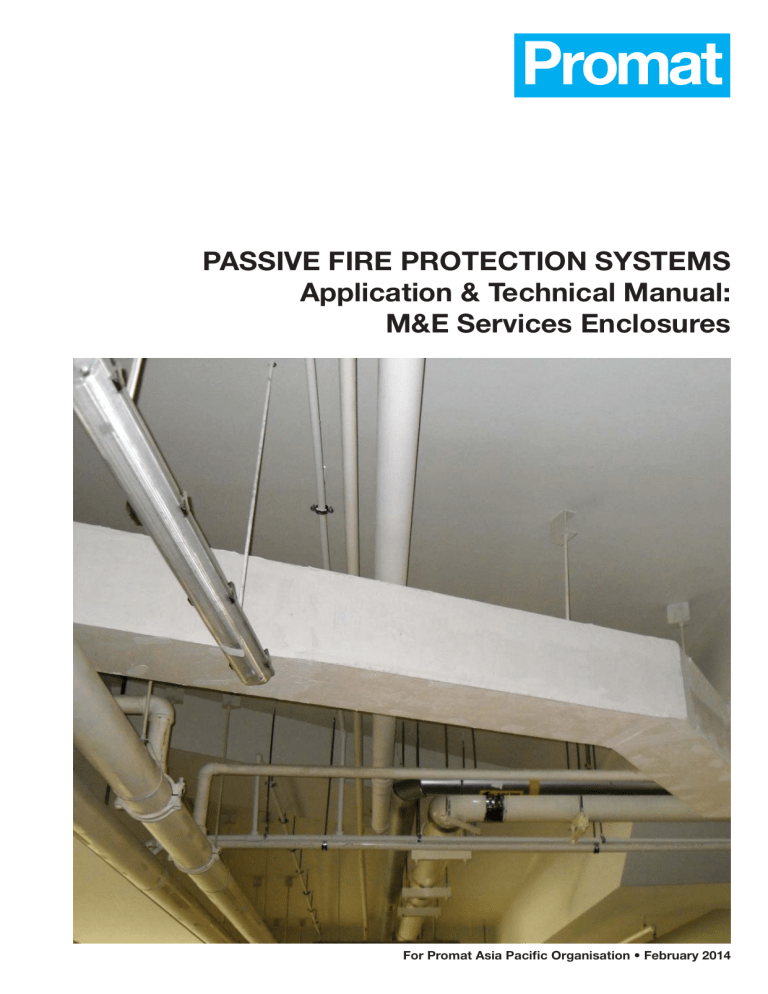

PASSIVE FIRE PROTECTION SYSTEMS Application & Technical Manual: M&E Services Enclosures For Promat Asia Pacific Organisation • February 2014 PASSIVE FIRE PROTECTION SYSTEMS Application & Technical Manual: M&E Services Enclosures – Contents M&E Services Enclosures General Information________ 1 - 3 M&E Services Enclosures System Index _____________ 4 - 5 PROMATECT®-H/ PROMATECT®-L/ PROMATECT®-L500 Electrical Cables Enclosure (External Fire For Circuit Integrity) ___________________ 6 PROMATECT®-H/ PROMATECT®-L/ PROMATECT®-L500 Electrical Cables Enclosure (Internal Fire) ____________________________________ 7 PROMATECT®-H/ PROMATECT®-L/ PROMATECT®-L500 Electrical Cables Enclosure Fixing Details_____________________________________ 8 - 9 PROMATECT®-H/ PROMATECT®-L/ PROMATECT®-L500 Electrical Cables Enclosure Architectural Specification _________________________ 10 PROMATECT®-H M&E Services Enclosure (Integrity & Insulation) _____________________________ 11 PROMATECT®-H M&E Services Enclosure (Integrity Only) ____________________________________ 12 PROMATECT®-L500 M&E Services Enclosure (Integrity & Insulation) _____________________________ 13 - 14 PROMATECT®-H/PROMATECT®-L500/PROMINA® 60 M&E Services Enclosure Fixing Details ______________ 17 - 19 PROMATECT®-H/PROMATECT®-L500/PROMINA® 60 M&E Services Enclosure Architectural Specification ___ 20 PROMATECT®-S M&E Services Enclosure (Integrity & Insulation) _____________________________ 21 PROMATECT®-S M&E Services Enclosure (Integrity Only) ____________________________________ 22 PROMATECT®-S M&E Services Enclosure Fixing Details_____________________________________ 23 - 24 PROMATECT®-S M&E Services Enclosure Architectural Specification _________________________ 25 Enclosure PROMATECT® 50 Riser Pipes Enclosu ulation) _____________________________ 26 (Integrity & Insulation) Enclosure PROMATECT® 50 Riser Pipes Enclosu ____________________________________ 27 Fixing Details_____________________________________ Enclosure PROMATECT® 50 Riser Pipes Enclosu Architectural Specification _________________________ 28 PROMATECT® 50 M&E Services Enclosure (Integrity Only) ____________________________________ 29 PROMATECT® 50 M&E Services Enclosure Architectural Specification _________________________ 30 Cables _____ ___ 31 PROMASTOP® CIS Coating For Electrical Ca PROMASTOP® CIS Coating For Electrical Cables Architectural Specification _________________________ 32 i M&E Services Enclosures General Information General M&E services enclosure at the carpark of Tseung Kwan O residential building in Sai Kung District, New Territories, Hong Kong (above) and outside the warehouse of 9 Benoi Sector, Singapore (left). Both use PROMATECT®-H boards. Electrical cables coated with PROMASTOP® CIS at a warehouse (below) in Ayer Rajah, Singapore. M echanical and electrical (M&E) services require fire protection for the following reasons: 1) To maintain function of certain essential electrical and/or mechanical systems and services, and 2) To prevent fire, smoke and toxic fume propagation from one building compartment to another. It is necessary to ensure the continued function of essential electrical systems and services is maintained during fire, for a specified period of time, until all the building occupants have escaped. Electrical systems that need protection from fire may include: Smoke extraction venting systems Electrically operated fire alarms Water mains supply and pumps servicing sprinkler systems Emergency escape route lighting Essential life support and/or computer, communication or information technology networks Electrically operated extinguishing systems Power supply for fire service elevators in high-rise buildings 1 i M&E Services Enclosures General Information It is worth noting that most electrical and to some extent mechanical services contain a high component of plastic materials such as polyvinylchloride, polypropylene, polyethylene, synthetic rubbers etc. The risks associated with these combustible plastics are such that fire can and will spread or propagate through the services. Intensive combustion also means that plastics frequently release toxic and corrosive fumes that can include particulates, unburned fuel, carbon dioxide and carbon monoxide which are not only harmful to the building and its contents but also to its occupants. Such fires can also cause the following problems: Production of highly corrosive and extremely toxic gases, Long term destruction of buildings and equipment, Smoke development and toxic gases in corridors and escape routes, Difficult evacuation, IEC 60331 fire test Impedance of rescue activities by firefighters. Reliability Of Fire Resistant Cables requirement to maintain the integrity of the encasement and any penetrations through walls or floors, the standard requires that: Typical uses of cables to, in and from M&E enclosure include fire alarms, emergency lighting, addressable alarm systems, CCTV systems, emergency power supplies and smoke and fire shutters. These cables are normally designed to meet the standards for “Fire Detection and Fire Alarm Systems for buildings” (BS 5839: Part 1: 2002 + A2: 2008) and “Codes of Practice for Emergency Lighting of Premisses” (BS 5266: Part 1: 2005). 1) the cables continue to function for the duration of the exposure period, and Many fire resistant cables have been subjected to tests in accordance with BS 6387: 1994 “Specification for performance requirements for cables required to maintain circuit integrity under fire conditions” and/ or ISO IEC 60331: Parts 11, 21, 23 and 25 “Test for electric cables under fire conditions – circuit integrity”. See also ISO IEC 60331: Parts 1, 2 and 3. 2) the temperature on the cable jacket should not exceed 150°C. The tested encasement system protects a wide range of different cable types. Electrical current is passed through the cables throughout the test. As an added safety factor, the system described on page 6 will ensure that the temperature on the cable jacket does not exceed 120°C. Unfortunately, these standards only test single cables or small bunches of cables, without any support system, exposed to a small gas flame by means of an elongated Bunsen burner. The heat applied during the test is localised to a small area. While such a test may be adequate for small cables carefully secured directly to a fire resisting wall or floor, it is arguably not suitable to assess the fire performance of larger cables or bunches of cables, exposed to a fully developed fire on all sides, especially if they are supported on a suspended cable tray which may pass through compartment walls or floors. The Australian/New Zealand standard AS/NZS 3013: 2005 “Electrical installations – Classification of the fire and mechanical performance of wiring system elements” describes the level of protection of a wiring system against fire and/or accidental mechanical damage. The test methods described within this standard call for wiring systems to maintain circuit integrity when subjected to fire tests, mechanical damage and fire and water tests. The resistance to fire test is to determine the ability of a wiring system to maintain circuit integrity under fire conditions for a specified period of time of up to 120 minutes. The wiring system shall be tested in a horizontal furnace complying with AS 1530: Part 4: 2005, which also employs the ISO 834 heating conditions. Although the cables may achieve the highest classification of the standard, they may not survive as expected if they are exposed on all sides to a fully developed fire as described, for example, by the ISO 834 time-temperature fire curve. Mechanical damage tests are to determine the degree of mechanical impact and cutting load to which the wiring system can be subjected without losing its circuit integrity. These tests are carried out separately from the fire test. Fire Resistance Test Standards For Cable Protection Systems The German standards DIN 4102, “Fire behaviour of building materials and building components”, Parts 11 and 12 specify fire resistance test for cable protection systems that simulate a fully developed fire scenario. Fire and water tests assess the ability of a wiring system to maintain its circuit integrity when subjected to fire conditions followed by hosing with water. DIN 4102: Part 12: 1991 and AS/NZS 3013: 2005 are designed to test the functionality of cables under fully exposed fire conditions, unlike the IEC 60331 test regimes. The systems detailed herein relate to maintaining compartmentation as well as the full function of the cables. For more information related to such systems, please consult Promat. DIN 4102: Part 11: 1985 assesses the encasement system when exposed to a fully developed internal fire. The integrity of the encasement, and any penetrations through walls and floors, is measured, as well as the temperature on the outer surface of the encasement (140°C mean temperature rise, 180°C maximum temperature rise). The heating curve for DIN 4102: Part 11: 1985 is the same as that used in BS 476: Part 20: 1987 and AS 1530: Part 4: 2005 and the failure criteria for integrity and insulation are identical. The systems detailed herein have been successfully tested and assessed and are approved for use to provide a performance in accordance with BS 476: Part 20 and AS 1530: Part 4 in terms of compartmentation. In the event of an internal or external fire performance, it has been established that an enclosure fabricated from fire resistant boards is one of the best solutions. Such systems have been tested successfully with encasement constructed from fire protective boards such as PROMATECT -H, PROMATECT -L, PROMATECT -L500, PROMATECT 50 or PROMATECT -S. These well established board systems are representative of the few systems which currently fulfil all performance requirements, especially to the DIN 4102 standards. DIN 4102: Part 12: 1991 assesses the encasement system when exposed to a fully developed external fire. In addition to the Continued on next page 2 General Design Considerations ® ® ® ® ® M&E Services Enclosures General Information i General Design Considerations 6 Access Hatches A suitably designed duct will: For future inspection and installation of cables, a loose lid construction, described on pages 6 and 7, can be considered. Alternatively, the lid can be fixed and the inspection openings with hatches can be provided in the side walls of the enclosure, as shown on page 9. The hatch is secured completely to the enclosure using threaded inserts such as “Tecserts” (Armstrong Fastening Systems) at maximum 200mm centres. prevent the propagation of fire from one building compartment to another, assist in maintaining smoke free escape routes, ensure the continuing operation of other services within a common service shaft, reduce damage to a localised area, contain smoke and toxic fumes from burning cables, and where required, ensure cable maintain their function when exposed to a fully developed fire. 7 Selection of Board Type The Promat system constructed from PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 is lighter than PROMATECT® 50, and would probably be used in most applications. The following are some of the factors to consider when determining the correct specification to ensure the enclosure system provides the required fire performance. Please consult Promat. PROMATECT®-H or PROMATECT® 50 offers a particularly robust system which is also highly resistant to impact and abrasion. Although these products are water tolerant, the latter is generally preferred for more onerous conditions. 1 Required Fire Exposure For tunnel environments and higher performance requirements, e.g. to resist hydrocarbon fires, please consult Promat. The specification of the enclosure system will depend on whether it is expected to resist external fire, internal fire or both. 8 Other Requirements 2 Required Fire Performance Generally, the most onerous requirement is to maintain the functional integrity of the circuit(s) when the system is exposed to external fire. If this is not needed, the performance requirements may be reduced by the approval authority to provide only stability, integrity and insulation of the enclosure system and/or wall and floor penetrations. On some occasions, further relaxations may be approved, e.g. a reduced insulation performance can sometimes be acceptable if no combustible materials or personnel are likely to be in contact with the enclosure. 3 Supporting Structure The supporting hangers and their fixings should be capable of bearing the load of the complete enclosure system including any applied insulation material or other services suspended from it. Chemical anchors are generally not suitable. It is usually not advisable to employ unprotected hangers if the stress exceeds 6N/mm2 for up to 240 minutes fire exposure and 10N/mm2 for up to 120 minutes fire exposure and/or if hanger lengths exceed 2m. Hanger centres should not exceed the distance limits given for the relevant Promat system. 4 Penetrations Through Walls & Floors Care should be taken to ensure that movement of the cable system in ambient or in fire conditions does not adversely affect the performance of the wall, partition or floor penetration seals. 5 Ventilation Openings Heat is generated as current flows through cable core conductors. The greater the electrical current, the hotter the conductor will get. Excessive current flow will cause overheating and may result in overload, short circuit or ground fault. The material of the cable sheath, commonly made from material such as PVC, polyurethane or polyethylene, usually has a self-ignition temperature between 340°C to 490°C. In general, the heat generated by cables is negligible if appropriately vented. Ventilation openings must have a self-enclosing capability in the event of fire so as to prevent fire spread via such openings. It is recommended that an electrical engineer is consulted to ensure heat build-up does not become an issue. Should ventilation be required, see page 9 for PROMASEAL® Ventilation Grille and Promat Ventbox. Acoustic performance, thermal insulation, water tolerance, strength and appearance can also be important considerations (see BS 8313: 1997 Code of practice for accommodation of building services in ducts). Fibre Optics Fibre optic cables have a lower failure temperature (typically 50-80°C) due to the fact that the conductor consists bundles of glass fibres which can be as thin as a human hair. Fibre optic cables are widely used for IT networking in many industries, especially in financial and healthcare services. For example, large banks depend on their network cabling systems for most of their routine business transactions. If fire occurs and even one metre of cabling is destroyed, it could cost the company millions of dollars each day their systems remain inoperative. These are problems that businessmen do not want to face and one reason why it is necessary to protect sensitive, strategically important cables against fire risk. Please consult Promat to determine the required board thickness and construction details. Riser Pipes The Fire Safety Bureau of Singapore requires that the pipe work for a rising main is adequately protected to prevent collapse and reduction of water pressure at the point of water egress in the event of a fire. In addition, fire will heat the water conveyed through the piping system. It is conceivable that water in the pipe could reach boiling point. This would result in additional pressure being placed upon the pipe system as water expands considerably (1:1700) as it turns to steam. This will result in premature failure of the pipes and joints transporting the water, leading to a loss of pressure and consequential inability to fight or extinguish the fire. Therefore it is required that the rising main pipe work is adequately protected to: prevent collapse of the piping system, maintain the fire integrity and insulation of the compartment wall or floor where the piping penetrates, and prevent water passing through the piping system from reaching boiling point. The temperature at any point on the pipe external surface, measured on the fire-exposed side, must not exceed 75°C above the initial temperature for at least the first 30 minutes of exposure to fire. The fire resistance test procedure is described in FSB/PSB/001/00 dated 8 November 2000. 3 M&E Services Enclosures System Index Type PROMATECT®-H/ PROMATECT®-L/ PROMATECT®-L500 electrical cables enclosure (external fire) PROMATECT®-H/ PROMATECT®-L/ PROMATECT®-L500 electrical cables enclosure (internal fire) PROMATECT®-H M&E services enclosure (integrity and insulation) PROMATECT®-H M&E services enclosure (integrity only) PROMATECT®-L500 M&E services enclosure (integrity and insulation / without cover strip) PROMATECT®-L500 M&E services enclosure (integrity and insulation) 4 Fire resistance performance Board thickness 30/30/30 From 20mm 60/60/60 From 35mm Mineral wool thickness x density Test/Approval no. Page no. Not required BRE CC1422.22 and BRE CC90659C to the requirements of BS 476: Part 20: 1987 and/or AS 1530: Part 4: 2005 based on DIN 4102: Parts 11 and 12 6 Not required BRE CC1422.22 and BRE CC90659C to the requirements of BS 476: Part 20: 1987 and/or AS 1530: Part 4: 2005 based on DIN 4102: Parts 11 and 12 7 BRE CC242335 to the requirements of BS 476: Part 20: 1987 11 Not required WF 169576 to the requirements of BS 476: Part 20: 1987 and AS 1530: Part 4: 2005 12 Not required WFRC C80076 and WF 176908 to the requirements of BS 476: Part 20: 1987 13 BRE CC90659B to the requirements of BS 476: Part 20: 1987 and AS 1530: Part 4: 2005 14 90/90/90 From 50mm 120/120/120 From 70mm 30/30/30 From 15mm 60/60/60 From 30mm 90/90/90 From 35mm 120/120/120 From 40mm 60/60/60 9mm 50mm x 60kg/m3 120/120/120 15mm 50mm x 80kg/m3 240/240/240 20mm 100mm x 100kg/m3 120/120/- 9mm 240/240/- 12mm 120/120/30 25mm 240/240/120 50mm 120/120/120 20mm 240/240/240 50mm 50mm x 100kg/m3 80mm x 80kg/m3 M&E Services Enclosures System Index Type Fire resistance performance Board thickness Mineral wool thickness x density Test/Approval no. Page no. 15 60/60/60 9mm 50mm x 100kg/m WF 171133 to the requirements of BS 476: Part 20: 1987 120/120/- 9mm Not required WF 177444 to the requirements of BS 476: Part 20: 1987 16 120/120/120 6mm 100mm x 140kg/m3 BRE CC91117 to the requirements of BS 476: Part 20: 1987 21 BRE CC86559 to the requirements of BS 476: Part 20: 1987 22 BWA 23445-03 to the requirements of BS 476: Part 20: 1987 and FSB/PSB/001/00 test procedure 26 Not required FSRG 2010-019 and FSRG 2010-021 to the requirements of BS 476: Parts 20 and 22: 1987 29 Not required FM 3046711 to the requirements of FM 3971 Approval Standard 31 3 PROMINA® 60 M&E services enclosure (integrity and insulation) PROMINA® 60 M&E services enclosure (integrity only) PROMATECT®-S M&E services enclosure (integrity and insulation) 240/240/240 9.5mm 120/120/- 6mm 140mm x 140kg/m3 Not required PROMATECT®-S M&E services enclosure (integrity only) PROMATECT® 50 riser pipes enclosure (integrity and insulation) 240/240/- 9.5mm 120/120/120 15mm 240/240/240 19mm 50mm x 100kg/m3 50mm x 100kg/m3 PROMATECT® 50 M&E services enclosure (integrity and insulation) -/60/60 External fire for circuit integrity PROMASTOP® CIS electrical cables coating 30mm -- 5 PROMATECT®-H/PROMATECT®-L/PROMATECT®-L500 Electrical Cables Enclosure (External Fire For Circuit Integrity) 51.30/51.60/ PH/PL/PE 51.90/51.12 6 7 5 4 1 9 3 8 2 Up to 120/120/120 fire resistance in accordance with the requirements of BS 476: Part 20: 1987 and AS 1530: Part 4: 2005 1 PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 board, thickness in accordance with table below Internal Cross Section: Equal or smaller than 110mm x 100mm Internal Cross Section: Equal or greater than 110mm x 100mm and equal or smaller than 520mm x 250mm Lid type Board type Up to 30/30/30 Up to 60/60/60 Up to Up to 90/90/90 120/120/120 Up to 30/30/30 Up to 60/60/60 Up to 90/90/90 Up to 120/120/120 Fixed 24mm 45mm 60mm 75mm 20mm 40mm 50mm 65mm PROMATECT®-H Fixed 25mm 40mm Loose fit 25mm 45mm 60mm 80mm 20mm 35mm 50mm 70mm 60mm 80mm 20mm 40mm 60mm 70mm PROMATECT®-L or PROMATECT®-L500 The board thicknesses given in the above table will ensure that when the encasement is exposed to a fully developed cellulosic external fire (BS 476 curve), the cable jacket temperature rise will not exceed 120°C and the cables will remain functional. If the cables are not required to maintain circuit integrity it may be possible to reduce the board thickness after consultation with Promat. Promat can also advise on specifications for larger duct sizes. The board thickness is dependent on the internal dimensions of the duct and whether the duct has a loose fit lid or a fixed lid 2 PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 internal cover strip 100mm x 20mm thick, located between tray and base of duct only. Strips positioned at maximum 625mm centres and coinciding with board joints and supports 7 3 PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 external cover strip to top and side joints only. Not required for multi layer construction providing the joints between the layers are staggered by at least 80mm and are fixed to each other Up to 30/30/30 100mm x 20mm thick Up to 90/90/90 100mm x 25mm thick Up to 60/60/60 100mm x 20mm thick Up to 120/120/120 100mm x 25mm thick 4 PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 batten, 25mm x 20mm thick fixed to loose fit lid. Not required for fixed lid option 5 PROMASEAL® Ventilation Grille, if required 6 Fixings in accordance with the table on page 8. Screws should be deep threaded, self-tapping, drywall type, e.g. Buildex HILO. Alternatively, steel wire staples can be used 7 Threaded steel hanger rod, minimum diameter 8mm at maximum 1220mm centres, ensure maximum stress does not exceed 10N/mm² for up to 120/120/120 fire resistance. Note that when calculating the stress on the support system, the weight of the cables must be considered 8 Supporting galvanised steel angle or channel, size according to weight and dimensions of the enclosure. Maximum permissible bending stress 10N/mm² for up to 120/120/120 fire resistance. Supports should be at maximum 1220mm centres and should coincide with an internal cover strip 2. The cable duct should be supported not more than 500mm from either side of any wall or floor through which it passes 9 Electrical cables and steel cable tray. Cables contaning fibre optics will have a lower failure temperature. Please consult Promat to determine the required board thickness. Note, steel cable trays are required for systems exposed to external fire 6 PROMATECT®-H/PROMATECT®-L/PROMATECT®-L500 Electrical Cables Enclosure (Internal Fire) 52.30/52.60/ PH/PL/PE 52.90/52.12 6 7 5 4 1 9 3 8 2 Up to 120/120/120 fire resistance in accordance with the requirements of BS 476: Part 20: 1987 and AS 1530: Part 4: 2005 1 PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 board, thickness in accordance with table below For stability, integrity in fire compartment / Insulation in adjacent compartment For stability, integrity and insulation in fire compartment Lid type Board type Up to 30/30/30 Up to 60/60/60 Up to 90/90/90 Up to 120/120/120 Up to 30/30/30 Up to 60/60/60 Up to 90/90/90 Up to 120/120/120 Fixed 15mm 30mm 35mm 40mm 20mm 35mm 40mm 50mm PROMATECT®-H Fixed 20mm 30mm 35mm 40mm 25mm 35mm 40mm 52mm Loose fit 20mm 30mm 35mm 40mm 25mm 35mm 40mm 52mm PROMATECT®-L or PROMATECT®-L500 The board thicknesses given in the above table will ensure that the stability, integrity and insulation of the encasement will be maintained when exposed to fully developed cellulosic internal fire (BS 476 curve). For ducts which are not required to satisfy insulation criteria, and for larger ducts, please consult Promat 2 PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 internal cover strip 100mm x 20mm thick, located between tray and base of duct only. Strips positioned at maximum 625mm centres and coinciding with board joints and supports 7 3 PROMATECT®-H external cover strip, 100mm x 9mm thick, to top and side joints only. For ducts with an internal height greater than 300mm replace the external strip with an PROMATECT®-H internal strip 100mm x 15mm thick. Fix side boards to ends of internal strip to strengthen casing, external strips not required for multi layer construction providing the joints between layers are staggered by at least 80mm and are fixed to each other 4 PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 batten, 25mm x 20mm thick fixed to loose fit lid. Not required for fixed lid option 5 PROMASEAL® Ventilation Grille, if required 6 Fixings in accordance with the table on opposite page. Screws should be deep threaded, self-tapping, drywall type, e.g. Buildex HILO. Alternatively, steel wire staples can be used 7 Threaded steel hanger rod, minimum diameter 8mm at maximum 1220mm centres, ensure maximum stress does not exceed 10N/mm². Note that when calculating the stress on the support system, the weight of the cables must be considered 8 Supporting galvanised steel angle or channel, size according to weight and dimensions of the enclosure. Maximum permissible bending stress 10N/mm². Supports should be at maximum 1220mm centres and should coincide with an internal cover strip 2. The cable duct should be supported not more than 500mm from either side of the wall 9 Electrical cables and steel cable tray. Steel cable tray not required for systems exposed to internal fire only unless the cable weight exceeds 25kg/m when a cable tray should be used or the hanger centres reduced 7 PROMATECT®-H/PROMATECT®-L/PROMATECT®-L500 PH/PL/PE Electrical Cables Enclosure Fixing Details 51/52 Fixing of Boards Internal Cross Section Dimensions The Promat cable protection system is fabricated from PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 boards with thickness according to the tables on pages 6 and 7. The boards can be fixed together with steel staples at maximum centres of 100mm or screws at maximum centres of 200mm in accordance with the table below. Up to three layers of boards can be used to fabricate the required thickness. The internal cross section of the enclosure system shall not be more than 1000mm wide x 500mm high. Please consult Promat for cross sections not within this range. This is a self-supporting system and does not require any internal steel framework (subject to width and height of the enclosure not exceeding set limits). Board thickness Screws at 200mm centres Staples at 100mm centres 9mm 25mm x No.6 28/10/1.2 15mm 30mm x No.6 32/10/1.2 20mm 38mm x No.6 50/11/1.5 25mm 50mm x No.6 63/11/1.5 30mm 63mm x No.8 63/11/1.5 35mm 63mm x No.8 70/12/2 40mm 75mm x No.8 80/12/2 50mm 100mm x No.10 80/12/2 60mm 100mm x No.10 90/12/2 75mm Multi layer Fix first layer with screws 100mm Multi layer Fix first layer with screws Joints between the sections of enclosure are reinforced with external cover strips of PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 board, each 100mm wide and a minimum of 9mm thick. The cover strips are fixed with steel staples or screws. Cables And Enclosure Support Cables are normally supported on steel cable trays within the enclosure but these are not always required when the enclosures are subject to internal fire exposure only. The enclosure system must be supported, either by direct fixing to other structural elements with suitable proprietary steel fixings or by hangers at maximum centres of 1220mm. The hanger supports should coincide with enclosure joints. The hangers consist of steel threaded rods and a steel angle bearer section under the protection system. The tensile and bending stresses of the unprotected hangers and bearers must not exceed 10N/mm2 for up to 120 minutes fire resistance. One, Two or Three Sided Protection A one, two or three sided enclosure is acceptable where the other sides of the rectangle are formed from an adjoining wall and floor/ceiling of a fire resistance at least equal to that of the enclosure system, and where under fire conditions the substrates will suffer no deflection or excessive movement. General view of two sided enclosure for external fire protection 6 1 2 Brackets or hanger rods and angles at maximum 1220mm centres 1 2 3 4 5 6 8 3 Cantilever brackets at maximum 1220mm centres Cable tray supported independently within the enclosure on brackets or hangers PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 board, thickness in accordance with the table on page 6 PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 board, thickness in accordance with the table on page 7 Board joints to coincide with bracket positions Board joints covered with PROMATECT®-H cover strip 100mm x 9mm thick PROMATECT®-L or PROMATECT®-L500 cover strip or light steel angle 6 General view of two sided enclosure for internal fire protection 5 4 PROMATECT®-H/PROMATECT®-L/PROMATECT®-L500 PH/PL/PE Electrical Cables Enclosure Fixing Details 51/52 Wall Penetrations The enclosure system, where it passes through a fire compartment wall, has to be fire stopped. At this penetration, gaps up to 20mm wide may be sealed with mineral wool and PROMASEAL®-A Acrylic Sealant. For wider gaps, a PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 collar is required on both sides of the wall. The minimum collar dimensions should be 150mm x 20mm thick. Please refer to illustration at right. PROMATECT® collar PROMATECT® collar Access hatches have to be properly constructed to maintain the fire resistance level of the enclosure system. Hatches generally are comprised of an inner board stapled or secured to the outer board. The inner board should be a close fit to the opening and should be the same thickness as the wall of the enclosure. The outer board should be at least 20mm thick and overlap the opening by at least 50mm on all sides. Mineral wool seal 6 1 3 1 2 3 4 General view of construction of inspection opening for external or internal fire protection 1 2 3 4 5 6 5 General construction of PROMASEAL® Ventilation Grille and Promat Ventbox PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 electrical cable enclosure Outer board sized 50mm larger all around than inner dimensions of opening and 20mm thick Inner board stapled to outer board, sized to fit opening and same thickness as side wall of duct “Tecserts” or similar at maximum 200mm centres PROMASEAL® Ventilation Grille if required and as detailed in illustration at right Promat Ventbox When the cables exit the enclosure, the opening made must be stiffened with PROMATECT®-H, PROMATECT®-L or PROMATECT®-L500 board of at least 50mm width x 20mm thickness. The gaps in the opening must be fully sealed with PROMASEAL®-A Acrylic Sealant for the full depth of the board and the thickness of the stiffener board. See illustration below. PROMASEAL® Ventilation Grille Standard grille size is 93mm x 93mm overall. Can be combined in multiples to create a larger free area. Free area of one grille is 0.0035m2. Friction fit grille in aperture. Use VICUBOND® WR adhesive if a loose fit. Grilles supplied in various thicknesses as follows: 35mm (for 30 minutes), 60mm or 2 x 35mm (for 60 minutes), 75mm (for 90 minutes) and 75 + 35mm (for 120 minutes). Secure 50mm wide cover strips if necessary to ensure grille fully surrounded by board. The grille is supported on the inside of the duct by a perforated steel plate (supplied) secured to the duct wall. Promat Ventbox The ventbox consists of an integral outer frame with collar and an automatically operated closing lid which is activated by a thermal link in the event of a fire. Ventilation openings if required must also be fitted with PROMASEAL® Ventilation Grille or Promat Ventbox. These fittings will ensure that the fire resistance level of the enclosure system is maintained in case of a fire. Free area 0.021m2. Outer dimensions of frame and collar are 515mm x 130mm. Insert ventbox frame into aperture, 465mm x 80mm, and screw down to the board through the collars. 9 PROMATECT®-H/PROMATECT®-L/PROMATECT®-L500 Electrical Cables Enclosure (External Fire For Circuit Integrity/Internal Fire) PH/PL/PE Architectural Specification 51.30/51.60/ 51.90/51.12/ 52.30/52.60/ 52.90/52.12 Following is the standard Architectural Specification for electrical cable enclosure system using PROMATECT®-H/PROMATECT®-L/ PROMATECT®-L500.(1) The designer must determine the suitability of the design to the application and performance requirements before undertaking or constructing any works relating to the specifications and where in doubt should obtain the advice of a suitably qualified engineer. External Fire For Circuit Integrity / Internal Fire (1) Up to 120 minute fire resistance, integrity and insulation in accordance with the criteria of AS 1530: Part 4: 2005 or BS 476: Part 20: 1987(1). Supporting Structure Care should be taken that any structural element by which the enclosure system is supported, e.g. a beam, floor or wall, has at least equivalent fire resistance. Lining Boards Single-layer or multi-layer(1) ____________mm(2) thick PROMATECT®-H/PROMATECT®-L/PROMATECT®-L500(1) matrix engineered mineral boards as manufactured by Promat International (Asia Pacific) Ltd. Internal and external cover strips made of 100mm wide and a minimum of 9mm thick boards, where applicable, are secured to the enclosure over the board joints. Type of Fixing The boards can be fixed together with steel staples at maximum 100mm or screws at maximum centres of 200mm according to the manufacturer’s recommendations. The complete enclosure system will be suspended with hangers at maximum centres of 1220mm with threaded rods, the whole support system is to have less than 10N/mm2 of stress. Tests & Standards The complete system along with material and framing is approved to meet the requirements of AS 1530: Part 4: 2005 and/or BS 476: Part 20: 1987. Jointing Plain butt joints between machined edges of boards.(1) Joints filled in preparation for painting.(1) Joints filled and taped in preparation for decoration.(1) Follow-on Trades Surface of boards to be prepared for painting/plastering/tiling(1) in accordance with manufacturer’s recommendations. NOTE: • (1) delete as appropriate. • (2) insert thickness as appropriate taken from tables on pages 6 and 7. • Perimeter gaps will be filled with fire resistant PROMASEAL®-A Acrylic Sealant. 10 PROMATECT®-H M&E Services Enclosure (Integrity & Insulation) 8 0 5 2 1 58.60/ 58.12/ 58.24 PH 3 4 9 7 7 8 4 2 6 Hanger and stud fixing Up to 60/60/60, 120/120/120 or 240/240/240 fire resistance in accordance with the requirements of BS 476: Part 20: 1987 1 PROMATECT®-H board and mineral wool, requirements in accordance with table below 2 PROMATECT®-H cover strips 100mm wide, thickness in accordance with table below Fire resistance Board/cover strip/collar thickness Mineral wool thickness x density Screw length to frame Screw length to cover strips Maximum stress allowance of hangers 60/60/60 9mm 50mm x 60kg/m³ 25mm 20mm 15N/mm² 120/120/120 15mm 50mm x 80kg/m³ 32mm 25mm 10N/mm² 240/240/240 20mm 100mm x 100kg/m³ 35mm 25mm 6N/mm² Where the enclosure penetrates a fire compartment wall, use 100mm wide PROMATECT®-H collars, thickness in accordance with the above table, fitted around the duct on both sides of the wall forming an L shape using M6 anchor bolts at nominal 600mm centres. See details on page 18 3 Galvanised steel collars minimum 50mm x 50mm x 0.9mm thick coinciding with board joints at nominal 1220mm centres 4 Galvanised steel angles minimum 50mm x 50mm x 0.7mm thick (60/60/60 to 120/120/120 fire resistance) or minimum 50mm x 50mm x 2mm thick (240/240/240 fire resistance) for one, two, three sided construction at corner joints, or galvanised steel angles minimum 30mm x 30mm x 0.7mm thick for four sided construction at corner joints 5 Threaded steel hanger rod, maximum stress allowance in accordance with the above table 6 Galvanised steel angles, minimum 30mm x 30mm x 3mm thick and vary in accordance with weight and dimensions of the enclosure and maximum stress allowance of the hanger 7 Service steel hanger and support, size according to weight and dimensions of the services 8 No. 8 self-tapping screws at maximum 200mm centres, length in accordance with the above table 9 General M&E services, e.g. electrical cable, cable tray, steel pipes etc 0 Fill all penetration gaps with PROMASEAL®-A Acrylic Sealant 11 PROMATECT®-H 58I.12/ 58I.24 PH M&E Services Enclosure (Integrity Only) 2 Nom inal 125 1 0m m 5 3a 9 4 7 7 7 4 8 6 Hanger and stud fixing Fire resistance Board/cover board/collar thickness Maximum stress allowance of hangers 120/120/- 9mm 10N/mm² 240/240/- 12mm 6N/mm² 3b Galvanised steel collars 50mm x 25mm x 0.5mm thick 50mm x 25mm x 0.7mm thick 3a Galvanised steel collars coinciding with board joints at nominal 1220mm centres, size and thickness in accordance with the above table 3b Additional support galvanised steel collars at middle span of the enclosure, size and thickness in accordance with the above table 4 Minimum 30mm x 30mm x 0.5mm thick galvanised steel angles at corner Typical double/large span enclosure Up to 120/120/- or 240/240/- fire resistance in accordance with the requirements of BS 476: Part 20: 1987 5 Threaded steel hanger rod, maximum stress allowance in accordance with 1 PROMATECT®-H board, thickness in accordance with the 6 Galvanised steel angles, minimum 30mm x 30mm x 3mm thick and vary in table at top right 2 PROMATECT -H cover plates 75mm x 75mm and filled ® 12 joints, consult Promat for appropriate dimensions specification the above table as per the required fire resistance performance accordance with weight and dimensions of the enclosure and maximum stress allowance of the hanger with PROMASEAL®-A Acrylic Sealant in all gaps where rod hanger penetrates the enclosure, thickness in accordance with the table at top right 7 Service steel hanger and support, size according to weight and dimensions Where the enclosure penetrates a fire compartment wall, use 100mm wide PROMATECT®-H collars, thickness in accordance with the above table, fitted around the duct on both sides of the wall forming an L shape using M6 anchor bolts at nominal 600mm centres. See details on page 18 8 Minimum 25mm long self-tapping screws at nominal 200mm centres of the services 9 General M&E services, e.g. electrical cable, cable tray, steel pipes etc PROMATECT®-L500 PE M&E Services Enclosure (Integrity & Insulation / Without Cover Strip) 58.12.1/ 58.24.1 9 1 8 4 2 7 6 3 5 Up to 120/120/120 or 240/240/240 fire resistance in accordance with the requirements of BS 476: Part 20: 1987 1 PROMATECT®-L500 board, thickness in accordance with table below Fire resistance Board thickness Screw length Maximum stress allowance of hangers 120/120/30 25mm 50mm 10N/mm² 240/240/120 50mm 75mm 6N/mm² Where the enclosure penetrates a fire compartment wall, use 100mm wide x 9mm thick PROMATECT®-H collars, fitted around the duct on both sides of the wall forming an L shape using M6 anchor bolts at nominal 600mm centres. See details on page 18 2 Galvanised steel collars minimum 50mm x 25mm x 0.5mm thick at nominal 1220mm centres. All board joints to coincide with a framing member 3 Galvanised steel angle minimum 30mm x 30mm x 0.5mm thick at corners 4 Threaded steel hanger rod, maximum stress allowance in accordance with the above table 5 Galvanised steel angles, minimum 30mm x 30mm x 3mm thick and vary in accordance with weight and dimensions of the enclosure and maximum stress allowance of the hanger 6 Service steel hanger and support, size according to weight and dimensions of the services 7 No. 8 self-tapping screws at maximum 200mm centres, length in accordance with the above table 8 General M&E services, e.g. electrical cable, cable tray, steel pipes etc 9 Fill all penetration gaps with PROMASEAL®-A Acrylic Sealant 13 PROMATECT®-L500 M&E Services Enclosure (Integrity & Insulation) 7 0 5 2 1 58.12.2/ 58.24.2 PE 3 4 9 6 7 8 4 2 6 Hanger and stud fixing Up to 120/120/120 or 240/240/240 fire resistance in accordance with the requirements of BS 476: Part 20: 1987 and AS 1530: Part 4: 2005 1 PROMATECT®-L500 board and mineral wool, requirements in accordance with table below 2 100mm wide PROMATECT®-H cover strips, thickness in accordance with table below (1) Fire resistance Board/cover strip/collar thickness Mineral wool thickness x density Screw length Maximum stress allowance of hangers 120/120/120 (1) 20mm 50mm x 100kg/m³ 45mm 10N/mm² 240/240/240 50mm 80mm x 80kg/m³ 75mm 6N/mm² Tested to BS 476: Part 20: 1987 only Where the enclosure penetrates a fire compartment wall, use 100mm wide PROMATECT®-H collars, thickness in accordance with the above table, fitted around the duct on both sides of the wall forming an L shape using M6 anchor bolts at nominal 600mm centres. See details on page 18 3 Galvanised steel collars 50mm x 50mm x 0.9mm thick coinciding with board joints at nominal 1220mm centres. See more details on page 17 4 Galvanised steel angles minimum 50mm x 50mm x 0.9mm thick for one, two, three sided construction at corner joints, or galvanised steel angles minimum 30mm x 30mm x 0.5mm thick for four sided construction at corner joints 5 Threaded steel hanger rod, maximum stress allowance in accordance with the above table 6 Galvanised steel angles, minimum 30mm x 30mm x 3mm thick and vary in accordance with weight and dimensions of the enclosure and maximum stress allowance of the hanger 7 Service steel hanger and support, size according to weight and dimensions of the services 8 No. 8 self-tapping screws at maximum 200mm centres, length in accordance with the above table 9 General M&E services, e.g. electrical cable, cable tray, steel pipes etc 0 Fill all penetration gaps with PROMASEAL®-A Acrylic Sealant 14 PROMINA® 60 PMF M&E Services Enclosure (Integrity & Insulation) 9 58.60 2 6 1 3 4 5 0 8 8 5 9 7 Hanger and stud fixing Up to 60/60/60 fire resistance in accordance with the requirements of BS 476: Part 20: 1987 1 PROMINA® 60 board 9mm thick Where the enclosure penetrates a fire compartment wall, use 100mm wide x 9mm thick PROMINA® 60 collars fitted around the duct on both sides of the wall forming an L shape using M6 anchor bolts at nominal 600mm centres. See details on page 18 2 PROMINA® 60 cover plates 75mm x 75mm x 9mm thick and filled with PROMASEAL®-A Acrylic Sealant in all gaps where rod hanger penetrates the enclosure 3 Mineral wool 50mm x 100kg/m³ 4 Galvanised steel collars 50mm x 30mm x 0.6mm thick coinciding with board joints at nominal 1220mm centres 5 Galvanised steel angles minimum 50mm x 50mm x 0.5mm thick for one, two, three or four sided construction at corner joints 6 Threaded steel hanger rod, maximum stress allowance 15N/mm² 7 Galvanised steel angles, minimum 30mm x 30mm x 3mm thick and vary in accordance with weight and dimensions of the enclosure 8 Service steel hanger and support, size according to weight and dimensions of the services 9 No. 8 x 25mm self-tapping screws at maximum 200mm centres 0 General M&E services, e.g. electrical cable, cable tray, steel pipes etc 15 PROMINA® 60 PMF M&E Services Enclosure (Integrity Only) 58I.60 2 Nom inal 122 1 0m m 5 3a 9 7 7 7 4 4 8 6 Hanger and stud fixing 3a Galvanised Galvanised steel collars 50mm x 30mm x 0.6mm coinciding with board joints at nominal 1220mm centres 3b Additional support galvanised steel collars 50mm x 30mm x 0.6mm at middle span of the enclosure 3b 4 Minimum 30mm x 30mm x 0.5mm thick galvanised steel angles at corner joints, consult Promat for appropriate dimensions specification 5 Threaded steel hanger rod, maximum stress allowance 10N/mm² Typical double/large span enclosure 6 Galvanised steel angles, minimum 30mm x 30mm x 3mm thick and vary in accordance with weight and dimensions of the enclosure Up to 120/120/- fire resistance in accordance with the requirements of BS 476: Part 20: 1987 1 PROMINA® 60 board 9mm thick Where the enclosure penetrates a fire compartment wall, use 100mm wide x 9mm thick PROMINA® 60 collars fitted around the duct on both sides of the wall forming an L shape using M6 anchor bolts at nominal 600mm centres. See details on page 18 2 PROMINA® 60 cover plates 75mm x 75mm x 9mm thick and filled with PROMASEAL®-A Acrylic Sealant in all gaps where rod hanger penetrates the enclosure 16 7 Service steel hanger and support, size according to weight and dimensions of the services 8 No. 8 x 25mm self-tapping screws at nominal 200mm centres 9 General M&E services, e.g. electrical cable, cable tray, steel pipes etc PROMATECT®-H/PROMATECT®-L500/PROMINA® 60 M&E Services Enclosure Fixing Details PH/PE/ PMF 58/58I Internal Steel Framework Building Services And Enclosure Support The corner junctions of the enclosure are reinforced with internal steel angles, minimum size according to system specification. These corner angles are not necessary if boards of thickness 20mm and above are used, as the boards can be fixed to each other using deep thread drywall type screws or steel wire staples. The hangers used to support the building services enclosure must have tensile and bending stresses not exceeding 15N/mm2, 10N/mm2 and 6N/mm2 for fire resistance up to 60, 120 and 240 minutes respectively. If these stress levels are exceeded, the size of the hanger members must be increased or, alternatively, the spacing of the hangers reduced. The fixings used to fasten the threaded hanger rods to concrete soffits must be all steel expanding anchors with at least 80mm length penetrating into the concrete of at least 40mm for 120 minute fire resistance and 60mm for 240 minute fire resistance. The anchors must match the size of the threaded rods, be of sufficient strength to support the weight of the enclosure and be fitted in accordance with the manufacturer’s specification. When the hanger rods are suspended from protected structural steel beams, the rods must be protected for at least 300mm from the beams with the same levels of protection as the structural beams. External steel angle Internal steel angle Four-sided steel channel collars are positioned at approximately 1220mm centres to support the boards. The steel channels are of minimum size 50mm x 25mm x 0.5mm, up to 50mm x 50mm x 1.2mm thick depending on the system specification. Collar section with external cover strips Steel channel framed enclosure Fixing of Boards & Mineral Wool The type of board and thickness shall be selected according to system specification and the required fire resistance level. The boards are fastened to the channel frames and corner angles with self-tapping screws of appropriate length at 200mm nominal centres. For systems where corner angles are not used, i.e. for 20mm or thicker boards, the boards are to be fastened at the corners with steel self-tapping screws at 200mm nominal centres or steel staples at 100mm nominal centres as per the below table. Board thickness Screws at 200mm centres Staples at 100mm centres 9mm 25mm x No.6 – 15mm 30mm x No.6 – 20mm 38mm x No.6 63/10/1.0 50mm 100mm x No.10 80/12/2.0 Longitudinal joints in the boards (other than the corner joints) must be backed by a steel channel. All butt joints, as required by system specification, are covered with 100mm x 9mm thick PROMATECT®-H cover strips that may be placed either externally or internally. The cavity between the boards and the building services is filled with mineral wool with thickness and density corresponding to the system’s requirement. The steel channels are also filled with the same mineral wool. See the illustrations of Collar section with external or internal cover strips. Collar section with internal cover strips Where the hangers exceed 2000mm in length, the hangers should be clad with a material of similar thickness to the enclosure to prevent excessive thermal expansion. Where the hanger rods emerge from the enclosure, the hole/slot must be sealed with PROMASEAL®-A Acrylic Sealant and with or without a cover plate depending on the gap at penetration. Please consult Promat when in doubt. If the building service being encased is a plastic pipe, external hangers and angles will be required to independently support the enclosure. 17 PROMATECT®-H/PROMATECT®-L500/PROMINA® 60 M&E Services Enclosure Fixing Details PH/PE/ PMF 58/58I Wall Penetrations Where the enclosure passes through a fire compartment wall, the penetration must be properly fire stopped. At this penetration, gaps up to 20mm wide may be sealed with mineral wool and PROMASEAL®-A Acrylic Sealant. For wider gaps, a PROMATECT®-H, PROMATECT®-L, PROMATECT®-L500 or PROMINA® 60 collar is required on both sides of the wall. The minimum collar dimensions should be 150mm x 20mm thick. The space between the enclosure and the reveal of the opening in the wall is filled with mineral wool of minimum 110kg/m3 density. One layer of L-shaped PROMATECT®-H collar is required to be fitted around the enclosure on both sides of the wall. See tables on pages 11 to 14 for thicknesses suitable for different types of enclosure and fire resistance requirements. Please refer to illustration at right. PROMATECT®-H collar PROMATECT®-H collar Mineral wool seal Internal Cross Section Dimensions (more than 1500mm x 1500mm) The maximum approved internal dimensions of the enclosure is 6000mm wide x 2500mm high. For enclosures with internal dimensions greater than 1500mm x 1500mm, additional threaded rods are fitted at each hanger position, at 1220mm maximum centres across the width of the enclosure. These threaded rods pass through the enclosure and support the horizontal hanger support element beneath the enclosure. The rods also support the top of the enclosure using a nut and large steel washer, this prevents bowing under fire conditions of wide enclosure systems. As the width of the enclosure system increases, the spacing of the channel collars must be reduced so that the maximum area of unsupported board does not exceed 1.5m2. Typical enclosure up to 6000mm wide x 2500mm high The penetrations of the rods through the enclosure are sealed with PROMASEAL®-A Acrylic Sealant. Please note, the requirements for additional hanger support within the duct for greater width, e.g. 6000mm duct, will require two central supports at maximum 1220mm centres. One, Two or Three Sided Protection One, two or three sided enclosures are constructed in the same way as a four sided enclosure. Steel angles of 50mm x 50mm x 0.9mm thick and 3mm thick for up to 120 and 240 minutes fire protection respectively, are fastened to the floor soffit or wall with M8 all steel expanding anchors at 500mm nominal centres. The PROMATECT®-H, PROMATECT®-L500 or PROMINA® 60 boards forming the walls of the protection to the building services are then fastened to the angles with steel self-tapping drywall type screws in appropriate length at 200mm nominal centres. The services are independently supported. Two sided M&E services enclosure One sided M&E services enclosure 18 Three sided M&E services enclosure PROMATECT®-H/PROMATECT®-L500/PROMINA® 60 M&E Services Enclosure Fixing Details PH/PE/ PMF 58/58I Transformation Sections The figure to the right shows a common transformation section. Where board joints abut at an angle and it is not possible to back the joint with steel channels, angles bent to the appropriate degree are used to back these joints. The steel channels should always be placed to limit the total unsupported area of board to a maximum of 1.5m2. Bends or curved shapes must be supported with hangers at mid-span. Vertical Enclosures Access Panels The construction of vertical enclosures is the same as for the horizontal enclosures. Where a vertical enclosure is located adjacent to a wall, the enclosure should be restrained back to the wall with threaded rods and support sections. Maximum allowable dimensions of access panels are 600mm x 600mm. The panels are fixed to the enclosure through steel channels using steel bolts and nuts at nominal 200mm centres. The thickness of the boards and the mineral wool specifications should be according to system requirements. The mineral wool can be encapsulated within the C-channel sections which in turn are fixed to the access panel by means of steel self-tapping screws. Enclosure The weight of the enclosure assembly must be fully supported at each floor level. Steel angles may be fitted to the enclosure at floor penetration level and sit upon the floor slab, supporting the weight of the enclosure. Access panel Cross section of access panel 19 PROMATECT®-H/PROMATECT®-L500/PROMINA® 60 M&E Services Enclosure (Integrity & Insulation/Integrity Only) Architectural Specification PH/PE 58.60/58I.60 58.12/58I.12/ 58.24/58I.24 Following is the standard Architectural Specification for general building services enclosure system constructed using PROMATECT®-H/ PROMATECT®-L500/PROMINA® 60.(1) The designer must determine the suitability of the design to the application and requirements before undertaking or constructing any works relating to the specifications and where in doubt should obtain the advice of a suitably qualified engineer. External & Internal Fire ____________ minute integrity and ____________ minute insulation in accordance with the criteria of AS 1530: Part 4: 2005 and/or BS 476: Part 20: 1987.(1) Supporting Structure Care should be taken that any structural element by which the enclosure system is supported, e.g. a beam, floor or wall, has at least equivalent fire resistance. Lining Boards Single-layer ____________mm(2) thick PROMATECT®-H/PROMATECT®-L500/PROMINA® 60(1) matrix engineered mineral boards as manufactured by Promat International (Asia Pacific) Ltd. Internal or external cover strips made of 100mm wide and a minimum of ____________mm(2) thick boards, where applicable, are secured to the enclosure over the board joints. Type of Fixing Galvanised steel frame made of channel sections minimum 50mm x 25mm x 0.5mm thick, up to 50mm x 50mm x 1.2mm thick depending on the system specification, at 1220mm centres or at every butt joint of boards, with corner angles 30mm x 30mm with thickness of 0.5mm or 0.7mm, depending on the system specification, are fixed to the channel collars at the corners. The services will be suspended with hanger rods with hanger diameter sized to limit stress, ____________N/mm2 (3). PROMATECT®-H/PROMATECT®-L500/PROMINA® 60(1) boards will be screw fixed to the frame with ____________mm(4) self-tapping screws at 200mm centres. Where applicable, butt joints should be covered with 100mm wide x ____________mm(2) thick cover strips. Mineral wool in accordance with the system specification will be tightly filled around the existing services, i.e. between the gap of boards and the services. Tests & Standards The complete system along with material and framing is approved to meet the requirements of AS 1530: Part 4: 2005 and/or BS 476: Part 20: 1987. Jointing Plain butt joints between machined edges of boards.(1) Joints filled in preparation for painting.(1) Joints filled and taped in preparation for decoration.(1) Follow-on Trades Surface of boards to be prepared for painting/plastering/tiling(1) in accordance with manufacturer’s recommendations. NOTE: • (1) delete as appropriate. • (2) insert appropriate board thickness taken from which system detailed on pages 11 to 14. • (3) insert hanger stress limits by not exceeding 15N/mm2 for 60 minutes, 10N/mm2 for 120 minutes or 6N/mm2 for 240 minutes. • (4) insert screw length as appropriate taken from which system detailed on pages 11 to 14. • Perimeter gaps will be filled with fire resistant PROMASEAL®-A Acrylic Sealant. 20 PROMATECT®-S 58.12/ 58.24 PS M&E Services Enclosure (Integrity & Insulation) 2 1 3 6 7 4 2 5 Up to 120/120/120 or 240/240/240 fire resistance in accordance with the requirements of BS 476: Part 20: 1987 1 PROMATECT®-S board and mineral wool, requirements in accordance with table below Fire resistance Board thickness Mineral wool thickness x density 120/120/120 6mm 100mm x 140kg/m³ 240/240/240 9.5mm 140mm x 140kg/m³ 2 Galvanised steel flanges, fabricated by cutting and welding 50mm x 50mm x 3mm thick angles, are bolted together with M10 nuts and bolts at nominal 200mm centres to form continuous sections 3 Corner galvanised steel angle reinforcement, 50mm x 50mm x 3mm thick, these corner angles do not require any mechanical fixing to the flanges 2 4 Enclosure steel hanger and supporting angle, size according to weight and dimensions of the enclosure and the required fire resistance. Maximum spacing of hanger is 1800mm centres. Stress limits less than 10N/mm² for 120/120/120 fire resistance and 6N/mm² for 240/240/240 fire resistance 5 Service steel hanger and support, size according to weight and dimensions of the services 6 35mm x 5.5mm Teks screws at nominal 200mm centres 7 General M&E services, e.g. cable trunking, steel pipes etc The above M&E services enclosure is suitable for providing protection to services even under extremely aggressive environments The maximum permissible dimensions for this enclosure are 2000mm x 500mm for up to 240/240/240 fire resistance. The width may be increased to 3000mm if an additional threaded rod is fitted at each hanger position at about mid width which passes through the enclosure and supports the angle of the hanger under the enclosure 21 PROMATECT®-S 58I.12/ 58I.24 PS M&E Services Enclosure (Integrity Only) 1 2 3 6 7 4 5 2 Up to 120/120/- or 240/240/- fire resistance in accordance with the requirements of BS 476: Part 20: 1987 1 PROMATECT®-S board, thickness in accordance with table below Fire resistance Board thickness 120/120/- 6mm 240/240/- 9.5mm 2 Galvanised steel flanges, fabricated by cutting and welding 50mm x 50mm x 3mm thick angles, are bolted together with M10 nuts and bolts at nominal 500mm centres to form continuous sections 3 Corner galvanised steel angle reinforcement, 50mm x 50mm x 3mm thick for enclosure up to 1500mm x 1500mm; 50mm x 50mm x 5mm thick for enclosure up to 2000mm x 2000mm 4 Enclosure steel hanger and supporting angle, size according to weight and dimensions of the enclosure and the required fire resistance. Maximum spacing of hanger is 1800mm centres 5 Service steel hanger and support, size according to weight and dimensions of the services 6 35mm x 5.5mm Teks screws at nominal 200mm centres 7 General M&E services, e.g. cable trunking, steel pipes etc The above M&E services enclosure is suitable for providing protection to services even under extremely aggressive environments The maximum permissible dimensions for this enclosure are 6000mm x 2000mm for up to 240/240/- fire resistance. Where the enclosure is more than 2400mm wide, all intermediate longitudinal board joints will require additional steel framing at the joints of 50mm x 50mm x 3mm thick double angles (back to back) or 50mm x 50mm x 6mm thick T-section 22 PROMATECT®-S M&E Services Enclosure Fixing Details PS 58/58I Steel Framework The corner junctions of the PROMATECT®-S M&E services enclosure are reinforced with internal steel angles, minimum size 50mm x 50mm x 3mm. The PROMATECT®-S board is connected with M5.5mm steel self-tapping Teks screws at 200mm centres. Transverse board joints are connected in the same manner but with 100mm x 3mm thick steel flat. 2 1 3 External steel angle 2 1 3 Internal steel angle 1 PROMATECT®-S board, 6 or 9.5mm thick depending on required fire resistance performance 2 Galvanised steel flanges, fabricated by cutting and welding 50mm x 50mm x 3mm thick angles, are bolted together with M10 nuts and bolts at nominal 500mm centres to form continuous sections 3 Corner galvanised steel angle reinforcement, 50mm x 50mm x 3mm thick for enclosure up to 1500mm x 1500mm or 50mm x 50mm x 5mm thick for enclosure up to 2000mm x 2000mm Fitting of Mineral Wool Mineral wool insulation is laid in the soffit boards of the PROMATECT®-S enclosure. For the top and sides, however, the insulation is fixed in place using nominal M4 selftapping screws with 25mm diameter steel washers at nominal 300mm centres in a grid formation. If the insulation is fitted in two or more layers, the joints between the slabs are staggered by at least 300mm between layers. If the insulation is fitted in a single layer, the joints between slabs are sealed and bonded together using VICUBOND® WR adhesive. 23 PROMATECT®-S M&E Services Enclosure Fixing Details PS 58/58I Internal Cross Section Dimensions Wall Penetrations The maximum approved internal dimension of the enclosure is 2500mm wide x 500mm high. The width may be increased to 3000mm if an additional rod is fitted at each hanger position at mid width. The rod passes through the enclosure and supports the horizontal bearer of the support system beneath the enclosure. The rod also supports the top of the enclosure with a nut and large steel washer on each side of the board. The penetration of the rod through the enclosure must be sealed with PROMASEAL®-A Acrylic Sealant. Where the enclosure passes through a fire compartment wall, the penetration must be properly constructed and sealed. Angles 50mm x 50mm x 3mm are fixed to the top and sides of the enclosure and should be set in a position central to the thickness of the compartment wall. The gap between the exterior surface of the enclosure and the perimeter of the wall aperture should be filled either side and over the angles using 140kg/m3 mineral wool slabs friction fitted. The aperture is then covered by an L-shape PROMATECT®-S collar which should extend from the surface of the enclosure and overlap the wall aperture by a minimum of 100mm. The PROMATECT®-S collar should be fixed to the wall using all-steel anchors at nominal 500mm centres. Building Services & Enclosure Support The hangers used to support the building services enclosure must have tensile and bending stresses not exceeding 10N/mm2 and 6N/mm2 for fire resistance up to 120 and 240 minutes respectively. If these stress levels are exceeded, the size of the hanger members must be increased. Alternatively, the spacing of the hangers can be reduced. The maximum spacing of the hangers is 1800mm centres but this depends on the length of the individual sections. PROMATECT®-S collar PROMATECT®-S collar The fixings used to fasten the threaded hanger rods to concrete soffits must be all steel expanding anchors with a penetration into the concrete of at least 40mm for 120 minute fire resistance and 60mm for 240 minute fire resistance. The anchors must match the size of the threaded rods and be of sufficient strength to support the weight of the enclosure. Anchors must be fitted in accordance with the manufacturer’s specification. When the hanger rods are suspended from protected structural steel beams, the rods must be protected for at least 300mm from the beams with the same levels of protection as the structural beams. Mineral wool seal If the building service being encased is a plastic pipe, external hangers and angles will be required to independently support the enclosure. One, Two or Three Sided Protection One, two or three sided enclosures are constructed in the same manner as a four sided enclosure. The PROMATECT®-S board is connected to the masonry/concrete wall or concrete floor soffit using the same steel angle and screws to the board and M12 all steel expansion bolts, at 500mm maximum centres into the substrate. The bolts must have a minimum penetration into the wall or floor of 60mm. The services are independently supported. Two sided M&E services enclosure One sided M&E services enclosure Three sided M&E services enclosure 24 PROMATECT®-S M&E Services Enclosure (Integrity & Insulation/Integrity Only) Architectural Specification PS 58.12/58.24/ 58I.12/58I.24 Following is the standard Architectural Specification for general building services enclosure system using PROMATECT®-S. The designer must determine the suitability of the design to the application and requirements before undertaking or constructing any works relating to the specifications and where in doubt should obtain the advice of a suitably qualified engineer. External & Internal Fire Up to 240 minutes fire resistance, integrity and where pertinent insulation in accordance with the criteria of BS 476: Part 20: 1987. Supporting Structure Care should be taken that any structural element by which the enclosure system is supported, e.g. a beam, floor or wall, has at least equivalent fire resistance. Lining Boards Single-layer 6mm/9.5mm(1) PROMATECT®-S cement/steel composite boards as manufactured by Promat International (Asia Pacific) Ltd. Type of Fixing The services will be suspended with hanger rods of diameter sized to limit stress, = 10N/mm2 and = 6N/mm2 for 120 minute and 240 minute fire exposure respectively. Mild steel frame made of steel angles, minimum size 50mm x 50mm of thickness 3mm or 5mm, depending on the system specification, are used at the corners of the enclosure. 100mm x 3mm thick steel flat plates are positioned such that they coincide with the transverse joints of the boards. The steel framework may be mechanically connected or welded together at all junctions. PROMATECT®-S boards will be screw fixed to the frame with 35mm x 5.5mm Teks screws at 200mm centres. Mineral wool in accordance with the system specification will be tightly filled around the existing services, i.e. between the gap of boards and the services. External hangers to support the enclosure with hanger diameter sized to limit stress, = 10N/mm2 and = 6N/mm2 for 120 minute and 240 minute fire exposure respectively are located at not more than 1800mm centres. Tests & Standards The complete system along with the material and framing is approved to meet the requirements of BS 476: Part 20: 1987. NOTE: • (1) delete as appropriate. • Perimeter gaps will be filled with fire resistant PROMASEAL®-A Acrylic Sealant. 25 PROMATECT® 50 P50 Riser Pipes Enclosure (Integrity & Insulation) 5 54.12/ 54.24 3 4 2 7 6 1 Up to 120/120/120 or 240/240/240 fire resistance in accordance with the requirements of BS 476: Part 20: 1987 and FSB/PSB/001/00 test procedure 1 PROMATECT® 50 board and mineral wool, requirements in accordance with table below Fire resistance Board thickness Mineral wool thickness x density Screw length Maximum stress allowance of hangers 120/120/120 15mm 50mm x 100kg/m³ 45mm 10N/mm² 240/240/240 19mm 50mm x 100kg/m³ 65mm 6N/mm² 2 Galvanised steel angle or collar minimum 50mm x 50mm x 0.6mm thick at maximum 1220mm centres 3 Joints to be fully sealed with all purpose plaster jointing compound 4 Galvanised steel angle minimum 30mm x 30mm x 0.6mm at corners 5 Riser pipe steel hanger and support, maximum stress allowance in accordance with the above table 6 No. 6 self-tapping screws at nominal 200mm centres, length in accordance with the above table 7 Riser pipe, with diameter and pipe thickness fall within following range Nominal pipe diameter 100mm to 600mm 26 Pipe thickness 5mm to 12.5mm Hp/A -1 210m to 12.6m-1 PROMATECT® 50 P50 Riser Pipes Enclosure Fixing Details 54 Wall Penetrations Where the enclosure passes through a fire compartment wall, the penetration must be properly sealed. The gap between the enclosure and the wall opening is fully filled with PROMASEAL®-A Acrylic Sealant. Typical riser pipes enclosure in wall penetration Alternative method for riser pipes enclosure in wall penetration One, Two or Three Sided Protection One, two or three sided enclosures are constructed in the same way as a four sided enclosure. Steel angles of 40mm x 40mm x 0.6mm thick are fastened to the floor soffit or wall with M6 all steel expanding anchors at 600mm nominal centres. The PROMATECT® 50 boards forming the walls of the protection to the building services are then fastened to the angles with steel self-tapping screws in appropriate length at 200mm nominal centres. The services are independently supported. Two sided riser pipes enclosure One sided riser pipes enclosure Three sided riser pipes enclosure 27 PROMATECT® 50 Riser Pipes Enclosure (Integrity & Insulation) Architectural Specification P50 54.12/ 54.24 Following is the standard Architectural Specification for general building services enclosure system using PROMATECT® 50. The designer must determine the suitability of the design to the application and requirements before undertaking or constructing any works relating to the specifications and where in doubt should obtain the advice of a suitably qualified engineer. External & Internal Fire Up to 240 minutes fire resistance, integrity and where pertinent insulation in accordance with the criteria of BS 476: Part 20: 1987 and FSB/PSB/001/00 Test Procedure. Supporting Structure Care should be taken that any structural element by which the enclosure system is supported, e.g. a beam, floor or wall, has at least equivalent fire resistance. Lining Boards Single-layer 15mm/19mm(*) PROMATECT® 50 cement bound matrix boards as manufactured by Promat International (Asia Pacific) Ltd. Type of Fixing The services will be suspended with hanger rods of diameter sized to limit stress, = 10N/mm2 and = 6N/mm2 for 60 minutes and 240 minutes fire exposure respectively. Steel frame is comprised of mild steel collars of 50mm x 50mm thickness and 6mm steel angle or “U” channel, located at maximum 1220mm intervals, and connected by steel corner angle of 30mm x 30mm x 0.6mm at four corners. PROMATECT® 50 boards will be screw fixed to the frame with No. 6 self-tapping drywall screws of appropriate length at nominal 200mm centres. Mineral wool in accordance with the system specification will be tightly filled around the existing riser pipe, i.e. between the gap of boards and the pipe. Tests & Standards The complete system along with the material and framing is approved to meet the requirements of BS 476: Part 20: 1987 and FSB/PSB/001/00 dated March 2007. NOTE: • (1) delete as appropriate. • Perimeter gaps will be filled with fire resistant PROMASEAL®-A Acrylic Sealant. 28 PROMATECT® 50 P50 M&E Services Enclosure (Integrity & Insulation) 58I.60 2 6 1 5 7 2 8 4 1 7 Up to -/60/60 fire resistance in accordance with the requirements of BS 476: Parts 20 and 22: 1987 1 Two layers of PROMATECT® 50 board 15mm thick 2 Two layers of PROMATECT® 50 board 15mm thick access panel, maximum size 450mm x 350mm (optional) 3 Galvanised steel angle minimum 50mm x 50mm x 1mm 4 Galvanised steel angle minimum 60mm x 30mm x 1mm 5 Galvanised steel channel minimum 30mm x 50mm x 30mm x 1.2mm 6 M6 steel anchor bolts at nominal 500mm centres 7 No. 6 self-tapping screws at nominal 200mm centres 8 General M&E services 29 PROMATECT® 50 M&E Services Enclosure (Integrity & Insulation) Architectural Specification P50 58I.60 Following is the standard Architectural Specification for general building services enclosure system using PROMATECT® 50. The designer must determine the suitability of the design to the application and requirements before undertaking or constructing any works relating to the specifications and where in doubt should obtain the advice of a suitably qualified engineer. External & Internal Fire Up to 60 minutes fire resistance, integrity and insulation in accordance with the criteria of BS 476: Parts 20 and 22: 1987. Supporting Structure Care should be taken that any structural element by which the enclosure system is supported, e.g. a beam, floor or wall, has at least equivalent fire resistance. Lining Boards Double layer 15mm PROMATECT® 50 cement bound matrix boards as manufactured by Promat International (Asia Pacific) Ltd. Type of Fixing The services will be fixed to wall or floor slab with appropriate steel anchor fixing. Steel frame comprised of 30mm x 50mm of thickness 1.2mm steel channel and minimum 50mm x 50mm x 1.0mm angle, are constructed around services forming an enclosure for protection purposes. Depending on dimensions of enclosure, additional supporting brackets may be incorporated where necessary. Both layers of PROMATECT® 50 boards will be screw fixed to the frame with No. 6 self-tapping drywall screws of appropriate length at nominal 200mm centres. Where necessary, access panel of maximum dimensions 350mm x 450mm, fabricated using 2 x 15mm PROMATECT® 50 boards may be incorporated. Tests & Standards The complete system along with the material and framing is approved to meet the requirements of BS 476: Part 20: 1987. NOTE: • Perimeter gaps will be filled with fire resistant PROMASEAL®-A Acrylic Sealant. 30 PROMASTOP® CIS Coating For Electrical Cables CIS 57 1 3 2 Circuit integrity in accordance with the requirements of FM 3971 Approval Standard 1 PROMASTOP® CIS coated electrical cable and cable tray to provide DFT (dry film thickness) of minimum 1.6mm 2 Service steel hanger and support, size according to weight and dimensions of the services 3 General M&E services, e.g. electrical cable and cable tray NOTE: In general coatings to cables are designed to restrict the spread of flame along the cables and thus reduce propagation of fire. Thin film coatings will maintain circuit integrity to small diametrical cables in restricted applications. The specifier must use with caution when recommending cable coatings to ensure the performance criteria clearly matches their expectations and requirements. If there is any doubt regarding performance and the maintenance of the circuit integrity is imperative, the specifier should consider the use of a board cladding system. For further clarification and assistance, please consult Promat 31 PROMASTOP® CIS Coating For Electrical Cables Architectural Specification CIS 57 Following is the standard Architectural Specification for cable coating system using PROMASTOP® CIS. The designer must determine the suitability of the design to the application and requirements before undertaking or constructing any works relating to the specifications and where in doubt should obtain the advice of a suitably qualified engineer. External & Internal Fire Maintain circuit integrity of cables in accordance with the criteria of FM 3971 Approval Standard. Supporting Structure Care should be taken that any structural element by which the enclosure system is supported, e.g. a beam, floor or wall, has at least equivalent fire resistance. Coating DFT of minimum 1.6mm of PROMASTOP® CIS cable coating as supplied by Promat International (Asia Pacific) Ltd. Application The services will be suspended with hanger rods of diameter sized to limit stress = 15N/mm2 to withstand at least 60 minutes fire. PROMASTOP® CIS is applied to the cables for a DFT of minimum 1.6mm. Cable trays, if supporting cables, should be coated in a similar manner. Tests & Standards The complete system along with the material and framing is approved to meet the requirements of FM 3971 Approval Standard. 32 For latest information of the Promat Asia Pacific organisation, please refer to www.promat-ap.com. ASIA PACIFIC HEADQUARTERS HONG KONG Promat International (Asia Pacific) Ltd. Unit 19-02-01, Level 2 PNB Damansara No.19 Lorong Dungun, Damansara Heights 50490 Kuala Lumpur MALAYSIA Tel: +60 (3) 2095 5111 Fax: +60 (3) 2095 6111 Email: info@promat-ap.com Promat International (Asia Pacific) Ltd. Room 1010, C.C. Wu Building 302-308 Hennessy Road Wanchai Tel: +852 2836 3692 Fax: +852 2834 4313 Email: apromath@promat.com.hk AUSTRALIA Promat (Malaysia) Sdn. Bhd. (India Representative Office) 610-611, Ansal Imperial Tower C-Block, Community Centre Naraina Vihar, Naraina New Delhi 110028 Tel: +91 (11) 2577 8413 Fax: +91 (11) 2577 8414 Email: info-india@promat-asia.com Promat Australia Pty. Ltd. 1 Scotland Road Mile End South, SA 5031 Tel: 1800 PROMAT (776 628) Fax: +61 (8) 8352 1014 Email: mail@promat.com.au New South Wales Office Promat Australia Pty. Ltd. Unit 1, 175 Briens Road Northmead, NSW 2152 Tel: 1800 PROMAT (776 628) Fax: +61 (2) 9630 0258 Email: mail@promat.com.au Victoria Office Promat Australia Pty. Ltd. Suite 205, 198 Harbour Esplanade Docklands, VIC 3008 Tel: 1800 PROMAT (776 628) Fax: 1800 334 598 Email: mail@promat.com.au Queensland Office Promat Australia Pty. Ltd. 1/68 Lisgar Street Virginia, QLD 4014 Tel: 1800 011 376 Fax: 1800 334 598 Email: mail@promat.com.au CHINA Promat China Ltd. Room 506, Block A, Qi Lin Plaza 13-35 Pan Fu Road 510180 Guangzhou Tel: +86 (20) 8136 1167 Fax: +86 (20) 8136 1372 Email: info@promat.com.cn © Promat International (Asia Pacific) Ltd. 02/2014 Beijing Office Promat North China (Division of Promat China Ltd.) Room 1507 Building 5, SOHO Xiandaicheng No.88 Jianguo Road, Chaoyang District 100022 Beijing Tel: +86 (10) 8589 1254 Fax: +86 (10) 8589 2904 Email: info@promat.com.cn For Promat International and its worldwide group, see www.promat-international.com. • The technical data provided in this publication is based on mean values prevalent at time of publication and is thus subject to fluctuation. It should not be regarded as a guarantee to system performance. • All data contained herein conforms to and frequently surpasses generally accepted fire protection standards recognised by most professional fire science practitioners and regulatory authorities worldwide. The same general principle is equally applicable to all Promat products and systems. Promat has access to a considerable body of test authentication data and this can be provided on a complimentary basis upon request. It should be noted however that this publication replaces all previous editions in its entirety. Any form of reproduction by any means – manual, electronic, digital or otherwise – is strictly prohibited and subject to prior approval in writing from Promat. All rights related or connected to the Promat logo, Promat registered trademarks, featured illustrations, written information and technical reports in this publication are the sole, exclusive and copyright property of Promat and its legal partner companies. INDIA Bangalore Office Promat (Malaysia) Sdn. Bhd. (India Representative Office) Cabin No. BC-10 Oculus Workspaces, No.66/1, 2nd Floor Coles Road, Frazer Town Bangalore 560005 Tel: +91 (80) 4031 4151 Fax: +91 (80) 4125 2135 Email: info-india@promat-asia.com MALAYSIA Promat (Malaysia) Sdn. Bhd. Unit 19-02-01, Level 2 PNB Damansara No.19 Lorong Dungun, Damansara Heights 50490 Kuala Lumpur Tel: +60 (3) 2095 8555 Fax: +60 (3) 2095 2111 Email: info@promat.com.my SINGAPORE Promat Building System Pte. Ltd. 10 Science Park Road, #03-14 The Alpha Singapore Science Park II Singapore 117684 Tel: +65 6776 7635 Fax: +65 6776 7624 Email: info@promat.com.sg SOUTH KOREA Promat International (Asia Pacific) Ltd. (Korea Branch Office) Room 406, 811-2 Yeoksam-dong Gangnam-gu Seoul 135080 Tel: +82 (70) 7794 8216 Email: apromath@promat.com.hk Your local Promat supplier