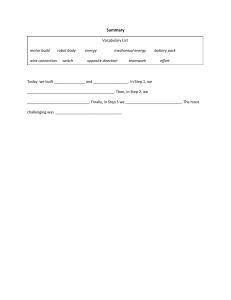

KIET GROUP OF INSTITUTIONS, GHAZIABAD Mid Term Internship & Project Progress Submitted By: Abdul Amaan 2000290210002 Section A Mentor: Prof. Alok Pandey Project Guide: Dr. Sourav Diwania ELECTRICAL & ELECTRONICS ENGINEERING DEPARTMENT KIET GROUP OF INSTITUTIONS, GHAZIABAD Dr. A. P. J. ABDUL KALAM TECHNICAL UNIVERSITY, UTTAR PRADESH, LUCKNOW MID TERM INTERNSHIP AMREST ELECTRICALS LTD. AMREST Electricals Limited manufacture World class Indoor and Outdoor Transformer. Add: H.F: LGF-81, Pocket-1, Jasola Vihar-110025 Unit - 1/75, Industrial Area Siyana Road, Bulandhshar203001, India Instrument Transformers • Instrument transformers are devices used in power systems to transform high currents and voltages into measurable and manageable levels. • They are essential for safety and accuracy in electricity generation, transmission, and distribution systems Types of Instrument Transformers INSTRUMENT TRANSFORMER 3 CURRENT TRANSFORMER POTENTIAL TRANSFORMER Current Transformer (CT) A Current Transformer, often referred to as a CT, is a type of instrument transformer used to measure alternating current (AC) flowing in a circuit. Its primary function is to step down the current in a power system to a manageable level for measurement purposes. Construction: A CT consists of a primary winding and a secondary winding. The primary winding is connected in series with the circuit carrying the current to be measured, while the secondary winding is connected to a measuring instrument, such as an ammeter. Types of CT: • Dry Type (INDOOR) • Oil Cooled (OUTDOOR) Potential Transformer (PT) A Potential Transformer, also known as a PT or Voltage Transformer (VT), is another type of instrument transformer used to measure voltage in electrical power systems. Similar to CTs, PTs are designed to step down the voltage to a safe and measurable level. Construction: A PT consists of a primary winding, connected across the voltage to be measured, and a secondary winding connected to the voltmeter or any other measuring device. Types of PT: • Dry Type (INDOOR) • Oil Cooled (OUTDOOR) Few other things left to cover because my internship is still on PROJECT D esign an d developm ent ofB LD C based E -vehicle Electric vehicles are the future, and BLDC motors offer benefits like better efficiency and lower maintenance costs. Let's explore how we can design and develop a BLDC-based E-vehicle for a sustainable future. INTRODUCTION Electric vehicles (EVs) have come to be recognized as a ground-breaking approach to overcoming environmental issues and lowering carbon emissions as the globe works to make the transition to a greener and more sustainable future. The BLDC-based electric vehicle (EV), which offers the ideal balance of efficiency, performance, and reliability, has emerged as the dominant electric propulsion technology. The abbreviation BLDC, or Brushless DC, stands for the advanced motor technology that has transformed the automobile sector. BLDC motors, in contrast to traditional brushed DC motors, use electronic commutation, which eliminates the need for mechanical brushes and commutators. With this design improvement, efficiency is increased, maintenance costs are decreased, and the driving experience is generally better. BLDC MOTOR Due to its efficiency, dependability, and compact design, Brushless DC (BLDC) motors are a type of electric motor that are frequently utilized in electric vehicles (EVs). Its use of electronic commutation as opposed to brushes and a commutator makes it different from ordinary brushed DC motors. Without brushes, there is less wear and friction, which leads to greater effectiveness and a longer lifespan. KEY FEATURES: • Better Efficiency • Supports Regenerative Breaking • High Power-to-Weight Ratio • Quiet Operation • Precised Control CONTROLLER A crucial part of an electric vehicle powered by brushless DC (BLDC) is the controller, which regulates the motor's functioning and ensures accurate and effective management of the vehicle's speed and torque. As the brain of the electric vehicle's drivetrain, it processes information from multiple sensors and sends the appropriate signals to the BLDC motor to ensure peak performance. KEY FUNCTIONS: • Commutation Control • Speed-Torque Control • Regenerative Breaking Control • Battery management system (BMS) Integration • Communication Interfaces • Safety Features BATTERY MANAGEMENT SYSTEM In a BLDC (Brushless DC) based electric vehicle, the battery is a crucial component responsible for storing and supplying electrical energy to power the motor and other electrical systems. The battery's capacity, performance, and management play a vital role in determining the overall range, efficiency, and performance of the electric vehicle. Key points that needs to be remember while opting a batter for the e-vehicle: • Battery Chemistry • Battery Pack • Battery Capacity & Range • Cell Blancing Why BLDC Motor? 1 Efficiency BLDC motors have high efficiency, lower losses, and can operate on battery power. 2 Low Maintenance As there is no brush friction, the wear and tear on the motor is minimal compared to traditional motors. 3 No Electromagnetic Interference BLDC motors produce less electromagnetic interference and noise, making them suitable for various applications from transportation to medical devices. 4 Fuel Efficiency Optimization BLDC motors can be paired with a battery for fuel efficiency optimization, thus reducing energy costs and conserving the environment. Benefits of BLDC Motor Compact Design High Torque BLDC motors come in a compact size, making BLDC motors have high torque, enabling better them ideal for a variety of applications from performance and acceleration over regular drones to electric vehicles. motors. Long Life Expectancy More Control BLDC motors have a longer life expectancy and BLDC motors enable more precision and control can last up to four times longer than traditional over speed and torque, and can change direction motors, making them a cost-effective option. easily. Vehicle Structure Adjustable Suspension System The suspension system is adjustable based on road conditions for better handling, steering, and braking in varying road conditions. 1 2 3 Battery and Motor Placement On-Board Charging The battery pack is located towards the bottom The E-vehicle comes with a built-in charger, of the car, giving the vehicle a low center of enabling users to charge batteries in a variety of gravity for better stability, while the motor is settings from houses to charging stations. typically installed in-line with the rear wheels. Conclusion 1 Future Possibilities The future is bright for sustainable energy sources, and E-vehicles and their components will be a significant part of it. B en efits ofE -V ehicle E-Vehicles can reduce greenhouse gases, improve air quality and provide cost-saving benefits. 2