Pharmaceutical Product Design & Development Guide

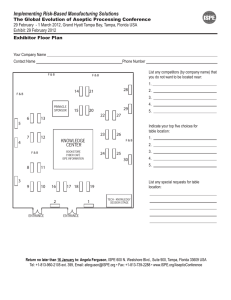

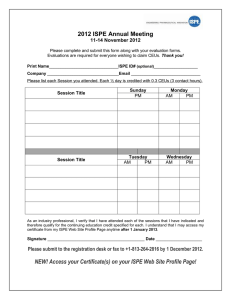

advertisement