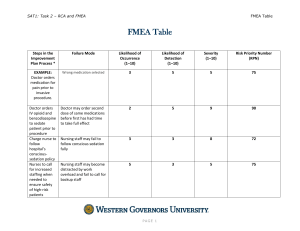

IE0324 Quality Engineering Topic 6B: Failure Mode and Effects Analysis (FMEA) 1 Quality Tools FMEA Failure Mode and Effect Analysis (FMEA) is an analytical technique that combines the technology and experience of people in identifying foreseeable failure modes of a product, service, or process, and planning for its elimination. FMEA consists of a group of activities intended: 1. to recognize and evaluate the potential failure of a product, service, or process and its effects 2. identify actions that could eliminate or reduce the chance of the potential failure occurring 3. document the process. FMEA is initially before-the-event action requiring a team effort to alleviate most easily and inexpensively changes in design and production. There are two types of FMEA: 1. Design FMEA 2. Process FMEA https://www.weibull.com/basics/fmea.htm FMEA ■ “Failure modes” means the ways, or modes, in which something might fail. Failures are any errors or defects, especially ones that affect the customer, and can be potential or actual. ■ “Effects analysis” refers to studying the consequences of those failures. ■ Failures are prioritized according to 1) how serious their consequences are, 2) how frequently they occur and 3) how easily they can be detected. ■ FMEA is used during design to prevent failures. ■ FMEA is used for control, before and during ongoing operation of the process. Ideally, FMEA begins during the earliest conceptual stages of design and continues throughout the life of the product or service. WHEN TO USE FMEA 1. When a process, product or service is being designed or redesigned, after quality function deployment (QFD). 2. When an existing process, product or service is being applied in a new way. 3. Before developing control plans for a new or modified process. 4. When improvement goals are planned for an existing process, product or service. 5. When analyzing failures of an existing process, product or service. 6. Periodically throughout the life of the process, product or service FMEA FMEA PROCEDURE ■ Preparation for the FMEA 1. Design tree/process map: identify all of the different components of a product/design 2. Function tree: identify all of the function for overall design/process and each component the design 3. Failures: determine ways each function can fail ■ * https://www.youtube.com/watch?v=M0Ej466IfZs FMEA PROCEDURE 1. Identify the scope of the FMEA. – Is it for concept, system, design, process or service? What are the boundaries? How detailed should we be? Use flowcharts to identify the scope and to make sure every team member understands it in detail. 2. Assemble a cross-functional team of people with diverse knowledge about the process, product or service and customer needs. – Functions often included are: design, manufacturing, quality, testing, reliability, maintenance, purchasing (and suppliers), sales, marketing (and customers) and customer service. FMEA PROCEDURE 3. Develop process map and identify the functions of your scope from . – Ask, “What is the purpose of this system, design, process or service? What do our customers expect it to do?” – Name it with a verb followed by a noun. – Usually one will break the scope into separate subsystems, items, parts, assemblies or process steps and identify the function of each. 4. For each function, identify all the ways failure could happen. – These are potential failure modes. If necessary, go back and rewrite the function with more detail to be sure the failure modes show a loss of that function. 5. For each failure mode, identify all the consequences on the system, related systems, process, related processes, product, service, customer or regulations. – These are potential effects of failure. Ask, “What does the customer experience because of this failure? What happens when this failure occurs?” FMEA PROCEDURE 6. Determine how serious each effect is. This is the severity rating (S). Severity is usually rated on a scale from 1 to 10, where 1 is insignificant and 10 is catastrophic. If a failure mode has more than one effect, write on the FMEA table only the highest severity rating for that failure mode. 7. For each failure mode, determine all the potential root causes. Use tools classified as cause analysis tool, as well as the best knowledge and experience of the team. List all possible causes for each failure mode on the FMEA form. 8. For each cause, determine the occurrence rating (O) . This rating estimates the probability of failure occurring during the lifetime of your scope. Occurrence is usually rated on a scale from 1 to 10, where 1 is extremely unlikely and 10 is inevitable. On the FMEA table, list the occurrence rating for each cause. FMEA PROCEDURE 9. For each cause, identify current process controls. These are tests, procedures or mechanisms that you now have in place to keep failures from reaching the customer. These controls might prevent the cause from happening, reduce the likelihood that it will happen or detect failure after the cause has already happened but before the customer is affected. 10. For each control, determine the detection rating (D). This rating estimates how well the controls can detect either the cause or its failure mode after they have happened. Detection is usually rated on a scale from 1 to 10, where 1 means the control is absolutely certain to detect the problem and 10 means the control is certain not to detect the problem (or no control exists). On the FMEA table, list the detection rating for each cause. 11. Optional for most industries: Ask, "Is this failure mode associated with a critical characteristic?" (Critical characteristics are measurements or indicators that reflect safety or compliance with government regulations and need special controls.) If so, a column labeled “Classification” receives a Y or N to show whether special controls are needed. Usually, critical characteristics have a severity of 9 or 10 and occurrence and detection ratings above 3. FMEA PROCEDURE 12. Calculate the risk priority number, or RPN, which equals S × O × D. Also calculate Criticality by multiplying severity by occurrence, S × O. These numbers provide guidance for ranking potential failures in the order they should be addressed. RPN value does not mean anything stand alone, but its meaning is shown only in comparison to other RPNs FMEA Analysis Function or Failure Type Process Step Potential Impact What is the Briefly outline impact on the Describe what function, step key output has gone or item being variables or wrong analyzed internal requirements? SEVERITY Potential Causes OCC Detection Mode DET RPN What are the existing controls that How either prevent How severe is What causes frequently is the failure How easy is it Risk priority the effect to the the key input this likely to from to detect? number customer? to go wrong? occur? occurring or detect it should it occur? FMEA Analysis Function or Failure Type Process Step Potential Impact SEV Potential Causes OCC Detection Mode DET RPN What are the existing What is the controls that Briefly outline impact on the How either prevent Describe what How severe is What causes function, step key output frequently is the failure How easy is it Risk priority has gone the effect to the key input or item being variables or this likely to from to detect? number wrong the customer? to go wrong? analyzed internal occur? occurring or requirements? detect it should it occur? Tire function: support weight of car, traction, comfort Flat tire Stops car journey, driver and passengers stranded 10 Puncture 2 Tire checks before journey. While driving, steering pulls to one side, excess noise 3 60 FMEA PROCEDURE 13. Identify recommended actions. These actions may be design or process changes to lower severity or occurrence. They may be additional controls to improve detection. Also note who is responsible for the actions and target completion dates. 14. As actions are completed, note results and the date on the FMEA form. Also, note new S, O or D ratings and new RPNs Severity Rating Scale * 10 Dangerously High Failure could injure the customer or employee. 9 Extremely High Failure would create noncompliance with federal regulations. 8 Very High Failure renders the unit inoperable or unfit for use. 7 High Failure causes a high degree of customer dissatisfaction. 6 Moderate Failure results in subsystem or partial malfunction of the product. 5 Low Failure creates enough of a performance loss to cause the customer to complain. 4 Very Low Failure can be overcome with modification to the customer’s process or product but there is minor performance loss. 3 Minor Failure would create a minor nuisance to the customer but would have minor effects on the customer’s process or product. 2 Very Minor Failure may not be readily apparent to the customer but would have minor effects on the customer’s process of product. 1 None Failure would not be noticeable to the customer and would not affect the customer’s process or product. Occurrence Rating Scale* 10 Very High: Failure is almost inevitable 9 8 1 occurrence every 3 to 4 days or a probability of 3 occurrences in 10 events. High: Repeated failures 7 6 More than 1 occurrence per day or a probability of more than 3 occurrences in 10 events 1 occurrence per week or a probability of 5 occurrences in 100 events. 1 occurrence every month or 1 occurrence in 100 events. Moderate: Occasional failure 1 occurrence every 3 months or 3 occurrences in 1,000 events. 5 1 occurrence every 6 months to 1 year or 1 occurrence in 10,00 events. 4 1 occurrence per year or 6 occurrences in 100,000 events. 3 Low: Relatively few failures 2 1 1 occurrence every 1 to 3 years or 6 occurrences in 1 billion events. 1 occurrence every 3 to 5 years or 2 occurrences in 1 billion events. Remote: failure is unlikely 1 occurrence in greater than 5 years or less than 2 occurrences in 1 billion events. Detection Example FMEA ** https://www.youtube.com/watch?v=oZ7CSFA-Jd0 Design Tree- think of everything in your design Severity Occurrence Detection Post FMEA FMEA Analysis Function or Failure Type Process Step Potential Impact SEV Potential Causes OCC Detection Mode DET RPN Addressing Risks: SEV, Criticality, RPN The order in which risk should be addressed: SEV Criticality (SEV × OCC) RPN = SEV × OCC × DET RPN numbers should not be used alone to prioritize risk! As a general rule, special attention should be given to high severity, and then to high criticality (SEV x OCC), regardless of RPN Quality Tools 33