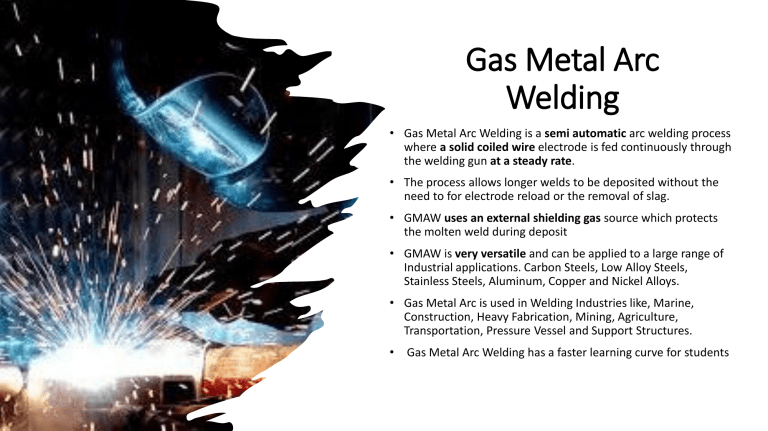

Gas Metal Arc Welding • Gas Metal Arc Welding is a semi automatic arc welding process where a solid coiled wire electrode is fed continuously through the welding gun at a steady rate. • The process allows longer welds to be deposited without the need to for electrode reload or the removal of slag. • GMAW uses an external shielding gas source which protects the molten weld during deposit • GMAW is very versatile and can be applied to a large range of Industrial applications. Carbon Steels, Low Alloy Steels, Stainless Steels, Aluminum, Copper and Nickel Alloys. • Gas Metal Arc is used in Welding Industries like, Marine, Construction, Heavy Fabrication, Mining, Agriculture, Transportation, Pressure Vessel and Support Structures. • Gas Metal Arc Welding has a faster learning curve for students Major Components of the Gas Metal Arc System The GMAW welding system is typically made of up of several major parts that allow the setup to function as it was designed, of course there are many individual parts the discussion today focuses on key features that a wire fed system must contain. Constant Voltage power source or Voltage sensing power source Wire feeder Shielding Gas Supply Regulator / Flowmeter Ground and Gun assembly Consumable wire spool electrode Major Components of the Gas Metal Arc System Constant Voltage power source ( C.V.) • Unlike stick welding which is a manual process where you must keep adjusting your arc length as the electrode becomes shorter, this type of power source allows the arc length to remain near constant as the wire electrode is fed into the arc. • As Voltage is directly relatable to arc length adjusting the voltage up and down changes the arc length and width. The power source keeps the voltage steady and responds to changes in the wire sickout by increasing the amount of amperage required to keep the consumable wire burning off at a steady rate. Constant voltage power sources often have extra controls such as Inductance and slope control added to assist in fine tuning the performance of wire deposition. Major Components of the Gas Metal Arc System Wire Feed Systems: • The wire feed system of wire fed processes is a key component, it feeds the wire through a drive mechanism through the welder's gun (Whip) to the weld pool. This can be done by feeding from a coil of wire (spool) as small as 1.1 lbs up to giant production drums of over 1000lbs. The typical feeder uses a direct drive, constant speed motor to feed the wire at a set rate or constant speed, a common variation allows more portability by allowing the operator to carry the feeder with him. A suitcase feeder (shown to the right) uses a constant current power source then the portable feeder has a voltage sensing clip attached to the work. The voltage sensing feeder changes its speed based on electrode burn off rate. Using this information, the power source can dynamically adjust the speed of the wire feed. Major Components of the Gas Metal Arc System External Shielding Gas Supply : GMAW requires the use of an external shielding gas supply, depending on demands the size of the supply container will vary. High pressure cylinders come in an assortment of size from a small #3 hobby cylinder to #33 light Industrial . The tanks can store 2400psi of compressed gas with large demand customers using Bulk packs which manifold 16 of the large cylinders. In GMAW four gases are commonly selected, Carbon Dioxide CO2, Argon Ar , Oxygen O2, and Helium He. Each of these gases have properties that effect the welding process, density, ionization potential, thermal conductivity, these gases may be inert, oxidizing ,reducing or slow reacting. Shielding gases may be used alone or in a combined form of as many as four combined in a specific ratio to offer the best properties of each. Shielding Gas Regulators and Flowmeters: As the GMAW process requires an external source of shielding gas we require a method of reducing the high-pressure gas to a more useable working pressure. A regulator is attached to the cylinder and by passing the shielding gas through a series of diaphragms and individual chambers inside the regulator we reduce the gas pressure from 2400psi – 50psi. In processes that require external gas supply pressure of the gas is not as critical as the volume of the gas covering the molten weld pool, in order to control this flow a second component is added to device used to control the gas delivery. A flowmeter is used so the welder can deliver the gas to the weld zone in the proper volume in Cubic Feet per Hour. Major Components of the Gas Metal Arc System • Flowmeters shown at right come in two stiles, Needle and Gauge or Tube and Ball. • Flowmeters are designed to measure a specific gas on there measurement scale. • Flowmeters measure Volume not Pressure • Flow rates very depending on environmental conditions, weld position and joint design. • Each gas has a distinct density and requires a different scale to volume. Major Components of the Gas Metal Arc System Welding Gun Assembly & Ground Clamp: In any arc welding system we are essentially building an electrical circuit, our work piece is one pole and the other being the electrode. The ground clamp pictured at right is connected to the negative terminal in the power source while the gun assembly which delivers the electrode is connected to the positive connection which in turn is the drive mechanism in the wire feeder. The gun directs the wire from the feeder through a conduit liner in the gun assembly to the weld pool. Shielding gas, electricity, and the electrode wire are all actuated when a trigger on the gun is depressed. Major Components of the Gas Metal Arc System Consumable Filler Wire: Wire filler metal was a huge advancement in welding process’s, a bare wire filler eliminates the constant starting and stopping of process like stick as well as having no flux almost eliminates the smoke and fume plume. Welding wire is available in diameters from 0.6-3.2mm (0.024”1/8”) , these wires are available for most weldable metals and in the case of gas metal arc welding are solid and for steel may be coated with a copper coating. Each wire type is given a classification code which identifies the supplier, size and weight, lot# control or heat#, country of origin and certification standards. Process’s that feed wire have variations in there design such as Flux Core welding, Submerged Arc welding and Metal Cored welding use hollow wire types with fluxing agents or iron powder inside the wire.