of 35 times the outside diameter of the largest conductor required under the Contract or as necessary to suit the requirements of the OPGW, and will have multiple grooves lined with neoprene such that conductors smaller than the groove or as required diameter will seat into the lining without being flattened. Brakes and controls shall be hydraulically operated to minimise danger of brake failure. The tensioner design shall be such that once the required tension is obtained, the conductor will remain at that tension so long as the brake setting remains unchanged. Conductor running out blocks shall be so designed as to allow conductors to be pulled out smoothly and shall have a minimum diameter of 600mm at the bottom of the conductor groove. Blocks will be of low friction design and the block groove shall be lined with neoprene. Blocks are to be designed so that the pilot wire does not damage the neoprene lining during conductor running. Running out blocks which do not run freely or operate properly shall be removed from site for repair and must receive the Engineer's approval before they may be re-used. The blocks shall have an electrical conducting path between their suspension fittings and the conductors supported by the blocks. The above shall be applied for all span length 2.3.4.3 Drum Lengths and Joints The Contractor must note that the Company's policy is not to permit the use of midspan joints. The Contractor shall make use of maximum conductor lengths in order to avoid midspan joints and to reduce the wastage to a minimum. A Drum Schedule shall be prepared by the Contractor and approved by the Company prior to stringing. If mid-span joints are finally approved, the number and location of such joints should be submitted to the Company for approval. These joints shall be not less than 25 m from the nearest conductor clamp, and joints between different phase wires in the same span should be adequately staggered to the satisfaction of the Company. Mid-Span joints shall not be used: • With less than 2 complete spans between joints. • In single spans or within 2 spans of a section pole. • In spans crossing power lines, roads, etc. Conductor repair sleeves shall not be used without the permission of the Company. Page 30 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 Only compression connections shall be used and comprise exclusively the type specified in the material lists, unless otherwise directed by the Company. Bimetallic compression connections, as specified in the Company Standard Drawings and Schedule of Overhead Line Materials, shall be employed where equipment with copper terminals are to be connected to line conductors. The Contractor shall test each joint, etc., in accordance with Section 2.6. Test results, together with the location of each fitting, date of assembly and name of the linesman responsible for the assembly, shall be recorded on functional test sheet (see Section 2.6). This record shall be handed over to the Company on completion of each section of line. The Contractor shall obtain approval from the Company for the Linesmen employed to make compression joints. The Contractor shall obtain this approval through the submission of a test joint for quality control check by the Company. Where records of joints made by any particular linesman show a repeated performance below the required standard, the Contractor, at the request of the Company, shall cease to employ the linesman on Company’s installation jointing operations and shall immediately replace him with other approved personnel. 2.3.4.4 Conductor Damage Since the ground that the transmission line traverses is in many parts boulder-strewn or rocky, the Contractor shall employ an approved method of pilot wire tension stringing to keep the moving conductor off the ground during stringing operations. Alternatively, the Contractor shall provide trestles or scaffolds to ensure that the conductor does not touch the ground whilst in motion. The Contractor shall forward to the Company for approval full details of the tension-stringing method, together with details of machine and equipment he proposes to use. When due to a mishap a conductor makes contact with the ground, stringing work shall stop whilst the conductor is examined and offered for inspection to the Company. The Company at its discretion may order such quantity of phase conductor or earth conductor to be discarded and replaced by the Contractor at his expense. In the case of local damage to individual wires of a conductor during erection, the use of repair sleeves of a type approved by the Company may be permitted. This shall be at the discretion of the Company. Any conductor that has been run-out and not finally tensioned shall not be left overnight either on the ground or within 4.5 m above ground level. Conductors should never be on the ground. 2.3.4.5 Stringing Procedure The Contractor shall employ an approved method of tension stringing that will not cause damage to conductors or over-tension the conductors, and at all times will not allow conductors to touch ground or any obstacle. The Contractor shall submit with his tender a general description of both method and type of equipment he proposes to use. Cutting of layers of conductors shall be executed with tools designed to prevent damage to underlying strands. Page 31 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 Cut-ends of conductors and joints, clamps and fittings attached to the conductors themselves shall be treated in a manner approved by the Company to prevent ingress of air or moisture. Conductor, joints and clamps shall be erected so that no bird-caging, overtensioning or other deformation can occur to the individual wires or layers of the conductor. Clamps or hauling devices shall, under erection conditions, allow no relative movement of strands or layers of conductors. If required by the Company, this property shall be demonstrated by actual tests. Application of tension-clamps shall be executed at pole/tower tops by use of 'come-along' clamps of an approved design. Transfer of conductors from snatch-blocks to post-top insulators shall not be effected before completion of anchor-clamps. Each conductor shall be clamped-in at intermediate poles not later than 48 hours after being tensioned-off at section poles. Tension gauging marks on conductor shall be applied with white cotton tape which shall be removed on completion of the fitting of each tension-clamp, which shall be suitable for live-line working. 2.3.4.6 Sags and Tensions The Contractor shall prepare the sag and tension charts and calculate tension values for pre- tensioning which are to be used for erection of 220kV, 132 kV and 33 kV lines. The lines shall be pre-tensioned for a minimum time of 1 hour and the pretension value shall be maintained by adjustment at 15 minutes intervals during the pre-tensioning period. For determining tension to be applied to a section having a number of different spans the 'equivalent span' method shall be used. For sag measurement a span having a length close to the equivalent span length shall be chosen. The Contractor shall submit to PDO for approval the following details applicable to each conductor or earthwire type used on the contract: (a) Final sag and tension charts for a range of equivalent spans applicable to the transmission line, considering the weight of spacer dampers, aircraft warning spheres etc. Final sag and tension charts for a range of spans applicable to the downleads to substations or slack span connections in the line. Sag and tension charts for downleads and slack spans shall take into account the weights of insulator sets. (b) The proposed regime for creep compensation including the basis for determining initial sag tension sags and tensions. (c) Initial sag and tension charts, or tables, for use in the actual sagging of the line for a range of actual possible conductor temperatures. Immediately after conductors have been erected and clamped-in, mean sag of conductors shall not depart from the correct erection sag by more than minus 5%. In addition, sag Page 32 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 of any one line conductor shall not depart by more than 150 mm from the sag of other line conductors in the same span. Vibration dampers or spacer-dampers shall be installed immediately following the clamping in of a section. When required by the Company prior to issue of a Certificate of Acceptance, the Contractor shall be responsible for checking that relative sags of conductors and earthwires are within the specified tolerance. Such checks shall be conducted at selected points along the route, as requested by the Company. Clearances between conductors and ground and between jumpers and structures shall be checked during erection and before handing over the line. The Contractor shall provide suitable dynamometers, sighting boards and levels or other approved apparatus necessary for the proper checking of the Works. When required by the Company dynamometers shall be tested and if necessary re-calibrated at the Contractor's expense. Sag adjustment should be done through sighting boards and sighting levels and sag should be adjusted and measured at mid-span, to the satisfaction of the Company, During progress of the Work the Contractor shall record on approved schedules (See Section 2.6) particulars of sagging of conductors on each section of the route. These schedules shall show section pole numbers, individual span lengths, equivalent span, design and erection sags, together with mean actual sag of phase conductors, as well as both temperature and dates of stringing and checking. At the end of the Contract these schedules shall be handed to the Company. Where vertical slope between supports exceeds 20% the Contractor shall make allowance for the difference in level when calculating the sag. 2.4 INSPECTION AND TESTING 2.4.1 Tests During Erection 2.4.1.1 Conductor Joint Tests The Contractor, in the presence of the Company, shall accurately measure contact resistance of all completed clamps, joints and terminal fittings. Where a Joint consists of several parts bolted together (e.g., dead end clamp with bolted-on jumper terminal), resistance to be measured is that of the complete assembly. Resistance of any such fittings shall not exceed 75% of the resistance of an equivalent length of conductor, measured adjacent to the fittings, and the current carrying capacity shall be at least 100% of that of the conductor. Measurements shall be recorded on Functional Test Sheet. (See Section 2.6). The Contractor shall provide suitable equipment (such as a Ductor or an APT/CERL Digital Micrometer Model DMO 310) for conducting the above tests, and shall submit details of the proposed instrument to the Company for approval. Suitable clamps also shall be supplied for connecting current leads of the measuring instrument to the test Page 33 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 sample to provide adequate surface contact at interfaces. Test probes as used for potential contacts are unsuitable for current connections. Stringing of conductors shall not commence until the instruments are on Site and ready for use. 2.4.1.2 Cable Tests Installation of cables used for underground road crossings, etc., shall be recorded on Check Sheets (see Section 2.6). Cables shall be subjected to an HV cable DC pressure test whilst disconnected from the overhead line and associated surge arresters. Results of tests shall be recorded on Functional Test Sheet FS 14. 2.4.2 Inspection 2.4.2.1 Inspection During Erection As the erection of the overhead line progresses the Contractor shall ensure that a record is kept of outstanding items of Work. Check Sheet (see Section 2.6) shall be used to note exceptions. 2.4.2.2 Final Inspection Upon notification by the Contractor that a Work section is finished as a complete line, the Company, prior to issuing the Certificate of Acceptance, shall inspect the completed Works, in order to ascertain that they have all been executed in full accordance with the Specifications and Drawings. In particular it shall be ascertained that: • Back-filling of excavations, ramming and levelling around foundations and stays, disposal of excess earth from excavations, etc., are completed. • Steel sections are correctly installed, straight and not damaged. • Bolts and nuts are correctly fitted with washers, as equipped, and are properly tightened and painted to indicate tightness check is complete. • • • • • Stays and accessories are complete and correctly fitted. Equipment, such as disconnectors surge arrestor , PMR, VT ,AB isolators and filed isolators and drop out fuses are fitted correctly and completely in accordance with the Company Standard Drawings and Specifications, and are operable without undue difficulties. Damage to galvanised parts has been made good to the Company's approval by the application of cold galvanising (zinc rich) paint. Insulators are clean and totally free from foreign materials and is undamaged. The Works are erected in complete accordance with the Company Drawings and Specifications. • Cable terminations • Correct installation of jumpers and droppers • Pole erection and wadi protection • phase sequence diagram ( identifying which conductor phase sequence ) • Line conductors are correctly clamped and made-off. • • Page 34 Structures are free of all construction equipment, loose materials and other foreign matter. Anti-climbing devices are correctly installed. Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC • Revision:5.0 Effective: August. 20 Conductors are clean and without any strand damage. • Conductors are erected in accordance with sag and tension schedule and clearances are correct. • Pole identification code plates, danger signs and reflectors are fitted correctly and Identification Code Schedule (see Section 2.6) completed. • All material surplus to requirements and all debris and rubbish have been removed and deposited as directed by the Company. Check Sheet (see Section 2.6) shall be completed by the Company to signify to the Contractor any unsatisfactory Work or outstanding items. * Detailed earth pits to be included 2.4.3 Pre-Commissioning Tests Subsequent to the inspection the Contractor in the presence of the Company shall test lines for: • Resistance to earth of each component and each completed earth system, measured and recorded before final connection. This shall include earth resistance tests of stay-anchor arrangements. • Line continuity, measured with an approved 1 kV Insulation Resistance Tester. • Insulation resistance of the line to earth and between phases, measured with an approved 5 kV Insulation Resistance Tester. • Electrical integrity of all tension joints, measured with equipment designated in Section 2.4.1.1. If specified in the project specifications, the Contractor shall perform line impedance test by tests by approved measuring devices like xxx . These shall include the measurement of: • Positive sequence impedance. • Zero sequence impedance. • the test pack should record the ambient temperature 2.5 MAINTENANCE The Contractor shall be responsible for making good all settlements of filled ground due to any cause, whatsoever which may occur up to the end of the period of maintenance. At the end of the maintenance period specified ground clearance plus conductor creepage allowance shall not be infringed. In addition, sag of any phase conductor shall not depart by more than 150 mm from the mean sag of all phase conductors in the same span. Tests shall be conducted at selected points along the route, as required by the Company, and the Contractor shall provide the necessary surveying instruments to enable checks to be conducted with the line live and in service. All sag and clearance corrections that may be required by the Company shall be undertaken in a prompt manner and at times specified by the Company, to minimise the service interruption of the line. 2.6 Page 35 CHECK SHEETS AND SCHEDULES Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 The following Functional Check and Test Sheets shall form part of the As-Built record of the overhead line. 2.6.1. Overhead Lines with Lattice Steel Towers Construction Check Sheets: • Installation of Overhead Line Foundation; • Erection of Overhead Line Steel Lattice Towers; • Painting Check Sheet; • Erection/Sag Chart Record; • Overhead Compression Joints. Pre-Commissioning Check Sheet: • Installation of O/H Lines on Steel Towers - Inspection • Installation of O/H Lines on Steel Towers - Tests. NOTE: *** shall be used to mark-up As-Built drawings and for noting where pole identification plates are required. Specimen copies of these check sheets and schedules are located in SP-1100 and Standard Drawings STD-00-000000-EA-2580-91410-0001. 2.7 AS-BUILT DRAWINGS As-Built drawings in accordance with SP-1131 shall utilise the contract drawings as the basis for recording the final status of the installation. As-Built drawings shall record all deviations, deletions and additions with respect to the original scope, such as, for example, route changes, pole locations, foundation types, stay arrangements, and all other variations. Add more info on the handover , sample of field ohl , sustaining as built drawings – Need to include points on how we manage OHL as building and how is it structured in PDO system. Need to ensure all OHL work including short span runs to be designed and updated into the system. Type test certificates for conductors, surge arrestors APPENDIX A : GLOSSARY OF DEFINITIONS, TERMS AND ABBREVIATIONS The following terms and abbreviations used in this documents are defined below: Page 36 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC General Terminology Shall - The word 'shall' is to be understood as mandatory. Should - The word 'should' is to be understood as strongly recommended. May - The word 'may' is to be understood as indicating a possible course of action. The Company - Petroleum Development Oman L.L.C. Muscat, Sultanate of Oman. User - A specified Engineer, Consultant or Contractor who applies these Standards in the execution of a PDO project. The Company representative - A person appointed from time to time by the Company, having the functions set forth in Article 2 of General Conditions for Construction Works, and whose authority shall be notified in writing to the Contractor by the Company The Consultant - The party to the contract with the Company who is responsible for providing the design, engineering and other related consultancy services under the contract. The Contractor - The party to the Contract with the Company who is responsible for the construction and other related works specified in the contract. On occasion, for example in 'turnkey contracts' the contractor may be responsible for design, engineering, manufacture, shipment, supply, installation, testing, commissioning and performance guarantee up to the defects liability period as defined in the individual contract. Manufacturer - The party responsible for the manufacture of equipment and services to perform the duties specified by the Consultant, Contractor or Company. Vendor/Supplier - A party responsible for the supply of equipment, materials or product- related services in accordance with the Purchase Order issued by PDO, its Consultant or Contractor, or its nominated Purchasing Office. Works - All Works to be executed and all services to be rendered by a Contractor under the terms of a Contract. Work-site - A defined place designated by the Company where all Works and services shall be executed by a Contractor under a Contract. CFDH - Corporate Functional Discipline Head OHL - Overhead Transmission Line Abbreviation Page 37 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC DCS - Document Control Section DMO - Digital Micrometer Model DMO LV - low Voltage HV - High Voltage Revision:5.0 Effective: August. 20 SP USER-COMMENT FORM Page 38 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision:5.0 Effective: August. 20 Petroleum Development Oman LLC SP User-Comment Form If you find something that is incorrect, ambiguous or could be better in an SP, write your comments and suggestions on this form. Send the form to the Document Control Section (DCS). They make a record of your comment and send the form to the correct CFDH. The form has spaces for your personal details. This lets DCS or the CFDH ask you about your comments and tell you about the decision. SP Details Number: Title Issue Date: Page number: Heading Number: Figure Number: Comments: Suggestions: User’s personal details Name: Ref. Ind: Signature: Date: Phone: Document Control Section Actions Comment Number: Dates Recd: To CFDH: CFDH Actions Recd Decision: Reject: Date: Accept, revise at next issue: Accept, issue temporary amendment Inits: CFDH Ref. Ind: Ref. Ind: Date: Comments: Originator Advised: Page 39 Date: Inits: Document Control Section Advised: Specification for Installation of Overhead Transmission Lines Date: Inits: Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision:5.0 Effective: August. 20 CHECK SHEETS AND SCHEDULES Overhead Lines with Lattice Steel Towers Page 40 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. PDO CW-NNNA1 CONSTRUCTION CHECK SHEET CIVIL WORKS INSTALLATION OF OVERHEAD LINE FOUNDATION PROJECT DESCRIPTION Sheet 1 of 1 REV 0 DATES CONTRACT No. EXCAVATION LOCATION No. CONCRETING TYPE OF FOUNDATION BACKFILLING REFERENCE DRAWING Installation Records 1. Deviation from alignment of central peg 2. Depth of excavation 3. Excavation dimensions (layout) 4. Undercut (under-ream) dimensions 5. Chimney/cap dimensions 6. Pad/foundation base dimensions 7. Ground water level 8. Stub angle inclination to vertical (stub rake) 9. Stub level (on 4 legs) Specified Result 10. Face dimensions between stubs 11. Diagonal dimensions between stubs 12. Twist of stub in plan 13. Concrete strength at 28 days (cube/cylinder) 14. Concrete volume 15. Reinforcement weight 16. Protection painting of chimney/cap/stub 17. Backfill compaction 18. Earthing B. REMARKS / OBSERVATIONS (include notes on bottom heaving, alignment of excavation walls, side caving, site cleaning etc.): CONTRACTOR SIGN & DATE Page 1 PDO CIVIL WORKS SIGN & DATE Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. PDO CW-NNNA2 CONSTRUCTION CHECK SHEET TOWERS Sheet 1 of 1 ERECTION OF OVERHEAD LINE STEEL LATTICE TOWERS REV 0 PROJECT DESCRIPTION DATES ERECTION START ERECTION COMPLETED FOUNDATION CONCRETING CONTRACT No. LOCATION No. TOWER TYPE REFERENCE DRAWINGS Installation Records 1. Tower verticality deviation (max 1/480) 2. Twisting at crossarm level [degree] 3. Missing tower elements: 3.1. Structural members 3.2. Bolts and nuts 3.3. Washers and fillers 4. Missing tower accessories 4.1. Anticlimbing device 4.2. Step bolts 4.3. Danger plates 4.4. Number plates 4.5. Bird guards 4.6. Circuit plates etc. 5. Tower elements with defects 5.1. Bended, members with distortion 5.2. Uncleaned members 5.3. Members with damaged galvanization 5.4. Members with white rust 5.5. Members with sectional dimensions less than required 5.6. Thickness of galvanizing less than specified 6. Bolts and nuts check 6.1. Grade of bolts 6.2. Tightening by torque wrench: 6.2.1. for 12 mm bolts (min. 6.0 daN.m) 6.2.2. for 14 mm bolts (min. 7.0 daN.m) 6.2.3. for 16 mm bolts (min. 9.7 daN.m) 6.2.4. for 20 mm bolts (min. 17.2 daN.m) 6.2.5. for 22 mm bolts (min. 20.3 daN.m) 6.2.6. for 24 mm bolts (min. 22.0 daN.m) 6.2.7. for 30 mm bolts (min. 25 daN.m) 6.3. Number of threads out of nuts (min.3) 7. Quality of painting 7.1. Stub angle painting 7.2. Tower painting B. Result REMARKS / OBSERVATIONS: CONTRACTOR SIGN & DATE Page 2 PDO CIVIL WORKS SIGN & DATE Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. PDO CW-NNNA3 CONSTRUCTION CHECK SHEET CIVIL WORKS OVERHEAD LINES ON LATICE STEEL TOWERS PAINTING CHECK SHEET PROJECT DESCRIPTION PROJECT WBS No. SUB-SYSTEM DESCRIPTION SUB-SYSTEM No. SERVICE DESCRIPTION TAG No. LINE NAME MINIMUM DFT REQUIRED FOR AIRCRAFT WARNING PAINTING PRIMER COAT INTERMEDIATE COAT FINISH COAT(S) TOTAL DFT REQUIRED LOCATION NO. TOWER TYPE Date of Painting Measurement READING ON GALVANISING [μm] Fabricated Steel Under 5mm Main Article 5mm thick and Member Article Mark over READING ON PRIMER COAT [μm] Under 5mm Main 5mm thick and Member over READING ON INTERMEDIATE COAT [μm] Under 5mm Main 5mm thick and Member over READING ON FINISH COAT(S) [μm] Under 5mm Main 5mm thick and Member over Total Average [μm] DFT [μm] Total DFT [μm] Total DFT requirement Measured by (Contractor) Name Checked by (Consultant) Name Signature Supervised by (PDO) Name RANDOM Page 3 Signature Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. REMARKS Signature μm μm μm μm PDO E-NNNA4 CONSTRUCTION CHECK SHEET Sheet 1 of 1 OVERHEAD LINES ONELECTRICAL LATTICE STEEL TOWERS ERECTION/SAG CHART RECORD PROJECT DESCRIPTION PROJECT WBS No. SUB-SYSTEM DESCRIPTION SUB-SYSTEM No. SERVICE DESCRIPTION TAG No. A. REV 0 INDENT / CONTRACT No: OVERHEAD LINE FROM: TO: SAGGING SECTION FROM: TO: B. INSPECTION 1. Section length 2. Equivalent span 3. Ambient temperature (°C) 4. Conductor temperature (°C) 5. Sagging Tower No. to Tower No. 6. Check Span Tower No. to Tower No. 7. Sagging span length (m) 8. Check span length (m) 9. Dynamometers Result 10. Thermometers 11. Sighting Boards 12. Sagscope 13. Final Sag (m) 14. Conductor Tension (kg) 15. Midspan Joints (between Tower Nos.) 16. Conductor Repair Sleeves (between Tower Nos.) C. REMARKS / OBSERVATIONS: COMPLETED BY CONTRACTOR APPROVED BY CONTRACTOR ACCEPTED BY PDO NAME NAME NAME COMPANY COMPANY REF. IND. SIGN & DATE SIGN & DATE SIGN & DATE Page 4 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. PDO E-NNNA5 CONSTRUCTION CHECK SHEET Sheet 1 of 1 ELECTRICAL OVERHEAD COMPRESSION JOINTS PROJECT DESCRIPTION PROJECT WBS No. SUB-SYSTEM DESCRIPTION SUB-SYSTEM No. SERVICE DESCRIPTION TAG No. A. REV 0 INDENT / CONTRACT No: LOCATION: SECTION LENGTH: DRAWING REF NO: TYPE OF STRUCTURE: TENSION / SUSPENSION OPERATING VOLTAGE: CONDUCTOR TYPE: CONDUCTOR SIZE: B TEST Results Tower No C R-phase Y-phase B-phase Shieldwire REMARKS / OBSERVATIONS: COMPLETED BY CONTRACTOR APPROVED BY CONTRACTOR ACCEPTED BY PDO ELECTRICAL NAME NAME NAME COMPANY COMPANY REF. IND. SIGN & DATE SIGN & DATE SIGN & DATE Page 5 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. PDO E-NNNB1 PRE-COMMISSIONING CHECK SHEET ELECTRICAL INSTALLATION OF OVERHEAD Sheet 1 of 2 LINES ON LATTICE STEEL TOWERS REV 0 INSPECTION PROJECT DESCRIPTION PROJECT WBS No. SUB-SYSTEM DESCRIPTION SUB-SYSTEM No. SERVICE DESCRIPTION TAG No. A. INDENT/CONTRACT No: LOCATION: SECTION LENGTH: POLE REF No: DRAWING REF No: TYPE OF STRUCTURE: □ TENSION OPERATING VOLTAGE: CONDUCTOR TYPE: CONDUCTOR SIZE: □ SUSPENSION SAG / TENSION DRAWING REF No: WORK COMMENCED ON: WORK COMPLETED ON: B. INSPECTION Results 1. Check and ensure that foundations are correctly installed 2. Check towers for mechanical damage 3. Check and ensure that all bolts and nuts are correctly fastened. 4. Check and ensure that the towers verticality tolerances are observed. 5. Check and ensure that backfilling, compacting and leveling are completed 6. Check and ensure that damages to galvanising or painting are repaired 7. Check and ensure that all the fittings are tightened and painted to specification requirements 8. Check and ensure that all the insulators are clean 9. Check and ensure that line conductors are correctly clamped/strapped 10. Check and ensure that anti-climbing devices, danger & reflector plates, number plates, phase plates and name plate are fitted in correct position. 11. Check and ensure that there are no damages to the conductor (strand damages) 12. Check and ensure that sagging is correct and the records submitted.(E-NNNA2) 13. Check and ensure that jumpers for all phases are fixed and the necessary clearances maintained Page 6 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. PDO PRE-COMMISSIONING CHECK SHEET E-NNNB1 ELECTRICAL INSTALLATION OF OVERHEAD Sheet 1 of 2 LINES ON LATTICE STEEL TOWERS REV 0 INSPECTION 14. Conduct a random check to ensure that all the clearances are correct and in accordance with specification requirements PROJECT DESCRIPTION PROJECT WBS No. SUB-SYSTEM DESCRIPTION SUB-SYSTEM No. SERVICE DESCRIPTION TAG No. INSPECTION Results 15. Check and ensure that the stub angles and foundation cap is painted according to specification requirements. 16. Check and ensure that there are not cracks on foundation cap (except hair cracks of max. 0.3mm). 17. Check and ensure that there are not bended elements on tower structure. 18. Check and ensure that there are not missing members on tower structure. 19. Check and ensure that all temporary earth and excess material are removed 20. Check and ensure that all tower areas are shaped to eliminate water ponding 21. Check and ensure that the area around the tower foundations is leveled and all excess earth removed 22. Ensure that tower painting inspection reports are attached. 23. Record the actual clearance at all road/river crossings. C. REMARKS / OBSERVATIONS: COMPLETED BY CONTRACTOR NAME Page 7 APPROVED BY CONTRACTOR NAME Specification for Installation of Overhead Transmission Lines ACCEPTED BY PDO NAME Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. PDO PRE-COMMISSIONING CHECK SHEET E-NNNB1 ELECTRICAL INSTALLATION OF OVERHEAD Sheet 1 of 2 LINES ON LATTICE STEEL TOWERS INSPECTION REV 0 COMPANY COMPANY REF. IND. SIGN & DATE SIGN & DATE SIGN & DATE PROJECT DESCRIPTION PROJECT WBS No. SUB-SYSTEM DESCRIPTION SUB-SYSTEM No. SERVICE DESCRIPTION TAG No. A. INDENT / CONTRACT No: LOCATION: SECTION LENGTH: DRAWING REF NO: TYPE OF STRUCTURE: TENSION / SUSPENSION OPERATING VOLTAGE: CONDUCTOR TYPE: CONDUCTOR SIZE: FROM TOWER NO: TO TOWER NO: SAG / TENSION DRAWING REF NO: B TEST Results 1. Ensure that prior to Site Tests, the Contractor provides Type Test and Routine Test Certificates confirming that during factory tests of equipment, the criteria for the behavior of the test object have been fulfilled and all tests have been passed successfully. 2. Ensure that pre-commissioning checks have been carried out and the relevant Construction Test sheet completed 3. Ensure that earth electrodes have been tested and relevant Functional Test sheets completed 4. Ensure that compression joints tested and relevant Functional Test sheets completed 5. Place danger notices and cordon off the test area 6. Ensure that at tower locations subject of special requirements of safety of public Step and Touch Voltage measurements have been performed and special earthing installed 7. Measure line resistance (complete): 8. R-phase to Y-phase (Ω) 9. Y-phase to B-phase (Ω) 10. R-phase to B-phase (Ω) 11. Ensure OTDR measurements are within the required / guaranteed limits and relevant test sheets are attached. 12. Ensure that the results of Optical Acceptance Test (end to end) are within the required / guaranteed limits and relevant test sheets are attached. C. REMARKS / OBSERVATIONS: COMPLETED BY CONTRACTOR NAME Page 8 APPROVED BY CONTRACTOR NAME Specification for Installation of Overhead Transmission Lines ACCEPTED BY PDO ELECTRICAL NAME Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. PDO PRE-COMMISSIONING CHECK SHEET ELECTRICAL INSTALLATION OF OVERHEAD E-NNNB1 Sheet 1 of 2 LINES ON LATTICE STEEL TOWERS INSPECTION REV 0 COMPANY COMPANY REF. IND. SIGN & DATE SIGN & DATE SIGN & DATE Page 9 Specification for Installation of Overhead Transmission Lines Printed 08/09/21 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED.