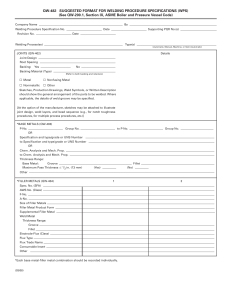

WELDING PROCEDURE SPECIFICATION (WPS) Contractor Name: Alishar Contracting Company Project: Al-Moghamas Reservoir Transmission System Package C W P S N o . ALISHAR/WPS/001 Revision No. 01 Date: 18-12-2023 Supporting PQR No. (s ACC/PQR/101 Revision No. 0 Date: -- Welding Process(es) SMAW Type(s) MANUAL (Automatic, Manual, Machine or Semi-Auto) CODE: ASME IX API 1104 ASME B31.3, B31.4, B31.8 AWS D1.1 JOINTS (QW-402) Details Joint Design Single V - Groove Backing (Yes) -- (Yes) Backing Material (Type) A : 2-4 mm B : 1-2 mm C : 60°-70° T : 6.35 mm -- Weld Metal (Refer to both backing and retainers) -- Metal -- Non-fusing Metal -- Non-metallic -- Other Sketches, Production Drawings, Weld Symbols or Written Description should show the general arrangement of the parts to be welded. Where applicable, the root spacing and the details of weld groove may be specified. (At the option of the contractor, sketches may be attached to illustrate joint design, weld layers and bead sequence, e.g., for notch toughness A-Root Gap, B-Root face procedures, for multiple process procedures, etc.) C-Included Angle T-Base metal thickness * BASE METALS (QW-403) P. No. 1 Group No. 1 to P. No. 1 Group No. 1 OR API 5L PSL2 Gr-B/X42/X46/X52 or Equivalent API 5L PSL2 Gr-B/X42/X46/X52 or Equivalent Specification type and grade to Specification type and grade OR Chem. Analysis and to Chem. Analysis and Mech. Prop. Mech. Prop. Thickness Range: Base Metal: As per applicable material specification As per applicable material specification Groove Pipe dia. range Groove 10.97 – 21.94 mm Fillet ALL Ø 2 7/8“ and above Fillet ALL Other * FILLER METALS (QW-404) Spec. No. (SFA) -- AWS No. (class) -- F. No. -- A. No. --- Size of Filler Metals Weld Metal 1 A5.1 E6010 3 1 Ø 2.6 - 2 A5.5 E7010 3 1 Ø 3.2 Thickness Range: Groove -- 10.97 – 21.94 mm Fillet -- ALL Supplemental -- Electrode-Flux (class) -- -- -- Filler product form Consumable Insert Other -- -- --- * Each base metal-filler metal combination should be recorded individually 1|Page WELDING PROCEDURE SPECIFICATION (WPS) POSITIONS (QW-405) Position(s) of Groove Welding Progression: Up Position(s) of Fillet POST WELD HEAT TREATMENT (QW-407) Temperature Range - 5G Root & Back weld Down All Hot, fill, capping Time Range - NA - NA - GAS (QW-408) PRE HEAT (QW-406) Preheat Temp. Min. Inter pass Temp. Max. Preheat Maintenance 10° C 150° C - Gas(es) (Continuous or special heating, where applicable, should be recorded) Percent Composition (Mixture) ---- Shielding Trailing Backing ---- Flow Rate ---- ELECTRICAL CHARACTERISTICS (QW-409) DC Current AC or DC Polarity EP Amps (Range) 60-110 Volts (Range) 24-28 (Amps and Volts range should be recorded for each electrode size, position and thickness etc. This information may be listed in a tabular form similar to that shown below) Tungsten Electrode Size and Type --NA -- Mode of Metal Transfer for GMAW --NA -- Electrode Wire feed speed range --NA -- TECHNIQUE (QW-410) String or Weave Bead Orifice or Gas Cup Size Initial and Inter pass Cleaning (Brushing, Grinding, etc.) STRINGER & WEAVE NA CHIPPING/BRUSHING/GRINDING GRINDING NO —NA— MULTIPLE SINGLE See electrical characteristics table NA NA Method of Back Gouging Oscillation Contact Tube to Work Distance Multiple or Single Pass (per side) Multiple or Single Electrodes Travel Speed (Range) Peening Other ELECTRICAL CHARACTERISTICS (QW-409) Filler Metal Weld Layer(s) Process Root Pass Volt Range Travel Speed (mm/min) Current Heat Input (KJ/mm) Class Dia Type Polar Amp Range SMAW E6010 Ø 2.6 DCEP 60-70 24-28 90-98 1.09 Hot Pass SMAW E7010 Ø 3.2 DCEP 70-90 26-28 100-110 1.23 Fill1 SMAW E7010 Ø 3.2 DCEP 80-90 26-28 110-120 1.19 Fill2 SMAW E7010 Ø 3.2 DCEP 84-90 26-28 112-120 1.21 Capping 1 SMAW E7010 Ø 3.2 DCEP 90-110 26-28 110-122 1.40 Capping 2 SMAW E7010 Ø 3.2 DCEP 100-110 26-28 108-120 1.49 24-28 90-98 1.09 Remarks Back Gouging Back weld SMAW E6010 Ø 2.6 DCEP 60-70 2|Page WELDING PROCEDURE SPECIFICATION (WPS) 3|Page