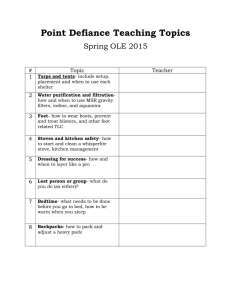

NEWQUAY-PAR LINE The Newquay-Par line, or the Atlantic Coast Line, opened in 1892 and linked the English Channel to the Atlantic Coast. It’s a 33km line with seven stations and at present, the line operates passenger services under Great Western Railway and occasional freight services from Goonbarrow Junction to Par, operated by DB Cargo. There are at most 3 freight services a day and 8 passenger services each way, with passenger numbers are returning to pre-COVID levels, with 129000 in 2023. The following sections on the nature of the line are discussed with respect to Network Rail’s Cost Driver Matrix (Railway Industry Association, 2019), with an intent to understand how much these factors will affect the cost. The matrix is shown in Figure: Figure 1: Cost Driver Matrix The Cost Driver Matrix was developed during the GWEP as a methodology with which to assess electrification projects before the outset and have a better understanding of why certain projects cost more than others. However, for this line, its usability will be limited, since there are so many differences between a low traffic line and a main line. OLE STRUCTURES A low-speed line like the Newquay-Par line can benefit from less rigorous OLE structures. The slow line speed means that the trains run at a similar speed to trams, which operate using trolley wiring, without a catenary wire Diagram/picture. This reduces the height and weight of the structure; therefore, the foundations can be shorter, and the masts can have a reduced cross section. Since tramways use these smaller OLE masts, they will be available for the project, as opposed to requiring new design. Moreover, Furrer+Frey in collaboration with Cranfield, Southampton and Newcastle Universities, Prodrive and TruckTrain have developed a composite material mast with the potential to greatly reduce weight without sacrificing strength (Hakimian, 2022). This would result in much shallower piles and therefore quicker installation from plant that produces less diesel emissions. Another result of the nature of the line is that it’s a single track along the entire length and, ignoring the freight services, which are generally three times a day, there will only be one train on the line at any time. This results in less strain on the feeder stations, which there will only need to be one of. ENVIRONMENTAL CONDITIONS The topography and ground conditions in the area are important considerations when it comes to OLE. The topography will affect the amount of wind on an OLE structure, although the wind conditions are fairly standard across the UK and the location will not affect OLE design differently to other projects. However, the land features will have affected the route layout, and as a result, the complexity of the track, which is a component in the cost driver matrix. For example, some of the curves with small radii will require smaller spans between OLE structures to keep the contact wire over the track. Rock cutting?? The ground conditions will affect the length of the piles, which should be shorter than usual with the lighter OLE structures. The route is predominantly clay on top of mudstone or sandstone (British Geological Survey, 2020), so the conditions are similar to other electrified routes for comparison. CIVIL ENGINEERING FEATURES A massive cost when electrifying a line usually goes to the civil engineering works, where clearances below overbridges or in tunnels are not large enough. As a result, these features are weighted at 30% in the cost driver matrix. In the past, suitable electrical clearances have been met by expensive demolition and reconstruction of bridges, but there has been progress made in avoiding this process. For example, an innovative solution was implemented on Intersection Bridge in Cardiff to avoid a very costly reconstruction in a builtup area. The combination of surge arrestors, which prevent an abnormally large voltage causing flashover, insulated coating on the bridge, again to prevent flashover, and a contact wire cover reduced the air gap to 20mm. Each of these technologies are in wide use and, when combined, the electrical clearance is a far less relevant factor. Before these technological improvements, it was suggested that a low-cost electrification on a low frequency line would be possible with 750DC (DeltaRail, 2010). The lower voltage would result in much smaller clearances and therefore less civil engineering work and is in use on metro systems like the Midland Metro. This benefit was seen to outweigh the cost of having three more substations and thicker contact wire. Currently, considering modern methods of reducing the air gap and how less voltage doesn’t affect the mechanical clearance, this would be unnecessary. Regardless, there is still a significant cost associated with alternative methods to reduce clearance, like insulated coatings and surge arrestors, and these methods won’t be applicable to every bridge. Having established that the limiting factor for bridge clearance is the mechanical clearance of the pantograph and contact wire, which, according to GL/RT1210, has a minimum height of 4165mm (Holbourn, 2020), how will overbridges that are still too low be made acceptable? There are at least two overbridges that are overgrown and no longer in use, and if necessary, it may be cheaper to demolish these instead of undergo track works to get through them. Many of the other bridges are either for farm use or for low traffic roads and only over a single track, so if necessary, the cost of reconstruction would be as low as it could be. However, reconstruction is rarely the most cost-effective option, even compared to other standard procedures like track lowering. An alternative currently being explored in Wales is to include earthed or catenary free sections of line where the train is expected to coast underneath a low overbridge since a contact wire either doesn’t have space to run or doesn’t have enough of an air gap to be electrified (Shirres, 2022). This is viable where there are no electric freight services operating and the trains have enough momentum to clear the overbridge and reconnect to the live section. Therefore, this system might not be applicable on some of the slower sections but is worth considering above 35mph. The maximum speeds on the line are in Figure (OpenRailwayMap, 2024) Figure 3: Maximum speeds on the Newquay-Par line Figure 2: Bridges on the Newquay-Par line Figure shows the line’s intersections with roads or pathways. This doesn’t include level crossings, nor does it include viaducts. The markers in purple represent the railway crossing over another feature, and the red markers indicate the railway going underneath a feature, like a tunnel or bridge. The red areas are the most important when deciding how much civil engineering work is required. There is also one viaduct along the line. The Trenance viaduct will cause added cost, as either special foundations are used on the viaduct, or the structures are connected directly to the viaduct. There is a cost incurred in the development and application of special supports. CAPACITY Given in the Passenger Demand Forecasting Handbook are the elasticities relevant to reducing generalised journey time (GJT). Since the better acceleration provided by electric trains will improve the overall journey time by an estimated 30 seconds at each station, the PDFH model predicts that the annual demand would increase by roughly 5000. ROLLING STOCK CONSTRUCTION It is common for the installation of OLE structures to run over schedule and poorly utilise man-hours. This comes as a result of only being able to work between midnight and four or five in the morning. If the plant needs time to get to the site too, a team hired for an 8-hour shift might only get 4 hours of work done. The procurement process can also be inefficient, as time is wasted when adjacent sections of track need to be separately blockaded, or construction occurs on different days on adjacent track. The benefit of a low traffic line is that this process is a lot more straightforward. The Newquay-Par line is largely a tourist line in the summer, so closing the entire line in autumn or winter and completing all the trackside works in a short amount of time causes minimal disruption than if a similar thing was done for a main line.