TM

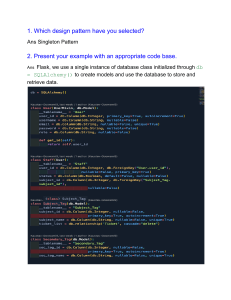

Strength of

Materials

R.K. Kaushik

Distributed by:

@seismicisolation

@seismicisolation

@seismicisolation

@seismicisolation

Strength of Materials

Dr. R.K. Kaushik

Professor

Department of Mechanical Engineering

Ganga Institute of Technology & Management

Kablana, Dist. Jhajjar (Haryana), India

@seismicisolation

@seismicisolation

©Copyright 2019 I.K. International Pvt. Ltd., New Delhi-110002.

This book may not be duplicated in any way without the express written consent of the publisher,

except in the form of brief excerpts or quotations for the purposes of review. The information

contained herein is for the personal use of the reader and may not be incorporated in any commercial

programs, other books, databases, or any kind of software without written consent of the publisher.

Making copies of this book or any portion for any purpose other than your own is a violation of

copyright laws.

Limits of Liability/disclaimer of Warranty: The author and publisher have used their best efforts in

preparing this book. The author make no representation or warranties with respect to the accuracy or

completeness of the contents of this book, and specifically disclaim any implied warranties of

merchantability or fitness of any particular purpose. There are no warranties which extend beyond the

descriptions contained in this paragraph. No warranty may be created or extended by sales

representatives or written sales materials. The accuracy and completeness of the information provided

herein and the opinions stated herein are not guaranteed or warranted to produce any particulars

results, and the advice and strategies contained herein may not be suitable for every individual.

Neither Dreamtech Press nor author shall be liable for any loss of profit or any other commercial

damages, including but not limited to special, incidental, consequential, or other damages.

Trademarks: All brand names and product names used in this book are trademarks, registered

trademarks, or trade names of their respective holders. Dreamtech Press is not associated with any

product or vendor mentioned in this book.

ISBN: 978-93-89307-31-3

EISBN: 978-93-89447-89-7

Edition: 2019

@seismicisolation

@seismicisolation

Dedicated to my wife dear Saroj Gaur Kaushik

@seismicisolation

@seismicisolation

@seismicisolation

@seismicisolation

Preface

Though in my 48 years experience, 28 years is in MNC ABB (earlier Taylor), but for 20

years I taught various subjects to Higher Diploma (equivalent to B.Tech, Mech), B.Tech

subjects. Strength of Materials, Material Science and Machine Design (Mech) have been

my favourite subjects.

This book covers the syllabuses of most universities of B.Tech as well as Diploma in

Mechanical Engineering. Enough solved examples and problems for exercise are given in

the book.

I wish to express my special thanks to my wife Saroj Gaur Kaushik who assisted me a

lot during preparation of the book.

I request students and teachers to point out mistakes, if any to give me opportunity to

correct the same in next edition.

R.K. Kaushik

@seismicisolation

@seismicisolation

@seismicisolation

@seismicisolation

Contents

Preface

vii

1.

Introduction

1

2.

Stress and Strains

Stress

Deformation of a Body Due to Self Weight

Extension of Tapered Rectangular Strip

Bar of Uniform Strength

Exercise

4

4

11

17

20

26

3.

Temperature Stress and Strain

Composite Tube or Bar

Thermal Stresses in a Bar of Tapering Section

Exercise

29

30

32

38

4.

Elastic Constants

Relation between Modulus of Elasticity and Modulus of Rigidity

Relation between Modulus of Elasticity and Bulk Modulus

Exercise

40

43

44

45

5.

Principal Stresses and Strains

Stresses on a Oblique Section

Material Subjected to Two Perpendicular Stresses

Material Subjected to Shear Stresses

Material Subjected to Direct and Shear Stresses

Graphical Method (Mohr’s Circle of Stresses)

Graphical (Mohr’s) Method

Exercise

47

47

50

54

55

59

69

77

6.

Shearing Force and Bending Moment

Shearing Force

Bending Moment

79

79

80

@seismicisolation

@seismicisolation

x

•

Contents

Shearing Force and Bending Moment Diagrams

Cantilevers

Exercise

82

89

94

7.

Centre of Gravity

Centroid for Plane Figures

Centre of Gravity for Solid Bodies

Centroid of Different Sections

Exercise

97

97

99

101

106

8.

Moment of Inertia

Rectangular Section

Radius of Gyration

Theorem of Parallel Axis

Theorem of the Perpendicular Axis

Moment of Inertia of a Hollow Rectangular Section

Moment of Inertia of a Circular Section

Moment of Inertia of a Triangle

Moment of Inertia of Semi-circular Lamina about its Centroidal Axis

Product of Inertia of Rectangle

Exercise

111

111

112

113

113

114

114

115

116

122

122

9.

Bending of Beams

Relationship Between Curvature and Strain

Moment of Resistance

Modulus of Section

Beams of Uniform Strength

Composite Beams or Flitched Beams

Combined Bending and Direct Stresses

Conditions for No Tension in the Section

Exercise

125

125

126

128

136

138

142

146

151

10.

Shear Stresses in Beams

(A) Shear Stress Distribution for Beam of Rectangular Section

(B) Shear Stress Distribution of a Solid Circular Section

(C) Shear Stress Distribution in an I Section

Exercise

157

159

160

162

170

11.

Torsion

Assumptions

Torsional Moment of Resistance

Twist of the Shaft

Composite Shaft

Twisting Beyond the Limit of Proportionality

175

175

176

182

185

185

@seismicisolation

@seismicisolation

Contents •

xi

Torsion of a Tapering Shaft

Thin Circular Tube Subjected to Torsion

Exercise

187

190

193

12.

Thin Cylindrical and Spherical Shells

(i) Hoop Stress or Circumferential Stress

(ii) Longitudinal Stress

Change in Volume

Wire-Bound Thin Cylindrical Shells

Exercise

196

196

197

198

205

212

13.

Thick Cylinders and Spheres

Solid Circular Shaft Subjected to External Pressure

Thick Spherical Shells

Exercise

214

219

229

231

14.

Deflection of Beams

Relation between Slope, Deflection and Radius of Curvature

(A) Double Integration Method

(B) Macaulay’s Method

(C) Moment Area Method

(D) Conjugate Beam Method

(E) Superposition Method

(F) Strain Energy Method

Props

Exercise

234

234

235

251

259

266

277

278

285

286

15.

Strain Energy, Impact Loading and Deflection Due to Bending

(A) Strain Energy Stored in a Body When the Load is Gradually Applied

(B) Suddenly Applied Load

(C) Strain Energy Stored in a Body, When the Load is Applied with Impact

Strain Energy in Pure Shearing

Strain Energy in Torsion

Strain Energy Due to Bending

Maxwell’s Reciprocal Theorem

Betti’s Theorem of Reciprocal Deflections

Exercise

291

291

292

294

305

306

307

311

312

318

16.

Theories of Elastic Failure

1. Maximum Principal Stress Theory (Rankine’s Theory)

2. Maximum Shear Stress Theory (Guest or Teresa’s Theory)

3. Maximum Principal Strain Theory (St. Venant’s Theory)

320

320

321

322

@seismicisolation

@seismicisolation

xii

•

Contents

4. Maximum Strain Energy Theory (Haigh’s Theory)

5. Maximum Shear Strain Energy Theory (Von Mises and Henkey’s Theory)

Exercise

323

324

339

17.

Combined Stresses (Direct, Bending, Torsion)

Combined Bending and Twisting

Exercise

342

343

355

18.

Fixed Beams

Fixed Beam with a Point Load at the Centre

Fixed Beam with Uniformly Distributed Load Over the Span

By Area Moment Method

Deflection for a Fixed Beam with Concentrated Load Anywhere

on the Span

Exercise

357

357

359

361

19.

Continuous Beams

Clapeyron’s Equation of Three Moments

Exercise

377

377

387

20.

Springs

Wahl’s Correction Factor

Close-coiled Helical Spring with Axial Couple

Springs in Series and Parallel

Open-coiled Helical Spring

Composite Action of Axial Load and Couple

Flat Spiral Spring

Leaf, Laminated or Carriage Springs or Semi-elliptic Spring

Quarter-Elliptic Leaf Spring

Exercise

388

390

391

396

402

404

405

408

410

421

21.

Columns and Struts

(a) Both Ends Hinged

(b) Column with One End Fixed and the Other Free

(c) Both Ends Fixed

(d) One End Fixed, Other End Hinged

Limitation for the Use of Euler’s Theory

Rankine’s Formula

Columns Subjected to Eccentric Loading (Secant Formula)

Perry’s Formula for Eccentrically Loaded Column

Exercise

424

426

427

428

429

437

438

446

449

452

@seismicisolation

@seismicisolation

362

375

Contents •

xiii

22.

Bending of Curved Bars

Beams with Large Radius of Curvature (or Small Curvature)

Beam with Small Initial Radius of Curvature (or Large Curvature)

Rectangular Section

Circular Section

Triangular Section

Trapezoidal Section

Stress in a Chain Link

Exercise

456

456

459

464

464

465

466

484

488

23.

Unsymmetrical Bending

Determination of Principal Axes and Principal Moments of Inertia

Beam with Unsymmetrical Bending Moment

Momental Ellipse

Deflection of Beams due to Unsymmetrical Bending

Method for Finding Bending Stream is Unsymmetrical Bending

Shear Centre for Channel Section

Exercise

491

492

493

495

496

497

508

516

24.

Rotating Discs and Cylinders

Rotating Ring

Rotating Disc of Constant Thickness

Solid Disc

Hollow Disc

Rotating Long Cylinder

Solid Cylinder

Disc of Uniform Strength

Exercise

520

520

524

526

527

542

545

554

557

25.

Frameworks

Bow's Notation for Graphical Solution

The Method of Sections

Exercise

559

560

580

587

26.

Dams

Rectangular Dams

Trapezoidal Dams with Water Face Vertical

Rule of Middle Third

Trapezoidal Dams with Water Face Inclined

Exercise

591

591

596

599

603

608

@seismicisolation

@seismicisolation

xiv

•

Contents

27.

Riveted Joints

Rivet

Types of Rivet Heads

Material of Rivets

Types of Riveted Joints

Some Definitions Related to Riveted Joints

Failure of a Riveted Joint

Efficiency of a Riveted Joint

Diamond Riveting

Exercise

610

610

610

612

612

614

615

617

621

625

28.

Welding Joints

Classification of Welding

Advantages and Disadvantages of Welded Joints over Riveted Joints

Unsymmetrical Welded Section

Fillet Welds Under Bending Moment

Eccentrically Loaded Welded Joint

Exercise

626

626

627

632

636

643

647

29.

Mechanical Testing of Materials

1. Tensile Test

2. Compression Test

3. Shear Tests

4. Modulus of Rupture

5. Impact Test

6. Cupping Test

7. Modulus of Rigidity of Rubber

8. Torsion of a Round Bar

9. Verification of Macaulay’s Method for Beam Deflection

10. Verification of Maxwell’s Reciprocal Theorem

11. Hardness Testing Machines

12. Experiment: Close-coiled Helical Springs

13. Experiment: Value of the Modulus of Rigidity C of

a Close-coiled Helical Spring

14. Experiment: Young’s Modulus of Elasticity of a Material Using Simply

Supported Beam

15. Fatigue Testing

Exercise

@seismicisolation

@seismicisolation

649

649

653

657

659

661

664

665

667

669

670

671

681

683

685

686

688

Contents •

30.

Miscellaneous Solved Problems: Stresses and Strains

Complex Stress and Strain

Shear Force and Bending Moment Diagram

Bending Stresses

Shear Stresses

Torsion

Springs

Application of Castigliano’s Theorem

Moment of Inertia

Strain Energy

Theories of Failure

Rotating Discs and Cylinder

Bending of Curved Bars

Fixed Beams

Columns and Struts

Combined Loading

Index

xv

689

697

698

699

702

703

706

710

714

716

719

726

727

728

730

732

737

@seismicisolation

@seismicisolation

@seismicisolation

@seismicisolation

C HAPTER

1

INTRODUCTION

In our life we come across many steel structures such as bridges, machine tools, etc., it is impossible

to construct these without thorough knowledge of strength of materials. As we know if the load

reaches a maximum stress beyond permissible limits, the structure is going to fail. Hence, it is very

important to study the strength of materials before their application in practical field. During one

study we will come across fundamental quantities such as length, stress and time.

In this book S.I. units are used everywhere for the convenience of students. Earlier units such

as F.P.S., C.G.S and M.K.S. have been discarded.

Following dimensions are used for various quantities:

Force: N (Newton = kg m/s2 )

Pressure: Pa (Pascal = N/m2 )

Length: metre or mm

Stress: Pa (1 N/m2 )

Remember 1 GN/m2 = 1 kN/mm2 , 1 MPa = 1 N/mm2 , G = 109 called giga.

Mass density = kg/m3

Before we plunge into details of strength of materials it is better to understand the following

abbreviations:

T (tera)

1012

G (giga)

109

M (mega) 106

k (kilo)

103

Some important formulae:

sin2 A + cos2 A = 1

sec2 A = 1 + tan2 A

cosec2 A = 1 + cot2 A

@seismicisolation

@seismicisolation

2

•

Strength of Materials

The law of sines: In any triangle

b

c

a

=

=

sin A sin B sinC

If a, b, and c are the sides and A, B and C their opposite angles.

sin (A + B) = sin A cos B + cos A sin B

sin (A − B) = sin A cos B − cos A sin B

cos (A + B) = cos A + cos B − sin A sin B

tan (A + B) =

tan A + tan B

1 − tan A tan B

tan (A − B) =

tan A − tan B

1 + tan A tan B

1 − cos 2A

2

1 + cos 2A

cos2 A =

, sin 2A = 2 sin A cos A

2

sin2 A =

2 cos A sin B = sin (A + B) − sin (A − B), cos 2A = cos2 A − sin2 A

If

ax2 + bx + c = 0

Then,

√

−b ± b2 − 4ac

x=

2a

dxn

= nxn−1

dx

dc

= a where c is a constant.

dx

d (u.v)

dv

du

= u. + v.

dx

dx

dx

d (sin x)

d (cos x)

= cos x,

= − sin x

dx

dx

d (tan x)

d (cot x)

= sec2 x,

= −cosec2 x

dx

dx

d

d (sec x)

= sec x tan x; (cosec x) = −cosec x · cot x

dx

dx

@seismicisolation

@seismicisolation

Introduction

xn dx =

(ax + b)n dx =

xn+1

+ c,

n+1

c is a constant

(ax + b)n+1

(n + 1) × a

logxe = 2.3(log x)

(a − bx)−n+1

−n

(a − bx) dx =

(−n + 1)(−b)

@seismicisolation

@seismicisolation

•

3

C HAPTER

2

STRESS AND STRAINS

Stress

Stress can be classified broadly in three types as described below:

l

dl

1. Tensile stress: It is illustrated in Fig. 2.1

where a tensile load W is applied to a uniform rod fixed at one end.

Tensile stress, σ =

W

Figure 2.1

W

W

=

Cross-sectional area of rod

A

unit is N/mm2 or MN/m2 , σ (Greek letter sigma).

2. Compressive stress: As shown in Fig. 2.2

when load W tends to compress a rod

of cross-section area A, then compressive

W

stress = .

A

W

Figure 2.2

3. Shear stress: If two plates are joined

together with rivet as shown in Fig. 2.3.

The stress in rivet is known as shear stress,

it is denoted by τ (Greek letter tau), shear

F

stress in rivet, τ = .

A

F

@seismicisolation

@seismicisolation

F

Figure 2.3

Stress and Strains

•

5

Behaviour of an elastic limit when subjected to a varying load.

Strain: It is defined as the ratio of change in length to original length. It is denoted by Greek

letter ε (epsilon).

Thus strain,

Change in length dl

=

ε=

Original length

l

It is illustrated in Fig. 2.1.

Hooke’s law: It states that stress is proportional to strain within elastic limit.

∴

Stress ∝ Strain

or

Stress

= a constant = E

Strain

Modulus of elasticity: E is called modulus of elasticity or Young’s modulus.

Following Table gives value of E for some important materials.

E(N/mm2 ) approx.

E(GN/m2 or kN/mm2 ) approximately

Steel

200 × 109

200

Cast iron

115 × 109

115

Wrought iron

175 × 109

175

Brass

85 × 109

85

Aluminium alloys

70 × 109

70

Copper

120 × 109

120

Timber

10 × 109

10

Spheroidal C.I.

175 × 109

175

Rubber

0.8 × 106

−

Material

Stress-Strain Curve: Figure 2.4 shows a graph for plain carbon steel during a tensile test.

D

F

C

σ

B

C'

A

(Stress)

ε (Strain)

Figure 2.4

@seismicisolation

@seismicisolation

6

•

Strength of Materials

It may be noted that point A is the limit of proportionality and B is the elastic limit. Between point

A and B it is a curve thus not linear relationship. Therefore, actually E is constant within the limit

of proportionality, though in Hooke’s law, we had mentioned, within ‘elastic limit’, because A and

B are very close to each other. Let us name the important points on the graph:

A: Limit of proportionality

B: Elastic limit: It may be noted that on removal of load up to elastic limits, specimen comes

back to its original dimension.

C: Higher yield point: This is the point where yielding of the material begins.

C : Lower yield point: The stress associated with the lower yield point is known as yield strength.

D: Maximum stress: Here the stress is maximum because due to plastic behaviour of the material, area of cross section is very low.

E: Point of fracture: At this point ‘waisting occurs’ as shown in Fig. 2.5.

Cone

Waisting

Cap

Figure 2.5

If the material is loaded beyond the elastic limit and then load is removed, a permanent extension

remains, called permanent set.

Proof Stress: For engineering purposes it is desirable to know the stress to which a highly

ductile material such as aluminium can be loaded safely before a permanent extension takes place.

This stress is known as the proof stress or offset stress and is defined as the stress at which

a specified permanent extension has taken place in the tensile test. Proof stress is found from the

stress-strain curve as given in Fig. 2.6. The extension specified is usually 0.1, 0.2 or 0.5 per cent of

gauge length.

Stress

0.1%

Proof

stress

0

0.001

Strain

Figure 2.6

@seismicisolation

@seismicisolation

Stress and Strains

•

7

The proof stress here is found on the basis of 0.1 per cent strain.

Procedure: Draw a line parallel to the initial slope of the curve. The stress at the point where this

line cuts the curve is the 0.1% proo f stress. The 0.2 per cent proof stress is also found in the same

manner.

Note: Though we define Hooke’s law to be taken without elastic limit, but strictly speaking it is

applicable up to the point of proportionality B in Fig. 2.4.

Brittle Materials: Fig. 2.6 shows that the stress-strain graph for brittle materials such as cast iron.

The metal is almost elastic and up to fracture but does not obey Hooke’s law. A material such as

this which has little plasticity or ductility and does not neck down before fracture is termed ‘brittle’.

The modulus of elasticity for cast iron is not constant but depends on the portion of the curve from

which it is calculated.

Fracture

Stress

Strain

Figure 2.7 Cast iron in tension

The following table is very useful for mechanical properties:

Material

⎧

⎪

⎪

⎪

⎨

⎪

⎪

⎪

⎩

Copper annealed

Copper hard

Aluminium soft

Aluminium hard

Black mild steel

Bright mild steel

Structural steel

Cast iron

Spheroidal

Graphite

Cast iron (annealed)

Stainless steel

Percentage

elongation

Yield stress

MN/m2

0.1% proof stress

MN/m2

Ultimate tensile stress

MN/m2

60

4

35

5

25–26

14–17

20

−

−

−

−

−

60

320

30

140

220

400

90

150

220–250

−

430–500

−

230

−

–

280–340

600

−

60

@seismicisolation

@seismicisolation

8

•

Strength of Materials

stress

strain

Let F, L, A, dl be the force, length, area of cross section, and extension or contraction

Now E =

respectively,

then E =

F.L

A.dl

E XAMPLE 2.1: A bar of mild steel has an overall length of 2.1 m. The diameter up to 700 mm

length is 56 mm, the diameter of the remaining 1.4 m is 35 mm. Calculate the extension of the bar

due to a tensile load of 55 kN.

E = 200 GN/m2 .

S OLUTION :

∴

Remember 1 GN/m2 = 1 kN/mm2

E = 200 kN/mm2

Fl

F.l

We know E =

∴ dl =

Adl

A.E

∴

Therefore, for portion of 700 mm,

the extension dl1 =

55000 × 700 × 7 × 4

5

=

mm = 0.0178 mm

200000 × 22 × 56 × 56 64

Now dl2 for 1400 mm length of 35 mm dia,

55000 × 1400 × 7 × 4

= 0.4 mm

200000 × 22 × 35 × 35

Total extension = dl1 + dl2 = 0.0178 + 0.4 = 0.4178 mm

dl2 =

Compound bars: When two or more materials (members) are rigidly fixed together so that they

share the same load and extend or compress by same amount, the two members form compound

bar. Let us say that in Fig. 2.7 we have to find stress in each material and amount of compression.

P

Material A

of ES

l

Material B

of EB

Let the outer tube of material A has outside

dia as d1 and inside dia as d2 and inner tube of

material B has outside dia as d3 and inside dia

as d4 . Both ends are joined rigidly to make compound bar of length l.

Figure 2.8

@seismicisolation

@seismicisolation

Stress and Strains

•

9

Now the basic method is very simple as we know that load P is shared in some proportion by

materials is A and B. That means

σa Aa + σb Ab = P

(i)

Also, since the tubes are rigidly connected so they will have same strain as length l is common.

stress

σ

=

ε

strain

σa σb

ε=

=

Ea Eb

E=

∴

since strain ε is equal.

(ii)

Since the modulus of material A and B is known, so equations (i) and (ii) can be solved to find σa

and σb . Now for compression,

σa

σ

x

or b

strain = , pick any strain

l

Ea

Eb

σa

Then x =

× l = Compression

Ea

E XAMPLE 2.2: A column is made up of a steel tube, 70 mm inside diameter filled with concrete.

If the maximum stress in the concrete is not to exceed 21 N/mm2 and the column is to carry a

compressive load of 200 kN, calculate the minimum outside diameter of the tube. For concrete

E = 20 kN/mm2 and for steel, E = 200 kN/mm2 .

S OLUTION :

Let suffixes c and s denote the concrete and steel, respectively

Ac =

π × 702

= 3850 mm2

4

As =

π (d 2 − 702 )

mm2

4

where d in mm = outside diameter of the tube. Since the steel and concrete are of equal length of

the compression of both are the same, strains are equal, then working throughout in kN and mm, we

know, strain in concrete = strain in steel

σs σc

σ

=

because

=E

Es Ec

ε

Es

200

× 21 = 210 N/mm2

σs =

× σc =

Ec

20

Total load, P = σc Ac + σs As

P = σc Ac + σs As

∴

200000 = 21 × 3850 + 210 ×

@seismicisolation

@seismicisolation

π (d 2 − 702 )

4

10

•

Strength of Materials

Hence,

or

d 2 = 5630 mm2

d = 75 mm

E XAMPLE 2.3: A steel bar of 20 mm diameter and 400 mm long is placed concentrically inside

a gunmetal tube (Fig. 2.9). The tube has inside diameter 22 mm and thickness 4 mm. The length of

the tube exceeds the length of the steel bar by 0.12 mm. Rigid plates are placed on the compound

assembly. Find: a) the load which will just make tube and bar of same length and b) the stresses in

the steel and gunmetal when a load of 50 kN is applied. E for steel = 213 GN/m2 , E for gunmetal =

100 GN/m2 .

S OLUTION :

P

0.12 mm

Area of gunmetal tube, Ag =

π

(0.032 − 0.0222 )

4

= 0.000327 m2

Area of steel bar As =

π

(0.02)2 = 0.0003142 m2

4

Figure 2.9

a) For tube to compress 0.12 mm:

0.12

= 0.0003, Let σ1 be the stress in the tube

400

σ1

σ1

= 0.0003

= 0.0003,

Eg

100

strain =

∴

σ1 = 0.0003 × 100 = 0.03 GN/m2 = 30000 kN/m2

Hence, load = 30000 × 0.000327 = 9.81 kN

b) Load available to compress bar and tube as a compound bar is given by, let σ2 be the additional stress produced in the gunmetal tube due to this load and σs be the corresponding stress

in the steel bar, then

Load on compound bar = 50 − 9.81 = 40.19 kN

P = σ2 Ag + σs As

40.19 = σ2 × 0.000327 + σ3 × 0.0003142

@seismicisolation

@seismicisolation

(i)

Stress and Strains

•

11

Also

σ2 σs

= ,

Eg Es

σ2 =

∴

100

σs

2100

(ii)

From Eqns. (i) and (ii)

σ2 = 40, 600 kN/m2 = 40.6 MN/m2

σs = 85300 kN/m2 = 85.3 MN/m2

Final stress in gunmetal = σ1 + σ2

= 40600 + 30000 = 70, 600 kN/m2

= 70.6 MN/m2

Deformation of a Body Due to Self Weight

B

Let us consider a bar AB which is hanging freely under its

own weight (see Fig. 2.10)

Let w = specific weight of the bar material

Now consider a small section dx at a distance x from A.

Weight of the bar for a length = w× volume

= wAx (A is cross section of the bar)

dx

l

x

A

Figure 2.10

Now elongation of the elementry length dx due to weight of the bar for length x, (wAx)

=

pl

(wAx) dx wx.dx

=

=

A.E

A.E

E

l

Total elongation =

wxdx w

=

E

E

0

∴

elongation, dl =

x.dx

0

=

l

2 l

w x

E 2

0

wl 2

2E

Because total weight of bar, W = wA.l.

wAl.l

Now elongation dl can be written as

2AE

Wl

Hence, dl =

2AE

@seismicisolation

@seismicisolation

12

•

Strength of Materials

This result also proves that the extension due to own weight is half if same weight is applied at

the end (of course neglecting extension due to self weight).

E XAMPLE 2.4: A steel bar ABC 18 m long is having cross-sectional area 4 mm2 weighs 22.5 N

(Refer Fig. 2.11). If modulus of elasticity of wire is 210 GN/m2 , find the deflections at C and B.

Deflection at C due to self weight of wire AC = dlc

A

9m

dlc =

B

22.5 × 18000

Wl

=

= 0.241 mm

2AE

2 × 4 × 210000

Deflection at B:

Now deflection at B is due to two reasons: i) due to self

weight of AB and ii) due to weight of BC.

9m

C

dlB =

W /2 × l/2 W /2 × l/2

+

2AE

A.E

dlB =

W /2 × l/2

AE

Figure 2.11

∴

=

1

+1

2

22.5 × 9000

(1.5) = 0.181 mm

2 × 4 × 210000

Sometimes a machine member is a acted upon by a number of forces, some acting at outer edges

while some are acting inside the body. In such cases in order to find out the total extension or

contraction, the principle of superposition is applied. This has been very well made clear by the

following examples:

E XAMPLE 2.5: A steel bar ABC of 400 mm length and 20 mm diameter is subjected to a point

load as shown in Fig. 2.12. Determine the total change in the length of bar. Take E = 200 GPa.

A

B

60 kN

C

20 kN

200 mm

200 mm

Figure 2.12

@seismicisolation

@seismicisolation

40 kN

Stress and Strains

•

13

S OLUTION :

For simplification split it into two parts as under:

A

C

40 kN

40 kN

400 mm

A

B

C

20 kN

20 kN

δ=

200 mm

A=

Pl

AE

π

(20)2 = 314 mm2

4

δAC =

40 × 103 × 400

= 0.255 mm

314 × 200000

δAB =

20 × 103 × 200

= 0.064 mm

314 × 200000

δ = 0.255 + 0.064 = 0.319 mm Ans.

Total

E XAMPLE 2.6: A copper rod ABCD of 800 mm2 cross-sectional area and 7.5 m long is subjected

to forces as shown in Fig. 2.13. Find the total elongation of the bar. Take E = 100 GPa

3.5 m

2.5 m

1.5 m

B

A

C

30 kN

40 kN

D

50 kN

20 kN

3.5 m

1.5 m

2.5 m

S OLUTION :

Splitting into three figures as shown below:

A

D

40 kN

40 kN

7.5 m

C

B

20 kN

20 kN

1.5 m

B

D

10 kN

10 kN

4m

Figure 2.13

@seismicisolation

@seismicisolation

14

•

Strength of Materials

S OLUTION :

δ=

δAD =

pl

;

AE

40 × 103 × 7500

800 × 100 × 10000

= 3.75 mm

δBC =

20 × 103 × 1500

800 × 100 × 1000

= 0.375 mm

δBD =

10 × 103 × 4000

800 × 100 × 1000

= 0.50 mm

∴ Total extention = δAD + δBC + δBD = 3.75 + 0.375 + 0.50

= 4.6 mm Ans.

Extension of Tapering Rod (Circular):

l

p

d1

d2

x

dx

Figure 2.14

Let the dia. of elementary strip x from dia d1 be d .

∴

let

d = d1 −

d1 − d2

l

d1 − d2

=k

l

∴ d = d1 − kx

@seismicisolation

@seismicisolation

x

p

Stress and Strains

Hence, cross-sectional area at distance x from larger end A =

∴

π d 2 π

= (d1 − kx)2

4

4

σ =

Extension of elementary length

4P

Total extention of the bar = δ =

πE

∴

15

P

4P

=

A π (d1 − kx)2

σ

4P

Strain = ε =

=

E

π E(d1 − kx)2

Stress at this section,

∴

•

l

0

dx = ε dx =

4P dx

π E(d1 − kx)2

l

4P (dl − kx)−1

dx

=

(d1 − kx)2 π E −1 × −k o

=

l

4P

1

π Ek d1 − kx 0

=

4P

π Ek

=

4P

1

1

−

π E(d1 − d2 ) d1 − d1 + d2 d1

=

4Pl

π E(d1 − d2 )

=

d1 − d2

4Pl

·

π E(d1 − d2 ) d1 d2

δ=

1

1

−

d1 − kl d1

but k =

d1 − d2

l

1

1

−

d2 d1

4Pl

π Ed1 d2

If both the diameters are equal to d.

Then

δ=

4Pl

π Ed 2

E XAMPLE 2.7: A round steel rod of different cross-sections is loaded as shown in Fig. 2.15. Find

the maximum stress induced in the rod and its deformations. Take E = 210 GPa.

@seismicisolation

@seismicisolation

16

•

Strength of Materials

A

S OLUTION :

Let AB be part I, BC part II and CD part III

A

75 mm φ

0.9 m

π

(75)2 = 4415.6 mm2

4

π

A2 = (45)2 = 1589.6 mm2

4

π

A3 = (452 − 302 ) = 883.1 mm2

4

A1 =

B

B

120 kN

45 mm φ

2.2 m

60 kN

C

C

D

D

To simplify the force 120 kN acting at B − B.

0.9 m

30 mm φ

20 kN

Figure 2.15

80 kN

A

0.9 m

Tensile stress in Part I

A

80 kN

B

40 kN

B B

80 kN

C

σ1 =

B

2.2 m 20 kN

C

C

C

0.9 m

40 kN

D

D

∴

Compressive stress in Part II

PBC

40000

= 25.16 MPa

σ2 =

=

A2

1589.6

Tensile stress in Part III

PCD 20000

σ3 =

=

= 22.65 MPa

A3

883.1

20 kN

Max stress induced is in BC = 25.16 MPa.

PAB

80000

= 18.1 MPa

=

A1

4415.6

Ans

80 × 103 × 0.9 × 1000

δ1 =

P1 l1

=

A1 E

δ2 =

40 × 103 × 2.2 × 1000

P2 l2

=

= 0.264 mm (Contr.)

A2 E

1589.6 × 210000

δ3 =

P3 l3

20 × 103 × 0.9 × 1000

=

= 0.097 mm (Ext)

A3 E

883.1 × 210000

4415.6 × 210000

= 0.0776 mm (Ext)

Deformation of the rod = δ1 − δ2 + δ3 = 0.0776 − 0.264 + 0.097

= −0.0894 mm

@seismicisolation

@seismicisolation

Contraction

Ans

Stress and Strains

Extension of Tapered Rectangular Strip

x

P

a

P b

x

x

dx

t

Figure 2.16

Consider any section x − x distant x from the bigger end

Width of the section = t

∴

∴

Area of the section =

Extension of an elemental length dx =

∴

P

t(a − kx)

Pdx

t(a − kx)E

Total extension of the rod = δ =

P

tE

l

0

dx

a − kx

P 1

· − loge [(a − kx)]l0

tE k

P

= − [loge (a − kl) − loge a]

tE

a

P

=

tkE a − k

=−

But

a−b

l

P.l

a

δ=

log e

Et(a − b)

b

k=

@seismicisolation

@seismicisolation

•

17

18

•

Strength of Materials

E XAMPLE 2.8: A straight bar of steel rectangular in section is 3 m long and of thickness of 12 mm.

The width of rod varies uniformly from 110 mm or one end to 35 mm at the other end. If the rod is

subjected to an axial load (tensile) of 25 kN, find the extension of the rod. Take E = 200000 N/mm2 .

Extension of the rod, δ =

a

Pl

log e

Et(a − b)

b

P = 25000 N, l = 3000 mm, t = 12 mm

a = 110 mm, ab = 35 mm & E = 200000 N/mm2

∴

δ=

=

25000 × 3000

110

loge

5

35

2 × 10 × 12(110 − 35)

25000 × 3000

× 1.1452

2 × 105 × 12 × 75

= 0.477 mm

Ans

E XAMPLE 2.9: A rigid bar AB is attached to two vertical rods as shown in Fig. 2.17 is horizontal

before the load is applied. Determine the vertical movement of P if it is of magnitude 60 kN.

Steel

Aluminium

For aluminium

L=3m

A = 500 mm2

E = 75 GPa

C

A

3.5 m

2.5 m

60 kN

Figure 2.17

@seismicisolation

@seismicisolation

For steel

B L=4m

A = 300 mm2

E = 210 GPa

Stress and Strains

S OLUTION :

For Al, ∑ MB = 0, 6PAl = 2.5 × 60

2.5 × 60

= 25 kN = 25000 N

6

25000 × 3000

PL

=

= 2 mm

δAl =

A.E

500 × 75000

∴

PA =

For steel ∑ MA = 0 gives

Pst = 3.5 × 60

3.5 × 60

= 35 kN

6

35000 × 4 × 1000

=

= 2.33 mm

300 × 200000

Pst =

σST

A

C

B

2 mm

C1

B1

2.33 mm

Y

A1

C2

B2

Figure 2.18

Now from similar triangles A1 C1 C2 and A1 , B1 , B2

B1 B2

Y

=

;

A1C1 A1 B1

∴

Y

2.33 − 2

=

3.5

6

Y = 0.1925 mm

Now vertical movement of

P = CC2

= CC1 +Y

= 2 + 0.1925 = 2.1995 mm

@seismicisolation

@seismicisolation

Ans

•

19

20

•

Strength of Materials

Bar of Uniform Strength

As we have seen earlier that the stress due to self weight is not constant. It increases with the

increase of distance from the lower end.

We wish to find the shape of the bar of which the self weight is considered and is having uniform

stress on all sections when subjected to an axial P. Figure 2.19 shows such a bar of uniform stress

in which the area increases from the lower end to the upper end.

Area A1

σ(A+dA)

Area A1

A

dA

L

dx

x

A

σA+wAdx

A2

Area A2

P

(a)

(b)

Figure 2.19

Let L be the length of bar, having area A1 , and area A2 be cross-sectional areas of the bar at top

and bottom, respectively.

Let w be the specific weight of the bar material (1.2. weight per unit volume of the bar).

The forces acting on the elementary stripe are:

i) Weight of the strip acting downward and is equal to w× volume of strip.

ii) Force on section AB due to uniform stress is equal to σ × A. This is acting downward. A is

area of elementary stripe.

iii) Force on section CD due to uniform (σ ) is equal to σ (A + dA). This is acting upwards.

Total force acting upwards = Total force acting downwards

σ (A + dA) = σ × A + wA dx

σA + σ dA = σ A + wA.dx

or

dA w

= dx

A

σ

@seismicisolation

@seismicisolation

Stress and Strains

•

21

Integrating,

w x

x

σ 0

A

wx

ln

=

A2

σ

wx

A = A2 .e

σ

[ln A]AA2 =

Therefore, cross-sectional area at upper side

A1 = A2 e

wL

σ

In order to calculate the extension of the bar, consider extension of the elementary stripe. Let du be

the extension of small length dx.

du σ

=

dx E

σ

or du = dx

E

Then strain =

Integrating

σ

u=

E

L

dx

(because σ is constant in the bar)

0

∴

u=

σL

E

E XAMPLE 2.10: A vertical bar fixed at the upper end and of uniform strength carries an axial

tensile load of 800 kN. The bar is 22 m long and having weight per unit volume as 0.000075 N/mm3 .

If the area of the bar at the lower end is 450 mm2 , find the area of the bar at the upper end.

S OLUTION :

P = 800 kN = 800000 N

L = 22 m = 22000 mm

w = 0.000075 N/m3

A2 = 450 mm2

Let the area at upper end be A1

uniform stress on the bar;

σ=

P

800000

= 1777 N/mm2

=

A2

450

@seismicisolation

@seismicisolation

•

22

Strength of Materials

Using equation,

wL

σ

0.000075 × 22000

−4

1777.8

= 450e9.28×10

A1 = 450 e

A1 = A2 e

A1 = 450.4 mm2

Ans

E XAMPLE 2.11: A steel rod of 25 mm dia passes centrally through a copper tube of 30 mm inside

diameter and 40 mm outside diameter. Copper tube is 850 mm long and is closed by rigid washers of

negligible thickness, which are fastened by nut threaded on the rod as shown in Fig. 2.20. The nuts

are tightened till the load on the assembly is 20 kN. Calculate: i) the initial stresses on the copper

tube and steel rod and ii) also calculate increase in the stresses, when one nut is tightened by onequarter of a turn relative to the other. Take pitch of the thread as 1.5 mm. E for copper = 100 GPa,

E for steel = 100 GPa

S OLUTION :

Steel rod

Washer

on each side

Copper tube

Figure 2.20

Let σs = Stress in steel rod

σc = Stress in copper rod

i)

π

π

(Ds )2 = (25)2 = 156.25π mm2

4

4

π 2

π

Ac = (D − d 2 ) = (402 − 302 ) = 175π mm2

4

4

As =

Tensile rod on steel = Compressive load on copper tube

σs =

Ac

175π

× σc =

× σc

As

156.25π

@seismicisolation

@seismicisolation

Stress and Strains

∴

•

23

σs = 1.12 σc

P = 20000 N

20000 = σs As + σc Ac

20000 = 156.25π × 1.12 σc + σc × 175π

20000 = 350πσc

σc =

20000

= 18.2 MPa

350π

Ans.

σs = 1.12σc , σs = 1.12 × 18.2 = 20.38 MPa Ans.

σs1 = Increase in stress in steel rod

ii)

σc1 = Increase in the stress in the copper rod

Increase in the length of steel rod,

δ ls =

σs1 l 1.12σc1 × 850

= 4.76 × 10−3 σc1

=

Es

200, 000

Decrease in the length of copper rod

δ lc =

σc1 l σc1 × 850

=

= 8.5 × 10−3 σc1

Ec

100000

Since the nut is tightened by 1/4 of the turn then its axial advancement

1

× pitch

4

1

= × 1.5 = 0.375 mm

4

=

Since the axial advancement of the nut is equal to the decrease in the length of the tube plus

increase in the length of the rod, therefore

0.374 = 4.76 × 10−3 σc1 + 8.5 × 10−3 σc1 = 13.26 × 10−3 σc1

0.374 × 103

= 28.2 MPa (Compressive) Ans.

13.26

σs1 = 1.12 × σc1 = 1.12 × 28.2 = 31.584 MPa (Tensile)

σc1 =

Ans.

E XAMPLE 2.12: Three long parallel wires equal in length are supporting a rigid bar connected at

their bottoms as shown in Fig. 2.21. If the cross-sectional area of each wire is 100 mm2 , calculate

the stresses in each wire. Take EB = 100 GPa, ES = 200 GPa.

@seismicisolation

@seismicisolation

24

•

Strength of Materials

Steel

Brass

Brass

10 kN

Figure 2.21

S OLUTION :

σs × 100 + 100σb + 100σb

(i)

100σs + 200σb = 10000

σs + 2σb = 100 N/mm2

(ii)

σs

σb

=

3

200 × 10

100 × 103

∴

σs = 2σb

(iii)

substituting for σs in (ii)

2σb + 2σb = 100;

σb =

100

= 25 MPa Ans.

4

σs = 2 × 25 = 50 MPa Ans.

E XAMPLE 2.13: Two steel rods and one copper rod each of 20 mm diameter together support a

load of 50 kN as shown in Fig. 2.22. Find the stress in each rod. Take Es = 200 GPa, Eb = 100 GPa

50 kN

Copper

2m

Brass

Brass

Figure 2.22

@seismicisolation

@seismicisolation

1.5 m

Stress and Strains

•

25

π

(20)2 = 314 mm2

4

Total area of steel A s + 314 × 2 = 628 mm2

Ac = As =

σs As + σc Ac = 50000

628σs + 314σc = 50000

2σs + σc = 159.24

(i)

σs ls σc lc

=

;

Es

Ec

σs × 2000 σc × 1500

=

200000

100000

σs = 1.5σc

(ii)

Substituting for σs from Eqn. (ii) in Eqn. (i)

2 × 1.5σc + σc = 159.24

∴

σc = 39.81 MPa Ans.

σs = 1.5 × 39.81 = 59.7 MPa Ans.

E XAMPLE 2.14: A uniform bar ABCD has built-in ends A&D. It is subjected to two point loads

P1 and P2 equal to 80 kN and 40 kN at B and C as shown in Fig. 2.23. Find values of reactions at

A and D.

A

B

C

P1

500 mm

D

P2

1000 mm

500 mm

S OLUTION :

A

B

RA

RA

500 mm

RB

RB

1000 mm

RC

RC

500 mm

Figure 2.23

@seismicisolation

@seismicisolation

26

•

Strength of Materials

RA + RB = P1 = 80 kN

(i)

RC − RB = P2 = 40 kN

(ii)

Adding Eqns. (i) and (ii)

RA + RC = 120 kN

RA × 500 RB × 1000 RC × 500

−

−

A×E

A×E

A×E

δ = RA − 2RB − RC = 0

0=δ =

substituting,

(120 − RC ) − 2(RC − 40) − RC = 0

200

= 50 kN Ans.

4

RA + RC = 120;

solving

∴

RC =

RA = 120 − 50 = 70 kN

Ans.

Note: RA and RC are reactions at A and D respectively.

Exercise

2.1 A bar of mild steel has an overall length of 2100 mm. The diameter of 700 mm length is 56

mm. The diameter of the remaining 1400 mm is 35 mm. Calculate the extension of the bar

due to a tensile load of 55 kN. E = 200 GN/m2 .

[Ans Extension = 0.478 mm]

2.2 The block of weight W hangs from the point A, the bars AB and AC are pinned to the support

at B and C. The cross-sectional area for AB is 800 mm2 and for AC is 400 mm2 . Neglecting

the weight of the bars, determine the maximum safe value of W , if the stress in AB is limited

to 110 MPa and in AC to 120 MPa (Figure 2.24).

B

C

40°

A

60°

W

[Ans

Figure 2.24

81.7 kN]

2.3 A rectangular bar of 2 m length and 12.5 mm thickness uniformly tapers from 100 mm at

one end to 20 mm at the other. If the bar is subjected to a tensile force of 25 kN, find its

deformation. Take E as 200 GPa.

[Ans 0.4 mm]

@seismicisolation

@seismicisolation

Stress and Strains

•

27

2.4 A brass bar having cross-sectional area of 900 mm2 is subjected to axial forces as shown in

Fig. 2.25 in which AB = 0.6 m, BC = 0.8 m and CD = 1.0 m.

A

40 kN

B

C

D

50 kN

20 kN

10 kN

Figure 2.25

Find the total elongation of the bar. Take E = 100 GPa.

[Ans. 0.11mm]

2.5 A 1200 mm long composite rod consists of a steel tube of 50 mm external diameter and

40 mm internal diameter. A copper rod of 30 mm dia is placed coaxially into the steel

tube. The assembly is held between to rigid plates and is subjected to an axial compressive

force of 200 kN. Find the stress induced in each material and the contraction produced. Take

Es = 200 GPa, Ec = 100 GPa.

[Ans σs = 188.63 MPa,

σc = 94.31 MPa

Contraction = 1.132 mm]

2.6 A 10 m long and 10 mm thick flat steel bar tapers from 60 mm at one end to 20 mm at the

other. Determine the change in length of the bar when a tensile force P = 12 kN is acting

along its axis. E = 200 GN/m2

[Ans 1.648 mm]

2.7 Two elastic rods, A and B, of equal length hang vertically 0.6 m apart and support a rigid bar

horizontally. The bar remains horizontal when a vertical load of 60 kN is applied to the bar

0.2 m from A. If the stress in A is 100 MN/m2 , find the stress in B and the cross-sectional

areas of the two rods. EA = 200 GN/m2 , EB = 130 GN/m2 .

[Ans 65 MN/m2 , 400 mm2 , 307.5 mm2 ]

2.8 If the modulus of elasticity of steel is twice that of the modulus of elasticity of brass, calculate

the outside diameter of a brass tube that should sheath a steel bar of diameter 50 mm so that

the steel and brass equally share an axial compressive load.

[Ans 86.6 mm]

2.9 A tubular steel tie-rod has an outside diameter of 50 mm, an inside diameter of 40 mm, and is

subjected to a tensile load of 88000 N. Taking E = 200 GN/m2 , calculate the extension over

a length of 2.7 m. If corrosion now reduces the effectual outside diameter of the tube to 49

mm and increases the effectual inside diameter to 41 mm, calculate the increase in extension,

over the length of 2.7 m, due to corrosion.

[Ans 1.68 mm, 0.42 mm]

@seismicisolation

@seismicisolation

28

•

Strength of Materials

2.10 Figure 2.26 shows a rigid bar ABC hinged at A and suspended at two points B and C by two

bars BD and CE, made of aluminium and steel, respectively. The bar carries a load of 20 kN

midway between B and C. The cross-sectional area of aluminium bar BD is 3 mm2 and that

of steel bar CE is 2 mm2 . Determine the loads taken by the two bars BD and CE.

D

E

B

C

1000 mm

500 mm

1000 mm

1000 mm

20 kN

[Ans

Figure 2.26

@seismicisolation

@seismicisolation

Pa = 3.481 kN, Ps = 13.26 kN]

C HAPTER

3

TEMPERATURE STRESS AND STRAIN

When the temperature of a body is raised (specially, metallic bodies), the dimensions of the body

tend to increase, if cooled the dimensions of the bodies tend to decrease. If we prevent this increase

or decrease in dimensions due to rise or fall in temperature, the thermal stresses are bound to occur.

Let a steel rod having linear coefficient of expansion (α ), shown in Fig. 3.1 be clamped or fixed

at both ends. Now if its temperature is raised by t ◦ c

L

Figure 3.1

Then prevented expansion = α l t

Now since this expansion has been prevented so thermal stress of compressive nature will be

induced.

α lt

strain =

= αt

l

stress

E=

, so stress will be E α t.

strain

Remember that thermal strain is =

Prevented expansion or contraction

Original length

E XAMPLE 3.1: A steel spacer of length 400 mm at 20◦ C has its temperature increased to 80◦ C. If

the spacer has a diameter of 56 mm, calculate the compressive load in the spacer in newtons, if it is

assumed that:

a) the expansion is completely prevented

b) the spacer has a length of 400.1 mm at 80◦ C,

Take E = 200 GN/m2 , α = 11 × 10−6 /C◦ ,

a) For completely restricted expansion:

E = 200 GN/m2 = 200000 N/mm2 , t = 80 − 20 = 60◦ C

@seismicisolation

@seismicisolation

30

•

Strength of Materials

Temperature stress = E α t

= 200000 × 11 × 10−6 × 60

= 132 N/mm2

Load = stress × area

π

= 132 × (56)2 = 32495.2 N

4

b) For partially restricted expansion:

Ans.

Natural expansion = l α t = 400 × 11 × 10−6 × 60

= 0.264 mm

Permitted expansion = 400.1 − 400 = 0.1 mm

Compression effect = 0.264 − 0.1 = 0.164 mm

x 0.164

= 4.1 × 10−4

Compressive strain = =

l

400

= 0.00041 mm

stress

E=

strain

∴ stress = E × strain

= 200000 × 0.00041 = 82 N/mm2

Load = stress × area

π

= 82 × (56)2 = 201864 N Ans.

4

It is obvious from the above answers that the stress is more when expansion is completly

prevented.

Composite Tube or Bar

Imagine we have a copper tube fitted with a steel rod inside. And this assembly is brazed at both the

ends. Now if its temperature is raised by t ◦ C we will analyse what happens:

xc

αslt

A

xs

A

αclt

l

Copper

Figure 3.2

@seismicisolation

@seismicisolation

Steel

Temperature Stress and Strain

•

31

Let αs and αc be the coefficient of linear expansion for steel and copper, respectively. When

we heat, steel will expand (if allowed) less than copper as shown in Fig. 3.2. Since copper expands

more than steel and both materials are bound together so copper will pull steel upward and steel

will push the copper downward. Let line A − A be where both settle eventually

xc + xs = αc lt − αs lt

xc xs

+ = αc t − αs t = (αc − αs ) t

l

l

εc + εs = (αc − αt )

(i)

Also push on copper = pull on steel

σc Ac = σs As

σc = Thermal stress in copper

σs = Thermal stress in steel

As = Cross-sectional area of steel

Ac = Cross-sectional area of copper

(ii)

Solving equations (i) and (ii) σs and σc can be found out.

E XAMPLE 3.2: A copper flat measuring 60 mm × 40 mm is brazed to another steel flat 60 mm ×

50 mm as shown in Fig. 3.3. If this composite flat is heated through 140◦ C, determine:

i) the stress produced in each of the bar

ii) shear force which tends to rupture the brazing

iii) shear force.

Take

αc = 18.5 × 10−6 /◦ C

αs = 12 × 106 /◦ C

Ec = 110 GN/m2

Es = 220 GN/m2

length of each flat = 450 mm

40 mm

Copper

50 mm

Steel

450 mm

Figure 3.3

S OLUTION :

i) Stress produced in each of the bar.

@seismicisolation

@seismicisolation

•

32

Strength of Materials

We shall solve this problem by the method derived from the last article.

εs + εc = (αc − αs ) t

αs

αc

+

= (13.5 − 12) + 10−6 × 140

220000 110000

αs

αc

+

= 910 × 10−6

220000 110000

Pull on steel = Push on copper

(i)

αs × As = αc Ac

αs × 60 × 50 = αc 60 × 40

or

αs = 0.8αc

(ii)

Substituting for σs in Eqn. (i)

αc

0.8αc

+

= 910 × 10−6

220000 110000

Multiplying the whole equation by 220000, we get

∴ 2.8σc = 200.2

0.8σc + 2σc = 200.2;

or σc = 71.5 MPa Ans.

σc = 0.8σc = 0.8 × 71.5 = 57.2 MPa

Ans.

ii) Shear force:

Shear force = σs As = σc Ac = 71.5 × 60 × 40

= 171600 N = 171.6 kN Ans.

iii)

171600

Shear force

=

Shear area

450 × 60

= 6.36 MN/m2

Shear stress =

Thermal Stresses in a Bar of Tapering Section

Consider a tapered round bar whose temperature is raised by Δt.

A

B

d2

d1

A

L

Figure 3.4

@seismicisolation

@seismicisolation

Temperature Stress and Strain

•

33

As the temperature increases the bar will expand. If the tapered bar is fixed at both ends, the

stress will develop in tapered bar.

Since we know δ L = L α Δ t

(i)

and also

δL =

4 PL

π Ed1 d2

(ii)

where P is the load required to bring the deformed bar to the original.

From Eqns. (i) and (ii)

π E d1 d2 α Δt

4 PL

∴ P=

π Ed1 d2

4

P

π Ed1 d2 α Δt

=

Maximum stress, σ t = π

π

d22

4 × d22

4

4

E. α . Δt.d1

d1

(σt )max =

= E α Δt

d2

d2

L α Δt =

∴

∴

When bar is of uniform cross section d1 = d2

σt = E α Δt

E XAMPLE 3.3: A steel rod of 320 mm2 cross-sectional area and a coaxial copper tube of 800 mm2

cross-sectional area are rigidly bounded together at their ends. An axial compressive load of 40 kN

is applied to the composite bar, and the temperature is then raised by 100◦ C.

Determine the stresses in the copper and steel after heating as stated above. The modulii of elasticity for steel and copper are 200 GN/m2 and 100 GN/m2 and the coefficients of linear expansion

are 12 × 10−6 /◦ C and 16 × 10−6 /◦ C, respectively.

S OLUTION :

as = 320 mm2

40 kN

ac = 800 mm2

t = 100◦ C

Steel

Es = 200 GN/m2

Copper

Ec = 100 GN/m2

αs = 12 × 10−6 /◦ C

Figure 3.5

αc = 16 × 10−6 /◦ C

@seismicisolation

@seismicisolation

34

•

Strength of Materials

S OLUTION :

Due to 40 kN load, let the stresses developed be σs and σc .

σs as + σc ac = 40000

320 σs + 800 σc = 40000

σs σc

=

Es

Ec

∴

(i)

σs

σ

= c

200 100

σs = 2σc

(ii)

Substituting Eqn. (i) from Eqn. (ii)

2 × 320σc + 800σc = 40000

∴ σc = 27.78 MPa(Compressive)

Hence,

σs = 27.78 × 2 = 55.56 N/mm2 (Compressive)

Now due to temperature:

εs + εc = (αc − αs )t

Let σs & σc be the stresses due to thermal effect.

σs σc

+

= (16 − 12)100 × 10−6

Es

Ec

σs

σc

+

= 400 × 10−6

200000 100000

σs

+ σc = 400 × 10−6

2

Also 320σs = 800 σc

∴

σs + 2σc = 80

(iii)

∴

σs = 2.5σc

(iv)

Substituting Eqn. (iv) in Eqn. (iii),

2.5σc + 2σc = 80

∴

σc = 17.78 N/mm2

σs = 2.5σc = 2.5 × 17.78 = 44.45 N/m2

σc =

44.45

= 17.78 N/mm2

2.5

(Compressive)

(Tensile)

(Compressive)

Net stresses:

σs = −55.56 + 44.45 = 11.11 N/mm2

(Compressive)

Ans.

σc = −17.78 − 27.78 = 45.56 N/mm2

(Compressive)

Ans.

@seismicisolation

@seismicisolation

Temperature Stress and Strain

•

35

E XAMPLE 3.4: A composite bar shown in Fig 3.6 is rigidly attached to the end supports. The

temperature of the composite system is raised by 65◦ C. Find out the stresses in three portions of the

bar: a) if the supports are rigid and b) the supports yield by 0.5 mm.

Es = 200 GPa;

Ea = 90 GPa;

αs = 12 × 10−6 /◦ C;

40 mm dia

Ec = 100 GPa

αa = 20 × 10−6 /◦ C;

90 mm dia

Copper

Aluminium

300 mm

450 mm

αc = 16 × 10−6 /◦ C

40 mm dia

Steel

300 mm

Figure 3.6

S OLUTION :

Free elongation of copper section = αctlc

= 16 × 10−6 × 65 × 300 = 0.312 mm

Free elongation of aluminium = 20 × 10−6 × 65 × 450 = 0.585 mm

Free elongation of steel = 12 × 10−6 × 65 × 300 = 0.234 mm

Total free extension of composite bar

= 0.312 + 0.585 + 0.234 = 1.131 mm

(i)

Because the extension is prevented by the rigid supports, therefore compressive stresses will set up

in the bar.

Let F be the compressive force in the bar in N.

∴ Stress are

F

4F

=

= 7.962 × 10−4 F N/mm2

Ac π (40)2

P

4F

σa =

=

= 1.573 × 10−4 F N/mm2

Aa π (90)2

P

4F

σs =

=

= 7.962 × 10−4 F N/mm2

As π (40)2

σc =

@seismicisolation

@seismicisolation

36

•

Strength of Materials

Strains are:

σc 7.962 × 10−4 F

=

= 7.962 × 10−9 F

Ec

100000

σa 1.573 × 10−4 F

= 1.75 × 10−9 F

εa =

=

Ea

90000

σs 7.962 × 10−4 F

εs =

=

= 3.981 × 10−9 F

Es

200000

εc =

Extensions

δ lc = εc × lc = 7.962 × 10−9 F × 300 = 2.389 × 10−6 F

δ la = 1.75 × 10−9 F × 450 = 0.7875 × 10−6 F

δ ls = 3.981 × 10−9 F × 300 = 1.194 × 10−6 F

Total extension = (2.389 × 10−6 + 0.7875 × 10−6 + 1.194 × 10−6 )F

= 4.3705 × 10−6 F

Also, δ lc + δ la + δ ls = 1.131 mm from Eqn. (i)

∴ 4.3705 × 10−6 F = 1.131

∴ F = 258780 N = 258 kN

4 × 258000

= 205.4 N/mm2 = 205.4 MPa

π × 1600

4 × 258000

= 40.6 N/mm2 = 40.6 MPa

σa =

π × 8100

4 × 258000

σs =

= 205.4 MPa

π × 1600

σc =

b) When the supports yield by 0.5 mm, then

δ la + δ lc + δ ls = 1.131 − 0.5 = 0.631 mm

43.05 × 10−6 F = 0.631

F = 144.4 kN

σs = σc = 7.962 × 10−4 × 144400 = 115 N/mm2 = 115 MPa

σa = 1.573 × 10−4 × 144400 = 22.7 N/mm2 = 22.7 MPa

E XAMPLE 3.5: A compound bar is made up by connecting a steel member and a copper member

rigidly fixed at their ends as shown in Fig. 3.7.

@seismicisolation

@seismicisolation

Temperature Stress and Strain

1 mm dia

copper bar

37

Es = 200 GN/m2 ,

15 dia

αs = 12 × 10−6 /◦ C

20 dia

Steel

200 mm

•

Ec = 100 GN/m2 ,

200 mm

αc = 16 × 10−6 /◦ C

Figure 3.7

If the composite bar’s temperature is raised by 70◦ C, determine the stresses in copper end two

areas of steel.

S OLUTION :

Let σs be the stress in 15 mm dia of steel & σs is the stress in 20 mm dia of steel σc is the

stress in copper bar of dia 15 mm. Total tension in the steel bar is the same as the compression in

the copper bar.

π

π

π

σc × (15)2 = σs × (15)2 = σs × (20)2

4

4

4

225σc = 225σs = 400σs

∴ σc = σs = 1.78σs

If l in the actual length of the compound bar due to rise in temperature, then

σc

×l

Ec

σs

σ

× 200 + s × 200

For steel rod l − l(1 + αst) =

Es

Es

l(1 + αct) − l =

For copper rod

Adding the two eqs.,

σc

σs

σ

× l + × 200 + s × 200

Ec

Es

Es

1.786s

1.786s

× 400 +

× 200

l(αct − αst) =

100000

200000

σs

+

× 200

200000

400 × 10−6 (16 × 70 − 12 × 70) = 7.12 × 10−3 σs + 1.78 × 10−3 σs

l(1 + αct) − l(1 + αst) =

+ σs × 1 × 10−3

0.112 = 9.9σs × 10−3

∴

∴

σs = 11.31 N/mm2 = 11.31 MPa

σc = σs = 1.78 × σs

σc = σs = 1.78 × 11.31 = 20.1318 MPa

(Compressive in copper & tensile in steel)

@seismicisolation

@seismicisolation

(i)

(ii)

38

•

Strength of Materials

Exercise

3.1 A steel bar of 100 mm diameter is rigidly clamped at both ends so that all axial extension

is prevented. A hole of 40 mm diameter is drilled out at one third of the length. If the bar is

raised in temperature by 30◦ C above that of the clamps, calculate the maximum axial stress

in the bar. E = 210 GN/m2 , α = 0.000012/◦ C

[Ans 84.7 MN/m2 ]

3.2 Two steel bars are connected together so as to form a rod of total length 625 mm. One of

mild steel is 225 mm long and 25 mm diameter. If the bar is heated to 50◦ C above 50◦ C room

temperature calculate the stress in each part of the rod. For stainless steel, E = 175 GN/m2 ,

α = 18 × 10−6 /◦ C. For mild steel E = 200 GN/m2 , α = 12 × 10−6 /◦ C

[Ans Mild steel, 44.7 MN/m2 , stainless steel 195 MN/m2 ]

3.3 A steel bar of 50 mm diameter is placed between two stops, with an end clearance of 0.05

mm. The temperature of the bar is raised by 60◦ C and the stops are found to have been forced

apart a distance of 0.05 mm. Calculate the maximum stress in the bar if its total length is 250

mm and there is a hole of 25 mm diameter drilled along the length for a distance of 100 mm.

E = 200 kN/m2 , α = 12 × 10−6 /◦ C.

[Ans 75.3 MN/m2 ]

3.4 A compound tube is formed by a stainless steel outer tube of 50 mm outside diameter and

47 mm inside diameter, together with a concentric mild steel inner tube of wall thickness 6

mm. The radial clearance between inner and outer tubes is 2 mm. The two tubes are welded

together at their ends, the compound tube being free to expand when heated. Calculate the

stress in each tube due to a rise of 50◦ C. For stainless, E = 175 kN/m2 , α = 18 × 10−6 /◦ C.

For mild steel, E = 200 kN/m2 , α = 12 × 10−6 /◦ C.

[Ans Mild steel, 13.4 MN/m2 tensile; stainless steel, 41 MN/m2 comp]

3.5 A stainless steel bar of 25 mm diameter is placed inside and concentric with a mild steel tube

of 30 mm inside diameter and 50 mm outside diameter. The tube and bar are welded together

at the ends but are otherwise free to expand. Calculate the stress in each part of the compound

bar so formed due to a temperature rise of 25◦ C. If the length of the compound bar is 250 mm

what is the extension? For stainless steel E = 170 kN/m2 , α = 18 × 10−6 /◦ C. For mild

steel E = 196 kN/m2 , α = 12 × 10−6 /◦ C.

[Ans Steel bar, −19.05 MN/m2 , tube 7.42 MN/m2 ; 0.0845 mm]

3.6 A compound bar is made up of steel plate 50 mm wide, 10 mm thick clad on both sides

by copper plates each 50 mm wide, 5 mm thick. The plates are bonded together along their

length and at room temperature the original length is 1.2 m. Find the load taken by each plate

and the increase in length when the temperature rises to 100◦ C. For steel, E = 200 kN/m2 ,

α = 12 × 10−6 /◦ C. For copper E = 110 kN/m2 , α = 18 × 10−8 /◦ C.

[Ans Steel +21.28 kN, copper −10.64 kN; 1.41 mm]

@seismicisolation

@seismicisolation

Temperature Stress and Strain

•

39

3.7 In the arrangement shown in Fig 3.8, the steel bar is 30 mm in diameter and the bronze

bar 50 mm in diameter. The bars are of equal length and just fit between the end fixings at

room temperature. The distance between the fixings cannot change. Calculate the stresses

produced in the steel and bronze by a temperature rise of 100◦ C. For steel, E = 200 GN/m2 ,

α = 12 × 10−6 /◦ C. For bronze E = 110 kN/m2 , α = 18 × 10−6 /◦ C.

Bronze

Steel

Figure 3.8

[Ans

−363 MN2 /m2 , bronze, −130.5 MN/m2 , steel]

@seismicisolation

@seismicisolation

C HAPTER

4

ELASTIC CONSTANTS

Whenever a tensile load is applied axially to a bar, there will be a longitudinal or linear strain. But,

naturally there will be compressive strain on lateral side (sometimes called secondary strain). The

ratio of lateral strain to longitudinal strain is known as Poisson’s ratio.

or, Poisson’s ratio =

Lateral strain

= Constant

Linear strain

This is denoted by Greek letter μ (mu).

Material

Poisson’s ratio (μ )

Steel

Cast iron

Copper

Brass

Aluminium

Concrete

Rubber

Stainless steel

Wrought iron

Bronze

0.25 to 0.33

0.23 to 0.27

0.31 to 0.34

0.32 to 0.42

0.32 to 0.38

0.08 to 0.18

0.45 to 0.50

0.305

0.278

0.350

E XAMPLE 4.1: A metal bar 60 mm × 60 mm in section is subjected to an axial compressive load

of 600 kN. If the contraction of a 200 mm gauge length was found to be 0.65 mm and the increase in

thickness as 0.05 mm, find the values of Young’s modulus and Poisson’s ratio for the bar material.

P.L

600000 × 200

=

= 0.65

A.E

60 × 60 × E

600000 × 200

= 51282 N/mm2

∴ E=

0.65 × 60 × 60

= 51.3 GN/m2 approx. Ans.

0.65

Linear strain =

= 0.00325

200

0.05

= 0.000833

Lateral strain =

60

δl =

@seismicisolation

@seismicisolation

Elastic Constants

•

41

lateral 0.000833

=

= 0.256

linear

0.00325

∴ μ = 0.256 Ans.

Change in volume

Volumetric strain =

Original volume

δv

εv =

v

μ = Poisson’s ratio =

σy

σz

σx

σy

σx

σz

Figure 4.1

Referring to Fig. 4.1.

new length of side x = x(1 + εx )

new length of side y = y(1 + εy )

and new length of side z = z(1 + εz )

∴ new volume = xyz (1 + εx )(1 + εy )(1 + εz )

= xyz (1 + εx + εy + εz )

(Neglecting products of strains)

xyz (1 + εx + εy + εz ) − xyz

∴ εv =

xyz

i.e., volumetric strain = sum of perpendicular strains

∴

εv = εx + εy + εz

Alternately, v = xyz

∴

log v = log x + log y + log z

Differentiating w.r.t. x

∴

1 dv 1 1 dy 1 dz

·

= + ·

+ ·

v dx x y dx z dx

Multiplying Eqn. (i) by dx

∴

dv dx dy dz

=

+

+

v

x

y

z

@seismicisolation

@seismicisolation

(i)

42

•

Strength of Materials

εv = εx + εy + εz

or

E XAMPLE 4.2: A rectangular bar 600 m long and 120 mm × 60 mm in cross section is subjected

to forces as shown in Fig. 4.2. What is the change in the volume of bar? Take E = 200 GPa, μ = 0.3.

320 kN

180 N

150 kN

150 kN

60 mm

180 kN

320 kN

120 mm

600 mm

Figure 4.2

Original volume = l × b × t = 600 × 120 × 60 = 4320000 mm3

Stress in x-x direction

σx =

Px

150000

= 20.83 N/mm2 (Tension)

=

Ax 120 × 60

σy =

180000

= 5 N/mm2 (Tension)

600 × 60

σz =

320000

= 4.44 N/mm2 (Compressive)

600 × 120

Now resultant strain in each direction

σx μσy μσz

20.83

0.25 × 5 0.25 × 4.44

20.69

−

+

=

−

+

=

E

E

E

200000 200000

200000

200000

σy μσx μσz

5

0.25 × 20.83 0.25 × 4.44

0.9025

εy = + −

+

=

−

+

=

E

E

E

200000

200000

200000

200000

4.44

0.25 × 20.83 0.25 × 5

10.9

σz μσx μσy

−

=−

−

−

=

εz = + −

E

E

E

200000

200000

200000

200000

20.69

0.9025

10.9

δv

=

+

−

Volumetric strain =

v

200000 200000 200000

10.69

= 5.345 × 10−5

=

200000

εx = +

∴

δv = v × 5.345 × 10−5 = 4320000 × 0.5345 × 10−5

= 2309.04 mm3 .

Ans.

@seismicisolation

@seismicisolation

Elastic Constants

•

43

Bulk Modulus: When a body is subjected to three mutually perpendicular stresses of equal intensity, the ratio of direct stress to the corresponding volumetric strain is known as bulk modulus.

It is denoted by K.

Direct stress

σ

K=

=

δv

Volumetric strain

v

Direct stress occurs, for example, as hydrostatic pressure.

Principle of shear stress

If we apply shear stress in clockwise direction,

then automatically shear stress in anticlockwise

will set as complementary.

τ′

τ

τ

τ′

Figure 4.3

Relation between Modulus of Elasticity and Modulus of Rigidity

Modulus of rigidity =

Shear stress

Shear strain

τ'

Consider a cube

τ

AD2 + AD2 = BD2

∴ 2AD2 = BD2

√

BD = AD 2

τ

D

D1

C1 C

φ

τ'

Before

distortion

P

D2

φ

A

After

distortion

B

Figure 4.4

Strain of BD =

BD1 − BD D1 D2 DD1 cos 45 φ

√

=

=

=

BD

BD

2

AD 2

Linear strain of the diagonal BD,

φ

τ

=

2

2C

τ = shear stress

C = modulus of rigidity

=

(i)

We know that the effect of this stress will cause tensile stress on the diagonal BD and compressive

stress on the diagonal AC. Therefore, tensile strain on the diagonal BD due to tensile stress on the

diagonal BD is given by

τ

BD =

(ii)

E

@seismicisolation

@seismicisolation

44

•

Strength of Materials

And the tensile strain on the diagonal BD due to compressive stress on the

diagonal AC = μ ×

Z

E

(iii)

The combined effect of the above two stresses on the

diagonal BD =

τ

τ

τ

+ μ = (1 + μ )

E

E

E

(iv)

Equating Eqns. (i) & (iv),

τ

τ

= (1 + μ ) or

2C E

E

2C

=

1

1+μ

or

1

1

= (1 + μ )

2C E

C=

E

2(1 + μ )

C = Shear modulus or modulus of rigidity

Relation between Modulus of Elasticity and Bulk Modulus

Let us take a cube of each side l and subject it to direct stress (hydrostatic pressure) on the faces of

the cube.

Initial volume of cube v = l 3

By differentiation,

∴

∴

dv = 3l 2 dL

dv

Volumetric strain, εv =

v

3l 2 dl

l2

dl

= 3εl

εv = 3

l

εv =

∴

Now linear strain

dl

of any side of cube is,

l

dl

σ

σ

σ

= −μ −μ

l

E

E

E

σ

εL = (1 − 2μ )

E

3σ

εv =

(1 − 2μ )

E

σ

K=

εv

εl =

∴

∴

@seismicisolation

@seismicisolation

(i)

(ii)

Elastic Constants

∴

εv =

•

45

σ

K

Substituting in Eqn. (i)

∴

σ

3σ

=

(1 − 2μ )

K

E

∴

E = 3K(1 − 2μ )

Relation between E, C & K

Since C =

E

; E = 2C(1 + μ )

2(1 + μ )

∴

E

−1 = μ

2C

(i)

Also E = 3K(1 − 2μ )

E

− 1 = −2μ

3K

or

μ=

1

E

−

2 6K

(ii)

Equating Eqns. (i) & (ii)

1

E

E

−1 = −

2C

2 6K

1

1

3

1

+

= +1 =

E

2C 6K

2

2

1

1

E

+

=3

C 3K

E=

9CK

C + 3K

Exercise

4.1 A bar of 50 mm diameter and 300 mm length is made of a material having E = 200 GPa and

μ = 0.3, calculate its modulus of rigidity. Also determine the change in the volume of the bar

when subjected to a hydrostatic stress of 100 MPa.

[Ans C = 76.92 GPa, 353 mm3 ]

4.2 A square piece of steel 150 mm long by 25 mm square is subjected to a compressive load

of 100 kN. Find the change in length of the piece if all lateral strain is presented by the

application of uniform lateral external pressure of suitable intensity. E = 200 GPa, μ = 0.25.

[Ans 0.1 mm]

4.3 The gauge length marked on a steel rod of diameter of 10 mm is 60 mm. When this rod is

subjected to tension test, the gauge length increases to 80 mm. The rod yields at 40 kN and

maximum load applied is 80 kN after which the rod breaks at 45 kN. Determine: a) percentage

elongation, b) yield strength, c) ultimate strength and d) breaking strength.

[Ans 33.3%, 509.3 MPa, 1018.6 MPa, 572.9 MPa]

@seismicisolation

@seismicisolation

46

•

Strength of Materials

4.4 A bar of cross-section 10 × 10 mm is subjected to an axial pull of 8000 N. The lateral dimension of the bar is found to be changed to 9.9985 mm × 9.9985 mm. If the modulus of rigidity

of the material is 0.8 × 105 N/mm2 , determine the Poisson’s ratio and modulus of elasticity.

[Ans 0.43, 229 GPa]

4.5 A 50 mm diameter steel bar is subjected to a tensile load of 100 kN. The extension over

its 300 mm length was found to be 0.08 mm and change of its diameter was 0.0035 mm.

Determine the modulus of rigidity of bar.

[Ans 75.6 GPa]