Food Quality Control- Chapter 4- Quality Assurance & Management Systems-2

advertisement

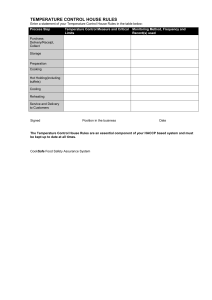

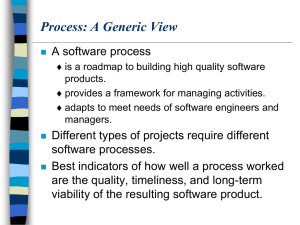

Food Quality Control Quality Assurance & Management Systems Chapter 4 OUTLINE • Quality Assurance & Management Systems: - Introduction. - Important Definitions. - Classification of Quality Assurance & Management Systems: ✓ Basic Safety Systems (GPs: GMP & GHP). ✓ Advanced Safety Systems (HACCP). ✓ Integrated Food Safety Management Systems (ISO 22000). ✓ Basic Quality Management Systems (ISO 9001). ✓ Advanced Quality Management Systems (ISO 9004). 1 introduction ▪ In order to cope with market needs and legal requirements, Food Industries have to satisfy both safety and quality criteria for their products. ▪ Remember: The reasoning behind separating food safety from food quality was due to the need to place the concept of safety first and above all the other quality aspects. 2 Introduction Quality Management Safety The management with regard to quality Quality Planning Quality Assurance Quality Control Quality Improvement setting quality objectives and specifying necessary operational processes to achieve the quality objectives providing confidence that quality requirements will be fulfilled fulfilling quality requirements increasing the ability to fulfil quality requirements 3 Important Definitions Definitions ▪ Food Quality Control: ✓ General: the maintenance of quality at levels and tolerance limits acceptable to the buyer while minimizing the cost for the vendor. ✓ Scientific: the utilization of technological, physical, chemical, microbiological, nutritional and sensory parameters to achieve the wholesome food. ▪ Food Safety: the extent to which those requirements relating specifically to characteristics that have the potential to be harmful to health or cause illness or injury are met. 4 • Quality control (the roof). • With either poor quality control, or even none at all, the house would be exposed to the elements and degrade over time. • Same like a system without quality control would likely not meet its quality needs and the external confidence would decrease. • Quality assurance (the house itself). • It sets up more specific ideas around how the house will look and function. • It’s also what most people see and admire, what they put their confidence in as to whether or not they believe the house will meet their needs. • Quality management (QM) (the foundation of a house). • It sets up your goals for everything inside the house with parameters for what is expected. • It’s hard to set a house up for success without a good foundation, the same way quality would suffer in a company with poor QM. 5 Important Definitions Definitions Cont. ▪ Quality Management System (QMS): A set of coordinated activities to direct and control an organization in order to continually improve the effectiveness and efficiency of it performance. ▪ Quality Assurance: The control, evaluation and audit of a food processing system that provides confidence that quality requirements will be fulfilled. 6 Quality Assurance & Management Systems ▪ Food quality management has become increasingly important, why? This is due to the changing consumer requirements, increased competition, environmental issues and governmental interests. ▪ Therefore, the food sectors utilize various quality assurance systems to successfully implement quality and safety in their products. 7 Quality Assurance & Management Systems ▪ Food Quality Assurance Systems are necessary at every stage of the food chain, and in every sector of the food industry, Why? To ensure both, the quality and safety of food. ▪ Food Quality Assurance Systems implementation and follow-up: 1. Governments’ responsibility: ✓ Establish standards and legislations (laws and regulations). ✓ Establish enforcement programmers and agencies. 2. Food Industries’ responsibility: ✓ Implement quality assurance systems (ensure compliance with standards and legislations). 8 Quality Assurance & Management Systems 9 Quality Assurance & Management Systems 10 Quality Assurance & Management Systems ▪ Some QA systems are obligatory/ legal by law and some are voluntary; that is to be implemented by the food chain industries. ▪ The distinction between obligatory and voluntary systems is based on the safety (hazard-free products) being the quality of food required by law. 11 Quality Assurance & Management Systems ▪ Obligatory/ legal standards are set up by law or through regulations and represent the minimum standards of quality. ▪ Voluntary standards generally represent consumer image, trademark, symbol of product quality. 12 Quality Assurance & Management Systems Quality Assurance & Management Systems Obligatory Systems: Safety Assurance Systems Voluntary Systems: Quality & Management Systems 13 Quality Assurance Systems Safety Assurance Systems ▪ There are obligatory systems that were established to assure food safety. ▪ These systems include: Basic safety systems (Prerequisite systems) & Advanced safety systems (HACCP). ▪ Basic safety systems (Prerequisite systems) include: GMP, GHP, GLP, GKP, GAP, & GCP. 14 Quality Assurance Systems 1. Basic Safety Systems - Prerequisite programs ▪ Prerequisite programs: are programs and practices that are put in place to maintain a sanitary environment and minimize the risk of introducing a food safety hazard. ▪ The two prerequisite programs for HACCP are generally: Good Manufacturing Practice (GMP) & Good Hygiene Practice (GHP). 15 Quality Assurance Systems Prerequisite programs- gmp ▪ Good Manufacturing Practice (GMP): A set of Guidelines specifying activities to be undertaken and conditions to be fulfilled in food manufacturing processes in order to assure that the food produced meets the standards of food safety. ▪ GMP covers all aspects of production from the starting materials, premises and equipment to the training and personal hygiene of staff. 16 Quality Assurance Systems Prerequisite programs- gmp (10 principles) 1. Writing procedures 2. Following written procedures 3. Documenting for traceability 4. Validating works 5. Designing facilities and equipment 10. Auditing for compliance 9. Component control 8. Cleanliness 7. Job competence 6. Maintaining facilities and equipment 17 Quality Assurance Systems gmp- Principles of GMP 1. Writing procedures ▪ The first principle of GMP is: to develop detailed step-by-step procedures, in writing, that provide a "road map" for consistency in performance. ▪ Importance of written procedures: Allow for workplace standards to be clearly established, ensuring that a job or procedure is performed in the same way each time, with each step followed as set out in the written instructions. 18 Quality Assurance Systems gmp- Principles of GMP 2. Following written procedures ▪ The written procedures will only be effective if they are followed to the letter (Following written procedures). ▪ Therefore: It is important that no shortcuts or modifications (even to save time and make easier) be permitted, Why? Bcoz any deviation from the written instructions may adversely affect consistency in product quality. 19 Quality Assurance Systems gmp- Principles of GMP 2. Following written procedures Cont. ▪ When can I deviate or modify some written procedures? ▪ Only with the approval of a supervisor or the Quality Department. “ Ideas for improvement are always encouraged” 20 Quality Assurance Systems gmp- Principles of GMP 3. Documenting for traceability ▪ The third GMP principle is Documenting for traceability. ▪ It asks for prompt and accurate documentation of work, thus allowing for compliance with regulations and the ability to trace any problems. 21 Quality Assurance Systems gmp- Principles of GMP 3. Documenting for traceability Cont. ▪ Importance of accurate records: 1. Provide a way to evaluate what happened if there is ever a problem or complaint regarding a product. 2. This record keeping also chronicles the precise steps taken relating to GMP regulations. 22 Quality Assurance Systems gmp- Principles of GMP 4. Validating works ▪ This GMP principle notes the importance of validating that all systems and processes are working as they are meant to. ▪ How this is achieved? Through documentation and properly following the written procedures, thus ensuring that quality and consistency are carried out 23 according to plan. Quality Assurance Systems gmp- Principles of GMP 4. Validating works Cont. ▪ Examples on things that need validation: 1. New facilities and equipment. 2. Significant changes to existing systems. 24 Quality Assurance Systems gmp- Principles of GMP 5. Designing facilities and equipment ▪ This fifth GMP principle outlines the importance of integrating productivity, product quality and employee safety into the design and construction of the company's facilities and equipment. ▪ Importance of this step: Reinforces the goals of quality and consistency at all stages of the process. 25 Quality Assurance Systems gmp- Principles of GMP 5. Designing facilities and equipment Cont. ▪ Help: 1. Remove unnecessary traffic in the production area which could result in a hazardous environment. 2. Segregate materials, products, & their components to minimize confusion and potentials for mix-ups and errors. ▪ Very important to control the following within a food production plant so that it does not impact product quality: Air, Water, Lighting, Ventilation, & Temp. 26 Quality Assurance Systems gmp- Principles of GMP 6. Maintaining facilities and equipment ▪ Here: equipment and facilities must be properly maintained, with documented written records to back up any work done. ▪ Importance of this step: Minimizes any safety concerns and avoids any potential issues relating to contamination and quality control. 27 Quality Assurance Systems gmp- Principles of GMP 7. Job competence ▪ Job competency must be clearly demonstrated by each employee relating to his job. ▪ GMP requires an employee to be completely competent in his role. ▪ However, the definition of competence may vary for different people. ▪ Therefore it's important that clearly defined and developed job competencies are in place relating to each job. 28 Quality Assurance Systems gmp- Principles of GMP 7. Job competence Cont. 29 Quality Assurance Systems gmp- Principles of GMP 7. Job competence Cont. ▪ How to make competent employees? By training all employees which include: 1. Basic training on the theory and practice of GMP. 2. Specific training relative to their role. 30 Quality Assurance Systems gmp- Principles of GMP 8. Cleanliness ▪ The importance of this eighth GMP principle: is to ensure a product is protected from contamination. ▪ The first step in achieving this is to make cleanliness in the workplace a daily habit. ▪ The degree of cleanliness needed depends on the type of product being manufactured. ▪ That’s why standards must be put in place to ensure the appropriate cleanliness guidelines are followed. 31 Quality Assurance Systems gmp- Principles of GMP 9. Component control ▪ This principle involves building quality directly into products via the systematic control of components and processes relating to each product. ▪ Quality control includes: Manufacturing, packaging, labeling, distribution and marketing. ▪ By placing clearly defined controls over all these areas and keeping accurate, timely records = quality is built into all stages of production. 32 Quality Assurance Systems gmp- Principles of GMP 9. Component control Cont. ▪ Check all materials/ components before they enter the plant. ▪ For employees: Must establish records & producers to make sure they preform same job every time. ▪ Must have a master record that: 1.outlines the specifications & manufacturing procedures. 2. Have individuals batch/ history (conformance). Approved materials/ components ▪ Identify materials/ components and store in quarantine areas for sampling & testing. Raw Materials Controls ▪ Rejected materials/ components must be identified and stored in secure area (to prevent accidental use). Manufacturing Process Controls 3. Have written schedule & procedures for cleaning & maintaining the equipment and areas. 33 ▪ Controls must be against contamination, mix-up, & errors (Records). Holding & Distribution Controls ▪ Assign a batch/ lot number to each product (to enable traceability). Packaging, Labeling, & Controls ▪ Make sure packaging & labeling areas are empty before each new batch. Quality Assurance Systems gmp- Principles of GMP 10. Auditing for compliance ▪ Finally, how to determine how well GMP is being implemented? ▪ Is by conducting planned periodic audits to assess the success of compliance with GMP regulations. 34 Quality Assurance Systems gmp- Principles of GMP 10. Auditing for compliance Cont. ▪ Types of audits: 1. External audits: Audits preformed by external bodies such as the Food & Drug Administration (FDA). 2. Internal audits: In-house audits & self-inspections, done periodically by independent & qualified people. Remember: “Audit” itself is a checking system, not a quality assessment. 35 Quality Assurance Systems gmp- Principles of GMP ▪ So GMP in Food Industry covers: 1. 2. 3. 4. 5. 6. 7. 8. Personnel Plant & grounds. Sanitary operations. Sanitary facilities & controls Equipment and utensils Processes and Controls Warehousing and distribution Maximum defect action level 36 Quality Assurance Systems Prerequisite programs- gHp ▪ Good Hygiene Practice (GHP): A set of Guidelines specifying activities to be undertaken and hygienic conditions to be fulfilled and monitored at all steps of the food chain in order to assure that the food safety is met. ▪ Sanitary Standard Operating Procedures (SSOPs): is a written document of procedures or programs used to maintain equipment and the environment in a sanitary condition for food processing. 37 Quality Assurance Systems Prerequisite programs- gHp ▪ Aim of GHP: To implement the essential principles of food hygiene applicable throughout the food chain (including primary production through to the final consumer). ▪ Why? To achieve the goal of ensuring that food is safe and suitable for human consumption. 38 Quality Assurance Systems Prerequisite programs- gHp 39 Quality Assurance Systems Prerequisite programs ▪ Both GMP and GHP constitute a precondition in a food enterprise for implementing the HACCP system. The relationship between these three food systems, where HACCP is a broader category which incorporates its prerequisites GMP and GHP. 40 Quality Assurance Systems Advanced Safety System-HACCP ▪ What is HACCP: 41 Quality Assurance Systems Advanced Safety System-HACCP ▪ Definition of HACCP: A systematic food safety assurance method to identify, evaluate and control of food hazard. ▪ History of HACCP: Developed by NASA and U.S. Army, why? To ensure that the foods developed for astronauts are free of pathogens and safe for consumption. Then later, HACCP were applied to all food company that care about consumers safety. 42 Quality Assurance Systems Advanced Safety System-HACCP ▪ HACCP System: The principles of HACCP system have been adopted by the Codex Alimentarius Commission and guidelines to its application are provided in an Annex to the General Principles of Food Hygiene (FAO and WHO, 2003). The system consists of 12 stages of implantation, of which 5 are preliminary tasks and 7 are HACCP principles. 43 44 Quality Assurance Systems Advanced Safety System-HACCP ▪ Difference between prerequisites (GMP & GHP) and HACCP: ✓ While prerequisite programs may impact upon food safety, they also are concerned with ensuring that foods are wholesome and suitable for consumption. ✓ However, HACCP plans are narrower in scope, being limited to ensuring foods safe to consume. 45 Quality Assurance Systems Voluntary Implemented systems ▪ Maintenance and / or introduction of the remaining qualities of food (nutritional, sensory and convenience values) is not requested by law, but by consumers desires. ▪ These voluntary systems include: ✓ Quality Assurance Control Points (QACP). ✓ Quality Management ISO-9000). System (QMS; ✓ Total Quality Management (TQM). 46 Quality Assurance Systems Quality Assurance Control Points - QACP ▪ Quality Assurance Control Points (QACP): One of the quality assurance systems in food production. ▪ QACP was created based on the HACCP concept. 47 Quality Assurance Systems Quality Assurance Control Points - QACP Differences Concerned Measuring Example QACP HACCP Quality assurance (not safety) Determine the assurance control points, parameters, and their critical values Sweetness in terms of amount of sugar Safety Determine the critical control points, parameters, and their critical limits Temperature in Celsius degrees QACP HACCP 48 Quality Assurance Systems Quality Assurance Control Points - QACP Similarity QACP HACCP Unique for each company Unique for each company Must be introduced individually for each enterprise and production line Must be introduced individually for each enterprise and production line QACP HACCP 49 50 Quality Assurance Systems GMP/ GHP Basic safety systems Food Hygiene HACCP Advanced safety systems Food Safety QACP Quality assurance systems Food Quality 51 Quality management Systems - QMS (ISO) & TQM 1. Quality Management Systems (QMS) ▪ ISO 9000 series: including ISO 9000 and ISO 9004. ISO 9001: the most recognized and implemented quality management system standard in the world (ISO 9001: 2015). ▪ ISO 14000 series: environmental management systems. ▪ ▪ ▪ ISO 13485: quality management systems for medical devices. ISO 19011: auditing management system. 2. Total Quality Management Systems ▪ TQM: Total Quality Management. 52 Quality management Systems - QMS (ISO) 1. ISO 9000 Standards ▪ ISO = International Organization for Standardization. ▪ ISO 9000 series: Represents the requirements which have to be addressed by every enterprise to assure the reliable production and timely delivery of goods and services to the marketplace. 53 Quality management Systems - QMS (ISO) 1. ISO 9000 Standards Cont. ▪ Many food chain actors require their suppliers to become registered to ISO 9000, that’s why? Those who register for ISO 9000 find that their market opportunities have increased. ▪ Remember: Although ISO 9000 series are very popular, yet they are not and will never become obligatory. 54 Quality management Systems - QMS (ISO) 55 Quality management Systems - QMS (ISO) 1. ISO 9000 Standards Cont. ▪ ISO 9000 series had a major revision in 2000 when 3 standards (9001, 9002, 9003) were combined into one called ISO-9001. ▪ ISO 9001: The international standard that specifies requirements for a quality management system (QMS). 56 Quality management Systems - QMS (ISO) A. ISO 9001 Standards ▪ ISO 9001 made a radical change in thinking, how? By actually placing the concept management front and center. of process ▪ Process Management: Monitoring and optimization of a company’s tasks and activities, instead of just relying on inspection of the final product. ▪ ISO 9001 is the only standard in the family that can be certified to (although this is not a requirement). 57 Quality management Systems - QMS (ISO) A. ISO 9001 Standards Cont. ▪ This standard is based on a number of quality management principles including a strong customer focus, the motivation and implication of top management, the process approach and continual improvement. ▪ Using ISO 9001 helps ensure that customers get consistent, goodquality products and services, which in turn brings many business 58 benefits. Quality management Systems - QMS (ISO) 59 Quality management Systems - QMS (ISO) A. ISO 9001 Standards Cont. ✓ The relationship between ISO 9001 and HACCP. ▪ HACCP principles are often combined with ISO 9001, why? So that the technological and management issues regrading food safety and quality are achieved. ▪ Therefore, ISO 9001 can be helpful for the application of HACCP. 60 Quality management Systems - QMS (ISO) A. ISO 9001 Standards Cont. 61 Quality management Systems - QMS (ISO) B. ISO 9004 Standards ▪ ISO 9004 goes beyond ISO 9001, how? By providing guidance on how one can continually improve it’s business’ quality management system. ▪ Beside benefiting the customers, ISO 9004 benefits also: employees; owners; suppliers; society in general. 62 Quality management Systems - QMS (ISO) Requirements of a Quality Management System (QMS) ISO 9000 Standards ISO 9001 Standards ISO 9004 Standards Describes vocabulary Describes only the requirements Describes guidelines for improvements Latest ISO-9000: 2015 Latest ISO-9001: 2015 Latest ISO-9004: 2018 63 Quality management Systems - TQM 2. TQM ▪ TQM = Total Quality Management. ▪ TQM: Is an integrative philosophy of management for continuously improving the quality of products and processes focusing on consumers satisfaction. 64 Quality management Systems - TQM 2. TQM Cont. ▪ It is a continuous process by the management and employees of a specific organization to make sure future customer satisfaction and customer loyalty. ▪ In other words, one satisfied and happy customer indeed brings ten new customers along with him. In comparison, one unsatisfied customer will spread bad word of mouth and harm the existing 65 environment and potential customers. Quality Assurance Systems Integrated food safety management- iso 22000 ▪ ISO 22000: Is a food safety management private standard that is developed based on the ISO 9001 approach. ▪ The standard ISO 22000 offers an alternative to food organizations which do not implement ISO 9001 and want to have an effective food safety management. 66 Quality Assurance Systems Integrated food safety management- iso 22000 ▪ ISO 22000: 2018 Certification is built around Seven Principles: 1. Analysis of food hazards: Biological, chemical or physical. 2. Identification of critical control points: Raw materials, storage, processing, distribution and consumption. 3. Establishment of critical control limits and preventive measures: For example, minimum cooking temperature and time. 67 Quality Assurance Systems Integrated food safety management- iso 22000 ▪ ISO 22000: 2018 Certification is built around Seven Principles: 4. Monitoring of these critical control points. 5. Establishment of corrective actions. 6. Keeping records. 7. Systematic and regular auditing of the system in place by independent third party certification bodies. 68 Quality Assurance & Management Systems “Management” refers to company “Assurance” refers to product IS0 22000 GMP/ GHP HACCP QACP QMS TQM Basic safety Total quality Quality management management systems Advanced safety Quality assurance systems Food Hygiene systems systems systems ISO 9000 Food Safety Quality Improvement Food Quality Obligatory Systems Voluntary Systems 69 Quality Assurance & Management Systems ▪ Quality Control vs. Quality Assurance vs. Total Quality Management. 70