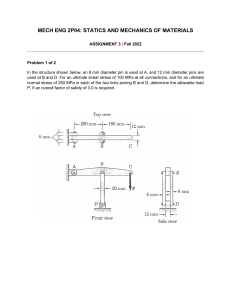

MECHANICS OF DEFORMABLE BODIES SAMPLE PROBLEMS Mechanics Simple Stress - may be defined as the science which - defined as the force per unit area considers the effects of forces on rigid bodies Formula: Mechanics of deformable bodies - deals with the relations between externally applied loads and their internal effects on bodies Types of loading resulting in different types of stress US SI Units Customary 1. Axial Force (P) Units - measures the pulling or pushing action perpendicular to Force 𝑵 𝒍𝒃 the section - pull represents a tensile force Area 𝒎𝟐 𝒊𝒏𝟐 that tends to elongate the Stress 𝑵/𝒎𝟐 𝒍𝒃/𝒊𝒏𝟐 member - push is a compressive force that tends to shorten the member Equivalence 2. Shear Force (V) - components of the total 𝟏 𝑷𝒂 = 𝑵/𝒎𝟐 resistance to sliding the portion 𝟏 𝒑𝒔𝒊 = 𝒍𝒃/𝒊𝒏𝟐 𝟏 𝒌𝒊𝒑 = 𝟏𝟎𝟎𝟎 𝒍𝒃 to one side of the section past 𝟏 𝒌𝒔𝒊 = 𝟏𝟎𝟎𝟎 𝒑𝒔𝒊 the other 3. Bending Moments (M) - These components measure Three types of simple stresses: the resistance to bending about an axis 1. Normal Stress 4. Torque (T) - The applied force is - This component measures the perpendicular to the resisting resistance to twisting the area member 2. Shear Stress - The applied force is parallel to Stress the resisting area - is defined as the strength of a 3. Bearing Stress material per unit area - It is the contact pressure - it is also called the unit strength between separate bodies. Sample Problem 1: MECHANICS OF DEFORMABLE BODIES SAMPLE PROBLEMS A hollow steel tube with an inside diameter of 100 mm must carry a tensile load of 400 kN. Determine the outside diameter of the tube if the stress is limited to 120 𝑀𝑀/𝑀2 Sample Problem 2: A homogeneous 800 kg bar AB is supported at either end by a cable as shown in Fig. P-105. Calculate the smallest area of each cable if the stress is not to exceed 90 MPa in bronze and 120 MPa in steel. Sample Problem 3: The homogeneous bar shown in Fig. P-106 is supported by a smooth pin at C and a cable that runs from A to B around the smooth peg at D. Find the stress in the cable if its diameter is 0.6 inch and the bar weighs 6000 lb. MECHANICS OF DEFORMABLE BODIES SAMPLE PROBLEMS Sample Problem 4: The homogeneous bar shown in Fig. P-106 is supported by a smooth pin at C and a cable that runs from A to B around the smooth peg at D. Find the stress in the cable if its diameter is 0.6 inch and the bar weighs 6000 lb. SHEAR STRESS: Sample Problem 1: Find the smallest diameter bolt that can be used in the clevis shown in the figure if P = 400 kN. The shearing strength of the bolt is 300 MPa. MECHANICS OF DEFORMABLE BODIES SAMPLE PROBLEMS Sample Problem 2: A 200-mm-diameter pulley is prevented from rotating relative to 60-mm-diameter shaft by a 70-mm-long key, as shown in Fig. P-118. If a torque T = 2.2 kN·m is applied to the shaft, determine the width b if the allowable shearing stress in the key is 60 MPa. Sample Problem 3: The members of the structure in Fig. P-120 weighs 200 lb/ft. Determine the smallest diameter pin that can be used at A if the shearing stress is limited to 5000 psi. Assume single shear. MECHANICS OF DEFORMABLE BODIES SAMPLE PROBLEMS Sample Problem 4: What force is required to punch a 20-mm-diameter hole in a plate that is 25 mm thick? The shear strength is 350 MN/m2. MECHANICS OF DEFORMABLE BODIES SAMPLE PROBLEMS BEARING STRESS: Sample Problem 1: In the clevis shown in Fig. 1-11b, find the minimum bolt diameter and the minimum thickness of each yoke that will support a load P = 14 kips without exceeding a shearing stress of 12 ksi and a bearing stress of 20 ksi. Sample Problem 2: In Fig. 1-12, assume that a 20-mm-diameter rivet joins the plates that are each 110 mm wide. The allowable stresses are 120 MPa for bearing in the plate material and 60 MPa for shearing of rivet. Determine (a) the minimum thickness of each plate; and (b) the largest average tensile stress in the plates. MECHANICS OF DEFORMABLE BODIES SAMPLE PROBLEMS Sample Problem 3: The lap joint shown in Fig. P-126 is fastened by four ¾-in.-diameter rivets. Calculate the maximum safe load P that can be applied if the shearing stress in the rivets is limited to 14 ksi and the bearing stress in the plates is limited to 18 ksi. Assume the applied load is uniformly distributed among the four rivets.