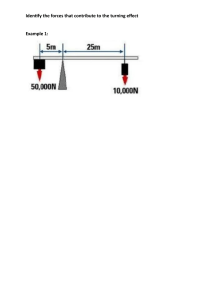

ME 341 FEM/FEA Homework P1: Truss Problem d) Model the truss in Abaqus First create a wire feature and sketch the structure. Then assign a section and material to the elements of the model. Add the load and boundary conditions to the model Apply nodes and a mesh to the model e) Find the displacements at each node Run a job to get results Probe values at each of the nodes to get the results. The displacement is given under the U column. f) Find the stress in each member Similar to the displacement, probe the elements for the stress data Note that the stress is given in the S column in KSI. P2 Stepped Bar with Radius (stress concentration) Only a quarter of the original shape needs to be modeled to save node availability. w Apply a shell section. Fix the left side and add a pressure to the other. Use a partition edge and the seed edge tool to layout the nodes. Run the Job to find the maximum stress of 2.5 MPa 3) Circular Stepped shaft (treat as beam elements) Sketch the wire for the beam Create and apply beam sections with a circular profile After assigning the sections and beam alignment you can choose to render the beam profile Use and encastre boundary condition and a concentration load in the load module Use the Seed edges tool to control the number of nodes placed along the beam. Find the maximum stress caused by this load and compare to the hand calculations. Run the job to see the results, the following results are with 17 nodes. With 17 nodes the maximum stress was 23.1 MPa After reducing the node count to 9, the maximum stress was only 21.5 MPa. Remember that the hand calculation value was 23.9. Now it’s time to increase the node count. With a node count of 41 the max value is 24 MPa, that is close enough to the hand calculation value for the purpose of this assignment. Find the maximum displacement caused by this load Use this menu and change the middle window to U to find displacement. The maximum displacement was found to be 0.411 mm at the right most side of the beam. 4) Pneumatic Cylinder Deflection Create this rod as a single truss element in Abaqus. Explain why we can treat it as such? We can treat the cylinder as a single truss element because it is a 2 force member. This makes the required calculations very simple. Sketch for the single truss element: Find the area and create the section properties for the truss. Seed the mesh along the edge of the beam. 40 elements were created for this problem. Solve for the maximum displacement: Run a job and review the results. The Abaqus calculations state that the maximum displacement is 2.6363E-04 inches while the hand calculations show 2.64E-4 as well. These are very similar to each other. 5) Practical Application (cantilever beam) Analyze within Abaqus and compare the maximum stress to your hand calculation. Reflect on the results. Set up a beam: Use the Pipe profile: Add the concentrated load and fixed boundary condition. Add the elements and run the job Re-run your model with 3,5,20, and 50 elements, and plot the number of elements (x-axis) vs. the maximum stress (y-axis). How many elements do you need to get an accurate result? Number of Elements 3 5 20 50 Maximum Stress (psi) 6652 7184 7783 7903 Element count vs Stress value 8000 7800 Stress value (psi) 7600 7400 7200 7000 6800 6600 6400 0 10 20 30 40 50 60 Number of Elements With a hand calculated result being 7152psi, 5 elements and up have been fairly accurate. This plot also shows the diminishing returns of adding more nodes. I would play it safe and use 20 elements.