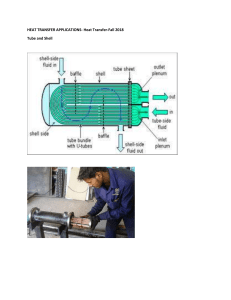

1. What is an Industrial Process? a) A small-scale procedure involving chemical or mechanical steps b) Large-scale procedures used in heavy industries to manufacture specific items c) A type of art form involving the creation of unique products d) A series of actions that lead to personal growth b) They make rare materials even more expensive c) They increase the economic feasibility of using costly materials d) They eliminate all by-products 7. Which of the following is NOT a type of industrial process? a) Chemical Processes b) Manufacturing Processes 2. Which of the following is NOT an example of a process industry? a) Food and beverages c) Heat Processes d) Physical Processes b) Pharmaceuticals c) Electronics d) Ceramics 8. Smelting is an example of which type of industrial process? a) Heat Process b) Chemical Process 3. Which of the following is NOT considered an input in an industrial system? a) Raw materials c) Physical Process d) Distillation Process b) Energy (electricity) c) Labor (skilled/unskilled) d) Finished products 4. What does "Processes" refer to in an industrial context? a) The raw materials used in manufacturing b) The methods and operations used to convert inputs into outputs 9. What is the main difference between manufacturing and production? a) Manufacturing involves converting raw materials using machinery, while production involves manual labor. b) There is no difference; the terms are interchangeable. c) Manufacturing is a subset of production. d) Production is a subset of manufacturing. c) The transportation of goods d) The communication links within a company 5. What does "Output" encompass in an industrial system? a) The primary materials used in production 10. What does "Process Technology" refer to? a) The use of science in everyday life b) The machines, equipment, and devices that create and deliver products and services c) The study of industrial processes d) The use of technology in cooking b) The waste generated during the process c) The products or by-products generated by the system d) The capital investment required for production 11. Which of the following is NOT a category of Process Technology? a) Material-Processing Technology b) Information-Processing Technology 6. What is one of the benefits of industrial processes? a) They always result in the production of valuable products c) Customer-Processing Technology d) Environmental-Processing Technology 12. What is an example of InformationProcessing Technology? a) A circular saw d) Mining b) E-commerce platforms c) Mass transportation systems d) Gym equipment 18. What is the definition of "Process" according to the Merriam-Webster Dictionary? a) A type of machine 13. Which category of Customer-Processing Technology involves customers using technology to create the service? a) Active b) Passive b) A series of actions that produce something or lead to a particular result c) The transformation of raw materials into finished goods d) A specific type of chemical reaction c) One-way monitoring d) None of the above 14. In the extractive industry, what is the main focus? 19. What is the definition of "Technology" according to the Merriam-Webster Dictionary? a) The use of science to invent new products a) Production of goods using nature b) The study of industrial processes b) Reproduction and multiplication of plants and animals c) A specific machine used in manufacturing c) Transformation of raw materials into finished products d) Extraction of resources from the soil, air, or water d) The use of science in industry and engineering to solve problems 20. Which of the following is NOT a category of Material-Processing Technology? a) Forging 15. Which industry is responsible for transforming raw materials into finished products with the help of machines and manpower? b) Casting c) E-commerce d) Machining a) Construction Industry b) Service Industry c) Manufacturing Industry d) Extractive Industry 16. What is the primary focus of the service industry? 21. What does a production system encompass? a) Only the final product b) All activities, procedures, inputs, and outputs required for production c) Only the inputs required for production d) Policies communicated by management a) Extraction of natural resources b) Manufacturing of consumer goods c) Providing various services like tourism and entertainment d) Construction of infrastructure 17. Which of the following is NOT an example of a process industry? a) Textiles b) Pharmaceuticals c) Food and beverages 22. How are production processes/systems classified? a) By the number of employees involved b) Based on product/output variety and product/operations/output volume c) According to the geographical location of production facilities d) By the cost of production 23. Which of the following is NOT a type of continuous production process? b) Custom production for each order a) Flow Shop c) Production in response to specific customer orders b) Mass Production d) Continuous production with no breaks c) Job Shop d) Project Production 24. What characterizes the Made-to-Order Production Process (MTO)? 29. What are the primary reasons for using Batch Manufacturing? a) To eliminate the need for skilled operators b) To maximize production rates a) Production in response to specific customer orders c) To accommodate variations between batches b) Items completed and placed in stock before receiving customer orders d) To produce goods with low durability c) High volume production of the same products d) Automation and special-purpose equipment 30. What types of products are typically produced using a Project Type production process? a) Mass-produced consumer goods b) Highly standardized products 25. Continuous Manufacturing Systems are also known as: a) Custom Manufacturing Systems b) One-time Production Systems c) Custom, large-scale products like ships and bridges d) Small, identical items like screws and bolts c) Repetitive Manufacturing Systems d) Discrete Manufacturing Systems 26. What is the primary focus of Continuous: Flow Shop production? a) Producing discrete products b) High-volume production of custom products c) Standardization of product and process sequence d) Production in response to specific customer orders 27. Which type of production process typically uses dedicated special-purpose machines with high production capacities? a) Flow Shop b) Batch Manufacturing 31. What is the primary objective of automation in manufacturing? a) Minimizing the quantity of production b) Reducing the durability of produced goods c) Maximizing both quantity of production and quality/durability of goods d) Eliminating the need for skilled operators 32. What is an automated process? a) A process that requires no machinery b) A process that uses machinery but is not controlled automatically c) A sequence of production activities done in an automatic manner d) A process that requires human intervention at all stages c) Project Type d) Mass Production 28. What distinguishes Batch Manufacturing from other types of production? a) High-volume production 33. How is manufacturing defined? a) As the conversion of finished goods into raw materials b) As the joining of multiple parts to make assembled products c) As the extraction of raw materials from nature d) As the application of physical and/or chemical processes to alter materials a) To maximize equipment flexibility b) To minimize variations between batches c) To achieve high-speed production d) To accommodate production interruptions 34. In which type of production process is equipment exclusively used for a specific product, ensuring uninterrupted output? 39. In the discrete manufacturing industries, what does continuous production mean? a) Flow Shop a) Production of work units one at a time b) Mass Production b) Production with no breaks for product changeovers c) Batch Manufacturing d) Project Type c) Production of work units in large batches d) Production of custom products in response to specific orders 35. What is the origin of the term "manufacturing"? a) Latin words meaning "mass production" b) Latin words meaning "made by hand" c) Greek words meaning "automated production" d) French words meaning "factory production" 36. What major shift occurred in the manufacturing industry with the rise of factories? a) Production became more manual and decentralized b) Smaller workshops became more prevalent c) Mechanized processes and larger sites replaced manual techniques d) Craftsmanship and hand-made goods became more popular 37. What does the term "Intermitted Production Process" refer to? a) Continuous production with no interruptions b) Production in response to specific customer orders c) Production of high-volume, standardized products d) Production of custom products with unique set-ups 40. What was the shift that occurred in manufacturing with the rise of factories? a) Smaller workshops became more prevalent b) Production became more decentralized and manual c) Mechanized processes and larger sites replaced manual techniques d) Craftsmanship and hand-made goods became more popular 41. What are the two major components of a production system? a) People and equipment b) Facilities and manufacturing support systems c) Facilities and product design d) Automation and manual labor 42. In production systems, who is responsible for operating the facilities? a) Professional staff b) White-collar workers c) Blue-collar workers d) Automated machines 43. What is the primary function of manufacturing support systems? a) Operating machinery 38. What is the primary reason for using batch production in manufacturing? b) Managing production and solving technical problems c) Designing products b) It requires constant human attention. d) Marketing products c) It operates for an extended period with no human attention. 44. What type of manufacturing system consists of a single production machine and a worker assigned to it? a) Automated system d) It is manually operated. 50. In certain fully automated processes, what is the role of human workers? b) Worker-machine system a) Continuously operate the machines c) Manual work system b) Monitor the operation and make occasional adjustments d) Production line c) Perform all production tasks manually 45. In a worker-machine system, what does the human worker operate? a) Manufacturing support systems b) Hand tools c) Powered equipment d) Automated machines d) Manage manufacturing support systems 51. Which function is NOT part of manufacturing support systems? a) Business functions b) Product design c) Manufacturing planning 46. Which type of manufacturing system involves no direct participation of human workers? a) Worker-machine system b) Automated system c) Manual work system d) Production line d) Product inspection 52. What is the beginning and end of the information-processing sequence in manufacturing support systems? a) Manufacturing planning b) Product design c) Business functions 47. What are the two levels of automation identified in automated systems? a) Manual and semi-automated b) Semiautomated and fully automated c) Manual and worker-machine d) Fixed automation and programmable automation d) Manufacturing control 53. What type of manufacturing system is suited to high production quantities and is relatively inflexible in accommodating product variety? a) Programmable automation b) Flexible automation c) Fixed automation 48. What does a semi-automated machine require a human worker to do? d) Worker-machine system a) Perform all tasks in the work cycle b) Continuously monitor the operation c) Tend to the machine for part of the cycle d) Operate the machine using hand tools 54. Which automation type is most suitable for batch production? a) Fixed automation b) Programmable automation c) Flexible automation 49. What is the key characteristic of a fully automated machine? a) It operates with no power source. d) Automated integrated production 55. What is the key advantage of an automation migration strategy? a) Immediate implementation of full automation b) Gradual introduction of automation as demand grows c) Low initial investment in customengineered equipment d) No need for any human workers in the production process 60. Which type of tool relies on an external power source to operate and is often used for tasks requiring significant power? a) Hand tool b) Simple machine c) Powered tool d) Automated machine 61. What is the primary function of process equipment in various industries? a) Transportation of materials 56. What is the primary purpose of simple machines? a) To amplify or modify force b) To operate without any external power source c) To perform complex mechanical tasks d) To minimize the number of moving parts b) Storage, transformation, or management of materials c) Electrical power generation d) Communication between machines 62. Which of the following is NOT a function of process equipment? a) Storage 57. Which of the following is an example of a complex machine? a) Screwdriver b) Flow Control c) Chemical Reaction Containment d) Transportation b) Bicycle c) Hammer d) Wrench 63. What are the two main types of process equipment based on their mobility during operation? a) Manual and automated 58. What is the primary distinction between hand tools and powered tools? a) Hand tools are manual, while powered tools rely on external power. b) Hand tools have more moving parts than powered tools. c) Hand tools are larger and stationary, while powered tools are portable. d) Hand tools require less force to operate than powered tools. b) Fixed/Stationary and Rotating/Rotary c) Portable and stationary d) Mobile and immobile 64. Which term is commonly used to describe stationary equipment primarily used in the oil, gas, and other process industries? a) Mobile equipment b) Rotating equipment c) Fixed equipment 59. What is the purpose of a level as a tool? d) Dynamic equipment a) To measure the diameter of shafts b) To perform complex machining operations 65. What are examples of Fixed Equipment? c) To indicate how parallel or perpendicular a surface is a) Pumps and compressors d) To move cartons in a warehouse c) Electric motors and control components b) Heat exchangers and pipelines d) Valves and boilers 66. What distinguishes certain components like pumps and compressors from Fixed Equipment? a) They are smaller in size. b) They have moving internal parts. c) They are always mobile. d) They are used primarily in the chemical industry. d) To enhance chemical reactions 72. What is the primary function of a valve in a process piping system? a) To create pressure in the system b) To regulate the flow of fluid c) To generate heat within the pipeline d) To store materials 67. What is the common term used for mechanical components that use kinetic energy to move fluids, gases, and other process materials? a) Stationary equipment b) Dynamic equipment c) Fixed equipment 73. How can valves be operated in a process system? a) Manually or Using Actuator b) Electronically only c) Through heat generation d) By gravitational forces d) Mobile equipment 68. What type of equipment is most often used to drive process fluids through a system? a) Fixed Equipment b) Rotating Equipment c) Manual Equipment d) Stationary Equipment 74. Which type of valve is suitable for scenarios requiring low flow resistance when fully open but not recommended for throttling service? a) Globe valve b) Ball valve c) Butterfly valve d) Gate valve 69. How is Rotating Equipment distinguished from Fixed Equipment? a) By their circular movements b) By their ability to rotate c) By their small size d) By their ability to transform materials 70. What are the three main components of rotary equipment? a) Blades, gears, and couplings b) Driver, connectors, and driven equipment c) Valves, pipes, and tanks d) Motors, fans, and compressors 75. What is the distinctive feature of a globe valve? a) It has a ball-shaped obstructor. b) It is operated by a screwed stem and handwheel. c) It is designed for both ON-OFF and throttling applications. d) It is leak-resistant under high pressure. 76. What type of valve is commonly used for system shut-off or isolation and provides precise flow control when fully closed? a) Globe valve b) Ball valve 71. What is the primary purpose of Damage Mechanisms in process equipment? c) Butterfly valve d) Gate valve a) To improve equipment performance b) To identify maintenance needs c) To cause problems or failures within the equipment 77. Which type of valve is small in size and requires a quarter turn to open or close it completely? a) Globe valve a) Conduction b) Ball valve b) Convection c) Butterfly valve c) Radiation d) Gate valve d) All of the above 78. What is the primary function of a relief valve? a) To control fluid flow b) To regulate temperature c) To respond automatically to sudden pressure increases d) To store materials 79. What is a control valve's primary function in an industrial system? a) To generate heat b) To regulate the flow of fluid c) To store chemicals d) To increase kinetic energy 84. In a heat exchanger with a conductive partition, how does heat transfer occur between the hot and cold fluids? a) Through direct fluid contact b) By radiation c) Through the partition by conduction d) Through magnetic fields 85. What are the main flow configurations used in heat exchangers? a) Co-current flow, counter flow, crossflow, hybrid flow b) Upward flow, downward flow, sideways flow c) Inflow, outflow, reverse flow d) Single flow, double flow, triple flow 80. Which principle of thermodynamics is related to the heat balance equation used in heat exchangers? a) Zeroth Law of Thermodynamics b) First Law of Thermodynamics c) Second Law of Thermodynamics d) Third Law of Thermodynamics 86. Which flow configuration typically exhibits the highest heat transfer efficiency in heat exchangers? a) Co-current flow b) Counter flow c) Crossflow d) Hybrid flow 81. What is the definition of fluid? a) A solid material that can change its shape b) A substance that changes its shape under force c) A gas that remains stationary d) A liquid that cannot flow 82. What are the two main types of fluids described in the context of heat transfer? a) Hot and cold fluids b) Working fluid and process fluid c) Solid and gas d) Liquid and gas 83. Which heat transfer mechanism is primarily involved in a heat exchanger? 87. How are heat exchangers categorized based on construction method? a) By color b) By flow rate c) By material composition d) By recuperative vs. regenerative and direct vs. indirect 88. What is the fundamental difference between recuperative and regenerative heat exchangers? a) Recuperative heat exchangers allow fluid mixing, while regenerative heat exchangers do not. b) Recuperative heat exchangers alternate between heating and cooling modes, while regenerative heat exchangers do not. c) Recuperative heat exchangers use direct contact heat transfer, while regenerative heat exchangers use indirect contact. d) Recuperative heat exchangers have fewer components than regenerative heat exchangers. c) Radiation d) Evaporative cooling 94. What is the fundamental working principle of a boiler? a) To cool water b) To heat water c) To evaporate water 89. In which type of heat exchanger do fluids remain separated by thermally conductive components throughout the heat transfer process? a) Recuperative d) To separate water and oil 95. Which type of boiler is typically designed for large industrial applications and uses water as the working fluid? b) Regenerative a) Fire-tube boiler c) Direct contact b) Water-tube boiler d) Indirect contact c) Condenser boiler d) Evaporator boiler 90. What are the two main types of heat transfer mechanisms employed by heat exchangers? a) Conduction and radiation 96. What is the primary function of a fired heater or furnace in a chemical process? b) Convection and radiation a) To produce electricity c) Single-phase and two-phase heat transfer b) To generate steam d) Direct and indirect heat transfer c) To heat hydrocarbons d) To cool down fluids 91. Which type of heat exchanger typically requires more complex design considerations due to its two-phase heat transfer mechanism? 97. What is a reactor used for in a chemical process? a) Shell and tube heat exchanger a) To separate mixtures b) Double pipe heat exchanger b) To transfer heat c) Plate heat exchanger c) To convert raw materials into products through chemical reactions d) Condenser 92. What is the primary purpose of a cooling tower in an industrial process? a) To generate steam d) To produce steam 98. In which type of heat exchanger does the heaviest component undergo stripping in a reboiler? b) To produce electricity a) Shell and tube heat exchanger c) To remove heat from water b) Double pipe heat exchanger d) To cool the surrounding air c) Plate heat exchanger d) Distillation column 93. Which principle does a cooling tower primarily operate on? a) Conduction b) Convection 99. What is the primary method of separation in the process of extraction? a) Distillation b) Filtration c) Evaporation d) Introducing a third material that dissolves one of the two materials 100. When is extraction a preferred method of separation over distillation? a) When the boiling points of the materials are close together b) When the materials are in solid form c) When the materials are immiscible d) When the materials are in gaseous form Answers: 1. b) Large-scale procedures used in heavy industries to manufacture specific items 2. c) Electronics 3. d) Finished products 4. b) The methods and operations used to convert inputs into outputs 5. c) The products or by-products generated by the system 6. c) They increase the economic feasibility of using costly materials 7. b) Manufacturing Processes 8. a) Heat Process 9. a) Manufacturing involves converting raw materials using machinery, while production involves manual labor. 10. b) The machines, equipment, and devices that create and deliver products and services 11. d) Environmental-Processing Technology 12. b) E-commerce platforms 13. a) Active 14. d) Extraction of resources from the soil, air, or water 15. c) Manufacturing Industry 16. c) Providing various services like tourism and entertainment 17. d) Mining 18. b) A series of actions that produce something or lead to a particular result 30. c) Custom, large-scale products like ships and bridges 31. c) Maximizing both quantity of production and quality/durability of goods 32. c) A sequence of production activities done in an automatic manner 33. d) As the application of physical and/or chemical processes to alter materials 34. a) Flow Shop 35. b) Latin words meaning "made by hand" 36. c) Mechanized processes and larger sites replaced manual techniques 37. d) Production of custom products with unique set-ups 38. b) To minimize variations between batches 39. b) Production with no breaks for product changeovers 40. c) Mechanized processes and larger sites replaced manual techniques 41. b) Facilities and manufacturing support systems 42. c) Blue-collar workers 43. b) Managing production and solving technical problems 44. b) Worker-machine system 45. c) Powered equipment 46. b) Automated system 47. b) Semiautomated and fully automated 48. c) Tend to the machine for part of the cycle 19. d) The use of science in industry and engineering to solve problems 49. c) It operates for an extended period with no human attention. 20. c) E-commerce 50. b) Monitor the operation and make occasional adjustments 21. b) All activities, procedures, inputs, and outputs required for production 22. b) Based on product/output variety and product/operations/output volume 23. c) Job Shop 24. a) Production in response to specific customer orders 25. c) Repetitive Manufacturing Systems 51. d) Product inspection 52. c) Business functions 53. c) Fixed automation 54. b) Programmable automation 55. b) Gradual introduction of automation as demand grows 56. a) To amplify or modify force 26. c) Standardization of product and process sequence 57. b) Bicycle 27. d) Mass Production 58. a) Hand tools are manual, while powered tools rely on external power. 28. b) Custom production for each order 29. c) To accommodate variations between batches 59. c) To indicate how parallel or perpendicular a surface is 60. c) Powered tool 61. b) Storage, transformation, or management of materials 96. c) To heat hydrocarbons 62. d) Transportation 97. c) To convert raw materials into products through chemical reactions 63. b) Fixed/Stationary and Rotating/Rotary 98. d) Distillation column 64. c) Fixed equipment 99. d) Introducing a third material that dissolves one of the two materials 65. b) Heat exchangers and pipelines 66. b) They have moving internal parts. 67. b) Dynamic equipment 68. b) Rotating Equipment 69. a) By their circular movements 70. b) Driver, connectors, and driven equipment 71. c) To cause problems or failures within the equipment 72. b) To regulate the flow of fluid 73. a) Manually or Using Actuator 74. d) Gate valve 75. c) It is designed for both ON-OFF and throttling applications. 76. b) Ball valve 77. c) Butterfly valve 78. c) To respond automatically to sudden pressure increases 79. b) To regulate the flow of fluid 80. b) First Law of Thermodynamics 81. b) A substance that changes its shape under force 82. b) Working fluid and process fluid 83. d) All of the above 84. c) Through the partition by conduction 85. a) Co-current flow, counter flow, crossflow, hybrid flow 86. b) Counter flow 87. d) By recuperative vs. regenerative and direct vs. indirect 88. a) Recuperative heat exchangers allow fluid mixing, while regenerative heat exchangers do not. 89. d) Indirect contact 90. c) Single-phase and two-phase heat transfer 91. d) Condenser 92. c) To remove heat from water 93. d) Evaporative cooling 94. b) To heat water 95. b) Water-tube boiler 100. a) When the boiling points of the materials are close together