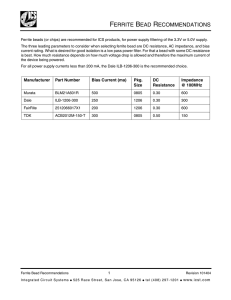

W W 10 min. 25 min. a 1 25 min. 65 min. 10 min. 1 10 min. 1 10 min. I Inter Pass <95OC >25mm STEP 1 SET UP THE WELD PAD Begin byinplacing two copper bars parallel to each other Dimensions in millimetres Dimensions millimetres on the base plate. This setup will form the foundation for a I 10 min. 10the min.weld pad. Carefully deposit single weld bead layers between the copper bars, ensuring the height reaches a minimum of 13 mm. Plate thickness plays a crucial role in maintaining the weld pad’s integrity during the welding process, so adhere to specified requirements. ASTM A240 or A160 >64mm STEP 3 DETERMINE WELDING PARAMETERS Before proceeding with the welding process, identify the appropriate welding current based on the electrode’s size. Ensure a short arc length for precise weld seams and uniform distribution of the weld metal. Ray diffraction techniques, coupled with optical microscopy, aid in evaluating the weld structure and ferrite content. 65 min. Dimensions in millimetres STEP 2 STEP 4 Approximate Dimensions Electrode diameter mm Welding currenta A width (w) mm length (l) mm 1.6 2 2.5 3.2 4 5 6.3 35 to 45 45 to 55 65 to 75 90 to 100 120 to 140 165 to 185 240 to 250 12.5 12.5 12.5 12.5 12.5 15 18 30 30 40 40 40 40 40 a Or 90% of the recommended maximum value esab.com ASTM A240 or A160 COPPER BAR The size of the base metal shall follow the following dimensions (according to the size of the electrode): >13mm COPPER BAR This comprehensive guide provides a step-by-step approach to prepare a pad for measuring delta ferrite content in duplex stainless steel. From setting up the weld pad and selecting the right material to determining welding parameters and employing optical microscopy, each step is crucial for accurate ferrite number measurement. By following this guide, welders can achieve high-quality welds with optimal ferrite content, enhancing the overall performance and longevity of the duplex stainlesssteel components. Short Arc Length COPPER BAR MEASURING FERRITE CONTENT IN DUPLEX STAINLESS STEEL: STEP-BY-STEP GUIDE SELECT THE RIGHT MATERIAL The choice of base plate material is vital for accurate ferrite content measurement. Opt for Type 301, 302, or 304 austenitic stainless steel, which complies with ASTM Specification A167 or A240. Alternatively, carbon steel may be used, but ensure the weld pad is built up to a minimum height of 18 mm to avoid adversely affecting the results. IMPLEMENT WELDING PROCEDURE To maintain homogeneity, alternate the welding direction with each pass. Position the weld stops and starts at the ends of the weld build-up to create consistent weld seams. Proper welding parameters and technique are crucial to achieving a high-quality weld with the desired ferrite content. MEASURING FERRITE CONTENT IN DUPLEX STAINLESS STEEL: STEP-BY-STEP GUIDE This comprehensive guide provides a step-by-step approach to prepare a pad for measuring delta ferrite content in duplex stainless steel. From setting up the weld pad and selecting the right material to determining welding parameters and employing optical microscopy, each step is crucial for accurate ferrite number measurement. By following this guide, welders can achieve high-quality welds with optimal ferrite content, enhancing the overall performance and longevity of the duplex stainlesssteel components. The size of the base metal shall follow the following dimensions (according to the size of the electrode): W W 10 min. 25 min. a 1 25 min. 65 min. 10 min. 1 10 min. 1 10 min. I CONTROL INTERPASS COOLING Proper interpass cooling prevents stress corrosion cracking and maintains the weld’s mechanical properties. Clean each pass before depositing the next weld bead, and limit the maximum interpass temperature to 95°C. Cooling the weld pad between passes can be achieved through quenching in water no sooner than 20s, ensuring no adverse effects on the ferrite number measurement. Each pass of the last layer shall be air cooled to a temperature below 425°C before water quenching. STEP 6 SURFACE PREPARATION FOR ACCURATE FERRITE MEASUREMENT Dimensions in millimetresin millimetres Dimensions When the anticipated ferrite content is 30 FN or less, a I 10 min. 10 utilize min. a 360 mm mill bastard file to draw file the surface. Achieving a smooth finish with no traces of weld ripple is vital for accurate optical microscopy and ferrite number readings. This step ensures precise ferrite content measurement. 65 min. Dimensions in millimetres Approximate Dimensions Electrode diameter mm Welding currenta A width (w) mm length (l) mm 1.6 2 2.5 3.2 4 5 6.3 35 to 45 45 to 55 65 to 75 90 to 100 120 to 140 165 to 185 240 to 250 12.5 12.5 12.5 12.5 12.5 15 18 30 30 40 40 40 40 40 a Or 90% of the recommended maximum value esab.com STEP 5 By following this step-by-step guide and incorporating plate thickness considerations, ray diffraction techniques, optical microscopy, and ferrite number measurement, welders can ensure high-quality welds with desirable ferrite content in duplex stainless steel. Properly prepared weld pads prevent stress corrosion cracking, contributing to the longevity and performance of welded components. STEP 7 EMPLOYING OPTICAL MICROSCOPY Using optical microscopy, examine the prepared surface to evaluate the weld’s microstructure and ferrite content. This analysis is essential for confirming the weld’s integrity and high-quality ferrite distribution. STEP 8 MEASURE FERRITE NUMBER Determine the ferrite number using appropriate methods such as ASTM E562. Accurate ferrite number measurement aids in assessing corrosion resistance and mechanical properties of the duplex stainless steel weld metal.