2022

V-A346 Appendix IX A

Appendix IX

A. Determination of Sulfated Ash

Use Method I unless otherwise directed.

Method I

(No Ph. Eur. method)

Heat a platinum dish £0 redness for 10 minutes, allow to cool

in a desiccator and weigh. Unless otherwise specified in the

monograph, place 1 g of the substance being examined in the

dish, moisten with suf/urie acid, ignite gently, again moisten

with sulfuric acid and ignite at about 8000 • Cool, weigh again,

ignite for 15 minutes and repeat this procedure until two

successive weighings do not differ by more than 0.5 mg.

sodium carbonate solution and gradually heat the liquid until it

boils. Maintain the current of nitrogen or carbon dioxide, allow

the solution to boil for about J 0 minutes and cool the flask

by gradual immersion in water. Introduce, while momentarily

removing the stopper of the flask, a weighed quantity of

50 to 100 g of the substance being examined, heat gently and

boil for 45 minutes. Disconnect the absorption tubes before

turning off the current of nitrogen or carbon dioxide and titrate

the combined contents with O.IM sodium hydroxide VS.

Each mL OrO.1M sodium hydroxide VS is equivalent to

3.203 mg of sulfur dioxide.

Repeat the operation without the substance being examined.

The solution in the absorption tubes remains neutral.

Method II

(ph. Eur. merhod 2.5.29)

Method III

EQUIPMENT

(Ph. Eur. method 2.4.14)

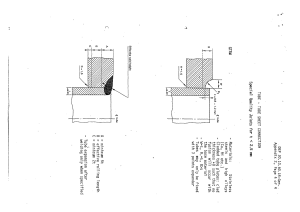

The apparatus as shown in Figure 2.5.29.-1 comprises:

- a ground-glass 3-neck round-bottomed flask (Al;

- a dropping funnel (B);

- a reflux condenser (G)j

- a receiving tube (D);

- a transfer tube (E);

- a gas pon.

Ignite a suitable crucible (for example, silica, platinum,

porcelain or quartz) at 600 ± 50°C for 30 min, allow to

cool in a desiccator over silica gel or other suitable desiccant

and weigh. Place the prescribed amount of the.substance to

be examined in the crucible and weigh. Moisten the

substance to be examined with a small amount of sulfuric

acid R (usually 1 mL) and heal gently at as Iowa

temperature as practicable until the sample is thoroughly

charred. After cooling, moisten the residue with a smaU

amount of sulfuri< acid R (usually 1 mL), heat gently until

white fumes are no longer evolved and ignite at 600 ± 50°C

until the residue is completely incinerated. Ensure that flames

are not produced at any time during the procedure. Allow

the crucible to cool in a desiccawr over silica gel or other

suitable desiccant, weigh it again and calculate the percentage

PROCEDURE

Method

Introduce 150 mL of warer R into lite flask (A) and

equilibrate the whole system by passing carbon dioxide R for

15 min at a rate of about 100 mIJmin.

E

of residue.

If the amount of the residue so obtained exceeds the

prescribed limit, repeat the moistening with sulfuric acid R

and ignition, as previously, for 30 min periods until

2 consecutive weighings do not differ by more than 0.5 mg

or until the percentage of residue complies with the

prescribed limb.

D

The amount of substance used for the test (usually 1-2 g) is

chosen so that at the prescribed limit the mass of the residue

(usually about 1 mg) can be measured with sufficient

accuracy.

B. Determination of Sulfur Dioxide

Method I

(No Ph. Eur. me/hod)

Apparatus A round-bottomed flask of 1000- 10 1500-mL

capacity is fitted with a water-cooled reflux condenser the

upper end of which is connected to two absorption tubes in

series. The flask is fitted with a gas inlet tube which reaches

nearly to the bottom of the flask. Each absorption tube

contains 10 mL of hydrogen peroxide solution (20 wi)

previously neutralised willt O.lM sodium hydroxide VS using

bromophenol bluesolution as indicator.

Method Place in lite flask 500 mL of warer and 20 mL of

hydrochloric acid. Pass through lite flask a steady current of

nitrogen or carbon dioxide that has been bubbled through di/uce

I This chapter has und~ phannacopoeiaJ hannonisation. S~ chapter

5.8 Phamuuqpoeial harmonisation.

Figure 2.5.29.-1.- Appararus for the determination of su/fur

dioxide rontenl

www.webofpharma.com

2022

Appendix IX C V-A347

To 10 mL of dilute hydrogen peroxide solution R, add 0.15 mL

of a I gIL solution of bromophenol blue R in ethanol

(20 per cent V/~ R. Add 0.1 M sodium hydroxide until a

violet-blue colour is obtained, without exceeding the

end-point. Pour the solution into the receiving tube (D) and

moum the tube on the apparatus as shown in Figure

2.5.29.-1.

Without interrupting the stream of carbon dioxide, remove

the dropping funnel (B) and introduce into the flask (A)

25.0 g (m ) of the substance to he examined, rinsing with

100 mL of water R. Replace the dropping funnel, close the

tap and pour 80 mL of dilute hydrochloric acid R into the

funnel. Open the tap to allow the hydrochloric acid solution

to flow into me flask. Make sure that no sulfur dioxide

escapes by closing the tap before the last few millilitres of

hydrochloric acid solution drain OU[. Boil for 1 h.

Open the tap of the dropping funnel then stop the flow of

carbon dioxide . Transfer the contents of the receivingtube

(D) to a 200 mL conical flask, rinsing the rube with a little

water R. Heat on a water-bath for 15 min and allow to cool.

Add 0.1 mL of a I gIL solution of bromophenol blue R in

ethanol (20 per cent V/~ R and titrate with 0.1 M sodium

hydroxide until the colour changes from yellow to violetblue (V,). Carry out a blank titration (V,).

Results

Calculate me content of sulfur dioxide, in parts per million,

using the following expression:

n

32 030x(V,- V,) x m

VI

V2

volume of tirranr used in the titration, in millilitresj

volume of titrant used in the blank urraucn, in miUilitresi

II

molarityof the sodium hydroxidesolution used as titrant, in

m

moles per litrej

mass of the sample. in gruns.

C. Determination of Water

Use Method IA unless otherwise directed.

Method I Semi-micro Determination of Water

(Ph. Bur. manod 2.5.12)

The semi-micro determination of water is based upon the

quantitative reaction of water with sulfur dioxide and iodine

in a suitable anhydrous medium in the presence of a base

with sufficient buffering capacity.

APPARATUS

The apparatus consists of a titration vessel with:

- 2 identical platinum electrodes;

- tight inlets for introduction of solvent and titrant;

- an inlet for introduction of air via a desiccant;

- a sample inlet fitted with a stopper Of, for liquids, a

septum.

Inlet systems for introduction of dry nitrogen or for

aspiration of solvents may also be fitted.

The titration is carried out according to the instrument

supplier's instructions. Care is taken throughout the

determination to avoid exposure of reagents and solvents to

atmospheric moisture. The end-point is determined using 2

identical indicator electrodes connected to an electrical

source that maintains between the electrodes either a

constant current (2.2.65. Voitametl'k titration) or a constant

voltage (2.2.19. Amperomerric tilration). Where direct titration

is used (method A), addition of titrant causes either a

decrease in voltage where constant current is maintained or

an increase in current where constant voltage is maintained,

until the end-point is reached. Instruments with automatic

end-point detection are commonly used. Instrument

qualification is carried out according to established quality

system procedures, for example using a suitable certified

reference material (sodium aminosalicylau dihydraufor

C'/uipmen' qualifi<arion CRS may be used),

STANDARDISATION

To the titration vessel, add methanol R, dried if necessary, or

the solvent recommended by the supplier of the titrant.

Where applicable for the apparatus used) eliminate residual

water from the measurement cell or carry out a pre-titration.

Introduce a suitable amount of water in an appropriate form

(water R or a certified reference material) and carry out the

titration, stirring for the necessary time. The water equivalent

is not less than 80 per cent of that indicated by the supplier.

Standardise the titrant before the first use and at suitable

intervals thereafter.

Unless otherwise prescribed, use Method A.

METHOD A

Introduce into the titration vessel methanol R, or the solvent

indicated in the monograph or recommended by the supplier

of the titrant. Where applicable for the apparatus used,

eliminate residual water from the measurement ceU or carry

out a pre-titration. Introduce the substance to be examined

rapidly and cany out the titration, stirring for the necessary

extraction time.

METHODB

Introduce into the titration vessel methanol R, or the solvent

indicated in the monograph or recommended by the supplier

of the titrant. Where applicable for the apparatus used,

eliminate residual water from the measurement cell or carry

out a pre-titration. Introduce the substance to be examined

rapidly and in a suitable state of division. Add an accurately

measured volume of the titrant, sufficient to give an excess of

about 1 mL or the prescribed volume. Allow to stand

protected from light for 1 min or the prescribed time, with

stirring. Titrate the excess of reagent using methanol R or the

prescribed solvent, containing an accurately known quantity

of water.

SUITABIUTY

The accuracy of the detennination with the chosen titrant

must be verified for each combination of substance, titrant

and solvent to be examined. The following procedure, given

as an example, is suitable for samples containing 2.5-25 mg

of water.

The water content of the substance to be examined is

determined using the reagent/solvent system chosen.

Thereafter, in the same titration vessel, sequential known

amounts of water, corresponding to about 50-100 per cent of

the amount found in the substance to be examined, are

added in an appropriate fonn (at least 5 additions) and the

water content is determined after each addition. Calculate

the percentage recovery (r) after each addition using the

following expression:

r=IOO

WI

W2

w,

W,

amount of water added, in mllllgrams;

amount of water found, in milligrams.

www.webofpharma.com

2022

V-A348 Appendix IX C

Calculate the mean percentage recovery

0').

The reagem/solvent system is considered to be acceptable if' is

between 97.5 percentand 102.5 percen.

Calculate the regression line. The x-axis represents the

cumulative water added whereas the y-axis represents the

sum of the initial water content determined for the substance

(M) and the cumulative water determined after each

addition. Calculate the slope (b), the intercept with the y-axis

(a) and the intercept of the extrapolated calibration line with

the x-axis (d).

Calculate the percentage errors (el and

~

using the

following expressions:

e,

e,

Q

d

M

s

c

N

IU

a-M

~IOO-­

M

=

1001dl~M

they-axis intercept. in milligrams of water,

me x-axis intercept, in milligrams of water;

Willer content l)f Ihe subsrance, in rni.Ulgnuns of water.

The reagentfsolvent system is considered to be acceptable if:

- le,1 and le,l are not greater than 2.5 per cent;

-

b is between 0.975 and 1.025.

Method II Determination of Water by Distillation

(Ph. Eur. method 2.2.13)

The apparatus (see Figure 2.2.13.-1) consists ofa glass

flask (A) connected by a tube (D) to a cylindrical tube (B)

filled with a graduated receiving tube (E) and reflux

condenser (G). The receiving tube (E) is graduated in

0.1 mL. The source of heat is preferably an electric heater

with rheostat control or an oil bath. The upper portion of the

flask and the connecting tube may be insulated.

Method Clean me receiving tube and the condenser of the

apparatus, thoroughly rinse with water, and dry.

Introduce 200 mL of toluene R and about 2 mL of water R

into the dry flask. Distil for 2 h, then allow to cool for about

30 min and read the water volume to the nearest 0.05 mL.

Place in the flask a quantity of the substance, weighed with

an accuracy of 1 per cent, expected to give about 2 mL to

3 mL of water. H the substance has a pasty consistency,

weigh it in a boat of metal foil. Add a few pieces of porous

material and heal the flask gently for 15 min. When the

toluene hegins to boil, distil at the rate of about two drops

per second until most of the water has distilled over, men

increase the rate of distillation to about four drops per

second. When the water has all distilled over, rinse the inside

of the condenser tube with toluene R. Continue the

distiUation for 5 min, remove the heat, aUow the receiving

tube to cool to room temperature and dislodge any droplets

of water which adhere to the walls of the receiving tube.

When the water and toluene have completely separated, read

the volume of water and calculate the content present in the

substance as millilitres per kilogram, using the formula:

m

R.

R2

the mass in grams of the substance to be examined,

the number of millilitres of water obtained in the lint:

distiUauon.

the total number of millilitres of water obtained in the 2

distillations.

o

B

: s

•

, 3

E

....

'"

~

2

! Gml

'"'"

A

165

I

I

I

I

I

Figure 2.2.13.-1. - Apparatus for the detenninarion of water by

disu"Ualion

Dimensions in mi//imeeres

Method III Coulometrlc TItration

(ph. Eur. method 2.5.32)

PRINCIPLE

The coulometric titration of water is based upon the

quantitative reaction of water with sulfur dioxide and iodine

in an anhydrous medium in the presence of a base with

sufficient buffering capacity. In contrast to the volumetric

method described in general chapter 2.5.12. Water: semi-micro

determination, iodine is produced electrochemically in the

reaction cell by oxidation of iodide. The iodine produced at

www.webofpharma.com

Appendix IX D V-A349

2022

the anode reacts immediately with the water and the sulfur

dioxide contained in the reaction cell. The quantity of water

in the substance is directly proportional to the quantity of

electricity (in coulombs), corresponding to electric current (in

amperes) multiplied by time (in seconds), used for iodine

generation up until the titration end-point. When all of the

water in me reaction cell has been consumed, the end-point

is reached and thus an excess of iodine appears. 1 mole of

iodine corresponds to 1 mole of water, an amount of

electricity of 10.71 C corresponds to 1 mg of water.

Moisture is eliminated from the reaction cell by pre-titration,

i.e. the electrolyte reagent is titrated to dryness before starting

the sample analysis. Individual determinations can be carried

out successively in the same reagent solution) under the

following conditions:

each component of the test mixture is compatible with

me other components;

- no other reactions take place;

- the volume and the water capacity of the electrolyte

reagent are sufficient.

Coulornetric titration is intended for the quantitative

determination of small quantities of water (from 10-llg),

however a working range of 100 J.tg to 10 mg of water is

recommended for reproducibility reasons.

Accuracy and precision of the method are predominantly

governed by the sample preparation and the extent to which

atmospheric moisture is excluded from the system. Control

of the system must be monitored by measuring the amount

of baseline drift.

-

APPARATUS

The apparatus consists of a reaction cell, electrodes and a

magnetic stirrer. The reaction cell consists of a large anode

companment and a smaller cathode compartment.

Depending on the design of the electrode, both

compartments can be separated by a diaphragm. Each

compartment contains a platinum electrode. liquid or

solubilised samples are introduced through a septum, using a

syringe. Alternatively, an evaporation technique may be used

in which me sample is heated in an oven and the water is

evaporated and carried into the cell by means of a stream of

dry inert gas. The introduction of solid samples into the cell

should in general be avoided. However, if it has to be done it

is effected through a sealable port; appropriate precautions

must be taken to avoid the introduction of moisture from air,

such as working in a glove box in an atmosphere of dry inert

gas. The analytical procedure is controlled by a suitable

electronic device, which also displays the results.

Instrument qualification is carried out according to

established quality system procedures, for example using a

suitable certified reference material. Sodium aminosalicylau

dihydrate for equipmen, qualification CRS may be used when

proceeding by direct or liquid sample introduction, whereas

amoxicilJin lrihydrate for performance verifica.wn CRS may be

used with the evaporation technique.

METIIOD

Fill the compartments of the reaction cell with e/e<lrolyte

reagent for the micro determination 0/ WtUer' R according to the

manufacturer's instructions and perform the coulometric pretitration to a stable end-point. Introduce the prescribed

quantity of the substance to be examined into the reaction

cell and titrate again to a stable end-point, stirring for at least

30 s, unless otherwise indicated in the monograph. If an oven

is used, me prescribed quantity of sample is introduced into

the oven and heated. After evaporation of the water from the

sample into the reaction cell, the titration is started.

Alternatively, the evaporated moisture is immediately titrated

while heating the sample in the oven to avoid loss of

evaporated water already collected in the reagent solution

during prolonged heating. Read the value from the

instrument's output and calculate if necessary me percentage

or quantity of water that is present in the substance. When

appropriate to the type of sample and the sample

preparation, perform a blank titration.

VERIFICATION OF ACCURACY

At appropriate intervals, such as at least at the beginning and

the end of a series of sample titrations, introduce a defined

quantity of water, in the same order of magnitude as the

quantity of water in the sample, using a suitable certified

reference material and perform the coulometric titration.

The recovery is within the range of 97.5 per cent to

102.5 per cent for an addition of 1000 ~g of H 2 0 and within

the range of 90.0 per cent to 110.0 per cent for the addition

of 100 ~g of H 2 0 .

D. Determination of Loss on Drying

(Ph. Eur. method2.2.32)

PRINCIPLE

Loss on drying is the loss of mass after drying under

specified conditions, calculated as a percentage (mlm).

Drying to constant mass means that 2 consecutive weighings

do not differ by more than 0.5 mg, the 2n d weighing

following an additional period of at least 30 min of drying

under the conditions prescribed for the substance to be

examined.

EQUIPMENT

The equipment typically consists of:

- weighing bottles that are made of suitable inert material

and can easily be dried to constant mass; their diameter is

large enough so that the layer of the substance to be

examined does not exceed about 5 mm;

- an analytical balance by which it is possible to determine

a change in mass of 0.1 mg;

- depending on the procedure to be applied, a desiccator) a

vacuum cabinet, a vacuum oven or an ordinary laboratory

oven; in any case, the temperature of ovens is adjustable

to the specified temperature ± 2 °Cj vacuum ovens in

which the pressure can at least be reduced to about 2 kPa

are suitable; ovens are qualified according to established

quality system procedures, for example by using a suitable

certified reference material (sodium aminosalicylate

dihydrate for equipment qualificalion CRS may be used).

Equipment using other means of drying such as microwaves)

halogen lamps, infrared lamps or mixed technologies may be

used provided they are demonstrated to be fit for purpose.

PROCEDURE

It is recommended to perform the test in an environment

that has minimal impact on sample measurement

(e.g. humidity).

Weigh an empty weighing bottle that has been previously

dried under the conditions prescribed for me substance to be

examined for at least 30 min, then weigh the weighing bottle

filled with the prescribed quantity of substance to be

examined. Dry to constant mass or for the prescribed time.

Where the drying temperature is indicated by a single value

rather than a range, drying is carried out at the prescribed

www.webofpharma.com

V-A3S0 Appendix IX E

2022

temperature ± 2°C. Use one of the following procedures,

unless otherwise prescribed in the monograph.

-

a If-tube (U,) containing 30 g of reaystallised iodine

pentoxide R in granules, previously dried at 200°C and

-

In a desiccator: the drying is carried out over about 100 g

of molecular sieve R at atmospheric pressure and at room

temperature.

- In vacuo: the drying is carried out over about 100 g of

molecular sieve-R-at-a pressure not exceeding 2.5 kPa, at

room temperature or at the temperature prescribed in the

monograph.

- In an oven at a specified temperature: the drying is

carried out at annospheric pressure in an oven at the

temperature prescribed in the monograph.

After drying in an oven, allow the weighing bottle and the

sample to cool to room temperature in a desiccator and

weigh the weighing bottle containing the dried sample.

The mass of the sample is the difference between the mass of

the filled weighing bottle and the mass of the dried empty

weighing bottle.

The loss on drying is the difference in the mass of the sample

before and after drying, expressed as a percentage) mlm being

implicit.

kept at a temperature of 120 °C (1) during the test; the

iodine pentoxide is packed in the robe in 1 ern columns

separated by 1 em columns of glass wool to give an

effective length of 5 cm;

- a reaction tube (F2 ) containing 2.0 mL of poeassium iodide

solution Rand 0.15 mL of starch solutUm R.

Method Flush the apparatus with 5.0 L of argon R and, if

necessary, discharge the blue colour in the iodide solution by

adding the smallest necessary quantity of freshly prepared

0.002 M sodium thiosulfate. Continue flushing until not more

than 0.045 mL of 0.002 M sodium thiosul/a,. is required after

passage of 5.0 L of argon R. Pass the gas to be examined

from the cylinder through the apparatus, using the prescribed

volume and the flow rate. Flush the last traces of liberated

iodine into the reaction tube by passing through the

apparatus 1.0 L of argon R. Titrate the liberated iodine with

0.002 M sodium thiosulfate. Carry out a blank test, using the

prescribed volume of argon R. The difference between the

volumes of 0.002 M sodium thiosulfate used in the titrations is

not greater than the prescribed limit.

METHODD

Gases absorb light at one or more specific wavelengths. This

property is widely used to aUow highly selective measurement

of their concentrations.

E. Limit Test for Carbon Monoxide in

Medicinal Gases

Description and principle of measurement

The concentration of carbon monoxide in other gases can be

determined using an infrared analyser.

The infrared analyser generally consists of a light source

emitting broadband infrared radiation, an optical device, a

sample cell and a detector. The optical device may be

positioned either before or after the sample cell; it consists of

one or several optical filters, through which the broadband

radiation is passed. The optical device in this case is selected

for carbon monoxide. The measurement light beam passes

through the sample cell and may also pasa througb a

reference cell if the analyser integrates such a feature (some

use an electronic system instead of a reference cell).

(ph. Bur. method 2.5.25)

METHOD I

Apparatus The apparatus (Figure 2.5.25.-1) consists of

the foUowing parts connected in series:

- • Ll-tube (U,) containing anhydrous ri&a gel R

impregnated with chromium trWxide Rj

-

a wash bottle (F,) containing 100 mL of a 400 gIL

solution of potassium hydroxide R;

a Uctube (U2 ) containing pellets of poUlSSium hydroxide R;

a U-tube (U.) containing diphosphoTUS pemoxide R

dispersed on previously granulated, fused pumice;

U1

F1

U2

U3

U4

F2

o

o

II

II

II

~

11-'1·-

-= I 1-.

100 m

::1 j_-

_1,--I,,1--,

_.1-

Figure 2.5.25.-1. - Apparatus for the determination of carbon monoxide

Dimensions in millimetres

www.webofpharma.com

Appendix IX G V-A3S1

2022

When carbon monoxide is present in the sample cell,

absorption of energy in the measurement light beam will

occur according to the Beer-Lambert law and this produces a

change in the detector signal. This measurement signal is

compared to a reference signal to generate an output related

to the concentration of carbon monoxide. The generated

signal is linearised in order to obtain the carbon monoxide

concentration. To prevent the entry of particles into the

sensors, which could cause stray-light phenomena, the

apparatus is fitted with a suitable filter.

Required technical specifications

When used for a limit test, the carbon monoxide infrared

analysermeets me following technical specifications:

- lim;' 0/detection: (generaUy defined as a signal-to-noise

me

ratio of 2) maximum 20 per cent of

maximum

admissible concentration;

- repeatability: maximum relative standard deviation of

10 per cent of the maximum admissible concentration,

determined on 6 measurements;

- linean'ty: maximum 10 per cent of the maximum

admissible concentration.

The technical specifications must be met in the presence of

the other gas impurities in the sample.

F. Determination of Carbon Dioxide in

Medicinal Gases

broadband radiation is passed. The optical device in this case

is selected for carbon dioxide. The measurement light beam

passes through the sampJe cell and may also pass through a

reference cell if the analyser integrates such a feature (some

use an electronic system instead of a reference ceJl).

When carbon dioxide is present in the sample cell,

absorption of energy in the measurement light beam will

occur according to the Beer-Lambert law and this produces a

change in the detector signal. This measurement signal is

compared to a reference signal to generate an output related

to the concentration of carbon dioxide, The generated signal

is linearised in order to obtain the carbon dioxide

concentration. To prevent the entry of particles into the

sensors, which could cause stray-light phenomena, the

apparatus is fitted with a suitable filter.

Required technical specifications

When used for a Jimit test, the infrared analyser meets the

following technical specifications:

- limit of detection: (generally defined as a signal-to-noise

ratio of 2) maximum 20 per cent of the maximum

admissible concentration;

- repeatability: maximum relative standard deviation of

] 0 per cent of the maximum admissible concentration,

determined on 6 measurements;

- linean·ty: maximum J 0 per cent of the maximum

admissibJe concentration.

The technical specifications must be met in the presence of

the other gas impurities in the sample.

(Ph. Eur. method 1.5.24)

Gases absorb light at one or more specific wavelengths, This

property is widely used to allow highly selective measurement

of their concentrations,

Descrlpdon and principle of measurement

The concentration of carbon dioxide in other gases can be

determined using an infrared analyser.

The infrared analyser generally consists of a light source

emitting broadband infrared radiation, an optical device, a

sample cell and a detector. The optical device may be

positioned either before or after the sample cell and it

consists of one or several optical filters, through which the

G. Determination of Nitrogen Monoxide

and Nitrogen Dioxide in Medicinal Gases

(ph. Eur. method 1.5.16)

Nitrogen monoxide and nitrogen dioxide in gases are

determined using a chemiluminescence analyser

(Figure 2.5.26.-1).

The apparatus consists of the following:

- a device for filtering, checking and controlling the flow of

the gas to be examined,

Sample now control

Converter

NO

N02~

Reaction chamber

Opllcal filler

IRefrigeraled chamber

~-

-0-

Filter 10eliminate

ozone

Photomultiplier lube

Ozone generator

~---10

system

. Controls

- NO - (NO+NO,) cycle

NO

(NO+NO,)

NO,

Figure 2.5.26.-J. - Chemiluminescence analyser

www.webofpharma.com

V-A352 Appendix IX H

-

-

-

a converter that reduces nitrogen dioxide (0 nitrogen

monoxide) [Q determine the combined content of nitrogen

monoxide and nitrogen dioxide. The efficiency of the

convener has to be verified prior to use,

a controlled-flow-rate ozone generator; the ozone is

produced by high-voltage electric discharges across two

electrodes; the ozone generator is supplied with pure

oxygen or with dehydrated ambient air and the

concentration of ozone obtained must greatly exceed the

maximum content of any detectable nitrogen oxides,

a chamber in which nitrogen monoxide and ozone can

react,

-

a system for detecting light radiation emitted at a

wavelength of 1.2 JIm, consisting of a selective optical

filter and a photomultiplier tube.

H. Determination of Oxygen in Medicinal

Gases

(ph. Bur. method 2.5.27)

Oxygen in gases is determined using a paramagnetic analyser.

The principle of the method is based on the high

paramagnetic sensitivity of the oxygen molecule. Oxygen

exerts a strong interaction on magnetic fields, which is

measured electronically, amplified and converted to a reading

of oxygen concentration. The measurement of oxygen

concentration is dependent upon the pressure and

temperature and, if the analyser is not automatically

compensated for variations in temperature and pressure, it

must be calibrated immediately prior to use. As the

paramagnetic effect of oxygen is linear, the instrument must

have a suitable range with a readability ofO.t per cent or

better,

Calibration of the instrument Make the setting in the

following manner:

- set the zero by passing nitrogen RJ through the instrument

until a constant reading is obtained;

- set the scale 10 100 per cent by passing oxygen R through

the instrument at the same flow rate as for nitrogen RJ

until a constant reading is obtained.

Assay Pass the gas to he examined through the instrument

at a constant flow rate until a constant reading is obtained.

Record the concentration of oxygen in the gas to be

examined.

.

J. Determination of Water in Medicinal

Gases

(ph. Bur. method 2.5.28)

Water in gases is determined using an electrolytic

hygrometer, described below.

The measuring cell consists of a thin film of diphosphorus

pentoxide, between 2 coiled platinum wires which act as

electrodes. The water vapour in the gas to be examined is

absorbed by the diphosphorus pentoxide, which is

transformed to phosphoric acid, an electrical conductor.

A continuous voltage applied across the electrodes produces

electrolysis of the water and the regeneration of the

diphosphorus pentoxide. The resulting electric current, which

is proportional to the water content in the gas to be

2022

examined, is measured. This system is self-calibrating since it

obeys Faraday's law.

Take a sample of the gas to be examined. Allow the gas to

stabilise at room temperature. Purge the cell continuously

until a stable reading is obtained. Measure the water content

in the gas to be examined, making sure that the temperature

is constant throughout the device used to introduce the gas

into the apparatus.

The electrolytic hygrometer achieves accurate sample flows

by using a mass flow controller to deliver a constant

volumetric flow rate to ensure that the water content is

determined accurately. The calibration of the mass flow

controller is normally performed using nitrogen. When using

gases other than nitrogen for calibration, consult the

manufacturer's instructions for the appropriate conversion

factors and ensure that the correct cell is used for the type of

gas to be examined.

K. Gas Detector Tubes

(Ph. Bur. method 2.1.6)

Gas detector tubes are cylindrical) sealed tubes consisting of

an inert transparent material and are constructed to allow the

passage of gas. They contain reagents adsorbed onto inert

substrates that are suitable for the visualisation of the

substance to be detected and, if necessary, they also contain

preliminary layers and/or adsorbent filters to eliminate

substances that interfere with the substance to be detected.

The layer of indicator contains either a single reagent for the

detection of a given impurity or several reagents for the

detection of several substances (monolayer tube or multilayer

tube).

The test is carried out by passing the required volume of the

gas to be examined through the indicator tube. The length of

the coloured layer or the intensity of a colour change on a

graduated scale gives an indication of the impurities present.

The calibration of the detector tubes is verified according to

the manufacturer's instructions.

Operating conditions Examine according to the

manufacturer's instructions or proceed as follows.

The gas supply is connected to a suitable pressure regulator

and needle valve. Connect the flexible tubing fitted with a

Y -piece to the valve and adjust the flow of gas to be

examined to purge the tubing in order to obtain an

appropriate flow (Figure 2.1.6.-1). Prepare the indicator tube

and fit to the metering pump, following the manufacturer's

instructions. Connect the open end of the indicator tube to

the short leg of the tubing and operate the pump by the

appropriate number of strokes to pass a suitable volume of

gas to be examined through the tube. Read the value

corresponding to the length of the coloured layer or the

intensity of the colour on the graduated scale. If a negative

result is achieved, indicator tubes can be verified with a

calibration gas containing the appropriate impurity.

In view of the wide variety of available compressor oils, it is

necessary to verify the reactivity of the oil detector tubes for

the oil used. Information on the reactivity for various oils is

given in the leaflet supplied with the tube. If the oil used is

not cited in the leaflet, the tube manufacturer must verify the

reactivity and if necessary provide a tube specific for this oil.

Arsine detector tube

Sealed glass tube containing adsorbent filters and suitable

supports for the gold salt or other appropriate indicator.

www.webofpharma.com

2022

Appendix IX M V-A353

The minimum value indicated is 0.25 ppm or less, with a

relative standard deviation of at most 20 per cent.

Carbon dioxide detector tube

Sealed glass tube containing adsorbent filters and suitable

supports for hydrazine and crystal violet indicators.

The minimum value indicated is 100 ppm with a relative

standard deviation of at most 15 per cent.

Carbon monoxide detector tube

Sealed glass tube containing adsorbent filters and suitable

supports for di-iodine pentoxide, selenium dioxide and

fuming sulfuric acid indicators. The minimum value

indicated is 5 ppm or less, with a relative standard deviation

of at most 15 per cent.

Hydrogen sulfide detector tube

Sealed glass tube containing adsorbent filters and suitable

supports for an appropriate lead salt indicator. The minimum

value indicated is 0.2 ppm or less, with a relative standard

deviation of at most 10 per cent.

Nitrogen monoxide and nitrogen dioxide detector tube

Sealed glass tube containing adsorbent filters and suitable

support. for an oxidelng layer (Cr(Vl) salt) and the

diphenylbenzidine indicator. The minimum value indicated is

0.5 pp~ with a relative standard deviation of at most

15 per-cent.

Oil detector tube

Sealed glass tube containing adsorbent filters and suitable

supports for the sulfuric acid indicator. The minimum value

indicated is 0.1 mglm3 with a relative standard deviation of at

most 30 per cent.

Phosphine detector tube

Sealed glass tube containing adsorbent filters and suitable

supports for the gold salt or other appropriate indicator.

The minimum value indicated is 0.2 ppm or less, with a

relative standard deviation of at most 20 per cent.

Sulfur dioxide detector tube

Sealed glass tube containing adsorbent filters and suitable

supports for the iodine and starch indicator. The minimum

value indicated is 0.5 ppm with a relative standard deviation

of at most 15 per cent.

Water vapour detector tube

Sealed glass tube containing adsorbent filters and suitable

supports for the magnesium perchlorate indicator.

The minimum value indicated is 67 ppm or less, with a

relative standard deviation of at most 20 per cent.

2

3

4

}---{>(1--G"<I------,------7

5

6

I. Gas supply

2. Pressure regulator

3. Needle valve

4. V-pioce

5. Indicator tube

6. Indicator rube pump

7. End open to atmosphere

Figure 2.1.6.-1. - Apparatus fqr gas detector tubes

L. Determination of Nitrous Oxide in

Gases

(ph. Eur. method 2.5.35)

Gases absorb light at one or more specific wavelengths. This

property is widely used to allow highly selective measurement

of their concentrations.

Description and principle of measurement

The concentration of nitrous oxide in other gases can be

determined using an infrared analyser.

The infrared analyser generally consists of a light source

emitting broadband infrared radiation) an optical device, a

sample cell and a detector. The optical device may be

positioned either before' or after the sample cell and it

consists of one or several optical filters, through which the

broadband radiation is passed. The optical device in this case

is selected for nitrous oxide. The measurement light beam

passes through the sample cell and may also pass through a

reference cell if the analyser integrates such a feature (some

use an electronic system instead of a reference cell).

When nitrous oxide is present in the sample cell, absorption

of energy in the measurement light beam will occur

according to the Beer-Lambert law and this produces a

change in the detector signal. This measurement signal is

compared to a reference signal to generate an output related

to the concentration of nitrous oxide. The generated signal is

linearised in order to obtain the nitrous oxide concentration.

To prevent the entry of particles into the sensors) which

could cause stray-light phenomena) the apparatus is fitted

with a suitable filter.

M. Water-Solid Interactions:

Determination of Sorption.Deso~tion

Isotherms and of Water Activity

(Ph. Eur. method 2.9.39)

INTRODUCTION

Pharmaceutical solids as raw materials or as constituents of

dosage forms most often come in contact with water during

processing and storage. This may occur (a) during

,

crystallisation, Iyophilisation, wet granulation) or spray

drying; and (b) because of exposure upon handling and

storage to an atmosphere containing water vapour or

exposure to other materials in a dosage fonn that contain

water capable of distributing it to other ingredients. Some

properties known to be altered by the association of solids

with water include rates of chemical degradation in the

"solid-state", crystal growth and dissolution, dispersibility

and wetting) powder flow, lubricity, powder compactibility,

compact hardness and microbial contamination.

Although precautions can be taken when water is perceived

to be a problem, i.e. eliminating all moisture, reducing

contact with the atmosphere) or controlling the relative

humidity of the atmosphere, such precautions generally add

expense to the process with no guarantee that during the life

of the product further problems associated with moisture will

be avoided. It is also important to recognise that there are

many situations where a certain level of water in a solid is

required for proper performance) e.g. powder compaction.

I 17Iis chapter has undergone ph~a1 harmtmisation. Su chapter

5.8. Pharmacopoeial hannonisotion.

www.webofpharma.com