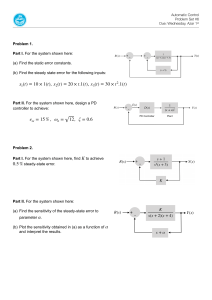

Inverted Pendulum Stabilization via Feedback Control ME 313 Dynamic Modeling of Engineering Systems, Submitted: 5 December 2023, Date of Experiment: 4 December 2023 Abstract (128 words). This report investigates the implementation of feedback control to stabilize an inverted pendulum in the vertical orientation. Two distinct feedback controllers are implemented: one to achieve a ~50% overshoot from a 90° initial displacement and the other focused on an ideal response to the same initial displacement. Both controllers operate on a proportional derivative approach to feedback control and were implemented into the Arduino-controlled inverted pendulum. The tuning process for the 50% overshoot controller involved slowly increasing the proportional gain until the desired response was achieved and was validated by plotting and analyzing data in MATLAB. The desired response controller attempts to optimize for minimal overshoot and rapid return to the vertical orientation. The results of the two experiments in this project validate the use of simple mathematical models and the efficacy of filtering and control strategies in unideal real-world systems. sinusoidal input. The third project entailed 1. Introduction conducting two experiments to determine the The junior-level mechanical engineering course system properties of the pendulum, including its dynamic modeling of engineering systems. The natural frequency, damping ratio, and static course learning outcomes include modeling gain. The experimental pendulum transient dynamic systems with differential equations, response was then compared with a simulated interpreting stability and time constants of the pendulum transient response. Moving forward to transient response of linear state space systems, the fourth project, the focus shifts to creating and and implementing feedback controllers. These implementing a digital controller for the inverted learning outcomes were accomplished by pendulum. assigning the pendulum project. This report 3. Methods explores the pendulum project's fourth and final assignment. The focus is twofold, creating a To implement feedback control to stabilize the feedback controller that achieves a 50% pendulum in the inverted orientation, existing overshoot and another feedback controller that code from prior projects must be modified. The achieves an ideal response from an angle step first step is to redefine the coordinate system so input. that θ = 0 when the pendulum is inverted. This is accomplished 2. Background by modifying the existing arctangent function in the code. The first project involved linking the MEMS Next, the code for the actual feedback controller accelerometer to the Arduino and utilizing the needs to be implemented in the existing Arduino IMU to measure the sensor's angle and angular code. The feedback controller for this specific velocity in both degrees and degrees per second. project is a proportional derivative controller. In the subsequent project, the Arduino was The controller outputs torque in bits based on the connected to an H-bridge circuit to drive the DC angle and angular speed of the pendulum that motor-powered gearbox in response to a 1 J. Planting Report restores the pendulum to its vertical position. Where 𝜃 is the angle, 𝜔 The equation governing this torque output is: frequency, and 𝜁 is the damping ratio. Using the is the natural experimentally determined natural frequency 𝑢 = −𝑘 (𝜃 − 𝜃 ) − 𝑘 (𝜃̇ − 𝜃̇ ) and damping ratio the 50% overshoot response where 𝑢 is the controller torque in bits, 𝑘 is the can be simulated in MATLAB. This simulated proportional gain, 𝑘 is derivative gain, 𝜃 − 𝜃 data can then be superimposed over the is the difference between the current and desired experimental angle vs time and motor torque vs angles, and 𝜃̇ − 𝜃̇ is the difference between the time plots. current and desired angular velocities. This 3.3 Tuning a desired response controller torque output is limited to − 255 ≤ u ≤255 to keep within the constraints of the motor’s The desired response of the controller is to capabilities. quickly bring the pendulum back to 0° from a 90° initial displacement with very little to no 3.1 Tuning a 50% overshoot controller overshoot. This result was achieved through For this part of the experiment, the proportional tuning 𝑘 and 𝑘 . 𝑘 had an initial value equal derivative controller was tuned by modifying to the 50% overshoot experiment and 𝑘 = 0. 𝑘 until a desired result of 50% overshoot from Both values were then adjusted in .01 increments a 90° initial displacement. This tuning process in either direction individually until the desired consisted of starting with a small value of 𝑘 ≈ response was achieved. The complementary filter from previous projects was also modified. 1 and 𝑘 = 0. 𝑘 was then incremented in steps The c value was reduced to .9 to process data that of .1 until the desired response of 50% or 45° was closer to the raw sensor value. This showed overshoot was achieved. Once the desired great improvements in the response time of the overshoot is achieved collect data on the controller. The baud rate was also increased to transient response. Export that data to MATLAB improve the fluidity of the controller response to the plot angle vs time and motor torque vs time. angle input. Once the desired response is Using the data and the plots calculate dynamic achieved, collect data and export the data to response properties such as natural frequency, MATLAB 𝜔 and damping ratio, 𝜁. and plot angle (filtered and unfiltered) vs time on one plot and motor torque 3.2 Simulating a 50% overshoot controller vs time on another. The pendulum system can be described by the 4. Results second-order differential equation: The graphs below depict the results of the two 𝜃̈ = −2𝜁𝜔 𝜃̇ − 𝜔 𝜃 project experiments: 50% overshoot controller and desired response controller. 2 J. Planting Report 3 J. Planting Report 4 J. Planting Report 5. Discussion achieved for this system. Graph four shows the The results of the two experiments are shown torque input from the controller required to above in the results section. Through a rather achieve such a response. Reducing the load on tedious tuning process, an overshoot of the Arduino further improved system response. approximately 50% was obtained from a 90° One way this was achieved was by eliminating initial displacement. The proportional gain, 𝑘 prints to the console. This response cannot be required to achieve this result was 2.72 [dim]. shown graphically or analyzed because the The following plot depicting motor torque vs prints to the console were how data was acquired time showcased the controller input necessary to and then transferred to MATLAB for plotting. achieve the roughly 45° overshoot. 6. Conclusions Superimposing the simulated data derived from The successful implementation of feedback the experimental natural frequency, 𝜔 , and damping ratio, control for the inverted pendulum system 𝜁, it can be seen that the demonstrated proficiency in the course learning experimental dynamic response closely follows outcomes, namely, dynamic systems and control what the simulation predicts. This means that the theory. second-order theoretical model is capable of capturing the system’s behavior with nontrivial In the 50% overshoot experiment, the similarity accuracy. However, the model’s accuracy could showcased between the experimental and be improved by adding terms that model simulated dynamic response provides a strong frictional forces and gravity. argument for the efficacy of filtering and proportional derivative control strategies on a The desired response controller proved to be system with high and varied friction and cheap more challenging in terms of tuning. Through components, as well as the validity of theoretical the process of incrementally increasing and models applicability in real-world scenarios. decreasing both 𝑘 and 𝑘 , the desired result was achieved with values of 2.8 and .15 The desired response experiment shows the respectively. Tuning the complementary filter importance of a meticulous approach to system and adjusting the baud rate also significantly tuning to achieve specific dynamic response improved the response time of the system. characteristics. It also demonstrated the need for Attempts to further increase the “snappiness” of additional control to account for friction and the system response by increasing either gravity to create a more desirable response. increasing 𝑘 or 𝑘 caused controller output to Acknowledgments exceed the motor’s limits as discussed in the References methods section. When the limits are exceeded, the system freezes or becomes intermittent. The third graph depicts the optimized response 5