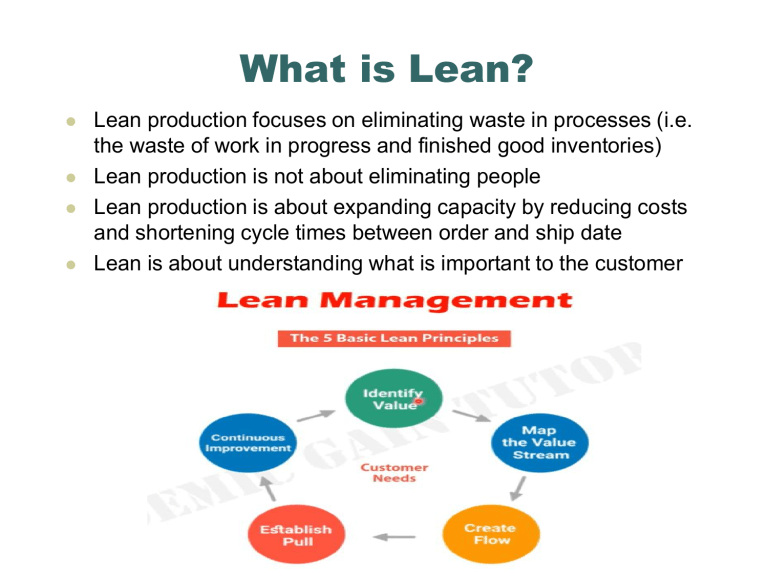

What is Lean? ⚫ ⚫ ⚫ ⚫ Lean production focuses on eliminating waste in processes (i.e. the waste of work in progress and finished good inventories) Lean production is not about eliminating people Lean production is about expanding capacity by reducing costs and shortening cycle times between order and ship date Lean is about understanding what is important to the customer 1 “go and see for yourself” WASTAGE: Muda , Mura , Muri Muda Muda means wastefulness, uselessness Two types of Muda Type 1 Non-value-added activities in the processes necessary for the end customer. (Inspection and safety testing) Type 2 Non-value added activities - unnecessary for the customer. Mura Mura means unevenness, non-uniformity, and irregularity. Mura is the reason for the existence of any of the 7 wastes. Mura drives and leads to Muda. Solution: Level out the workload so that there is no unevenness or waste accumulation. Just-In-Time Muri Muri means overburden, beyond one’s power, excessiveness Muri leads to absenteeism, illness, and breakdowns of machines. Standardize work and evenly distribute the workload Lean Is A Journey ⚫ ⚫ ⚫ ⚫ The Journey never ends Toyota estimates it is only 50% wastefree Where can we begin? Where can we improve? 5S 16 What is Six Sigma? A Vision and Philosophical commitment to our consumers to offer the highest quality, lowest cost products A Metric that demonstrates quality levels at 99.9997% performance for products and processs A Benchmark of our product and process capability for comparison to ‘best in class’ A practical application of statistical Tools and Methods to help us measure, analyze, improve, and control our process 17 How good is good enough? 99.9% is already VERY GOOD But what could happen at a quality level of 99.9% (i.e., 1000 ppm), in our everyday lives (about 4.6)? • 4000 wrong medical prescriptions each year • More than 3000 newborns accidentally falling from the hands of nurses or doctors each year • Two long or short landings at American airports each day • 400 letters per hour which never arrive at their destination 18 How can we get these results? ⚫ 13 wrong drug prescriptions per year ⚫ 10 newborn babies dropped by doctors/nurses per year ⚫ Two short or long landings per year in all the airports in the U.S. ⚫ One lost article of mail per hour 19 Six Sigma ROI Motorola ROI 1987-1994 • Reduced in-process defect levels by a factor of 200. • Reduced manufacturing costs by $1.4 billion. • Increased employee production on a dollar basis by 126%. • Increased stockholders share value fourfold. AlliedSignal ROI 1992-1996 • $1.4 Billion cost reduction. • 14% growth per quarter. • 520% price/share growth. • Reduced new product introduction time by 16%. • 24% bill/cycle reduction. 22 Definitions ⚫ – Standard Deviation, a measure of variability ⚫ Six Sigma – A quality improvement philosophy that focuses on eliminating defects through reduction of variation in a process ⚫ Defect – A measurable outcome that is not within acceptable (specification) limits TQM Versus Six Sigma TQM Six Sigma A management philosophy of quality improvement Encourages involvement of all employees A philosophy that focuses on defect reduction and cost reduction Relies on a selected group of highly-trained employees Senior management provides direct support Senior management is held accountable for results Key Success Factors for Six Sigma ⚫ ⚫ ⚫ ⚫ ⚫ ⚫ Committed leadership from top management Integration with existing initiatives, business strategy, and performance measurement Process thinking Disciplined customer and market intelligence gathering A bottom-line orientation and continuous reinforcement and rewards Training GE’s Six-Sigma Problem Solving Approach 1. Define 2. Measure 3. Analyze 4. Improve 5. Control DMAIC - Define ⚫ Identify customers and their priorities ⚫ Identify business objectives ⚫ Select a six sigma project team ⚫ Define the Critical-to-Quality (CTQ’s) characteristics that the customers consider to have the most impact on quality DMAIC - Measure ⚫ Determine how to measure the processes • Identify key internal processes that influence CTQ’s • Measure the defect rates currently generated relative to those processes DMAIC - Analyze ⚫ Determine the most likely causes of defects. • Identify key factors that are most likely to create process variation. DMAIC - Improve ⚫ Identify means to remove causes of the defects. • Confirm the key variables and quantify the effects on CTQ’s • Identify maximum acceptable ranges for the key variables and a system to measure deviations of the variable • Modify the process to stay within the acceptable ranges DMAIC - Control ⚫ Determine how to maintain the improvement • Put tools in place to ensure that the key variables remain within the maximum acceptable ranges under the modified process Outcomes Hospital-acquired infections are a big concern. In fact, in 2003, “each year roughly 80,000 patients become infected and 30,000 to 60,000 die at a cost of $3 billion nationally.” Observing the process and using Lean principles in a DMAIC framework can drive improvements. DEFINE: What are the specific infections concerned? In what hospitals over what time frame will improvement efforts happen? For example, there were central line-associated infections in 100 intensive care units (ICUs) in Michigan hospitals during 2007. MEASURE: Measure the current state (three infections per 1,000 catheter-hours). ANALYZE: Determine the root cause (specific process steps and procedures introducing contamination). IMPROVE: Implement a standardized checklist (basic steps related to hygiene, disinfectant, sterile barriers, and avoidance of susceptible areas). Enhance equipment (catheter-insertion cart). CONTROL: Incorporate training and reinforcement to change the culture and internalize the process. Empower the nursing staff to ensure enforcement. Fishbone (Ishikawa) Diagram Problem: Wrong/Delayed/Damaged Delivery Problem: Bad Burgers Problem: Increased Invoice Error What is Kaizen? ⚫ ⚫ ⚫ ⚫ ⚫ Kaizen (Ky’zen) “Kai” means “change” “zen” means “good (for the better)” Gradual, orderly, and continuous improvement Ongoing improvement involving everyone Kaizen isn’t a prescription for improvement; instead, it is a way of seeing the world. 37 Core Principles of Kaizen •The most essential principles of Kaizen are: •Every process can be improved •Continuous improvement is necessary to be competitive •Defects and failures are most often the fault of imperfect processes, not people •Every member of the organization must have a role in improvement •Small changes can have an enormous impact Kaizen The starting point for improvement is to recognize the need. This comes from the recognition of a problem. If no problem is recognized, there is no recognition of the need for improvement. Complacency is the arch enemy of Kaizen. Five instructions of Kaizen: • Know your customer – Identify their interests so that you can enhance their experience. • Let it flow – Everyone in the organization should aim to create value and eliminate waste. • Go to the Gemba – Value is created in the places where work is done. Leaders should go there. • Be transparent – Performance improvements should be tangible and visible. • Empower people – Set goals for teams and give them the tools to achieve them. Gemba Walk The original meaning of Jidoka was "Automation" just as in English. It was written in Kanji as shown. The Kamigo Engine Plant developed many stoppage devices to halt automated machines. This became the word "Autonomation". It was pronounced as Jidoka but the Kanji had a subtle difference-- the addition of a few strokes representing humans or people. Automation is focused on labor reduction. Autonomation (Jidoka) is focused on quality improvement, and the independence of the man from the process. Automation increases technicality, Autonomation reduces technicality. This allows skill levels to be lower in similar processes when comparing East to West. Another cost reducer! Tools for Six-Sigma and Quality Improvement ⚫ Elementary and advanced statistics ⚫ Product design and reliability analysis ⚫ Measurement ⚫ Process control & Process improvement ⚫ Implementation and teamwork ⚫ Customer survey and feedback ⚫ Lean thinking Organization for Six Sigma ⚫ ⚫ ⚫ ⚫ Project Champions – project selection and management, knowledge sharing Master Black Belts – instructors, coaches, technical leaders Black Belts – project team leaders and team members Green Belts – project team members, temporary team members