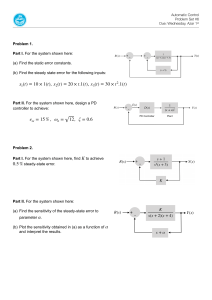

PID Control Pangun Park Chungnam National University Information Communications Engineering 1 Control Systems § Microcomputers are widely employed in control systems: Ø automotive ABS, ignition and fuel systems Ø household appliances Ø smart weapons Ø industrial robots Ø pacemakers Pangun Park (CNU) 2 Contents § Overview Control Systems § PID Control § PID Parameter Tuning § PID Implementation Pangun Park (CNU) 3 Control = Sensing + Computation + Actuation Feedback “Loop” Control = Sensing +InComputation + Actuation Actuate Sense Gas Pedal Vehicle Speed Compute Control “Law” § Control objectives Goals • within Performance: systemconditions). responds rapidly to changes (accelerate to 6 m/sec) operating • “normal” Robustness: system tolerates perturbations in dynamics (mass, drag, etc) • Robustness/Regulation: Ø system tolerates perturbations in dynamics (mass, Stability: systemmake maintains operating (hold steady speed) Ø Stabilization: sure desired the system does point not “blow up” (i.e., it stays drag, etc), Maintain a desired operating point in spite of disturbances. Ø Performance/Tracking: system responds rapidly to changes (accelerate to 6 Richard M. Murray, Caltech CDS m/sec), follow a reference trajectory that changes over time, as closely as possible. CDS 101/110, 29 Sep 08 Pangun Park (CNU) 8 4 Control Systems : Performance metrics Dynamic Behavior (and Stability) § Steady-state controller error Ø Average value of the difference between desired and actual performance Actuate § Transient Gas response Pedal Ø how quickly the system responds to change § Stability Sense underdamped Vehicle Speed tresponse Ø system output changes smoothly – without oscillation or unlimited excursions Ø Check if closed loop response is stable Compute Control “Law” Dynamic Behavior (and Stability) Goal #1: Stability Check if closed loop response is stable • Actuate Sense Gas Pedal Vehicle Speed Goal #2: Performance Look at how the closed loop system behaves, in a dynamic context • Compute Control “Law” Goal #3: Robustness (later) Goal #1: Stability Parkresponse CDS 101/110, 6(CNU) Oct 08 is stable Check if Pangun closed loop • Richard M. Murray, Caltech CDS control law control law system input Response depends on choice of control (all are stable) 5 2 Example : Speed Control Example #2: Speed Control Example #2: Speed Control “Bob” reference “Bob” reference ∑ ∑ disturbance disturbance Control Control Law ∑ Law ∑ Process -1Process Stability/performance mv̇ = av + Feng + Fhill Feng = kp (vdes v) desired velocity as k → ∞ Steady state velocity approaches Smooth response; no overshoot or • Stability/performance • desired velocity as k → ∞ oscillations Ø state velocity approaches Disturbance rejection • Steady Ø Smooth response; no overshoot velocity mv̇ = av + Feng + Fhill Feng = kp (vdes v) velocity § Stability/Performance -1 approaches • Steady state velocity desired velocity k → ∞ (eg, hills) disturbances • Effect ofas approaches zero as k → ∞ orresponse; oscillations kp 1 Smooth no overshoot or vss = vdes + Fhill Robustness a + kp a + koscillations p § Disturbance rejection on the specific Results don’t depend 0 as 1 as values of a, m or kp, for kp sufficiently Disturbance rejection k ⇥ k ⇥ large of disturbances (eg, hills) Ø Effect Effect of disturbances (eg, hills) time approaches zero as k→∞ approaches zero as k → ∞ kp 1 vss = vdes29+ Fhill CDS 101/110, Sep 08 Richard M. Murray, Caltech CDS 10 Robustness § Robustness a + kp a + kp Results don’t depend on the specific Ø Results don’t depend on the 0 as 1 as values of a, m or kp, for kp sufficiently k ⇥ k ⇥ large specific values of a, m or kp, for • • time CDS 101/110,Park 29 Sep(CNU) 08 Pangun Richard M. Murray, Caltech CDS kp sufficiently large 106 Basic control architectures: Feed-Forward Basic control architectures: Open-loop control/Feed-Forward r F u P y Basic idea: given r , attempt to compute what should be the control input u that would make y = r . § Basic idea: given r, attempt to compute what should be the control input uF that make yof=P.r. Essentially, shouldwould be an “inverse” § Essentially, F should be an “inverse” of P. Relies on good knowledge of P — sensitive to modeling errors. § Relies on good knowledge of P — sensitive to modeling errors. Ø State estimator eliminated : not well suited formake a complex plant system stable. Cannot alter the dynamics of P, i.e., cannot an unstable Ø Assumes disturbing forces have little effect on the plant Ø Less expensive than closed-loop control : example: electric toaster § CannotE. Frazzoli alter the dynamics of P, i.e., cannot make an unstable (ETH) Lecture 2: Control Systems I 09/29/2017 5 / 24 system stable. Pangun Park (CNU) 7 Open-loop control Noise Desired state variables – X*(t) Control Software Driving forces Actuators U(t) Pangun Park (CNU) Disturbing forces Control commands Plant D(t) Real state variables X(t) 8 Basiccontrol control architectures: architectures: Closed-loop Basic Feedback control/Feedback r e C u P y § Basic idea: given the error (r − y), compute u such that the error Basic idea: given the error r is “small.” y , compute u such that the error is “small.” Intuition: bigger C , the smaller the error e will the be, regardless of Pwill be, § Intuition: thethe well designed C, the smaller error “e” (under some assumption, e.g., closed-loop stability). regardless of P (under some assumption, e.g., closed-loop stability). Does not require a precise knowledge of P — robust to modeling errors. § Does Can not stabilize requireunstable a precise knowledge of P — robust to modeling systems. But can also make stable systems unstable errors.(!). § Can stabilize unstable systems. But can also make stable systems Needs an “error” to develop in order to figure out the appropriate control. unstable (!). § Needs an “error” to develop in order to figure out the appropriate control. E. Frazzoli (ETH) Pangun Park (CNU) Lecture 2: Control Systems I 09/29/2017 6 / 24 9 Benefits/Dangers of Feedback § Feed-forward control relies on a precise knowledge of the plant, and does not change its dynamics. § Feedback control allows one to Ø Stabilize an unstable system; Ø Handle uncertainties in the system; Ø Reject external disturbances. § However, feedback can Ø introduce instability, even in an otherwise stable system! Ø feed sensor noise into the system. Pangun Park (CNU) 10 manual and automatic control. It is important that there are no switching transients. Closed-loop controldo not generate It is also important that parameter changes transients. This can be avoided by proper coding. § Feedback is ubiquitous in natural and engineered systems Example: § Feedback loop implementation This implementation gives This implementation does not give bumps bumps Ø Suitable for complex plant § Sensors ! t k andi =state estimator e(s)ds Ti ! t k produce of i =representation/estimation e(s)ds Ti state variables pdated with 8 Sfrag replacementsThe basic issue is that multiplication with a time function does § These not values are compared to desired values commute with differentiation or integration. § Control software generates control commands based upon the differences between estimated and desired values Requirements n d r F Σ e C u Σ P x Σ y −1 • Reduce the effect of load disturbances Pangun Park (CNU) 11 Closed-Loop Control Ø plant is a system that is intended to controlled Ø collect information concerning the plant – data acquisition system (DAS) Ø compare with desired performance Ø generate outputs to bring plant closer to desired performance Disturbing forces Noise Real state variables Driving forces Actuators U(t) Plant Desired state variables – X*(t) Sensor outputs Noise Y(t) State estimator Analog Interface Errors Compare E(t)=X*(t)-X(t) Pangun Park (CNU) X(t) D(t) Control commands Control Software Sensors X’(t) Software ADC or input compare Estimated state variables 12 Contents § Overview Control Systems § PID Control § PID Parameter Tuning § PID Implementation Pangun Park (CNU) 13 PID Control § Advances in control theory have given a good insight into the design problem § PID control is most common feedback structure in engineering systems 302 CONTROL § Connect with the classic traditionCHAPTER of Ziegler10. andPID Nichols Error Present Past Future t t + Td Time Control Time Figure 10.1: A PID controllerPID takes controlover action based on past, present and prediction of future control errors. Pangun Park (CNU) 14 Summary of PID Controller PID control y We can build a PID controller that works well in practice in most situations without knowing control theory PID control § Intuition u = kp e + ki e dt + kd ė Ø Proportional term: provides inputs that correct for “current” errors Ø Integral term: insures steady state error goes to zero orrect for “current” errors Ø Derivative term: provides “anticipation” of upcoming changes goes to zero of upcoming changes § Utility of PID Ø For many systems, only need PI or PD (special case) Ø Many tools foroftuning PID loops and designing gains ky: “Directional stability automatically erm control” earization) could be used to understand the rol Pangun Park (CNU) 15 Proportional Feedback Proportional Feedback Proportional Feedback Simplest controller choice: u = kpe controller choice: § SimplestSimplest controller choice: u u== kkppe e e lifts gain withlifts nogain change inchange phasein phase • Effect: Effect: with no r • input tries to move the system in +r Ø The control for plants withforlow phase up phase to up to plants with low • Gooda direction • Good that isbandwidth opposite to the error, and is desired desired bandwidth proportional to the gain error in magnitude. • Bode: Bode: shift gain up shift by factorupofbykpfactor of kp • Step response: betterincreases, steady state error, • § Step As the proportional gain response: better steady state error, • but with decreasing stability + e - kp kp u u P(s) P(s) yy k >0 kp >p0 butØ with The decreasing closed-loop stability system remains stable; 50 50 Ø The steady-state error decreases; 0 Ø The response becomes faster; 0 -50 -100 -50 Ø The sensitivity Proportional gain selection -150 -100 0 1.2 -150 to noise increase 1 k=2 k=5 k=10 k=50 -100 0 0.8 -100 y -200 0.6 -300 -1 10 0 1 10 2 10 10 0.4 -200 0.2 -300 -1 10 CDS 101/110, 24 Nov 08 Richard M. Murray, Caltech CDS 0 0 0 10 1 1 2 3 4 5 6 10 4 2 7 8 9 10 10 t As the proportional gain increases, The closed-loop system remains stable; Pangun Park (CNU) The CDS 101/110, 24steady-state Nov 08 error decreases; Richard M. Murray, Caltech CDS 16 4 Proportional gain selection § As the proportional gain increases, Ø The closed-loop system become more oscillatory (warning!); Ø The steady-state error decreases; Ø The response becomes faster; Proportional selection Ø The sensitivitygain to noise increases. 1.8 1.6 1.4 1.2 y 1 0.8 0.6 0.4 0.2 0 0 1 2 3 4 5 6 7 8 9 10 t As the proportional gain increases, The closed-loop system become more oscillatory (warning!); Pangun Park (CNU) 17 Proportional + Integral Compensation Proportional + Integral Compensation Proportional + Integral Compensation Use to eliminateUse steady statesteady errorstate error to eliminate e e Effect: lifts gain at low frequency Effect: liftssteady gain• at low frequency kiki uu P(s) § Use to eliminate state error y r + k k+ y p+ r P(s) + p s Gives zero steady state error • state error s Gives zerostate steady Ø Gives zero steady error Bode: infinite SS gain + phase lag • gain + phase lag Bode: infinite SS Step response: zero steady state error, • Ø Integrating the error allows oneof to detect potential kp > 0, ki > 0 The Amazing Property Integral with smaller settling time, but moreAction The Amazing Property ofzero Integral Action Step response: steady state error, overshoot “biases”with in the system behavior. kp > 0, ki > 0 smaller settling time, but more Consider a PI controller of the overshoot der a PI§ controller In spite In of spite the widesp Consider a PI controller • • • • 100 ! t ! t u = ke +u k=i ke e+(τk)idτ e(τ )dτ 50 100 in ed attentionattention in education turers. PID is com turers. PID control 0 -50 50 0 0-100 0 0 Øthat Assume that is an equilibrium u(t) = ku is there an equilibrium with with constant ) == e0 meAssume that there is there an equilibrium with constant e(tconstant ) = e0(te(t) 0 and =e0uerror 0then . The must error e0be then must bezero. zero. Proof: and constant tThe ) = uerror . The e0 then must beProof: onstant u(t) e= uu0(.constant zero. 0 u(t) e0 Proof: != 0, then me Assume e0 != 0, then to co Ø Assume , then We haveWe to have consider ! t ! t ! t ! t • Derivative • Derivative filter -50 -100 -100 -200 0 -300 -2 10 -1 0 10 10 1 2 10 10 -100 u k=i ke0e+ (τ )0CDS d+ τ101/110, =i 24ke τ k=iRichard + kCaltech t u = ke0 + (τ )kdi τ =eke k τ i = kee00d+ eke 0e 0 Murray, i e0CDS Nov 08+ 0 dk 0 t M. 0 -200 0 0 0 5 • Set point • Set point (referen weigthing weigthing Øhand The right ishand is different from zero. Hence a right side different from zero.a Hence a contradiction ghtThe hand side is different fromside zero. Hence contradiction unless e0 = 0. 0. s e0unless = 0. e0 =contradiction • Integrator • Integrator Windup Ø A controller with integral action will always give the CDS 101/110,integral 24 Nov 08 will Richard M. Murray,the Caltechcorrect CDS A controller with action will give always ntroller with integral action always thegive correct withiss t5 Dealing Dealing with these correct steady state provided that a steady state exists. -300 -2 10 -1 10 0 10 1 10 2 10 steady state provided that a state steady state exists. y state provided that a steady exists. Pangun Park (CNU) implementatio implementation of any 18 Integral gain selection § As the integral gain increases, Ø The steady-state error is zero (as long as kI is not zero) Ø The response becomes more oscillatory (warning!) egral gainØ selection The sensitivity to noise does not change! 1.6 k P=2, k I = 2 k P=2, k I = 2 1.4 k P=2, k I = 5 k P=10, k I = 50 1.2 y 1 0.8 0.6 0.4 0.2 0 0 1 he integral gain increases, Pangun Park (CNU) 2 3 4 5 6 7 8 9 10 t 19 1 C(s) kp + ki +(PID) kd s +yIntegral += Derivative Proportional + Integral + D + C(s) s 1 = k(1e+ + Tdus) § Differentiating the error C(s) T s r y i P(s) + C(s) -1 to “predict” what allows one kTd (s + 1/Ti )(s + 1/Td ) = the error will do in the near Ti -1 s e r uProportional P(s) future. Bode Diagrams § An derivative control action tries to avoid overshooting, hence damping the system. 0 0 0 0 0 1 C(s) = kp + ki + kd s s 1 = k(1 + + Td s) Ti s kTd (s + 1/Ti )(s + 1/Td ) = Ti s 0 0 y 0 0 0 0 -3 10 -2 10 -1 10 0 10 1 10 2 10 50 40 Phase (deg); Magnitude (dB) egral + Derivative (PID) Bode Diagrams 30 20 10 0 100 50 0 -50 -100 -3 10 -2 10 3 10 -1 10 0 10 1 10 2 10 3 10 Frequency (rad/sec) Frequency (rad/sec) CDS 101/110, 24 Nov 08 Pangun Park (CNU) 10, 24 Nov 08 Richard M. Murray, Caltech CDS Richard M. Murray, Caltech CD 20 6 Derivative gain selection § As the derivative gain increases, Ø The steady-state error not affected; Ø The response becomes less oscillatory, but potentially slower Ø The sensitivity to noise increases! Derivative gain selection 1.4 k P=50, k D=2 k P=50, k D=5 1.2 k P=50, k D=10 k P=50, k D=50 1 y 0.8 0.6 0.4 0.2 0 0 1 2 3 4 5 6 7 8 9 10 t As the derivative gain increases, The steady-state error not a↵ected; Pangun Park (CNU) The response becomes less oscillatory, but potentially slower 21 Proportional-Integral-Derivative Control Proportional-Integral-Derivative Control Proportional-Integral-Derivative Control 5 5D Gain Derivative Derivative 1 s Integrator reference Step1 disturbance D Gain1 10 s D Gain1 10 error Step1 disturbance Step 10 1 Integrator reference Step D Gain control control P Gain error 10 2 s2+2s+2 control simout output To Workspace Transfer 2Fcn s2+2s+2 control P Gain simout output To Workspace Transfer Fcn measurement noise Band-Limited noise White Noise measurement Band-Limited White Noise § One alsocombine combine theof effects of and an ofintegrator and Onecan can also the e↵ects an integrator a di↵erentiator withof a basic controller. differentiator with the basic Onethe can alsoproportional combine the e↵ects proportional of an integratorcontroller. and of a di↵erentiator with the PID basic proportional controller. control: § PID control: Z t PID control: u(t) = kP e(t) + kI u(t) = kP e(t) kI + kI C (s) = kP + s Z0 t e(⌧ )d⌧ + kD ė(t), e(⌧ kD )d⌧ s 2 ++ kPksD+ė(t), kI + kD s0= s . kI kD s 2 + kP s + kI C (s) = kP + + kD s = . s s E. Frazzoli (ETH) Lecture 11: Control Systems I 1/12/2017 23 / 31 Pangun Park (CNU) E. Frazzoli (ETH) Lecture 11: Control Systems I 1/12/2017 22 23 / 31 Summary § Proportional control Ø Decrease the steady-state error; Ø Increase the closed-loop bandwidth; Ø Increase sensitivity to noise; Ø Can reduce stability margins for higher-order systems (2nd order or more). § Integral control Ø Eliminates the steady-state error to a step (if the closed-loop is stable); Ø Reduces stability margins, can make a higher-order system unstable. § Derivative control Ø Reduce overshooting, increase damping; Ø Improves stability margins; Ø Increase sensitivity to noise. Pangun Park (CNU) 23 Contents § Overview Control Systems § PID Control § PID Parameter Tuning § PID Implementation Pangun Park (CNU) 24 Performance Measures § Accuracy Ø Magnitude of the Error = Desired – Actual § Stability Ø No oscillations § Overshoot (underdamped, overdamped) Ø Ringing, slow § Response Time to new steady state after Ø Change in desired setpoint Ø Change in load underdamped tresponse Pangun Park (CNU) 25 How do the PID parameters affect system dynamics? § 4 major characteristics of the closed-loop step response. Ø Rise Time: the time it takes for the plant output y to rise beyond 90% of the desired level for the first time. Ø Overshoot: how much the the peak level is higher than the steady state, normalized against the steady state. Ø Settling Time: the time it takes for the system to converge to its steady state. Ø Steady-state Error: the difference between the steady- state output and the desired output. Pangun Park (CNU) 26 Time Specifications § td: delay time, time for s(t) to reach half of s(1) Ø A typical step response s(t) It is the time required for the response to reach 50% of the final value in first attempt. Step Response § tr: rise time, time for s(t) to first reach s(1) Ø 1.4 It is the time required to rise from 0 to 100% of the final value for the under damped system. 1.2 1 § tp: peak time, time for s(t) to reach first peak It is the time required for the response to reach the peak of time response or the peak overshoot. 0.8 Amplitude Ø 0.6 0.4 § Mp: Peak overshoot Ø It is the normalized difference between the time response peak and the steady output and is defined as, 0.2 0 0 5 10 15 Time (sec) § ts: settling time, time for s(t) to settle within a range (2% or 5%) of s(1) § Steady-state error Ø It indicates the error between the actual output and desired output as ‘t’ tends to infinity. Pangun Park (CNU) 27 How do the PID parameters affect system dynamics? § Effects of increasing a parameter independently Pangun Park (CNU) 28 How do we use the table § Typical steps for designing a PID controller are § 1. Determine what characteristics of the system needs to be improved. 2. Use Kp to decrease the rise time. 3. Use Kd to reduce the overshoot and settling time. 4. Use Ki to eliminate the steady-state error. This works in many cases, but what would be a good starting point? Pangun Park (CNU) 29 PID Tuning § PID tuning corresponds to choosing the parameters kp, ki and kd to reach the feedback control design specifications. § PID tuning can be done with tuning rules by hand or numerically using MATLAB or other tools (the latter requires a system model). § There exist heuristic methods to tune a PID controller without a model of the plant P(s), e.g. the tuning rules proposed by Ziegler and Nichols. § Zeigler-Nichols step response method Pangun Park (CNU) 30 Ziegler-Nichols’ Step Response Method § Design PID gains based on step response § Measure maximum slope + intercept Ø Conduct numerous experiments and proposed rules for determining values based on the transient step response of a plant. Ø Make a step in the control variable. Ø Log process output. Normalize the curve so that it corresponds to a unit step. Ø Determine intercepts of tangent with steepest slope i.e. parameters a and L. The controller parameters are obtained from a table. § Works OK for many plants (but underdamped) § Good way to get a first cut controller Pangun Park (CNU) 31 0 We will present a selection −1 Ziegler-Nichols’ Step Response Method Ziegler-Nichols’ Step Response Method § Data: Apparent time delay L 0 2 4 6 8 12 0.5 0 −0.5 Tp is an estimate of the response time of the from closed eters are obtained a table. loop system. § Parameter 40 −1 −0.5 30 20 10 c K. J. Åström, October 2002 ! 0 100 50 0 -50 -100 -3 10 -2 10 Pangun Park (CNU) -1 10 0 10 Frequency (rad/sec) 1 10 2 10 14 Ziegler-Nichols’ Frequency Res and intercept a. Controller parameters Proportional +byaIntegral + Derivative (PID) • Switch the controller to Data: apparent time delay Lare andgiven intercept . Controller parampure proportional. eters are given by 1 e u • Adjust C(s) = k + k p i + kthe d s gain so that the r Controller y + C(s) k Ti TP(s) T s d p closed loop system is at 1 P 1/a 4L = k(1 + the stability + Td s) boundary. Ti s PI 0.9/a -13L 5.7L • Determine the gain ku kTd (s(the + 1/T 1/Td )and i )(s +gain) ultimate PID 1.2/a 2L L/2 3.4L = Ti the period s Tu (the ultimate Diagrams Parameter Tp is an estimate Bode of the response time of the closed period) of the oscillation. loop system.50 • Suitable controller paramPhase (deg); Magnitude (dB) 10 3 10 32 Contents § Overview Control Systems § PID Control § PID Parameter Tuning § PID Implementation Pangun Park (CNU) 33 PID Controller Implementation Summary of PID Controller § Build a PID controller that works well in practice in most We can build a PID controller thattheory works well in practice situations without knowing control in most situations without knowing control theory Pangun Park (CNU) 34 PID Control : Motor Control Example X* E(n) - E(s) + X’(s) X'(n) PID Controller Actuator U(n) Ki PWM +Kd s Kp+ U(s) circuit s State estimator Period Measurement Ki G( s) = K p + K d s + s m H ( s) = 1+t s Pangun Park (CNU) m 1+s t Sensor Tachometer Plant X(t) X(s) X ( s) G ( s) H ( s) = X * ( s) 1 + G ( s) H ( s) 35 General Approach to PID t dE (t ) U (t ) = K p E (t ) + ò K i E (t )dt + K d dt 0 § Proportional Up = KpE Ui = Ui + KiEDt Derivative Ud = Kd(E(n)-E(n-1))/Dt PID U = Up + Ui + Ud Run ten times faster than motor t Run slower or equal to sensor sampling rate § Integral § § § § Pangun Park (CNU) 36 Example : PID Controller Implementation § DC Motor Position Control Ø Move the output shaft of the motor from current position to target position Ø Motor speed can be controlled by varying the PWM duty cycle used to drive the motor. § There are a few terms commonly used to describe the PID control loops, such as: Ø Control Variable (CV) – This is the output of the control loop. In this case, the CV is the duty cycle of the PWM signal that drives the motor. Ø Process Variable (PV) – This is the feedback value returned by the system to the controller. In this example, the PV is the current angle of the motor shaft. Set Point (SP) – Set point is the value that we desire for the system. In our case, the SP is the target position of the motor shaft in angle. Ø Ø Error (E) – Error refers to the difference between the set point and the process variable. In another words, it means how far the current position of the motor shaft from the target position. Pangun Park (CNU) 37 Proportional Controller § When the current position of the motor shaft is still far away from the target position, we want to apply more power to drive the motor towards the target position so that we can reach there faster. § When the shaft is getting nearer to the target position, we will reduce the power to slow it down. At the time the shaft reaches the target position, the motor needs to be stopped. § If the shaft position has overshot, we need to apply negative power to the motor (reverse the motor) to bring it back to the target position. § The PWM duty cycle (output) is the result of multiplying the error with a constant, Kp. Pangun Park (CNU) 38 Proportional Controller Pangun Park (CNU) 39 Proportional Controller § System response for proportional controller with low Kp § System response for proportional controller with high Kp § System response for proportional controller with excessively high Kp Pangun Park (CNU) 40 Integral Controller § As can be seen from the graph of P controller, the actual position of the motor shaft, when settles down will not reach the target position. Ø This is because when the current position is near to the target position, the error becomes very small and the computed PWM duty cycle is too small for the motor to overcome the friction and gravity. § The small error that exists when the system has settled down is called the steady state error. § The integral is merely an accumulated error signals encountered since startup. Pangun Park (CNU) 41 Integral Controller Pangun Park (CNU) 42 Integral Controller § System response for PI controller with no steady state error Ø Too low the value, the steady state error is corrected very slowly; too high the value, the system becomes unstable and oscillates. Ø Because the integral can grow quite large when the set point cannot be reached, some applications stop accumulating the error when the control variable is saturated. Pangun Park (CNU) 43 Derivative Controller § The derivative of any variable describes how that variable changes over time. In a PID controller, the derivative is the rate of change of the error. § In digital form, it can be described as: Ø Derivative = Error – Last Error § Negative values of derivative indicate an improvement (reduction) in the error signal. For example, if the last error was 20 and the current error is 10, the derivative will be -10. When these negative values are multiplied with a constant, Kd, and are added to the output of the loop, it can slow down the system when approaching the target. Pangun Park (CNU) 44 Derivative Controller Pangun Park (CNU) 45 Derivative Controller § The damping effect of the D controller allows the system to have a higher value of Kp and/or Ki without overshooting. Ø In consequent, this will give the system a better response time to set point changes. § However, too high the value of Kd will also have negative effect. The D controller tense to amplify the noise exists in the feedback loop. Ø If the Kd is too high, the system will become jerky if the feedback loop is noisy. Pangun Park (CNU) 46 Joining Them Together – PID Controller § P controller for fast system response, I controller to correct the steady state error and D controller to dampen the system and reduce overshoot. Pangun Park (CNU) 47 Joining Them Together – PID Controller Pangun Park (CNU) 48 Summary § Controller only as good as its sensor § Observe everything “What was it thinking?” § Change one parameter at a time § Choose stability over responsiveness Pangun Park (CNU) 49