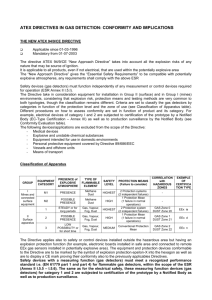

ATEX 2014/34/EU Guidelines: Equipment in Explosive Atmospheres

advertisement