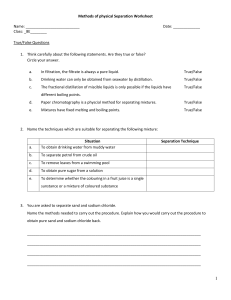

Distillery towers LEWIS METHOD Distillation tower is an important part in chemical engineering processes, and is used to separate different components in a mixture of materials. The LewisMatheson method is one of the methods used to calculate the number of trays in multi-component distillation towers. This method relies on roughly estimating the composition of the distillate. It is believed that compounds with greater volatility will appear in the distillate, while heavier compounds will appear in the bottom product - LEWIS-MATHESON Industrial distillation is typically performed in large vertical cylindrical columns known as "distillation or fractionation towers" or "distillation columns" with diameters ranging from about 0.65 to 6 m (2 to 20 ft) and heights ranging from about 6 to 60 m (20 ft). ) to 197 feet) or more. Distillation towers have liquid outlets at intervals at the top of the column allowing different fractions or products that have different boiling points or boiling ranges to be drawn. By increasing the product temperature inside the columns, the different products are separated. The "lighter" products (those with the lowest boiling point) exit from the top of the columns and the "heavier" products (those with the highest boiling point) exit from the bottom of the column - LEWIS-MATHESON The design and operation of a distillation column depends on the feed and products required. Given a simple two-component feed, analytical methods such as the method for a multicomponent feed can be used. Simulation models are used for the design. The efficiency of vapor-liquid contact devices (referred to as plates or trays) used in distillation columns is typically less than the 100% effective theoretical equilibrium stage. Thus, a distillation column needs more plates than the number of theoretical vaporliquid equilibrium stages. - Lewis-Matheson In the oil refining industry, the design and operation of crushing towers is still largely achieved on an experimental basis. The calculations involved in the design of oil fractionation columns in usual practice require the use of charts, computed tables and complex empirical equations. However, in recent years, a great deal of work has been done to develop efficient and reliable computer-aided design procedures for . fractional distillation CHEMICAL ENGINEERING DIAGRAM OF TYPICAL BUBBLE CAP TRAYS IN A DISTILLATION TOWER - Lewis-Matheson SCHEMATIC DIAGRAM OF A TYPICAL INDUSTRIAL DISTILLATION TOWER Calculate the number of "theoretical paintings" Liquids tend to wet the surface of the package and vapors pass through this wetted surface, where mass - Lewis-Matheson transfer occurs. Unlike traditional tray distillation in which each tray represents a separate point of vaporliquid equilibrium, the vapor-liquid equilibrium curve in a packed column is continuous. However, when modeling packed columns, it is useful to calculate a number of “theoretical panels” to indicate the separation efficiency of the packed column. Differently shaped packings have different surface areas and void space between packings. Each of these factors affects packing performance. Lewis-Matheson Conclusion - Lewis-Matheson • It is suggested that we consider only components with greater volatility in the distillate, while heavier compounds appear in the lower product. • This approach is considered an approximation for determining the composition of the distillate. • This method can be used to count the number of trays in distillation towers Lewis-Matheson - Lewis-Matheson Thank you all