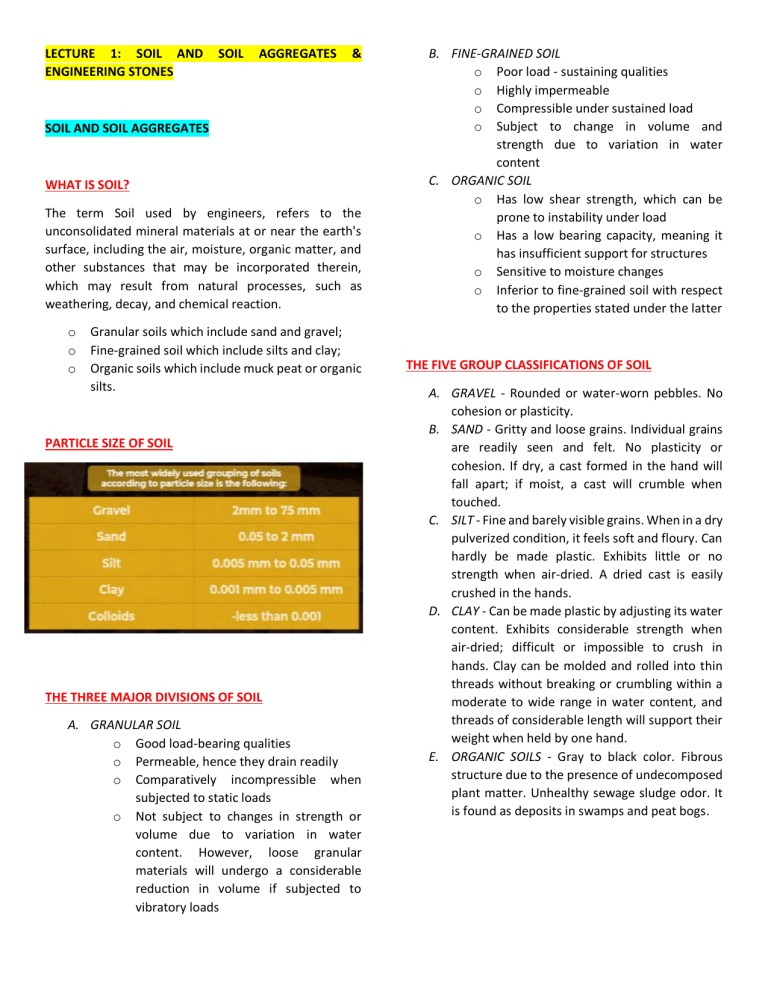

LECTURE 1: SOIL AND ENGINEERING STONES SOIL AGGREGATES & SOIL AND SOIL AGGREGATES WHAT IS SOIL? The term Soil used by engineers, refers to the unconsolidated mineral materials at or near the earth's surface, including the air, moisture, organic matter, and other substances that may be incorporated therein, which may result from natural processes, such as weathering, decay, and chemical reaction. o o o Granular soils which include sand and gravel; Fine-grained soil which include silts and clay; Organic soils which include muck peat or organic silts. PARTICLE SIZE OF SOIL THE THREE MAJOR DIVISIONS OF SOIL A. GRANULAR SOIL o Good load-bearing qualities o Permeable, hence they drain readily o Comparatively incompressible when subjected to static loads o Not subject to changes in strength or volume due to variation in water content. However, loose granular materials will undergo a considerable reduction in volume if subjected to vibratory loads B. FINE-GRAINED SOIL o Poor load - sustaining qualities o Highly impermeable o Compressible under sustained load o Subject to change in volume and strength due to variation in water content C. ORGANIC SOIL o Has low shear strength, which can be prone to instability under load o Has a low bearing capacity, meaning it has insufficient support for structures o Sensitive to moisture changes o Inferior to fine-grained soil with respect to the properties stated under the latter THE FIVE GROUP CLASSIFICATIONS OF SOIL A. GRAVEL - Rounded or water-worn pebbles. No cohesion or plasticity. B. SAND - Gritty and loose grains. Individual grains are readily seen and felt. No plasticity or cohesion. If dry, a cast formed in the hand will fall apart; if moist, a cast will crumble when touched. C. SILT - Fine and barely visible grains. When in a dry pulverized condition, it feels soft and floury. Can hardly be made plastic. Exhibits little or no strength when air-dried. A dried cast is easily crushed in the hands. D. CLAY - Can be made plastic by adjusting its water content. Exhibits considerable strength when air-dried; difficult or impossible to crush in hands. Clay can be molded and rolled into thin threads without breaking or crumbling within a moderate to wide range in water content, and threads of considerable length will support their weight when held by one hand. E. ORGANIC SOILS - Gray to black color. Fibrous structure due to the presence of undecomposed plant matter. Unhealthy sewage sludge odor. It is found as deposits in swamps and peat bogs. WHAT IS AN AGGREGATE? Aggregates are the most mined material in the world. Aggregate is a broad-encompassing boulder, cobbles, crushed stone, gravel, air-cooled blast furnace slag, native and manufactured sands, and manufactured and natural lightweight aggregates. Aggregates may be further described by their respective sizes. THE TWO TYPES OF AGGREGATES A. NORMAL WEIGHT AGGREGATE traditional aggregates, radiation attenuation for use in nuclear and medical facilities, higher compressive strength, options of natural materials like magnetite or manufactured materials with high specific gravity, and often a higher cost compared to lightweight aggregates due to the materials used. Heavyweight aggregates include magnetite, with a specific gravity of 4.3; barite 4.2; limonite 3.8; ferrophosphorus 6.3; and steel shot or punching 7.6. Such heavyweight aggregates may be used instead of gravel or crushed stone to produce a dense concrete for example, for shielding of nuclear reactions. These typically have specific gravities between 2.0 and 3.0. They are usually distinguished by size as follows: o o o o o Boulders - Larger than 6 in. Cobbles - 6 to 3 in. Coarse aggregate - 3 in. to No. 4 sieve Fine aggregate - No. 4 sieve to No. 200 sieve Mineral filler - Material passing No. 200 sieve 2 Used in most concrete construction, normal-weight aggregates are obtained by draining riverbeds or mining and crunching formational material. Concrete made with normal-weight fine and coarse aggregates generally weights about 144 lb. / ft3. Boulders and cobbles are generally not used in their as-mined size but are crushed to make various sizes of coarse aggregate and manufactured sand and mineral filler. Aggregates comprise the greatest volume percentage in portland-cement concrete, mortar, or asphaltic concrete. In a Portland-cement concrete mix, the coarse and fine aggregates occupy about 60 to 75% of the total mix volume. For asphaltic concrete, the aggregates represent 75 to 85% of the mix volume. B. LIGHTWEIGHT AND HEAVYWEIGHT AGGREGATE Lightweight aggregates, materials with low density used in construction and derived from natural resources or industrial by-products, exhibit characteristics such as significantly lower density than traditional aggregates, high porosity contributing to their lightweight nature, thermal insulation properties, generally lower compressive strength, and options like expanded shale, clay, or industrial by-products. In contrast, heavyweight aggregates, chosen for enhanced density and radiation shielding in construction, have characteristics including much higher density than GRADATION OF AGGREGATES The distribution of aggregate sizes in a concrete mix is important because it directly influences the amount of cement required for a given strength, workability of the mix (and amount of effort to place the mix in the forms), in-place durability, and overall economy. ASTM C33 provides ranges of fine- and coarse-aggregate grading limits. WHAT IS ASTM? American Society for Testing and Materials THE SEVEN PROPERTIES OF AGGREGATES A. HARDNESS – Coarse–aggregate hardness is measured by the Los Angeles Abrasion Test, ASTM C131 or C595. These tests break the aggregate down by impacting it with steel balls in a steel tumbler. The resulting breakdown is not directly related to the abrasion an aggregate receives in service, but the results can be empirically related to concretes exhibiting service lives. B. SOUNDNESS – Aggregate soundness is measured by ASTM C88, "Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate." This test measures the amount of aggregate degradation when exposed to alternating cycles of wetting and drying in a sulfate solution. C. PARTICLE SHAPE – Natural sand and gravel have a round, smooth particle shape. Crushed aggregate (coarse and fine) may have shapes that are flat and elongated, angular, cubical, disk, or rodlike. These shapes result from the crushing equipment employed and the aggregate mineralogy. Extreme angularity and elongation increase the amount of cement required to give strength, difficulty in finishing, and effort required to pump the concrete. Flat and elongated particles also increase the amount of required mixing water. The bond between angular particles is greater than that between smooth particles. D. POTENTIAL ALKALI REACTIVITY – Aggregates that contain forms of silicas or carbonates may react with the alkalines present in Portland cement (sodium oxide and potassium oxide). The reaction product cracks the concrete or may create pop-outs at the concrete surface. E. RESISTANCE TO FREEZING AND THAWING – The pore structure, absorption, porosity and permeability of aggregates are especially important if they are used to make concrete exposed to repeated cycles of freezing and thawing. Aggregates that become critically saturated and then freeze cannot accommodate the expansion of the frozen water. F. IMPURITIES IN AGGREGATES – Erratic setting times and rates of hardening may be caused by organic impurities in the aggregates, primarily the sand. Pop-outs and reduced durability can be caused by soft particles, chert, clay lumps and other friable particles, coal, lignite, or other lightweight materials in the aggregates. G. VOLUME STABILITY – It refers to susceptibility of aggregates to expansion when heated or to cyclic expansion and contraction when saturated and dried. Aggregates that are susceptible to volume change due to moisture should be avoided. CLASSIFICATION OF AGGREGATES BASED ON UNIT WEIGHT ENGINEERING STONES THE FIVE PARAMETERS CONSIDERED IN SELECTING A GOOD CONSTRUCTION STONE A. CHEMICAL COMPOSITION – Using/selecting a stone for construction, its chemical properties and composition must be tested and verified because different elements and compounds in stones have different properties. B. STRONGNESS AND HARDNESS – The more compact grained and heavier a stone, the stronger it is. The specific gravity of good stone should be above 2.7. Stones used for road metal, paving blocks, floor slabs and railway ballast have to withstand mainly abrasion or wear and tear. C. RESISTANCE TO HEAT – Resistance to heat means that the stone must have a very low amount of expansion due to large increase in temperature. D. BIO-DETERIORATION – Certain trees and creepers thrust their roots in the joints of stones and have both mechanical and chemical adverse effects. Special microbes can grow on the surface and in minute fissures, their by-products cause flaking and discoloration. E. APPEARANCE – The aesthetic aspect that is color, appearance, and show of stones must also be considered when being used in a project. Appearance depends on the color and the ease with which the stone can be dressed, rubbed or polished. THE THREE GEOLOGICAL CLASSIFICATION OF STONES A. SEDIMENTARY Characteristics: o Sandstone, limestone, dolomite originally formed mainly in sea water, or lakes, from the remains of animals and plants, also from transportation and deposition of rock products. Rounded and Angular in shape. Classifications: o o o Detrital is made from disintegrated preexisting rock. Biogenetic is made from shells and other fossilized fragments. Chemical is made from chemical precipitation. B. METAMORPHIC Characteristics: Marble, serpentine, onyx, slate, quartzite, gneiss are produced from sedimentary or igneous rocks by the action of heat and pressure. o No pressure - fossils survive o Low pressure - fossils distorted or destroyed o Moderate pressure - Grains form moderately o High pressure - Active fluids may circulate o Heat alone, Metamorphic Aureole surrounding a deep plutonic intrusions, possibly with active fluids o Dynamic Meta - Large scale movement phenomena o Crushing actions produce Xylonite Meta rock from powder o Low angle thrust fault: Plate pressure coupled with subsidence o Thrust movement, plate movement Classifications: According to Structure o Contact type is crystalline o Regional type is usually foliated According to Grain size o o o +0 Big grain, High pressure 00 Med grain, Med pressure -0 Small grain, Low pressure C. IGNEOUS Characteristics: o Intrusive - subsurface crystallization o Extrusive- above surface crystallization o Mineral content o Grain size, Plutonic >3/16" coarse. Extrusive 1/64" - 3/16" Medium and < 1/64" fine o Crystal shape o Texture % A, %B, crystal angle o Color Classifications: o o o o Acid rocks > 65% Si + > 10% Modal Quartz Intermediate rocks 55% - 65% Si Basic rocks 45% - 55% Si < 10% Modal Quartz Ultra-Basic < 45% Si TEST OF STONES Once a stone has been selected on aesthetic basis, it is important than to ensure whether it exhibits the necessary physical properties and durability to remain in working condition for a long time. Fixing method adopted for the construction of stones also affects the type of stones selected. Physical properties such as density, compressive strength and porosity are measured in order to determine its durability. APPLICATIONS AND USES OF STONES APPLICATIONS AND USES OF AGGREGATES USES OF STONES USES OF AGGREGATES – The uses of aggregates can be summarized in to the following three categories: o o o o o o o Sandstone is a popular stone with sculptors. Good and durable construction material Thresholds and steps in manor houses War memorials in the 19th and 20th centuries Limestone for burning lime and also for manufacture of cement Limestone as a flux in blast furnaces Insulators in electrical appliances BUILDING STONES o o o o o o o o o o o o o o Millions of tons of crushed rock are needed annually for road base, paving, ready-mixed concrete and asphalt. Sandstone which is not so hard-wearing or beautifully patterned is used for garden walls and paths in landscaping. Basalt: It is quarried and crushed as "Blue Metal" which is used as a road-base, and in reinforced concrete as aggregate. Although wood, straw and mud is used for houses in some parts of the world, most buildings are preferred to be built of stones. Building wells. Material for foundation and walling of buildings, dams, bridges, etc. Aggregate Stone walls Roof tile in the form of slates Murram for covering and flooring of road surface Limestone for burning lime and for the manufacture of Portland cement Shale is a component of bricks and may also be used in manufacturing of cement. Nite, another stone type is used for architectural construction, ornamental stones and monuments. Marble is widely used in construction industry, for aesthetic purposes, beautification and strength o o o As a Load Bearing Material As a Filling Material As an Infiltrating Material USES OF AGGREGATES IN CONCRETE – The purpose of aggregates in concrete is: o o o o o To provide a rigid structure To reduce the shrinkage and cracking Concrete aggregate is used in many structures and substructures e.g. different elements of a Building, bridges, foundations The smaller the aggregate size the greater its surface area and the more binding material (cement) will be required, resulting in a higher cost The greater the aggregate size the larger will be the voids, resulting in wastage of binding material (cement) USES OF AGGREGATES IN RAILWAY BALLAST o o A fully loaded train weighs in thousands of tons. To avoid damage to the rails, ground and other nearby structures a very tough aggregate is needed not only to support this high weight but also to distribute and transfer it properly to the ground. Railway ballast generally consists of a tough igneous rock (crushed), such as granite, with a larger diameter varying between 30mm to 50mm. Particles finer than this diameter in higher proportion will reduce its drainage properties. While a higher proportion of larger particles result in the load on the ties being distributed improperly.