Learning Physical Computing

with Raspberry Pi

for the Absolute Beginner

Version 1.0

Harry H. Cheng

UC Davis Center for Integarted Computing and STEM Education (C-STEM)

University of California-Davis

http://c-stem.ucdavis.edu

April 20, 2019

Copyright c 2018 by Harry H. Cheng, All rights reserved. No part of this publication may be reproduced

or distributed in any form or by any means, or stored in a database or retrieval system, without the prior

written consent of the author, including, but not limited to, in any network or other electronic storage or

transmission, or broadcast for distance learning.

1

Contents

Part I: Introduction to Physical Computing

1 Introduction

1.1 The Board . . . . . . . . . . . .

1.2 The Breakout Board . . . . . .

1.3 The External Circuitry . . . . .

1.4 The Breadboard . . . . . . . .

1.5 Analog Input Board - PCF8591

1.6 The Pins . . . . . . . . . . . . .

1.7 Circuit Diagrams . . . . . . . .

1.8 Exercises . . . . . . . . . . . .

7

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

8

10

10

11

15

16

16

18

18

2 Setting Up and Testing Circuitry with Raspberry Pi

2.1 Project: Blink through GPIOviewer . . . . . . . . . . .

2.2 New Concepts . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Required Components and Materials . . . . . . . . . . .

2.4 Getting Started . . . . . . . . . . . . . . . . . . . . . . .

2.5 Building the Circuit . . . . . . . . . . . . . . . . . . . .

2.6 Open C-STEM Studio on the Pi . . . . . . . . . . . . .

2.7 Using the GPIOviewer GUI . . . . . . . . . . . . . . . .

2.7.1 Understanding the Interface . . . . . . . . . . . .

2.7.2 Controlling a Raspberry Pi Board . . . . . . . .

2.8 GPIOviewer Basic Test . . . . . . . . . . . . . . . . . .

2.9 Exercises . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

19

19

19

19

19

20

22

23

23

24

25

25

3 Programming Raspberry Pi in Ch

3.1 Project: Blink through Ch Programs . . . . . . . . . . . .

3.2 Using ChIDE to Run Programs . . . . . . . . . . . . . . .

3.3 Accessing the Code . . . . . . . . . . . . . . . . . . . . . .

3.4 Required Components and Materials . . . . . . . . . . . .

3.5 Building the Circuit . . . . . . . . . . . . . . . . . . . . .

3.6 Writing the Code . . . . . . . . . . . . . . . . . . . . . . .

3.7 Using ChIDE to Understand and Troubleshoot Programs

3.8 Exercises . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

26

26

26

26

28

29

30

32

35

4 More Blinking

4.1 The Direct Method of Repetition . . . . . . . . . .

4.2 SOS . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Alternate Repetition Method Using the While-loop

4.4 Using an Infinite While-loop . . . . . . . . . . . . .

4.5 Debugging Revisited . . . . . . . . . . . . . . . . .

4.6 Multiple LEDs . . . . . . . . . . . . . . . . . . . .

4.7 Exercises . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

36

36

36

39

41

42

48

50

5 Controlling a Traffic Light with a Push-Button

5.1 Project: Traffic Light . . . . . . . . . . . . . . . .

5.2 New Concepts . . . . . . . . . . . . . . . . . . . .

5.3 Required Components and Materials . . . . . . .

5.4 Building the Circuit (Part 1) . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

51

51

51

51

51

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5.5

5.6

5.7

5.8

5.9

Writing the Code Without Input

Building the Circuit (Part 2) . .

GPIOviewer Basic Test . . . . .

Writing the Code for Input . . .

Exercises . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

53

54

55

56

58

6 Using a Potentiometer to Dim an LED

6.1 Project: Dimmer . . . . . . . . . . . . .

6.2 New Concepts . . . . . . . . . . . . . . .

6.3 Understanding Analog Inputs . . . . . .

6.4 Required Components and Materials . .

6.5 Building the Circuit . . . . . . . . . . .

6.6 GPIOviewer Basic Test . . . . . . . . .

6.7 Writing the Code . . . . . . . . . . . . .

6.8 Exercises . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

59

59

59

59

60

61

64

65

67

7 Data Acquisition and Plotting Using a Photo-resistor

7.1 Project: Graphing Light . . . . . . . . . . . . . . . . . .

7.2 New Concepts . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Required Components and Materials . . . . . . . . . . .

7.4 Learning How to Plot Using plotArray.ch . . . . . . . .

7.5 Building the Circuit . . . . . . . . . . . . . . . . . . . .

7.6 Writing the Code . . . . . . . . . . . . . . . . . . . . . .

7.7 Exercises . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

68

68

68

68

68

71

73

76

8 Using Photo-Resistors and Potentiometers

RGB LED

8.1 Project: Color Mixing Lamp . . . . . . . .

8.2 New Concepts . . . . . . . . . . . . . . . . .

8.3 Required Components and Materials . . . .

8.4 Building the Circuit . . . . . . . . . . . . .

8.5 Writing the Code . . . . . . . . . . . . . . .

8.6 Exercises . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

to Change the Brightness and Color of an

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Part II: Physical Computing with Robots

86

9 Using the Raspberry Pi to Control a Linkbot or Mindstorms

9.1 Project: Direction Bots . . . . . . . . . . . . . . . . . . . . . . .

9.2 New Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Required Components and Materials . . . . . . . . . . . . . . . .

9.4 Building the Circuit . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 Stopping a Linkbot or Mindstorms Robot . . . . . . . . . . . . .

9.6 Writing the Code for Linkbot . . . . . . . . . . . . . . . . . . . .

9.7 Writing the Code for Mindstorms . . . . . . . . . . . . . . . . . .

9.8 Writing the Code to Control Two Robots . . . . . . . . . . . . .

9.9 Exercises . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Control the Speed and Spin of a Mindstorms or Linkbot

10.1 Project: Potentiometer Bot . . . . . . . . . . . . . . . . . .

10.2 New Concepts . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Required Components and Materials . . . . . . . . . . . . .

10.4 Building the Circuit . . . . . . . . . . . . . . . . . . . . . .

3

77

77

77

77

78

82

85

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

87

87

87

87

88

89

89

92

93

96

with a Potentiometer

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

97

97

97

97

98

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

10.5 Writing the Code for Linkbot Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.6 Writing the Code for Linkbot Spin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.7 Exercises . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11 Adding Sensors to Linkbot Using Linkbot Pi Pack

11.1 Project: Police Car Siren . . . . . . . . . . . . . . .

11.2 New Concepts . . . . . . . . . . . . . . . . . . . . . .

11.3 Connecting to Power and Ground on the Breadboard

11.4 Connecting to Raspberry Pi Wirelessly . . . . . . . .

11.5 Required Components and Materials . . . . . . . . .

11.6 Building the Circuit . . . . . . . . . . . . . . . . . .

11.7 Writing the Code for Linkbot Siren . . . . . . . . . .

11.8 Project: Police Car and Ambulance . . . . . . . . . .

11.9 New Concepts . . . . . . . . . . . . . . . . . . . . . .

11.10Required Components and Materials . . . . . . . . .

11.11Linkbot Position . . . . . . . . . . . . . . . . . . . .

11.12Building the Circuit . . . . . . . . . . . . . . . . . .

11.13Writing the Code for Linkbot Siren . . . . . . . . . .

11.14Project: Police Car and Firetruck . . . . . . . . . . .

11.15New Concepts . . . . . . . . . . . . . . . . . . . . . .

11.16Required Components and Materials . . . . . . . . .

11.17Linkbot Position . . . . . . . . . . . . . . . . . . . .

11.18Building the Circuit . . . . . . . . . . . . . . . . . .

11.19Writing the Code for Linkbot Siren . . . . . . . . . .

11.20Exercises . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Part III: Advanced Physical Computing

12 Reading an Analog Temperature Sensor

12.1 Project: Thermostat . . . . . . . . . . .

12.2 New Concepts . . . . . . . . . . . . . . .

12.3 Required Components and Materials . .

12.4 Building the Circuit . . . . . . . . . . .

12.5 Writing the Code . . . . . . . . . . . . .

12.6 Exercises . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

105

105

105

105

106

106

107

108

110

110

110

111

111

112

115

115

115

115

116

117

119

120

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

121

121

121

121

122

125

130

13 Turning a Servo Motor with a Potentiometer

13.1 Project: Servo Control . . . . . . . . . . . . . .

13.2 New Concepts . . . . . . . . . . . . . . . . . . .

13.3 Required Components and Materials . . . . . .

13.4 Building the Circuit . . . . . . . . . . . . . . .

13.5 Writing the Code . . . . . . . . . . . . . . . . .

13.6 Exercises . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

131

131

131

131

132

136

138

14 Playing Notes with a Piezo and Photo-resistor

14.1 Project: Light Theremin . . . . . . . . . . . . . .

14.2 New Concepts . . . . . . . . . . . . . . . . . . . .

14.3 Required Components and Materials . . . . . . .

14.4 Building the Circuit . . . . . . . . . . . . . . . .

14.5 Writing the Code . . . . . . . . . . . . . . . . . .

14.6 Exercises . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

139

139

139

139

140

142

146

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4

15 Pressing Different Buttons to Play Different

15.1 Project: Piano . . . . . . . . . . . . . . . . .

15.2 New Concepts . . . . . . . . . . . . . . . . . .

15.3 Required Components and Materials . . . . .

15.4 Building the Circuit . . . . . . . . . . . . . .

15.5 Writing the Code . . . . . . . . . . . . . . . .

15.6 Exercises . . . . . . . . . . . . . . . . . . . .

Notes

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

on

. .

. .

. .

. .

. .

. .

a Piezo

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

147

147

147

147

148

153

156

16 Data Acquisition and Plotting with Multiple Inputs and

and a Potentiometer

16.1 Project: 3D Graphing . . . . . . . . . . . . . . . . . . . .

16.2 New Concepts . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 Required Components and Materials . . . . . . . . . . . .

16.4 Building the Circuit . . . . . . . . . . . . . . . . . . . . .

16.5 Writing the Code . . . . . . . . . . . . . . . . . . . . . . .

16.6 Exercises . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outputs Using a Photo-resistor

157

. . . . . . . . . . . . . . . . . . . . 157

. . . . . . . . . . . . . . . . . . . . 157

. . . . . . . . . . . . . . . . . . . . 157

. . . . . . . . . . . . . . . . . . . . 158

. . . . . . . . . . . . . . . . . . . . 161

. . . . . . . . . . . . . . . . . . . . 167

17 Using Data Acquisition to Verify Ohm’s

17.1 Project: Science! . . . . . . . . . . . . .

17.2 New Concepts . . . . . . . . . . . . . . .

17.3 Required Components and Materials . .

17.4 Building the Circuit . . . . . . . . . . .

17.5 Writing the Code . . . . . . . . . . . . .

17.6 Exercises . . . . . . . . . . . . . . . . .

Law

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

168

168

168

168

168

169

174

18 Timing a Program

18.1 Project: Timer . . . . . .

18.2 New Concepts . . . . . . .

18.3 Required Components and

18.4 Building the Circuit . . .

18.5 Writing the Code . . . . .

18.6 Exercises . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

175

175

175

175

175

178

182

19 Moving a DC Motor by Pressing a Button

19.1 Project: Transistor Switch . . . . . . . . . .

19.2 New Concepts . . . . . . . . . . . . . . . . .

19.3 Required Components and Materials . . . .

19.4 Building the Circuit . . . . . . . . . . . . .

19.5 Writing the Code . . . . . . . . . . . . . . .

19.6 Exercises . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

183

183

183

183

184

187

189

20 Controlling the Speed and Direction of a DC Motor

20.1 Project: Motor Command . . . . . . . . . . . . . . . .

20.2 New Concepts . . . . . . . . . . . . . . . . . . . . . . .

20.3 Required Components and Materials . . . . . . . . . .

20.4 Building the Circuit . . . . . . . . . . . . . . . . . . .

20.5 Writing the Code . . . . . . . . . . . . . . . . . . . . .

20.6 Exercises . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

190

190

190

190

191

196

200

. . . . . .

. . . . . .

Materials

. . . . . .

. . . . . .

. . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

5

21 Writing on an LCD Panel

21.1 Project: Magic Eight Ball . . . . . .

21.2 New Concepts . . . . . . . . . . . . .

21.3 Required Components and Materials

21.4 Building the Circuit . . . . . . . . .

21.5 Writing the Code . . . . . . . . . . .

21.6 Exercises . . . . . . . . . . . . . . .

21.7 Alternative Connections and Code .

21.8 Required Components and Materials

21.9 Building the Circuit . . . . . . . . .

21.10Writing the Code . . . . . . . . . . .

21.11Exercises . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

201

201

201

201

202

204

208

208

209

209

213

218

22 Using a Piezo as a Vibration Sensor

22.1 Project: Knock to Unlock . . . . . .

22.2 New Concepts . . . . . . . . . . . . .

22.3 Required Components and Materials

22.4 Building the Circuit . . . . . . . . .

22.5 Writing the Code . . . . . . . . . . .

22.6 Exercises . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

219

219

219

219

219

225

231

23 Appendix A: GPIOviewer Details

232

24 Appendix B: Getting Started in Pi with C-STEMbian

24.1 Download and Install C-STEMbian for Pi . . . . . . . . .

24.2 Getting Started With Pi Using Windows or Mac . . . . .

24.3 Getting Started With Pi Using a Chromebook . . . . . .

24.4 Getting Started With Pi Using a Monitor . . . . . . . . .

24.5 Getting Started With Pi Using a Wireless Connection . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

233

233

236

243

243

243

25 Appendix C: Functions and Classes

25.1 Functions in Ch . . . . . . . . . . . . . . . . . .

25.1.1 General Functions . . . . . . . . . . . .

25.1.2 Software PWM Functions in softPwm.h

25.1.3 Tone Writing Functions in softTone.h .

25.1.4 The LCD Functions in lcd.h . . . . . . .

25.2 Classes . . . . . . . . . . . . . . . . . . . . . . .

25.2.1 The CPlot Class in Ch . . . . . . . . . .

25.2.2 The Linkbot or Mindstorms Class in Ch

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

249

249

249

249

250

250

251

251

252

26 Appendix D: Resistors and Other

26.1 Resistor Color Codes . . . . . . .

26.2 Using the Multi-Meter . . . . . .

26.2.1 Current . . . . . . . . . .

26.2.2 Voltage . . . . . . . . . .

26.2.3 Resistance . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

253

253

254

254

254

255

Hardware

. . . . . . .

. . . . . . .

. . . . . . .

. . . . . . .

. . . . . . .

Index

.

.

.

.

.

256

6

Part I:

Introduction to Physical Computing

7

1 Introduction

With over ten million units sold, the Raspberry Pi single board computer has become one of the most

popular ways to learn computer science. Raspberry Pi s are ultra-low-cost, fully functional tiny computers.

While there are many models of the Raspberry Pi , their purpose remains the same: to provide an affordable way to get hands on experience in the world of programming and electronics. This book focuses on

providing examples that can be applied to real world applications of the board, such as controlling motors

and recognizing sensor inputs. To do this requires use of ChIDE in conjunction with the Ch programming

language.

Ch and ChIDE provide the ability to enter a line-by-line debugging mode which can be invaluable to the

absolute beginner programmer and breed a greater intuition about how a program actually works. Some

new projects are also added in order to highlight some of the salient capabilities of Ch, such as data plotting,

and how they can be used for practical purposes in conjunction with a single board computer.

Unlike a microcontroller, such as an Arduino, the Raspberry Pi runs on an actual operating system. For

this book, the use of C-STEMbian, a variant of Raspbian, is required. This allows the board to be much

more capable than the Arduino as it is a full computer; however, this also means that certain tasks are more

complicated, such as analog inputs.

These projects and lessons provide a basic knowledge of how single board computers function with

inputs (such as switches, knobs, temperature and light sensors) and outputs (such as LEDs, servos, motors).

This book assumes that the user has the hardware from C-STEM Center or C-STEM industrial partner.

As an expansion from previous C-STEM Center courses involving mathematic computing and robotics

programming with the Linkbot, this book gives practical applications for programming and explores some of

the inner-working of robotics programming. This will eventually lead a user to having the required knowledge

to use the Input/Output (I/O) capabilities of a single board computer to create a self-driving, autonomous,

vehicle. While a self-driving car is a classic goal for robotics, the possibilities for what a person can do with

the power of a Raspberry Pi is only limited by their creativity. The goal of this book is to give the user

enough knowledge to express their creativity with their own projects.

This book assumes that the user has the Arduino Uno Starter Kit , Arduino Uno and Pi Sensor

Kit , and Raspberry Pi Starter Kit which are available for purchase from Barobo, Inc.

(http://www.barobo.com).

8

(a) Arduino Uno Starter Kit

(b) Uno and Pi Sensor Kit

(c) Raspberry Pi Starter Kit

9

1.1 The Board

Figure 1.2: Raspberry Pi 3 Model B Single Board Computer

This is the Raspberry Pi, which is a single board computer. It contains a processor connected to many inputs

and outputs, such as USB and ethernet. Additionally, there are many pins that perform various functions

that will be used throughout the projects in this books. These I/O (input/output) pins are what make

the Raspberry Pi such a powerful tool as they allow the user to perform many tasks. Ch code currently

supports using a variety of Pi boards, including the newest Raspberry Pi 3 Model B and the Orange Pi. The

differences between the spectrum of Pi boards are the processor size and power, the board’s physical size

and layout, and the number of I/O pins. The Pi 3 Model B can be considered the standard board and will

work for all of the projects presented in this book. While other boards may work for projects in this book,

their layouts and capabilities can differ significantly.

Note: Before using the Raspberry Pi or any other variant, C-STEMbian operating system must be

installed. The Pi is versatile in that in can be used on its own by connecting a monitor, or it can be accessed

remotely via another computer either wirelessly or locally. For instruction on how all this can be done, see

Chapter 24, or visit the the http://c-stem.ucdavis.edu/c-stembian/ page for up to date info.

1.2 The Breakout Board

It can be difficult to directly wire components

to the pins of the Raspberry Pi . Because

of this issue, a breakout board (or extension

board) is often used. Think of the breakout

board as simply a bridge between the Raspberry Pi and the breadboard, which is used

for circuit building and will be discussed later.

The ribbon cable forms a connection from each

individual male pin on the Raspberry Pi to its

own row of female pins on the breadboard. It

also allows the ’5V’ and ’3V3’ power supplies

to be available without any extra wiring, saving time and reducing troubleshooting. The

example used in this book is shown in Figure

1.3.

Like many of the attachments and accesFigure 1.3: Breakout Board

sories for the Raspberry Pi many variations of

breakout boards exist. For this book, we will

be using the model by Vilros, included the C-STEM Starter Kit. In effect, they all behave the same way,

although some do not include the power rails on the side.

10

1.3 The External Circuitry

Breadboards

The circuits required for the projects could be wired directly to

the Raspberry Pi , but that would be very messy. That is why

a breadboard is typically used for building temporary circuits.

A breadboard contains a grid of sockets, like those on the

Raspberry Pi , that can have wires plugged into them. Some

pins in the rows of the breadboard are connected internally

so plugging certain pins into certain rows will connect those

wires. Breadboards allow for relatively complex circuits to be

built and modified easily for testing and troubleshooting. A

detailed explanation can be found in The Breadboard section

in this chapter.

Symbol

Hardware

Resistors

500

As the simplest electrical component, resistors impede current

flow and cause drops in voltage. Resistors are used in filtering

electric signals, controlling power input/output, and protecting other components from power overload. Resistors will be

used frequently in this book to protect LEDs from too much

power. They are color coded to indicate different values of resistance, measured in units called Ohms. Refer to 26.1 in the

Appendix for the resistor color-coding system. They have two

leads, or little wires sticking out, that connect to the circuit.

Resistors are bidirectional, meaning the leads do not have a

positive or negative.

LEDs

LEDs, or Light Emitting Diodes, have been the primary light

producing electrical component for the past few decades. They

are a special type of diode that create light when current is

passed through. They are used widely as indicator lights on

electrical devices, and share the property of controlling current

direction like a standard diode. They have a longer positive

lead and shorter negative lead.

RGB LEDs

RGB (Red Green Blue) LEDs are a type of light emitting

diode that can create any combination of colors by combining

3 LEDs into 1. They have 4 pins: red, green, blue, and ground.

Applying more voltage to the red pin gives a more red hue,

and the same goes for green and blue. Like normal LEDs and

diodes, current only flows in one direction from the color pins

to ground.

11

Symbol

Hardware

Switches/Buttons

After years of turning lights on and off, modern society has a

pretty intuitive understanding of how switches work. A switch

or button, when activated by being physically pressed, allows

current to flow through a circuit. Switches allow the user/operator to have control and give input to a system. Switches

are how the program knows what the user wants it to do.

Capacitors

A capacitor is an electrical component that stores electrical

energy. Once fully charged, it stops current flow completely

and discharges its stored energy. Capacitors are typically used

to store energy, like a temporary battery, and also for filtering electric signals. Capacitors will be used later in sections

with servo motors to smooth out the voltage changes across a

component. Many capacitors have a positive and negative side

that must be plugged in correctly. The side with the stripe on

your capacitor is always the negative or ground!

Tilt Sensor

A tilt sensor is a special type of switch. It contains a little

metal ball that, when the sensor is in an upright position, sits

on two metal plates which allows current to flow through the

sensor. When the sensor is tilted, the little ball rolls off of the

metal plates which stops the current and breaks the circuit.

Potentiometers

Another way a user can give input to a system is with a potentiometer, which is more commonly known as a knob. A potentiometer is technically a variable resistor. It can produce a

wide range of resistances which in turn creates various of voltages that can be detected by the computer. While switches

can only be on or off, a potentiometer gives the computer a

continuous range of feedback values. A classic implementation

would be a volume knob on a speaker or stereo. Because their

basic component is a resistor, potentiometers are bidirectional.

Diodes

A diode simply allows electrical current to flow in one direction. They must be set up in the correct orientation to work

properly. A diode will be used later in the Transistor Switch

project to prevent the current generated from a DC motor from

damaging the circuit. Think of the symbol like an arrow that

shows the direction of current toward the end with a marking.

12

Symbol

Hardware

Photo-resistors

A photo-resistor is a special type of resistor that changes its

resistance when it is exposed to light. Photo-resistors act as

variable resistors, similar to a potentiometer, and will create a

wide range of voltages depending on how much light it is exposed to. Photo-resistors have many applications as switches

where if something blocks a light signal, a photo-resistor can

detect it.

Temperature Sensors

A temperature sensor will change its resistance based on the

temperature of the surrounding environment. The changing

resistance changes the voltage output from the pins of the

component, which the single board computer can detect. The

voltages can be transformed into temperatures with formulas,

usually unique to the model of temperature sensor.

Piezos

A piezo is a buzzer that creates sound with a specific frequency

for a specific input voltage. Depending on the voltage supplied

it will vibrate, creating sound. It also can be used to detect vibrations. A piezo will be used later in Section 22 for detecting

vibrations.

LCD Screens

An LCD, or Liquid Crystal Display, is a way for the program to

give the user visual feedback from the single board computer.

It can display alpha-numeric characters that can give the user

information about data or errors and prompt the user to take

some action.

Servo Motors

A servo motor is a special type of electric motor that can only

rotate in a 180 degree range. The exact position the servo will

move to is determined by the voltage or frequency the single

board computer sends to the servo.

BJTs (Bipolar Junction Transistor)

While a BJT may resemble a temperature sensor, they behave

quite differently. BJTs are a type of transistor that have a base,

collector, and emitter pin. A transistor can be thought of as

an electrical switch. When a voltage is applied to specific lead

then current can flow through the other two leads. Transistors

are used for many applications and are the basis of modern

computing.

13

Symbol

Hardware

MOSFETs (Metal Oxide Semiconductor Field Effect

Transistor)

MOSFETs are a second type of transistor that work in essentially the same way as a BJT. They are slower at switching

but are better suited for high powered applications. Instead of

a base, collector, and emitter, MOSFETs have a gate, drain,

and source.

H-Bridges

An H-bridge is an integrated chip, or IC, that controls the polarity, positive-to-negative or the negative-to-positive, of the

voltage across a component. This is particularly useful in Section 20 to control the direction a DC motor will spin.

DC Motor

A DC motor rotates a shaft when a voltage is applied to it.

The direction of the shafts rotation depends upon the polarity

of the voltage applied.

Battery

A battery provides power to an electric circuit or component.

In this book batteries are used to power DC motors.

Multi-meter

A multi-meter is a tool used to measure current, voltages, and

resistances of electrical components or circuits. When measuring current, a multi-meter’s symbol is a circle with an ’A’

inside, and when measuring voltage the symbol is a circle with

a ’V’ inside.

14

1.4 The Breadboard

When looking at the breadboard with the shorter edge as the horizontal, notice that the two left-most and

two right-most columns are marked with a ’+’ and a ’-’. These are the power strips, and each column is

connected internally all the way across the board. Thus, if one wire is plugged into the far upper socket of

a column and another wire is plugged into the far lower socket, then those two wires are connected at the

same voltage. The strips marked ’+’ are typically where the positive power lead is connected and the strips

marked ’-’ are where the ground lead is connected. The breakout board plugs one end of a wire into one of

the columns marked ’+’ and plug the other end into one of the Raspberry Pi pins marked ’5V’, and it does

the same for a ’-’ column and the pin marked ’GND’. Other common names for these columns are rails or

buses, so do not be confused when these words are used interchangeably.

Look in between the two sets of power strips and see that there are two 5 x 30 socket grids with a trench

in between them. The five sockets in each row are internally connected to each other so that if two wires

are plugged into any of these 5 sockets then those wires are connected at the same voltage. The rows of one

grid are not connected to the rows of the other grid, the trench separates them. Thus for any row, pins a,

b, c, d, and e are connected internally and pins f, g, h, i, and j are also connected internally but separately

from a-e.

a b c d e

f g h i j

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

Row connected internally

Column connected internally

30

a b c d e

f g h i j

Figure 1.4: Breadboard Diagram

15

1.5 Analog Input Board - PCF8591

As previously mentioned, it would normally be impossible to read

an analog value using digital inputs. For example, if the real voltage (a measure of electrical energy) was 2.45V, this could only be

represented with 1 or 0.

Neither of these values would be correct, and therefore the input would not be useful. An analog input board is used to get around this issue, which uses 8 bits

(1s and 0s) to approximate a value as close as possible to the

real one.

This requires four pins on the Raspberry Pi to operate: power, ground, and two wires for I2C communication. Then,

multiple analog signals can be connected to the board to be read

by the Raspberry Pi. For this text, the PCF8591 A/D Converter

board will be used in the circuitry and the code.

More details

on wiring this board to the Raspberry Pi will be given in Chapter

5.

Figure 1.5: PCF8591 Analog/

Digital Converter Board

IMPORTANT: Be sure to remove the header pins as shown below before beginning any projects,

as they could give incorrect data. However, do not lose them because they are used to activate the

various electronic components embedded into the PCF8591.

1.6 The Pins

On the top of the Raspberry Pi board is a series of “pins” where wires can be attached. Each of these pins

has a dedicated purpose. For example, some are for power, communication, or input/output for external

devices. To identify which pin to use, there are three numbering systems commonly used for the Raspberry

Pi: board, BCM, and wiringPi. For this textbook, the BCM or Broadcom numbers will be used. Rather

than referring to the literal pin number like the board system does, the BCM system refers to where the pin

connects to on the Broadcom processor. The third option, wiringPi, are the numbers associated with the

wiringPi system used to interact with the pins through programming. Figure 1.6 and Table 1 below explain

the purpose of each of the pins on the Raspberry Pi along with their relative locations on the device.

16

Figure 1.6: Raspberry Pi Circuit Diagram Symbol

Pin Label

Description

3V3

These pins provide 3.3 volts output.

5V

These pins provide 5 volts output.

GND

These are the ground pins. Ground is the zero-point reference for voltages. Think of

it like the endpoint for a circuit. So, if every circuit starts at a high voltage, like 5 or

3.3, it needs to end at ground.

GPIO

This acronym stands for ”General Purpose Input/Output”. GPIO pins can read and

output digital signals, meaning they can detect a certain level of voltage or output 3.3

volts. Each has the capability of PWM output, which can mimic an analog signal.

For any analog inputs, an extra device is required. Note that some GPIO pins have

dedicated functions, discussed below, that allow for analog reading.

UART (TXD,

RXD)

UART stands for ”Universal Asynchronous Receive and Transmit.” It transmits and

receives data serially, or one bit at a time. For the scope of this textbook, these will

be ignored.

I2C (SDA1, SCL1)

I2C, pronounced ”I squared C,” is a form of communication in which data is sent in

packets over two wires. In SDA and SCL, the ’DA’ is for data and the ’CL’ is for the

clock. The clock here is essentially a timer that tells the Pi when to look for data. Many

devices use this form of signal communication to transmit analog signals digitally. It

can also be used as an ouptut for controlling displays.

SPI (MOSI, MISO,

SCLK, CE0, CE1)

Similarly to I2C, SPI pins are used to transmit data in packets to be processed. It

is a good alternative for sending analog signals as it is generally faster. The main

disadvantage compared to I2C is that it takes more connections to make use of.

Table 1: Raspberry Pi Pin Description Chart

17

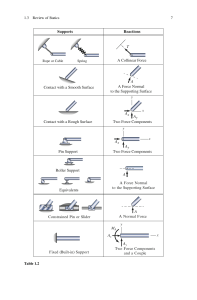

1.7 Circuit Diagrams

Using words and pictures to describe how circuits are built can only go so far. As circuits become more

complex they become harder to describe, and pictures become an impenetrable nest of wires. Enter the

circuit diagram. The standard circuit diagram is designed to layout how a circuit is built using lines as wires

and simple symbols to represent the various electrical components. The symbols to the left of the component

descriptions in the Section 1.3 are actually standard diagram symbols for each of those components. Figure

1.7 below is actually the circuit diagram for the second project. The little bits of zig-zag lines represent

resistors, the plunger looking symbol represents a push-button switch, and the triangle with the line at the

tip and the arrows represents an LED. Each of the lines represents a connection, in this case the connection

can either be an actual wire or a row on the breadboard. Notice that sometimes, due to the complexity of

the circuits, lines have to cross lines, such as in Figure 1.7 when the line comes out of the push-button and

crosses the three lines connecting the Raspberry Pi to the resistors. This does not mean that these lines

are physically connected when the circuit is built. Lines are only considered to be connected when there is

a dot at the point where they intersect. Circuit diagrams are provided for each circuit for reference only.

It can take some time to become used to, and interpret, circuit diagrams, so build the circuits using the

descriptions and pictures while comparing these to the circuit diagrams and hopefully by the end of this

book, you can become comfortable with how circuit diagrams work.

Figure 1.7: Example Circuit Diagram

1.8 Exercises

1. Why is a breakout board used? Is it required?

2. Which component(s) have a positive and negative lead?

3. Which sensor would be best to make a circuit that detects whether it fell over? Why?

4. Which sensor would be best to determine what time of day it is? Why?

5. Can GPIO pins receive an analog signal? If not, how is it done?

6. What is another name for the (+) and (-) columns of the breadboard?

18

2 Setting Up and Testing Circuitry with Raspberry Pi

2.1 Project: Blink through GPIOviewer

Project Description: This first project will have an LED turn on, blink a couple of times, and turn

off.

2.2 New Concepts