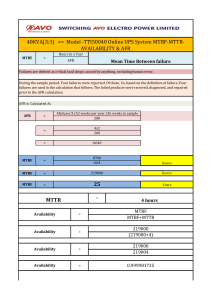

CMRP Exam Tutorial 3D-MDS Academy [www.3d-mds-academy.com] This document is supplementary to CMRP Exam tutorial series. It is intended to provide additional calculation examples for maintenance and reliability key performance indicators (KPI). Daniel Amevor, P. Eng., CMRP. 8/11/2018 EXAMPLE: A piece of equipment (centrifugal pump) was installed to transfer fluid from a lower tank to an upper tank at plant site. The pump ran continuously for 2000 hours and failed the impeller. The maintenance crew took 20 hours to fix it and return it to service. It ran for 100 hours and failed again due to seal leakage. The seal kit repair work took 10 hours and put back to service. The pump has run for additional 3000 hours without failure. Calculate the pump availability, MTTR, MTBF and failure rate? This narration is illustrated in the diagram below. down uptime 2000hrs down 100hr s 20hrs uptime 3000hrs 10hrs Pump Failure Data: Total uptime = 2000+100+3000= 5100Hrs Total Downtime = 20 + 10 = 30Hrs Total number of down events = 2 Total available time = 5130Hrs I.e. 2000+20+100+10+3000=5130Hrs a) Pump availability = Total Uptime Total Available Time = Uptime = Uptime + Downtime Availability = 99.4% b) MTTR = Total Repair Time = Total number of repairs Total Downtime Total number of repairs = 30 2 MTTR = 15Hrs CMRP Exam Tutorial by 3D-MDS Academy [www.3d-mds-academy.com] = 15 5100 5100 + 30 = 0.994 c) MTBF = Total Uptime = 5100 = 2550 2 Total number of repairs MTBF = 2550Hrs d) Failure rate ( λ) = 1 MTBF = 1 = 0.000392 2550 Failure rate (λ) = 0.000392 failures per hour Availability: Availability by definition is a measure of the likelihood that a system will be ready to operate (system is up) when it is called on to operate. Reasons the system would not be ready to operate (system is down) include the possibility that a failure has occurred and the corrective action has not been completed and the possibility that the system is not operable because preventive maintenance actions are necessary. What is MTBF and MTTR? MTBF, or Mean Time Between Failures, is a metric that concerns the average time elapsed between a failure and the next time it occurs. Whereas the MTTR, or Mean Time To Repair, is the average time it takes to carry out a repair after the occurrence of the failure. Check the ways to calculate MTBF and MTTR: MTBF - total time of correct operation in a period divided by number of failures For example: MTBF = 2550Hrs This index reveals that a failure in the system occurs every 2550 hours, leaving it unavailable and generating losses to the company. The opportunity to spot this index allows you to plan strategies to increase this time. MTTR - total hours of downtime divided by number of failures For example: MTTR = 15Hr above, this is the average time of each downtime. Therefore, the company knows that every 2550 hours, the pump will be unavailable for 15 hours. Being aware of our limitations is the first step to eliminate them. CMRP Exam Tutorial by 3D-MDS Academy [www.3d-mds-academy.com]