Indian Journal of Fibre & Textile Research

Vol. 16, March 1991 , pp.52-64

Advances in high performance fibres

Safish Kumar

School of Textile and Fiber Engineering, Georgia Institute of Technology, Atlanta , GA 30332, USA

Received 7 November 1990

This paper briefly describes the structure, properties, manufacture and applications of various high

performance fibres such as polymeric fibres (a ram ids, extended chain polyethylene, and ordered polymeric

fibres) , carbon fibres, inorganic fibres (silicon carbide, boron , alumina and glass fibres), fibres for optical

communication and electrically conducting polymeric fibres. Various other industrial fibres are also considered . Some issues related to the compressive and tensile properties of these fibres are also discussed.

Keywords: Carbon fibres , High performance fibres, Inorganic fibres. Polymeric fibres

Introduction

The field of high performance fibres has witnessed

considerable growth in the last three decades l - 4 . A

large number of high performance polymeric fibres ,

carbon fibres and inorganic fibres are in the market

today . It is not possible to discuss in detail all the

aspects of this subject in this paper due to the

limitation of space and, therefore, an attempt has

been made to briefly present the structure, properties,

manufacture, and a pplications of some of the high

performance fibres a vailable today ; the list of fibres

covered is by no mea ns exhaustive. Only a limited

number of references have been documented as many

texts and encyclopedia articles referenced at the end

serve as comprehensive source mate ri a l. Significant

research in many diverse aspects of high performance

fibres continues and , therefore , further improvements in properties and development o f newer a rea s

of applications can be expected. The high cost of

many of these fibres continues to be one of the growth

restricting factors. The present approximate pri ce

range in the USA for high pe rformance polymeric

fibre s is $ 10-50/ lb; ca rbon fibres, $ 25-1000/ lb; SiC

fibre s, $ 100-4000/l b ; alumina fibres, $ 250/lb; and

boron fibres , $ 600/lb. The properties of various fibres

arc given in Table I.

2 Polymeric Fibres

2.1 Aramid Fibres

The most common aramid fibre is poly(p-phenylene

terephthalamide) (PPT A). PPT A is synthesized by

the condensation of terephthaloylchloride (CICOC 6 H 4-COCI)

and

p-phenylene

diamine

52

(H 2N-C 6 H4-NH2) in a mixture of hexamethylpho

phoramide and n-methylpyrrolidone. The latter t",

chemicals act as solvents. The product is conl

nuously stirred and cooled and subsequently grour

in water and filtered . The resulting solid polymer

thoroughly washed. A polymer of minimum intrins

viscosity of 4 dl/g, measured in s ulphuric acid ,

preferred for satisfactory fibres . This fibre is SpL

from nematic liquid crystalline solution using

dry-jet wet spinning technique, where sulphuric ac

has been used as II solvent and cold water :

coagulant. The coagulated fibre is washed , dried an

heat treated . Kevlar™ 149 is the highest tensi

modulus aramid fibre currently available. The cryst.

structure of PPT A is pseudo-orthorhomb

(essentially monoclinic) witli a = 0.719 nm , b = 0.51

nm , c(fibre axis)= 1.29 nm , and y =90°. There al

two chains per unit cell and the theoretical cryst:

density is 1.48 g/cm 3 . However, Kevlar™ 149 is

relatively newer fibre and most of the structural dal

is available on Kevlar™ 49. Apparent crystallite si;

in Kevlar™ 49 is 6.5, 5.3 and > 10.9 nm measure

from (110) , (200) and (006) reflections respective

using wide-angle X-ray scattering (WAXS). Base

primarily on electron microscopy observations (

peeled sections ofKevlar™ 49, it was concluded tho

the supermolecular structure has radially oriente

crystallites. This fibre is also characterized by

pleated structure along the fibre axis, the ang

between pleats reportedly being about 170°, and tt

overall fibre structure being fibrillar. The pleate

structure has not been reported in Kevlar™ 141

PPT A degrades in air above 450°C, and does not me

below this temperature. The value of optic:

SAllSH KUMAR: HIGH PERFORMANCE FIBRES

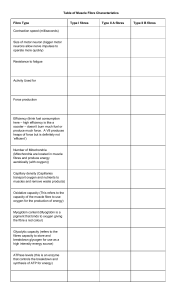

Ta ble I- Properties of various high perfonnance fibres

Fibre

CTE b

(ppm/"q

Mod ulus

(GPa)

Tensile

strength

(GPa)

Density

(g/cmJ)

Compressive"

strength

(GPa)

280-360

3.5-5.7

125

3.5

1.58

1.44

0.2-0.4

0.39-0.48

-7 to - 10

-4.0 (59)1

185

170

3.4

3.0

1.47

0.97

0.32-0.46

0. 17

-1.5

90

75

415

200

186

393

400

210

350-380

4.5

3.5

2.46

2.58

2.5-2.6

> I.l e

Thermal

conductivity

W/(mK)

Electrical

resistivity

(11 ohm-m)

Polymeric fibres

PBom

Kevlar™ 49

Kevlar™ 149

Spectra ™ 1000

0.04

Inorga nic fibres

S-Glass

E-glass

Boron k

Nicalo n™

Nextel™ 440 P

Sigma q

SiC (CVD)k

SijTi/C/on

AI 20 3 fibre

Asbestos;

169

3.5

2.8

2. 1

3.5

3.45

2.8

>0.8I c

5.9

2.5

4.9

4.5

1.04

-

1()8

2.8

3.05

3.4

3.0

2.37

3. 1

3. 1

5.0

3.0

1.5-2.3

1.7

3.li

3.7

2. 5

6.9

6.8

1.15

0.48

- 1.48 (9.4)

300-500

2.5-3.6

-0.5 (12)

- 1.22 (6. 7)

15

15

3. 1

Pitch-based carbon fibres

P_25 d

P_IOOd

725

1.4

2.2

E-1 30'

900

3.9

1.90

2. 15

2.19

T-300d

235

T-50d

T_IOOOf

390

295

3.2

2.4

1.76

1. 8 1

2.88

1.61

2.76

1.06

14

520

235

7. 1

1. 8

1. 82

K

2.69

1. 67

15

160

PAN-based ca rbo n fibre s

GY-70

AS-4 h

M60 Jf

585

3.6

3.8

1.96

1. 80

1.94

a-Compressive strength va lues a re measured from different tests, refer to reference 21 for details. b-CTE values are in the longitudinal direc ti on, values in pa rentheses are CTE val ues in tra nsverse direction. c- Higher compressive strength fo r glass fibre has been

reported 3 • - 36 d - Amoco fibres. e- DuPont fib res . f- Toray fibre s. g- Celi on ™ fibre. h- Hercules fib re. i-Chrysolite.

j - Tensile strength ex trapo lated fo r zero fibre cross-section . k- Fibre fro m Textron Speciality Ma terials. I-CTE values in

Kevlar are ~e portedJ 8 to have significant va riation with moist.ure and tension, va lues of up to - 11 .8 ppm/"C are reported for Kevlar™

49. m- Fi bre at pilot plant stage at Dow C hemical Co. n- Fi bre from Ube Industri es (Japan), ava ilable in USA from Textro n

Speciality Mate ria ls. p-Fi bre from 3M. q- Fi bre fro m BP Ameri cas.

-For 20/80 (by vo lume) Boron/AI composite Elect rical resistivit y value is 0.04 11 oh m-m.

birefringence for Kevlar™ 29 fibre is 0.652 a nd that

for Kevlar™ 49 fibre, 0.662

(n II = 2.267 ,

n..L = 1.605); the fo rm birefrin gence correction was

not reported in either case. Due to the presence of

radial structure, Kevlar™ also ex hibits latera l

birefringence in the range of 0.022-0.065, where the

lateral birefringence is defined as ~nl ate ra l =nr - n l , nr

and nt being the radial and tangential refractive

indices perpendicular to the fibre axis. Strain

birefringence has a lso been repo rt ed in Kevl a r and it

has been concluded tha t birefringe nce increases with

strain even at rel atively constant fibre modulu s 5 .

Aramids have high radiation resistance; however,

prolonged exposure to light and ultra-violet

radiation has a detrimental effect on mechanical

properties. Aramids have hi gh corrosion resistance,

and are generally extremely resistant to chemical

attack except by strong acids a nd bases at high

concentrations. Small-angle X-ray sca ttering (SAXS)

indicates diffuse small-angle scattering on the equator

indica ting void s elongated along the fibre axis. In

Kev lar™ 29 and Kevlar™ 49, the voids have been

estimated to be abo ut 25 nm long and 5-10 nm wide 1 .

Non-linear elastic deformation in Kevla r™ has also

53

INDIAN 1. FIBRE TEXT. RES., MARCH 1991

been studied 6 . Aramid fibre from Akzo is available

under the trade name Twaron TM.

These fibres are used in body armour and cables.

Kevlar™ 49 and Kevlar™ 149 are used in composites

for applications in aerospace and sports goods.

Another a ramid fibre is poly(m-phenylene

isophth.nlamide). It is availa ble under the trade name

Nomex NM and its significant use is in fire protective

clothing. Aramid fibres ha ve been discussed in detail

in Chapter XVII (ref. I) and in references 7-9.

2.3 Ordered Polymeric Fibres

The term 'ordered polymers' is generally used fo

aromatic heterocyclic rigid-rod and semi rigid-rol

polymers because of their ability to form highl

?rdered structures in the solid state. These polymer

Include the rigid-rods PBZT (poly p-phenylen

benzobisthiazole), and PBO (poly p-phenylen

benzobisoxazole), and semi rigid-rods ABPBO (pol:

2, 5-benzoxazo le), ABPBT (poly 2, 6-benzothiazole

and ABPBI [poly 2, 5(6)-benzimidazole]. Significan

development work on these polymers has been doni

at t~e US Air Force Materials Laboratory since th,

2.2 Extended Chain Polyethylene

High modulus fibres can also be made from flexible sIxtIes. Developments in the last decade in synthesi

chain polymers, if the molecules in the fibre are in the (including an economic monomer synthetic route fo

extended state. Extended chain polyethylene fibres PBO) and processing of aromatic heterocyclil

have been made and commercialized. This can be polymers have led to the consideration 0

of

poly(p-phenylenl

done by (i) solid state extrusion, and (ii) spinning of commercialization

benzobisoxazole) PBO fibres , while most earl'

ultra-high molecular weight polyethylene gel.

The work on solid sta te extrusion was carried out by development work was done on PBZT fibre. Th;

compiled in tW(

Ward and coworkers [Chap. XVIII (ref. I) a nd the work on ordered polymers ha s been

l4 . 1 5

recent

encyclopedia

chapters

and in the

10 11

references therein], and Porter and coworkers • .

Materials

Research

Society

Symposium

Proceed

The high modulus fibres prepared from so lid state

ings4.

extrusion are currently limited in tensile strength and,

Cis-PBO is polymerized using 4, 6-diamino-1

therefore, have not yet been commercialized, even

3-benzenediol

dihydrochloride (DABDO) and tere

though this process would have economy of scale as

phthalic

acid

(T

A) in polyphosphoric acid (Fig. 1)

no solvents are involved . The gel spinning of

PBO

and

other

ordered polymers are soluble ir

polyethylene is mostly due to the work of Pennings

strong

protic

aci

ds such as polyphosphoric acid

and his coworkers at Dutch State Mines Laboratory

(PPA),

methanesulphonic

acid (MSA), chlorosul·

to begin with and a fter that at the Univers:ty of

phonic

acid

(CSA),

and

100%

sulphuric acid. The

Groningen with la ter refinements by Smith and

PBO

fibre

has

a

degradati

on

tempera

ture of > 600

Lemstra 12.13 . Typica ll y, a so lution of 5% ultra-high

in

air

and

>

700°C

in

inert

atmo

sphere.

No Tg or Trr

molecular weight (> one million, generally 3-7

has

been

observed

below

degradation

temperature.

million) polyethylene in paraffin oil (other solvents

have also been used) is extruded in n-hexane.The fibre I so th~rm a l ageing studies on PBO indicate virtuall)

is dried under vacuum and then drawn in a tube no weIght loss after hea ting in air at 300°C for 200 h.

containing silicon oil with a temperature gradient of and 90% weight retention after heating at 343°C (alsc

100-148°C The so lution sp un extended chain for 200 h in air). Typical molecular weight used for the

polyethylene fibres are made by Allied Chemical spinning of this fibre is generally in the ra nge 01

Corp. , USA (trade name Spectra TM) , DSM , 50000-100000 dalton s; this corresponds to abou1

Netherlands (trade name Dyneema TM), and Mitsui , 200-400 repeat units per chain. The estimate of the

Japan (trade name Tekmilon TM) . Extended chain

NH 'HCI

polyethylene fibres exhibit significant creep, and their HCI'H2N

modulus and tensile strength exhibit high strain rate

2

+ HOOC-Q-COOH

dependence. Creep and the strain rate dependence of

HO

OH

mech anical properties is significantly less in other

reinforcing fibres . In addition to being considered as

DABDO

TA

reinforcements in composites, the extended chain

polyethylene fibres are used in bullet proof vests,

ropes, sail cloth , etc. It is possible that the

gel-spinning technology may prove to be successfully

in making high modulus fibres from other flexible

n

chain polymers also. Extended chain polyethylene

PSO

fibres have been described in detail in Chapter XVIII

(ref. I).

Fig. I- Synthesis of PBO

0

(

)0(

1

t~~

54

SATISH KUMAR: HIGH PERFORMANCE FIBRES

persistance length ofPBO is > 50 nm. Mark-Houwink

relationship for PBO in methanesulphonic acid is

given by:

[11]=2.77 x 10 - 7 M;8

Very high value of Mark-Houwink exponent (l.8)

and large value of persistence length indicate high

chain rigidity of PBO .

These fibres are spun using dry-jet wet spinning

technique from a nematic liquid crystalline solution.

Polyphosphoric acid is the preferred solvent for this

purpose; however, methanesulphonic acid has also

been used. This technique involves the extrusion of

polymer solution under heat and pressure through an

air gap into a coagulating bath (generally water has

been used as coagulant in the case of PBOjPPA

solutions) followed by washing, drying and heat

treatment under tension in an inert atmosphere. For

the PBO fibre , heat treatment temperature of

500-700°C with a residence time of a few seconds to

several minutes is typically used .

Presence of three-dimensional order has been

observed using W AXS and electron diffraction. This

is at variance with PBZT where the structure is axially

disordered . The crystallite size increases on heat

treatment. In a typically heat-treated PBO fibre ,

crystallite size measured from (200), (0 I 0) and (001)

are approximately 17,8 and 20 nm respectively, and

these sizes vary with the processing and heat

treatment conditions. The SAXS of heat-treated

PBO fibre results in a four point radial pattern, the

origin of which is not yet clearly explained. The

Raman spectroscopy ofPBO fibre shows the presence

of three bands at 1615, 1540 nd 1280 cm - I and these

positions are sensitive to tensile and compressive

strains in the fibre .

'

The crystal structure of PBO is reported to be

monoclinic and non-primitive with two chains per

unit cell of dimensions a = 1.120 nm, b = 0.354 nm, c

(fibre axis)= 1.205 nm , and y= 101.3° with a

theoretical crystal density of 1.66 gj cm 3 • The PBO

fibres are characterized by extremely high orientation

and order. The concept of amorphous phase as

commonly understood in flexible chain polymers

does not exist in ordered polymeric fibres . A scanning

electron micrograph of PBO fibre is given in Fig. 2,

indicating a fibrillar structure. A W AXS and a SAXS

pattern of a heat-treated PBO fibre are given in Fig. 3.

Fig. 2- Sca nning electron micrograph of fractured PBO

fibre (ref. 15)

Fig. 3-(a) Wide-angle and (b) small-angle X-ray scattering of

PBO fibre

55

INDIAN J. FIBRE TEXT. RES., MARCH 1991

Typical stress-strain curve of wet, dry (as spun) and

heat-treated PBO fibres are given in Fig. 4. Both

tensile stregth and modulus generally increase on

tension heat treatment, while some reduction in

elongation-to-break is observed. The fibre stressstrain curve in compression is schematic based on the

compression behaviour of the uniaxial composites of

this fibre. The direct compression stress-strain curve

on single fibres is ra ther difficult to obtain. Modulus

has also been measured using W AXS. The modulus

values for two PBO fibres obtained from X-ray

studies were 477 and 433 GPa, while the macroscopic

mod ul us val ues for these two fibres were 318 and 290

GPa respectively. The theoretical chain modulus of

PBO is 730 GPa. PBO fibres also show excellent

retention of tensile strength and modulus with

temperature. PBZT fibre is. reported to exhibit

non-linear elastic behaviour. PBZT, PBO and other

ordered polymers are among the most radiationresistant polymers16. The flammability tests on PBO

and other ordered polymeric fibres indicate that these

are intrinsically non-combustible materials.

PBO fibres are highly ordered and have the highest

thermal stability and tensile modulus of any known

polymeric fibre . Their environmental, chemical and

radiation resistance are also excellent. The use of the

current reinforcing polymeric fibres including PBO is

limited to those applications when~ axial compressive

loading is minimized, or hybrids of these fibres with

good compressive strength fibre can be used. Possible

applications which have been suggested for PBO are:

use as reinforcements in composites, multilayer

circuit boards, athletic equipment, marine applications, woven fabrics , cables, and ballistic and fire

protection fabrics.

3 Carbon Fibres

Carbon fibres were first made in the nineteenth

century from cellulosic fibres by Edison and

Swanson, and were used in light bulb application.

The modern carbon fibre development dates back to

1960s and originated from the work of Shindo in

Japan, Watt in England, and Singer and Bacon in

USA. Though a large number of polymeric precursors have been tried for modern carbon fibres, the

three main precursors used commercially in order of

decreasing curtent use are polyacrylonitrile (PAN),

petroleum- or c9al-based pitch , and rayon. The

current production of rayon-based carbon fibres is

very small. The history of development of carbon

fibres has been traced by Bacon and Moses17.

Fibres prepared from isotropic pitch have

relatively low modulus ( < 70 GPa) and low tensile

strength ( < I GPa). These fibres can be converted

into high modulus fibres by stress graphitization.

However, this method of making high modulus

carbon fibres is too expensive and, therefore, has not

been commercialized . Liquid crystalline mesophase

pitch is used for high modulus carbon fibre

production, a nd carbon fibres prepared from this

process were commercialized in early 1980s. The

average molecular weight of the pitch used for carbon

fibre production is about 400-500 daltons .

......

Polyacrylonitrile used for carbon fibres is generally

e

not

100% PAN. Typically, it is a copolymer

•

containing polymers such as methylacrylate, methyl

a:

<OJ

methacrylate, vinyl acetate, or vinyl chloride. Up to

b

15% comonomer content has been reported . Conventionally PAN fibre is spun using dry-jet spinning

• of PAN copolymer solution in dimethylformamide

(DMF). However, melt-spinning process is also

currently being used. The PAN fibres are stabilized in

air between 200 e and 300°C. The stabilization

-2

-I

5

2

•

STRAIN (\\'

process is accompanied with stretching to induce

molecular

orientation required for obtaining high

-I

modulus fibre . These fibres are carbonized above

1000°C in nitrogen atmosphere. Heat treatment

-2

temperatures of up to 3000°C can be used for very high

modulus (> 100 MPSI) fibres (High modulus fibres

are,

however, currently made from meso phase pitch).

-3

Heat

treatment above 2000°C is carried out in an inert

Fig. 4-Typical tensile (a, b and c) and compressive (d)

atmosphere rather than in nitrogen. PAN-based

stress-strain curves of PBO fibre [(a) as coagula ted (wet); (b) as

carbon fibres heat treated at lower temperatures

spun (dried); and (c) and (d) heat treated] (ref. 15)

..

0

56

SAllSH KUMAR: HIGH PERFORMANCE FIBRES

( < I 700°C) have typically up to about 8% nitrogen

content.

Other polymers which have been tried for carbon

fibre precursor are aromatic hetrocyc1ic polymers,

aromatic non-hetrocyc1ic polymers and linear

polymers (mixtures of polyethylene/polypropylene

and aromatic distillation residues, polyvinyl

chloride, copolymers of vinyl chloride and vinyl

alcohol). Generally speaking, these did not meet one

or more of the following requirements for carbon

fibre precursors: cost, yield, speed of carbonization,

and ultimate mechanical and electrical properties.

Carbon fibres have also been prepared from chemical

vapour deposition (CVD). Such fibres are currently

not being commercially produced .

The basic structural unit of carbon fibres is

hexagonal planar arrangement of carbon atoms. In

highly oriented fibre the stacking of planes is quite

perfect like in graphite, while lower modulus fibres

have a more random stacking, generally referred to as

turbostratic. The graphite planes have bends, twists,

defects, vacancies, dislocations, grain boundaries

and impurities. The crystal structure of graphite is

hexagonal with lattice constants of a = 0.2462 nm,

and c = 0.6707 nm, which gives a in-plane bond length

of 0.1421 nm and the interplanar separation of c/2 is

0.3354 nm . The interplanar spacing in carbon fibres is

generally found to be between 0.3354 nm and 0.35 nm.

W AXS' and SAXS patterns of P-IOO and T -300

carbon fibres are given in Figs 5 and 6 respectively and

the scanning electron micrographs of fractured

surfaces of the two fibres are given in Fig. 7. WAXS

indicates the expected high orientation, order and

larger crystallite size in P- 100 compared to T -300.

From the comparison of the small-angle X-ray

scattering of the two fibres one can qualitatively say

that the voids in P-I 00 a re long and narrow while in

T-300 they are shorter a nd thicker. From the SEM

micrographs, the structure of P-I 00 fibre appears to

be like planar fibrils while that of the T-300 fibre is

more akin to particulate structure.

in the range of 5-13 GPA and of rayon-based carbon

fibres in the range of 10-15 GPA. The torsional

modulus of carbon fibres increases significantly with

increased axial stress 18. The stress-strain curves of

PAN- and pitch-based carbon fibres exhibit some

non-linearity I9, as modulus increases with increasing

strain.

The coefficient of thermal expansion (CTE) of

carbon fibres has a significant non-linear variation '

with temperature. The values ofCTE at room temperature are given in Table 1. Thermal conductivity

increases with an increase in temperature and with an

increase in crystal perfection. Carbo]J. fibres have low

thermo-oxidative stability as compared to SiC fibre.

Thermogravimetric analysis of carbon fibres in air

suggests the onset of degradation between 500°C and

700°C, with most of the fibres losing almost all their

weight below 800°e. Oxidative-resistant coatings of

8 2 0 3 , SiC or Si0 2 are applied on the carbon fibres for

improved thermo-oxidative stability.

Carbon fibres can be intercalated to influence the

fibre properties such as electrical conductivity.

Intercalation compounds are formed by the insertion

of atomic or molecular layers of guest molecules

between layers of host material such a graphite. Guest

atoms can be either electron donors which transfer

electrons to the graphite or electron acceptors which

receive electrons from the graphite. If the guest atom

layer is in between every graphite layer, then it is

referred to as stage I intercalation, if there are two

graphite layers between the layers of guest atoms,

then it is referred to as stage II intercalation, and so on.

The intercalation process does not affect the in-plane

ordering of the graphite layer. Halogen and alkali

atoms have been used as guest atoms in graphite.

Intercalation is possible only if the structure is

sufficiently ordered. Therefore, very high modulus

pitch-based carbon fibres are easier to intercalate.

Intercalation of P-IOO carbon fibres with Br was

reported to have increased its electrical conductivity

by a factor of five , while its mech anical properties

Lattice constants of individual carbon fibres have (tensile strength and modulus, and compressive

not been determined. Various elastic stiffness strength) were essentiaIlYunchanged 2o •2 1 • However,

coefficients of single crystal graphite are given in with many other intercalants a more than an order of

Table 2. These elastic coefficients are expected to vary magnitude increase in electrical conductivity has

with disorder/defects in the fibre. Fibre torsional been achieved.

modulus would depend on the manner in which the

For composite applications, the surfaces of both

fibrils are arranged. For example, for radia l fibre pitch- and PAN-based carbon fibres are treated for

structure (where graphite planes radiate from fibre obtaining good bonding between the fibre and the

centre), torsional modulus G = C 44 =4 GPA and for a matrix. Oxidative treatment in air or oxygen,

highly ordered perfectly faceted graphite surface, oxidative treatment in nitric acid, or plasma

G=(C,, - Cd/2=44 GPA. Torsional modulus of treatment have been used for carbon fibre surface

PAN-based carbon fibres is generally reported to be in modifications. To increase the interfacial bonding

the range of 15-28 GPA, of pitch-based carbon fibres between the fibre and the matrix, carbon fibres have

57

INDIAN J. FIBRE TEXT. RES., MARCH 1991

Fig. 5-Wide-a ngle X-ray scattering of ca rbo n fib res: (a) P-IOO a nd (b) T-300

Fig. 6-Small-angle X-ray scattering of P-IOO and T-300 carbon fibres

58

SATISH KUMAR : HIGH PERFORMANCE FIBRES

these fibres heat treated to 300°C have high structural

perfection .

The major application of carbon fibres is in

polymer matrix composites; however, they are also

used in metal matrix and carbon matrix composites.

So me of the features of the carbon fibres and

associated applications are as follows: (i) High

specific strength and stiffness- aerospace, road and

ma rine tra nsportation , and sports goods, (ii) Low

coeft1cient of thermal expansion a nd low abrasionmi ssiles, aircraft brakes and antenna, (iii) Biological

inertness and X-ray permeability- medical applications and X-ray equipment, (iv) Fatigue resistance,

self lubrication and high damping- textile

mac hinery and general engineering, (v) Chemical

inertness and high corrosion resistance--<:hemica l

industry and nuclear field, and (vi) Good electrica l

co nduetivity-electromagnetic interference shields

fo r computers, electrical instruments.

4 Inorganic Fibres

4. 1 Glass Fibres

The documented use of gl ass fibres in composites

was reported in I 940s. Glass is one of the most

eco nomic reinforcing fibre s available today. It is

made from commonl y available raw materials and a

simple technology is used for its production . A typical

glass fibre composition includes Si0 2, Fe20 3, CaO,

MgO, Na 20 , K 20 and 8a20 3. Most glasses generally

co ntain over 50% ofSi0 2 . Glass fibre is produced by

Fig. 7-Scann ing electron mi crograph, o f fractured end, or

co ntinuous drawing of molten raw material. The fibre

carbon fibre s: (a) P-I 00 and (h) T-300

is drawn at speeds of typically over 1000 m/ min.

Homogenization and degassing of melt is of critical

Table 2- Elastic conSlanlS o f a single crys ta l graphit e (ref. 3)

importance

in achieving good mechanical properties.

1060 ± 20 GPA

C II

A

lubricated

feed is given in the region of fibre

180 ±20 GPA

CI ~

formation

to

reduce

fibre breakage. The strength of

15±5 GPA

CI.1

glass

fibre

is

significantly

higher than that of bulk

36.5 ± I GPA

C 33

glass,

the

latter

being

around

25 KPSI. For the

4. 51 0.5 GPA

C~4

production of high strength gl ass fibre, an optimal

ratio of cooling velocity and tension in the fibre

also been coated with organic polymers such as formation zone is important. Freshly formed glass

polydivinyl benzene, polyamide, polyimide, and has a great affinity for water and the adsorption of

organosi lanes. The requirements for a polymer to be water leads to loss in strength .

used as a coating are that it forms some type of

Vitrification and softening temperatures of glass

chemical bonding (preferably covalent) with the depend on composition and vary from 630 to 1200°C

carbon fibre and that it has a functional group capable and 700 to 1600°C respectivel y. Vitrification and

of reacting with the resin. Interfacial strength is also softening temperatures for the most common glass

presumed to be influenced by increased surface area fibre (that is E-glass fibre) are 630°C and 78YC

(pits created in the fibre surface through oxidative respectively. The composition of E-glass is

treatments) as well as by the functional groups on the approximately as follows : Si0 2 , 55 %; A1 20 3, 14%;

fibre surface capable of reacting with the matrix . Ion 8a203, 6%; CaO, 17% ; MgO, 5% ; and some Fe203,

implantation also provides a technique for carbon Na20 , K 20 , etc. The diameter of the fibre is controlled

fibre surface modification, mostly vapour grown through appropriate choice of melt viscosity (which

carbon fibres have been employed for this purpose as 111 turn IS controlled by temperature and

59

INDIAN J. FIBRE TEXT. RES., MARCH 1991

composition), spinnerette hole size and winding

speed. E-glass fibre is produced with an average fibre

diameter of 11 ~m . Alkali-resistant glass fibre has

been developed for reinforcing cement-based

materials. The main difference in composition of

ordinary glass fibre (e.g. E-glass) and alkali-resistant

glass fibre is that the latter contains 10-20% Zr02.

When these two fibres are kept in an aqueous solution

of portland cement at 80°C for 24 h, ordinary glass

retains only 25 % of its original strength whereas

alkali-resistant glass retains more than 80% of its

original tensile strength. Other glass fibres which

have been made are C-glass (C for corrosion

resistance) and S-glass (S for strength). The corrosion

resistance of C-glass fibre is better than that of the

E-glass fibre in acids though poorer in alkalies. Glass

is believed to form a three-dimensional isotropic

amorphous network. Small-angle X-ray scattering

shows the presence of elongated voids in S-glass fibre

(Fig. 8). Some attributes of glass fibre are: fire

resistance, corrosion resistance, thermal and

acoustic insulation, and resistance to biological

action . Detailed discussion on glass fibres appears in

Chapters I and II (ref. 1).

4.2 Silicon Carbide Fibre

The commercially produced continuous and

multifilament Nicalon ™ fibre is prepared using

polydimethylsilane; however, other organosilicon

polymers have also been used for the production of

SiC fibre. Polydimethylsilane is first distilled to

remove the low molecular weight component, and

polymer of average molecular weight of 1500 is

Fig. 8- Small·angle X-ray scattering of S-glass fibre

60

melt-spun at 280°C and cured in air at 20(tC. The fibre

is then heat treated between 800°C and 1500°C in

nitrogen or vacuum. Optimum mechanical

properties are achieved at about 1250°C. Besides

silicon carbide, this fibre has approximately 30%

excess carbon . During heat treatment, H2 and CH 4

gases are released at about 700°C and additional Hi! is

released at 1200°C, the amount of H2 released being

significantly more. This probably explains the

presence of excess carbon in the fibre , as is obvious

from the following reaction.

CH3

I

- Si -

-t

SiC+CH 4 + H2

I

CH 3

The amorphous to crystalline transition occurs

at about 1100°C. The crystal grain size of the

fibre heat treated at 1500°C is about 10 nm. The fibre

heat treated at about 1250°C has very small ~-SiC

crystals. The presence of graphite d-spacing due to

excess carbon is not observed from W AXS and si nce

SiC exists as a separate phase, it is presumed that the

excess carbon exists as a separate disordered phase.

However, the (002) graphite plane has been detected

from high resolution transmIssIon electron

microscopy . The Nicalon ™ fibre has a diameter of

about 20 ~m.

Continuous SiC fibres can also be prepared using

chemical vapour deposition (CYD) on a substrate

fibre. For this process, tungsten or ca rbon substrate

fibre and vapours of CH 3 SiHCI 2 , C 2 H sSiCI 3 or

CH 3 SiCI 3 have been used. Textron (USA) has

developed 2 2 a SiC filament whose properties a re

listed in Table I. This fibre is produced in a tubu lar

glass . reactor by CVD process on a carbo n

monofilament substrate of about 38 ~m diameter, the

la tt er being melt-spun from coal tar pitch . Thi s

process is ca rried out in two steps : First,

appro xima tely I ~m thick pyrolytic graphite is

depos ited to render the substrate fibre smooth and

enhance its electrical conductivity. In the second step.

the coated substrate fibre is exposed to silane and hydrogen gases. The former decomposes to form ~-SiC

continuously on the substrate, and the final fibre has a

diameter of about 140 ~m. Preci se temperature

control is important in the CVD process . Textro n

process uses a peak decomposition temperature of

about 1300°C. Significantly higher temperatures

than this would result in rapid deposition and grain

growth but in a lowering of the tensile strength . On the

other hand, significantly lower temperatures would

result in high internal stresses in the fibre.

SATISH KUMAR: HIGH PERFORMANCE FIBRES

Silicon carbide has high thenno-oxidative stability

and good thermal and electrical insulation

properties. In composite application, this fibre can be

used to reinforce polymer, metal and ceramic

matrices. Detailed discussion of SiC fibres appears in

Chapter VI (ref. I).

4.3 Boron Fibres

Boron fibres are· produced by chemical vapour

deposition on tungsten filament. Boron deposition

on carbon filament has also been attempted but a

good quality boron fibre has not yet been produced

using carbon substrate. This process is similar to the

CVD process for SiC fibre. The diameter of tungsten

filament used for this purpose is approximately 12.5

Jlm. A gaseous mixture ofH 2 and BCI 3 is used for the

production of boron vapours , through the following

chemical reaction:

2 BC1 3 +3 H 2

--+

2 B+6 HCI

Rheological aids are necessary so that the fibre can be

extruded continuously. The fibre is then heat treated

for the following reasons: (i) to dry the fibre without

distortion or internal voids or bubbles, (ii) to

dehydrate the fibre to generate anhydrous oxide. At

this stage, organic matter such as rheological aids

may be burned out, and (iii) to generate the desired

ceramic phase having appropriate crystal size and to

complete the removal of porosity. In the manufacture

of alumina fibres , low heat treatment temperature is

generally preferred for obtaining low grain size

(because tensile strength goes down as the grain size

increases), and high heat treatment temperature is

preferred to eliminate porosity. One way to solve this

dilemma is to incorporate a se~ond phase, such as

oxides ofSi , P, Band Zr. With the presence of second

phase the fibre can be_ heat treated at a high

temperature to reduce porosity, while the presence of

the second phase will inhibit crystal growth.

Continuous alumina fibres are manufactured by

Sumitomo (Altex TM) with a fibre diameter of8~ I 0 Jlm

and by DuPont (Fibre FP) with a fibre diameter of

about 20 Jlm. Staple alumina fibre is manufactured by

ICI (Saffil) with a fibre diameter of 2-4 Jlm.

Alumina fibres are also coated with SiC for use in

metal matrix composites. Mats offine staple alumina

fibres have good acoustic absorption . Alumina .fibre

surface has a positive charge and staple fibre mats

made from this fibre fonn good filters against bacteria

with a negative charge. Other applications are

thermal insulation, auto monolithic support, and in

catalytic converter. Alumina fibre is discussed in

more detail in ChapterIV (ref. I).

During the deposition process, the tungsten

filament is electrically heated to .about 1200T. As in

the deposition process of SiC, the control of

deposition kinetics (controlled by tungsten

temperature, speed. at which tungsten filament is

passed through the vapour chamber, and the flow of

gases) is important to achieve maximum tensile

strength . Boron deposited according to the above

process is polycrystalline with most probably a

~-rhombohedral structure . The crystal size is so small

(about 2 nm) that the boron fibre is generally regarded

as amorphous. This fibre is produced in fibre

diameters of 100 and 140 Jlm.

Boron reacts with aluminium and titanium at

temperatures used for composite processing with 4.5 Asbestos Fibres

Asbestos is a natural mineral fibre. The chemical

these matrices. Therefore, a coating of SiC and/or

fonnulae

for some of the asbestos fibres are

B4 C is applied on boron fibre. Boron fibres are used

Mg

Si

0

s(OH)4

(chrysolite), Na2Fe3'Fe2"Sig022(OH)2

3 2

for reinforcement of both metal and polymeric

(crocidolite),

Ca

2MgsSisOnCOHh (tremolite) and

matrices. Other potential applications include

Mg

Si

(OHh

(anthophyllite). Asbestos costs less

0

7

s 22

cryogenic engineering, superconducting electrothan glass fibre. Ninety percent of the asbestos used

magnets, and top quality sports goods. Boron fibres

commercially is chrysolite . The individual fibre

are specially suited for applications requiring high

consists of single crystal fibrils. The typical diameter

compressive strength. The major limiting factor in

. of a fibre and fibril are reported to be 10 Jlm and 0.1 Jlffi

the application of boron fibre is their high cost; the use

respectively. The tensile strength of the fibre is

of carbon fibre substra tecan help in reducing the cost.

reported to vary as a function offibre length and fibre

A more detailed discussion on boron fibres appears in

cross-section; the tensile strength reported in Table I

Chapter V (ref. I).

is an extrapolated value for zero cross-section23 .

4.4 Alumina Fibres

Asbestos fibres are now known to be carcinogens with

The refractory material such as AI 20 3 and Zr02 do serious health effects and, therefore, are not used. The

not have the necessary rheological properties for melt adverse health effects mainly arise due to the fine fibril

drawing into fibres. One method which has been used size. However, these fibres have high temperature

for the production of alumina fibre is to extrude resistance and high modulus and it is worth exploring

an aqueous solution of aluminium oxychloride ifflbres of identical structures can be synthesized so

[AI 2(OH)sCI] containing some rheological aids. that they will not separate into small fibrils. The

61

INDIAN J. FIBRE TEXT. RES., MARCH 1991

possible uses of asbestos as reinforcing fibre have

been reviewed by Hollingsworth 24 .

5 Other Fibres

5.1 Optical Fibres

Alexander Graham Bell demonstrated in the

nineteenth century the use of light in transmitting a

telephone signal over a di sta nce of 200 meters 2 5 .

However, this invention was not commercialized

because of the non-availability of high intensity light

and low transmission efficiency of glass. High

intensity light sources, lasers, became available in the

I 96Os; at about the same time, research in

manufacturing techno logy of glass fibres led to a

significant increase in the transmittance of light

through glass fibre . About twenty years ago this led to

the realization that as a replacement for copper wire

glass fibre offers considerable advantage as a

communication medium at optical frequencies.

Optical fibres are formed when a tra nsparent

material of relativel y high refractive index forms the

fibre and this fibre is coated with a material oflower

refractive index. At present, glass is the common

material for optical fibre ; however, some polymers

are also being examined for this purpose. The

refractive index of glass fibre is controlled by the glass

composition. The coating oflower refractive index on

the glass fibre is necessary to achieve the condition of

total internal reflec tion required for long distance

optical transmission. In the new si lica glass fibres ,

absorption loss has been substantially reduced by

decreasing the concentration of optically absorbing

impurities to below one part per billion (I ppb).

Propagation losses of fused si lica fibres are now at an

intrinsic minimum of 0.1 dB/km. Typical diameter of

the optical fibre is 100 11m. A strand of optical fibres

protected by a plastic jac ket forms the optical cable.

The conversion of most long distance communicati on systems to opt ica l fibre s is now complete in the

U nited States. Optical glass fibre s are also currently

being used in med ical devices. Detailed information

on optica l fibres appears in references 26-28.

metallophthalocyanine increases; however, process

optimizations have not yet been done. Defect-free

conjugated flexible linear chain structures exhibit

intrinsic electrical conductivity; however, because of

chain flexibility, defect-free chain structures Cire

difficult to synthesize and process into useful

electrically conducting fibres 31 . Ladder polymers are

generally good electrical conductors; however, their

production involves processing difficulties as they do

not melt, and dissolve only in strong acids 3 0 .

Predictions of superconductivity in polymers 3 2 were

also made in the I 960s; however, so far no such

polymeric materials have been synthesized and/or

processed. However, if these prediction s turn out to

be true then it will act as a stimulus to this area of

research .

5.3 Miscellaneous Fibres

There are a number of fibres which are used in

non-conventional textile applications and are

characterized by at least one unique property. Some

examples of these fibres and the unique property

associated with each of these fibres are: (i)

poly(tetrafluoroethylene) (PTFE) fibre- has the

lowest coefficient of friction (~l = 0.05), (i i)

Elastomeric fibres- have very high elongation

(300-500%) with excellent recovery, (iii) Thermoplastic fibres ofpoly(phenylene sulphide) (PPS), and

poly aryl(ether ether ketone) (PEEK) fibre can be

comingled with carbon and other reinforcing fibres.

These comingled fibres can be used to make various

preforms for complex composite structures, (iv)

Hollow aramid and hollow cellulose acetate fibres

can be used in sea water purification a nd kidney

dialysis, a nd these and other hollow fibres are also

used in industrial ultra-filtration, (v) Po lyester, nylon,

collagen and polyglycolic acid fibres are among the

fibres used for surgical sutures. Significant use of

fibres is also made in geotextiles. More detailed

information on engineering fibres is given in reference

33.

6 Mechanical Properties

6.1 Compressive Properties

5.2 Electrically Conducting Polymeric Fibres

Polymers are generally good insulators of

electricity. However, electrically conducting

polymers have been prepared, and currently

significant research activity is focussed in this area,

though a t the moment electrically conducting

polymeric fibres are not yet commercially available .

Electrically conducting PBZT and PPT A fibres have

bee n spun from spinning dopes containing metallophthalocyanine 29 •3o . Mechanical properties of these

fibres are adversely affected as the concentration of

62

Axial compressive properties of fibres are of

importance in certain composite applications. To

date, alumina and boron fibres followed by SiC and

some PAN-based carbon fibres represent the high

compressive strength fibres (Table I). Tests on small

glass fibres indicate that these fibres may also have

high compressive strength 34 ; however, this high

compressive strength of glass fibre is not realized in

the composites 3 5.36. Compressive strength of carbon

fibres varies sigl11ficantly with modulus and

precursor material; in general, for the same modulus

SATISH KUMAR: HIGH PERFORMANCE FIBRES

and precursor material, PAN-based carbon fibres

exhibit greater compressive strength than the

pitch-based carbon fibres, and in both cases

compressive strength decreases with increase in

modulus (Fig. 9). All polymeric fibres- have low

compressive strength. The use of high performance

polymeric fibres in composites is presently limited to

those applications where compressive loading is

minimized or these fibres are used as hybrids with

high compressive strength fibres. Some possible

reasons for low compressive strength in polymeric

fibres are:

(i) Weak intermolecular interactions characterized by van der Waals' interactions in PBO and

polyethylene, and by hydrogen bonding in aramids.

(ii) Highly oriented microfibrillar st ructure .

In addition , the glass tran sition tempera ture is also

considered to playa part in the low compressive

strength of polymers 21 • However, considering that

no Tg is observed in PPT A or PBO below their

degrada tion temperature , the low compressive

strength of PPT A and PBO is not likely to be

limited by Tg. However, Tg may be a limiting factor for

the low compressive strength of polyethylene.

A comparison of typical compressive and ten sile

properties indicates that the compressive and ten sile

moduli for many high performance fibres , which

include PBO, most carbon fibres , and boron fibres,

a re equal. Compressive moduli for Kevlar™ and

Spectra ™ fibres are significantl y lower than their

respective tensile moduli . While for some carbon and

boron fibres, the compressive st rength equal to or

greater th a n their tensile strength has been reported ,

for polymeric fibres, the compressive strength is o nly

about 10 % of their tensile strength . Significant

resea rch activity is currently focussed on understa nding and improving the compression behaviour

of these fibres . Issues rel ating to the behaviour of high

FIBRE TENSILE MODULUS (GPe)

r-~20rO~==.-~4~

0~0______~

~0~0______~8~0~3

~400

3~Theo retical

moduli of various fibres (ref. 37)

Fibre

PBO

PBZT

PPTA

Polyethylene

Graphite

Modulus

(GPA)

730

610

250

320

1060"

"Modulus for graphite reported in reference 37 is 1500 GPA

performance fibres , when subjected to compression,

were recently discussed in detail by Kumar a nd

Helminiak 2 1 . .

6.2 Ultimate Tensile Properties

The maximum achievable mechanical properties

have been determined for various fibres . The

predicted 37 theoretical chain moduli of various

polymers and graphite are given in Table 3.

Approximately 75% of theoretical chain modulus of

PPTA has been achieved in Kevlar™ 149. Similar

modulus translation in PBO would result in a

polymeric fibre with a modulus of over 500 GPa .

Further refinement in processing technology may

lead us to achieve this . Carbon fibre modulus close to

its theoretical modulus is currently achievable.

According to conservative estimates there is at

least a n order of magnitude difference in currently

achieved and theoretically predicted tensile strengths

of most materials and fibres. For example, the

observed tensile strength of extended chain

polyethylene fibre (Spectra TM) is a bout 3.5 GPa.

According to various theoretical estimates the tensile

strength of polyeth ylene can be in the ra nge of25-40

GPa. The tensile strengths of the whiskers are closer

to the theoretical strength values. It is hoped that

significant breakthroughs in further improving the

ten sile strength of the reinfo rcing fibres will be

achieved . More detailed di scussion on tensi le

strength appears in reference 34.

T-

A~~ ®'Sr-

CL

~ 7 Concluding

~

...

l:

l:

'~" 30

Z

2

...

U)

w

T-60

>

O loleOJ

~ 200

g:

PAN eASED F8'E

:1

OV -70

o

o

1

..

~ 100

;;:

PfTCH BASED FIJRE

25

50

75

~

w

~

~

~

iii

o

Table

100

~

~

~

125

FIBRE TENSILE MQOU.US (MPSI)

Fig. 9~Carbo n fibre co mpressive strength vs. fibre tensile

m o dulu ~ (rer. 2 1)

Remarks

Even though fibres such as glass and asbestos have

been around for a long time, the 'field of hi gh

performance fibres is only a bout two to three decades

old. Only recently have fibres with one or more of the

following exceptiona l properties become available.

The properties are: mechanical , optical , therma l,

a nd/or electrical. The promise of significa nt further

improvements in properties a nd/ or the possibili ty of

cost reduction with processing and synthesis

innovations continues the excitement of research in

this area . Specifically, some of the a reas of research

63

INDIAN J. FIBRE TEXT. RES., MARCH 1991

where significant activity continues incJud~: (i)

Improvement in tensile strength- theoretical

predictions indicate that further significant

improvements in ten sile strength of most fibres

shou ld be within practical reach, (ii) A comparison of

theoretical and experimental values of the modulus of

PBO fibre indicates that with further improvements

in synthesis and processing technology, higher

modulus PBO fibre than currently achieved shou ld be

possible, (iii) The possibility of forming extended

chain fibres from other flexible chain polymers

(besides polyethylene) continues to energize the

research in the gel spinning of flexible chain polymers,

(iv) The development of high compressive strength

polymeric fibre wo uld be a significant breakthrough

in the technology of high performance fibres and

composites, (v) Research on the surface treatment of

fibres for optimum bonding with the matrix for

applications in composites, and also surface

treatment for improving the thermo-oxidative

stabi lity cont inu e to be important areas of research ,

and (vi) Attempts .to make polymeric fibres with

enhanced electrical cond uctiv ity and fibres with

non-linear opt ica l properties are also underway.

With this diversity of research in the area of high

performance fibres , it is only natura l to expect

significant brea ktl;lrough s in the high performance

fibre technology in the near future.

References

I Wall W & Perov B V, Strongfibers. Handbo ok o./composites

series. Vo l. I (No rth-H o ll a nd Publisher), 1985.

2 Donnet J B & Bansal R C, Carbonfibers (Marcel Dekker [nc.) .

1984.

3 Dresselh a us M S, Dresselh a us G , Sugiha ra K , Spain [ L &

Goldberg

H

A,

Graphite fibers and .filaments

(Springer- Verla g), 1988.

4 Adams W W, Eby R K, McLemo re D E, The materials science

and engineering of rigid-rod po lymers, Mater Res Soc Symp

Proc. Vo l. 134. 1989.

5 Yang H H. Chouinard M P, Lingg W J, J Appl Polym Sci. 34

(1987) 1399.

6 (a) Ko F K, Chen H Y -L & Lundberg J L. Bull Alii Phys S oc.

(March 1976) 415 ; (b) Allen S. Pnlv mer (i n press).

7 Preston J. in Encrclopcr/ia o/jmlrm"r sci<'ll('e (l lId engineerillg.

Vo l. II (J o hn Wiley). 1988 . .18 1.

8 Wilfo ng R E & Zimmerman J. J Appl Pol\'III Sci. Appl Po/rlll

S\·mp . 3 1 (1977) I.

9 Tennonia Y & Smith P. Pohlller . 27 ( 19X6) 1845.

64

[0 Kanamoto T, T suruta A, Tanaka K, Takeda M & Porter R S,

Polym J . 15 (1983) 327.

II Zachariades A E & Porter R S, in The strength and stiffness of

polymers. edited by A E Zachariades & R S Porter (Marcel

Dekker, New York), 1983, I.

12 Pennings A J , Schouteten CJ H & Kiel A M, J Polym Sci~C.38

( 1972) 167.

13 Smith P & Lemstra P J , Colloid Polym S ci. 258 (1980) 7.

14 Wolfe J , in Ency clopedia of polym er science and engineering,

Vol. II (John Wiley) , 1988.601.

15 Kumar S. in Encyclopedia of composites . Vol. 4 (VCH

Publishers). 1990.

16 Kumar S & Adams W W. Polymer. 31 ( 1990) 15.

17 Baco n R & M oses C T. in High per/orman ce polymers: Th eir

origin and development . edited by B E Seymour & C S

Krishenbaum (Elsev ier Science Publishing Co .), 1986. 341 .

18 Srinivasago palan S, Dynamic torsional beha viour of some

carbonjibres. Ph .D. dissertati o n, University of Washingto n,

1979.

19 Dresselha us M S, Dresselhaus G , Sugihara K . Spain [ L &

Goldberg H

A , Graphite fibers

and filamen ts

(Springer-Verlag) , 1988, 120.

20 Jaworske D A , Vannucci R 0 & Zinolabedini R, J Compos

Mater. 2 1 (1987) 580 .

21 Kumar S & Helmini a k T E, Mater Res Soc Symp Proc, 134

( 1989) 363.

22 Textron speciality malerials in/ormation brochure on SiC

jiber.

23 Aveston J . J Mat er Sci , 4 (1969) 625 .

24 Ho llingsworth , Compostles. I (I 'J69) 28 .

25 Bruce R V, Alexander Graham Bell and the conquest ofsolitude

(Go ll ancz, Lo nd o n) . 1973.

26 Levy A C. Taylor C R . in Encyclopedia o./polymer sciencealld

engineering , Vo l. 7 (J o hn Wiley), 1988. I.

27 Allan W B. Fiber optics (Plenum Press), 1973.

28 Kapa n y N S. Fiber optics (A cademic Press), 1967.

29 W ynne K J , Zachariades A E, Inabe T & Marks T J , Polym

Comm. 26 (1985) 162.

30 Poli s D W, Dalto n L R & Vachon D J , Mater Res Soc Symp

Proc. 134 ( 1989) 679; Belaish I {'t a/. , Mater Res Soc Symp Proc.

134 ( 1989) 689.

or

3 1 Bl ythe A R. Electrical pmperties

polrl1lers (Cambridge

lJ ni\ersi ty P ress). 1979.

32 L. ittle W A. PhI'S Rev, IJ4(6A) (1964 ) A1416.

33 Dhingra A K. La uterbach H G. in Ellcrc/opedia of polymer

science alld clIgilleerillJZ. Vol. 6 (John Wil ey ). 1988,7 56.

34 Kelly A & Mac Milla n N H. Strong solids. 3rd edn (Oxford Sci.

Publication), 1986. 165, 21.

35 Lee R J. Composit{'s, 18 (198 7) 35.

36 Diefe ndo rf R J. in Carbonfibers and their composites, edited by

E Fi tze r (Springer-Verlag), 1985.

37 Wi erschke S G, Mater Res Soc Sy mp Proc . 134 ( 1989) 313 .

38 1m J. Mater Res Soc Symp Proc , 134 ( 1989) 307.