HVAC & Refrigeration Study Problems: Psychrometrics & Calculations

advertisement

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

MECHANICAL ENGINEERING

HVAC & REFRIGERATION

STUDY PROBLEMS

PSYCHROMETRICS & BASIC HVAC

CALCULATIONS

www.SlaythePE.com

1

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

How to use this book

The exam specifications in effect since April 2017 state that approximately 8 of the 32 problems (25%)

from the “Psychrometrics” topic will be in the morning “Principles” portion of your HVAC&R exam.

Reviewing all the problems in this book will prepare you for all these problems in the morning

“Principles” portion. Additionally, the problems in this book provide additional review for the

“Energy/Mass Balances” topic, which is expected to contain 5 of the 32 problems (16%) of the

“Principles” portion.

The exam specifications also state that the “Heating/Cooling Loads” topic comprise 8 of the 48

problems (17%) in the “Applications” portion of the exam. The problems in section 8 of this book are

designed to help you review this topic. Furthermore, cooling towers are listed as one of the relevant

examples of “Equipment and Components” in the afternoon “Applications” portion. The problems in

section 7 of this ebook are designed to help you cover this topic.

How it works

This study problems book works on what we call the “principle of progressive overload”. With this

technique you start with very easy problems and smoothly progress towards more complex problems.

A good example of progressive overload is the story of the famous wrestler Milo of Croton in ancient

Greece. This extraordinarily strong man was allegedly capable of carrying a fully grown bull on his

shoulders. He was reported to have achieved this tremendous strength by walking around town with a

new born calf on his shoulders every single day. As the calf grew, so did the man's strength.

We recommend you work the problems in this book in the order they are presented. Within each

section of the book, the first problems will feel “light”, like carrying that baby calf – you might even be

tempted to skip them. We strongly urge you to resist this temptation. As you progress, the problems

become harder, but the work you've been putting in with all the previous problems will bear fruit. You

will be pleasantly surprised at how relatively easy those “hard” problems will seem. You will soon be

carrying intellectual bulls on your shoulders! The problems that are considered “exam-level

difficult” are denoted with an asterisk.

www.SlaythePE.com

2

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

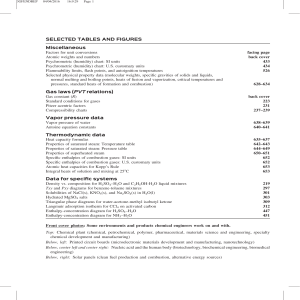

This book is comprised of the following sections:

Sections

Page

01: Properties of Moist Air

5

02: The Psychrometric Chart

13

03: Simple Cooling and Heating

19

04: Adiabatic Mixing

23

05: Cooling with Dehumidification and Heating with Humidification

27

06: Evaporative Cooling

33

07: Wet Cooling Towers

35

08: Basic HVAC System Calculations

41

09: Answers

51

For the most part, these sections are not independent and build from the previous ones. We recommend

you go through them in the order presented, and be sure to review them all. Each section begins with a

brief discussion of the relevant concepts and equations. These discussions are laser-focused on the

aspects that are relevant to the P.E. exam and do not go into derivations with academic rigor.

www.SlaythePE.com

3

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

This page was intentionally left blank

www.SlaythePE.com

4

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

SECTION 01: Properties of Moist Air

Psychrometrics is the science involving thermodynamic properties of moist air and the effect of

atmospheric moisture on materials and human comfort.

Air is a mixture of nitrogen, oxygen, and small amounts of some other gases. Air in the atmosphere

normally contains some water vapor (or moisture) and is referred to as atmospheric air. Conversely,

air that contains no water vapor is called dry air. At the relatively low atmospheric temperature we can

treat dry air as an ideal gas with constant specific heat. The water vapor in atmospheric air is typically

at very low pressures (i.e., the partial pressure of water in the mixture 1) and thus can be treated as an

ideal gas without loss of accuracy (even if it is saturated vapor).

Consider a container with 10 pounds of dry air and 0.1 pounds of water vapor, thoroughly mixed, at

atmospheric pressure (14.7 psia) and 75°F. The humidity ratio ω (also known as specific humidity)

is the ratio of the mass of water vapor to mass of dry air:

ω=

mv

ma

(1-1)

where the subscript “v” denotes water vapor, and “a” denotes dry air. In our example,

ω =0.1/10=0.01 lbm H2 O /lbm dry air . The mass of water vapor is sometimes expressed in grains,

which is a unit of mass such that 7,000 grains = 1 pound-mass. Therefore, in our example,

ω =70 grains H 2 O/lbm dry air . The humidity ratio is not to be confused with the water vapor mass

fraction: mf v=mv /(mv +ma )= ω /(1+ ω )

In our example, the moles of dry air N a=m a / M a=10 lbm/ 28.97(lbm/lbmol )=0.3452 lbmol and the

moles of water vapor N v =mv / M a=0.1 lbm /18(lbm /lbmol)=0.0056 lbmol . Therefore, the mole

fraction of water vapor y v=0.0056 /(0.0056+0.3452)=0.01584 . We can can thus obtain the partial

pressure of the water vapor (or vapor pressure) from its definition:

(1-2)

pv= yv p

thus p v =0.01584×14.7=0.2328 psia in our example. At this pressure, the saturation temperature is

57.3°F, so the vapor in the mixture is actually superheated vapor with a superheat of 75 – 57.3 =

17.7°F.

1 For a review of the concept of partial pressure and the modeling of mixtures of ideal gases consult our

“Thermodynamics and Energy Balances” e-book

www.SlaythePE.com

5

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

We can repeat these calculations for a mixture of 10 pounds of dry air and this time with 0.15 pounds

of water (i.e, we are increasing the amount of water in the mixture by 50%, so now

ω =0.015 lbm H 2 O /lbm dry air ). In this case;

N a=m a / M a=10 lbm/ 28.97(lbm/lbmol )=0.3452 lbmol

N v =m v / M a =0.15 lbm /18(lbm/lbmol )=0.00833 lbmol

y v=0.00833/(0.00833+0.3452)=0.02357

p v =0.02357×14.7=0.3465 psia

We see that for this mixture (which contains more water) the vapor pressure is higher, and the

saturation temperature corresponding to it is lower. For 0.3465 psia, T sat =68.6 °F and thus the

superheat is reduced to 75 – 68.6 = 6.4°F. If the mass of water is further increased again, this time to

0.1873 pounds, the vapor pressure will be 0.43017 psia – the saturation pressure at 75°F – thus the

water vapor in the mixture will be saturated vapor.

This example shows that, as we increase the mass of vapor in the mixture the closer that vapor comes

to the saturated vapor state. We denote with mg the mass of water in the mixture such that the water

vapor is saturated (i.e., not superheated, that is, when the vapor pressure corresponds to the saturation

pressure at the mixture temperature). In our example, mg =0.1873 lbm . Saturated air is a mixture of

dry air and saturated water vapor. The amount of water vapor in moist air varies from zero in dry air to

a maximum value mg (which depends on the pressure and temperature) in saturated air (when the vapor

is saturated.) The relative humidity ϕ (sometimes also referred to as “rh”) is defined as the ratio of the

mass of water in the air to the mass of water in saturated air at the same temperature and pressure:

ϕ=

mv

mg

(1-3)

In our example for the container with 10 pounds of dry air and 0.1 pounds of water, the relative

humidity would be ϕ =0.1/0.1873=0.534=53.4 % . When the mass of water vapor is increased to 0.15

pounds, the relative humidity increases to ϕ =0.15/0.1873=0.8=80 % .

Note that, since mg depends on temperature, we can change the relative humidity of the mixture by

changing the temperature, without adding or removing any water. Consider our example of 10 pounds

of dry air and 0.1 pounds of water vapor ( ω =0.01 lbm /lbm ) at 14.7 psia and 75°F. We saw earlier

www.SlaythePE.com

6

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

that N a=0.3452 lbmol ; N v =0.0056 lbmol and y v=0.01584 . Consider what happens when we cool the

mixture down to 65°F, without adding (or removing) any water vapor: At 65°F, the saturation pressure

for water is 0.306 psia. We would like to determine mg , the mass of water vapor that would be required

to make the water in the mixture a saturated vapor. A vapor pressure of .306 psia means that the mole

fraction of water is: y v= p v / p=0.306 /14.7=0.02081 . It can be shown that this mole fraction is

obtained when the mass of water vapor is 0.13212 pounds. That is, for a mixture temperature of 65°F,

mg =0.13212 lbm if ma=10 lbm . So, when the mixture temperature is decreased to 65°F,

ϕ =0.1/0.13212=0.7569=75.7 % .

So, humidity ratio provides a measure of the concentration of water vapor in atmospheric air and

relative humidity provides a measure of how close the vapor in atmospheric air is to being saturated

vapor. The relative humidity of air changes with temperature even when its humidity ratio remains

constant. The amount of moisture in the air has a definite effect on how comfortable people feel in an

environment. However, the comfort level depends more on how close the water vapor is to being

saturated; that is, the comfort level is more related to the relative humidity.

We can re-cast equation (1-1) by inserting the ideal gas law:

pv V

m

R T R p

p

ω = v = v = a v =0.622 v

ma pa V R v p a

pa

Ra T

Now use Dalton's law of additive pressures: p= pa+ p v ,

ω =0.622

(

pv

p− pv

)

(1-4)

which can be rearranged as:

ω

( ω +0.622 ) p

pv=

(1-5)

Similarly, we can use the ideal gas law with equation (1-3):

pv V

m

R T

p

ϕ = v= v = v

m g p g V pg

Rv T

www.SlaythePE.com

7

(1-6)

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

where p g = psat @ T is the saturation pressure at the mixture temperature. Combining (1-6) with (1-5) we

obtain:

ϕ=

ω

p

( ω +0.622 ) p

(1-7)

g

or alternatively:

ω=

0.622 ϕ p g

p− ϕ p g

(1-8)

T he humidity ratio at saturation ω s – which is the amount of water vapor in saturated air at a

specified temperature and pressure – can be determined from equation (1-4) by replacing p v by p g , the

saturation pressure of water at that temperature, or by setting ϕ =1 in equation (1-8).

The degree of saturation μ is the ratio of the actual humidity ratio ω to the humidity ratio ω s of

saturated air at the same temperature and pressure:

μ =ω / ω s

(1-9)

Relative humidity and specific humidity are frequently used in engineering and atmospheric sciences,

and it is desirable to relate them to easily measurable quantities such as temperature and pressure. The

term dry-bulb temperature T (sometimes simply referred to as the temperature) is the temperature

measured by an ordinary thermometer placed in atmospheric air. The wet-bulb temperature T wb , is

read from an ordinary liquid-in-glass thermometer whose bulb is enclosed by a wick moistened with

water. When unsaturated air passes over the wet wick, some of the water in the wick evaporates. As a

result, the temperature of the water drops, creating a temperature difference (which is the driving force

for heat transfer) between the air and the water. After a while, the heat loss from the water by

evaporation equals the heat gain from the air, and the water temperature stabilizes. The thermometer

reading at this point is the wet-bulb temperature. The wet-bulb temperature is an excellent

approximation to another concept known as the adiabatic saturation temperature T as . It can be shown

that relative and absolute humidity can be obtained if T as , T , and p are all known.

Consider a mass of moist air at a known temperature T and pressure p . Equation (1-7) indicates that

these two variables are not enough to determine ϕ and ω . The additional relationship involves ω and

T as (and therefore T wb because T as≈T wb ). In customary US units, this relationship is:

www.SlaythePE.com

8

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

ω=

( 1,093−0.556T w.b. ) ω s−0.24 ( T −T w.b. )

1,093+0.444 T −T w.b.

(1-10)

where temperatures are in °F, and ω *s is the humidity ratio at saturation for the wet bulb temperature.

The condensation of part of the water vapor in atmospheric air when the temperature is reduced is an

important aspect of the behavior of moist air. This is encountered in the condensation of vapor on

window panes and on cold pipes, as well as condensation of water vapor from cool flue gases. The

dew-point temperature T dp is defined as the temperature at which condensation begins when moist air

is cooled at constant pressure. In other words, T dp is the saturation temperature of water corresponding

to the vapor pressure, T dp =T sat ( pv ) .

In most practical applications, the amount of dry air in the air–water-vapor mixture remains constant,

but the amount of water vapor changes. Therefore, the enthalpy of atmospheric air is expressed per

unit mass of dry air instead of per unit mass of the air–water vapor mixture. The enthalpy of a mixture

of perfect gases is equal to the sum of the individual partial enthalpies of the components. The enthalpy

of moist air is then:

h=ha + ω h v

where ha is the specific enthalpy for dry air and hv is the specific enthalpy for water vapor at the

temperature of the mixture. For most HVAC applications, hv≈h g where h g is the enthalpy of saturated

vapor at the mixture temperature, thus:

h=ha+ ω h g

(1-11)

For most HVAC applications, the following correlation in the form of equation (1-11) works quite

well:

h=0.24T + ω ( 1,061+0.444 T )

(1-12)

which yields the enthalpy in Btu/(lbm of dry air) as long as T is in °F and ω is in (lbm H2O)/(lbm dry

air). The specific volume v of a moist air mixture is expressed in terms of a unit mass of dry air:

pa V =ma R a T

Ra T

V

⇒ =

ma

pa

Ra T

⇒ v=

pa

www.SlaythePE.com

9

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

and using Dalton's law, we get:

v=

=

Ra T

p− pv

Ra T

(

p 1−

pv

p

)

which can be combined with equation (1-5):

Ra T

v=

( (ω ω ))

p 1−

+0.622

thus yielding:

v=

(

Ra T

ω

1+

p

0.622

)

(1-13)

where

{

53.34 ft⋅lbf / lbm⋅°R

3

0.3704 psia⋅ft /lbm⋅°R

Ra = 640.08 psia⋅in 3 /lbm⋅°R

0.0686 Btu /lbm⋅°R

0.287 kJ / kg⋅K

}

is the gas constant for dry air.

PROBLEMS

01-01. A sample of air at 14.7 psia and 75°F has a humidity ratio of 0.015 lbm H 2 O/lbm dry air .

Determine:

a) the partial pressure of water vapor, in psi.

b) the dew point temperature, in °F.

c) the relative humidity.

d) the degree of saturation.

e) the enthalpy in Btu/lbm dry air

f) the specific volume in ft3/lbm dry air

www.SlaythePE.com

10

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

01-02. A sample of air at 14.7 psia and 75°F has a dew point of 52°F. Determine the humidity ratio and

the relative humidity.

01-03. A sample of air at 14.7 psia and 75°F has a wet bulb temperature of 55°F. Determine the

humidity ratio and the relative humidity.

01-04. A sample of air is at 70°F, 50% rh, and 14.7 psia. What is the lowest temperature to which the

air can be cooled at constant pressure if condensation is to be avoided?

01-05*. The conditions at the intake of an air conditioning system are 95°F, 30% rh, and 14.7 psia. The

air flows at a rate of 1,000 cubic feet per minute (cfm). The rate (lbm/hour) at which water vapor enters

the system is most nearly:

(A) 0.74

(B) 10.5

(C) 44.5

(D) 55.4

01-06*. The air conditions at the intake of an air compressor are 70°F, 50% rh, and 14.7 psia. The air is

compressed to 50 psia, then sent to an intercooler. If condensation of water vapor from the air is to be

prevented, the lowest temperature (°F) to which the air can be cooled in the intercooler is most nearly:

(A) 31

(B) 46

(C) 51

(D) 86

www.SlaythePE.com

11

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

This page was intentionally left blank

www.SlaythePE.com

12

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

SECTION 02: The Psychrometric Chart

Many of the properties of moist air discussed in the previous section can be estimated from a

psychrometric chart, a plot of dry-bulb temperature (horizontal axis) and humidity ratio (vertical axis).

In other words, the chart is a graphical representation of all the equations in the previous section.

Psychrometric charts for sea level altitude are available for free download from the “Free Resources”

section of www.SlayThePE.com. Lines of constant humidity ratio are horizontal on the graph. Lines of

constant (dry-bulb) temperature exhibit a slight tilt to the left of vertical, with the degree of tilt

increasing with lower temperature. The left top portion of the plot is terminated at the saturation line,

which represents both the 100% relative humidity curve and the plot for dew-point temperature. Lines

of constant enthalpy appear as straight lines that slope down as the temperature increases. Lines of

constant wet-bulb temperature are nearly parallel to lines of constant enthalpy. Lines of constant

specific volume also slope down as temperature increases but at a much greater angle compared to

enthalpy and wet-bulb lines. Lines of constant relative humidity curve up as temperature increases.

Processes performed with air can be plotted on the chart for quick visualization, as well as for

determining changes in significant properties such as temperature, humidity ratio, and enthalpy for the

process.

To demonstrate the use of the chart, obtain one for sea level altitude and locate the point corresponding

to a dry-bulb temperature of 80°F and a wet-bulb temperature of 67°F:

www.SlaythePE.com

13

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

67°F (wb)

80°F

Using this condition as a starting point on the chart, make sure you can verify that:

• Humidity ratio—Move right horizontally to the axis and read, ω ≈0.0112 lbm /lbm (78 grains/lbm)

67°F (wb)

80°F

www.SlaythePE.com

14

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

• Relative humidity—Interpolate between the ϕ =50 % and ϕ =60 % lines, ϕ ≈52 % .

67°F (wb)

80°F

• Enthalpy—Follow a constant enthalpy line and read from the enthalpy scale, h≈31.5 Btu / lbm :

67°F (wb)

80°F

www.SlaythePE.com

15

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

• Dew point—Move left horizontally to the saturation curve ( ϕ =100 % ) and read T dp≈60.5 °F

67°F (wb)

80°F

• Specific volume—Interpolate between the 13.5 and 14.0 lines, to get v=13.85ft 3 /lbm

67°F (wb)

80°F

www.SlaythePE.com

16

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

PROBLEMS

02-01. A sample of air at 14.7 psia and 75°F has a humidity ratio of 0.015 lbm H 2 O/lbm dry air . Use a

psychrometric chart to determine:

a) the dew point temperature, in °F.

b) the relative humidity.

c) the degree of saturation.

d) the enthalpy in Btu/lbm dry air

e) the specific volume in ft3/lbm dry air

02-02. Use a sea-level psychrometric chart to complete the following table:

Dry Bulb

°F

Wet Bulb

°F

70

55

Dew Point

°F

100

Humidity Ratio

lbm/lbm

R.H.

%

Enthalpy

Btu/lbm

40

40

70

0.01

60

13.8

40

40

50

60

85

80

Specific Volume

ft3/lbm

30

0.012

80

02-03*. The conditions at the intake of an air conditioning system are 95°F, 30% rh, and 14.7 psia. The

air flows at a rate of 1,000 cubic feet per minute (CFM). The rate (lbm/hour) at which water vapor

enters the system is most nearly:

(A) 0.74

(B) 10.5

(C) 44.5

(D) 55.4

www.SlaythePE.com

17

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

This page was intentionally left blank

www.SlaythePE.com

18

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

SECTION 03: Simple Cooling and Heating

The air in heating systems is heated by circulating it through a duct that contains a heat exchanger (for

the hot combustion gases) or electric resistance wires. The amount of moisture in the air remains

constant during this process since no moisture is added to or removed from the air. That is, the specific

humidity of the air ω remains constant during a heating (or cooling) process with no humidification or

dehumidification. Such a heating process proceeds in the direction of increasing dry-bulb temperature

following a line of constant specific humidity on the psychrometric chart, which appears as a horizontal

line.

Notice that the relative humidity of air decreases

during a heating process even though the specific

humidity remains constant. Therefore, the relative

Simple Heating

ϕ 2< ϕ 1

T 2>T 1

h

2

humidity of heated air may be well below

comfortable levels, causing dry skin, respiratory

h1

ϕ2

ϕ1

difficulties, and an increase in static electricity.

As air flowing at a rate ṁa is heated from 1 to 2, an

ω =const

1

2

amount of heat is added at a rate Q̇ . This could occur

in the heating section of an HVAC device. This

could also occur as cold air warms as it flows from

T1

T2

the supply register(s) in a room towards the return

register(s). An energy balance reveals that:

Q̇= ṁa ( h2 −h1 )

(heating)

where h1 and h2 are enthalpies per unit mass of dry air at the inlet and the exit of the heating section,

respectively.

A cooling process at constant specific humidity is similar to the heating process discussed above,

except the dry-bulb temperature decreases and the relative humidity increases during such a process.

Cooling can be accomplished by passing the air over some coils through which a refrigerant or a

chilled coolant flows. The heat transfer rate for a simple cooling process can be obtained from an

energy balance on the cooling section as:

Q̇= ṁa ( h1−h 2 )

www.SlaythePE.com

(cooling)

19

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

Since the specific volume of air varies with temperature, all calculations should be made with the mass

of air instead of the volume. Nevertheless, volume values are required when selecting coils, fans, ducts,

and other components. One method of using volume while still including mass is to use volume values

based on measurement at standard air conditions. ASHRAE defines one standard condition as dry air at

20°C and 101.325 kPa (68°F and 14.7 psia). Under that condition the density of dry air is about 1.204

kg/m3 (0.075 lbm/ft3) and the specific volume is 0.83 m 3/kg (13.3 ft3/lbm). Saturated air at 15°C

(59.5°F) has about the same density or specific volume. Thus, in the range at which air usually passes

through the coils, fans, ducts, and other equipment, its density is close to standard and is not likely to

require correction.

The heat transfer to or from the air in simple heating and cooling processes is known as sensible heat

which corresponds to the change in dry-bulb temperature for a given airflow (standard conditions). The

sensible heat in Btu/h as a result of a difference in temperature ΔT in °F between the incoming air and

leaving air flowing at ASHRAE standard conditions is:

Q̇sens = ṁa Δ h= ṁa c p , a Δ T

Which can be written in terms of volumetric flow, and combined with equation (1-12):

Q̇sens = ρ a V̇ a ( 0.24+0.444 ω ) ΔT [ °F ]

Now, use ρ a=0.075lbm /ft 3 , the density of dry air at standard conditions and define a new variable,

CFM which is the volumetric flow rate in cubic feet per minute. Then the following equation yields the

sensible heat in Btu/h:

Q̇ sens [ Btu /h ] =0.075

∣

∣

lbm

60 min

×CFM×

( 0.24+0.444 ω ) Δ T [ °F ]

3

1h

ft

Since ω ≈0.01 in many air-conditioning problems, the sensible heat is typically approximated by:

Q̇sens [ Btu /h ] =1.1×CFM×ΔT [ °F ]

(3-1)

If standard conditions are specified as 70°F and 50% RH, replace 1.1 with 1.08 in equation (3-1). For

the purposes of the P.E. exam, equation (3-1) yields results that are accurate enough. However, you

must exercise caution if the air experiences a very large temperature difference across the heating or

cooling section (say, 30°F or greater) in which case it is advisable to use the mass flow based

equations, Q̇= ṁa ( Δ h ) .

If the actual volumetric airflow is needed at any particular condition or point, the corresponding

www.SlaythePE.com

20

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

specific volume is obtained from the psychrometric chart (or equation 1-13) and the volume at standard

conditions is multiplied by the ratio of the actual specific volume to the standard value of 13.3. For

example, assume the outdoor airflow rate at ASHRAE standard conditions is 1,000 cfm. The actual

outdoor air condition is 95°F dry bulb, and 75°F wet bulb [v = 14.3 ft 3/lb]. The actual volume flow rate

at this condition would be 1,000(14.3/13.3) = 1,080 cfm.

PROBLEMS

03-01. Air is heated to 80°F without adding water, from 60°F dry-bulb and 50°F wet-bulb temperature.

Use a sea-level psychrometric chart to find:

(a) relative humidity of the original mixture, (b) original dew-point temperature, (c) original humidity

ratio, (d) initial enthalpy, (e) final enthalpy, (f) the heat added, and (g) final relative humidity.

03-02. Air at 14.7 psia is cooled down to 55°F, 90% rh from 90°F. Use a sea-level psychrometric chart

to find the enthalpy change in Btu per pound of dry air.

03-03.* A gas furnace produces 60,000 Btu/h with an airflow of 2,800 cfm heated air with an inlet

condition of 65°F, 45% rh. The relative humidity of the outlet air is most nearly:

(A) 23

(B) 46

(C) 62

(D) 85

03-04.* A stream of 500 cfm of saturated air at 50°F and 14.7 psia is heated without adding or

removing water until its relative humidity drops to 40%. The heat input (Btu/h) required of the heater is

most nearly:

(A)

245

(B) 9,200

(C) 14,540

(D) 25,500

www.SlaythePE.com

21

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

03-05.* A heating section consists of a 15-in.-diameter duct that houses an electric resistance heater.

Air enters the heating section at 14.7 psia, 50°F, and 40% rh at a velocity of 25 ft/s and is discharged

with a relative humidity of 31 percent. The heater input (kW) is most nearly:

(A) 4.3

(B) 6.2

(C) 80.3

(D) 14,000

www.SlaythePE.com

22

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

SECTION 04: Adiabatic Mixing of Air Streams

Mixing of two moist air streams is a common air-conditioning process. The point of the

thermodynamic analysis of such processes is typically to determine the flow rate and state of the

exiting stream for given flow rates and states of each of the two inlet streams. It is typically assumed

that the heat lost to the environment surrounding the mixing chamber is negligibly small, hence the

adjective “adiabatic”. As shown in Figure 4-1, two streams at states 1 and 2 enter the chamber (at

steady state) and one stream leaves at state 3.

ṁ a1 , T 1, ω 1

ṁ a2 , T 2, ω 2

1

2

Mixing Chamber

3

ṁ a3 , T 3, ω 3

Perfect Insulation

Figure 4-1: Adiabatic mixing of two moist air streams.

The mass balances for dry air and water vapor are, respectively:

(4-1)

ṁa1 + ṁa2= ṁa3

ṁv1+ ṁv2= ṁ v3

and since ṁv= ω ṁa , this water vapor mass balance becomes:

ω 1 ṁa1+ ω 2 ṁa2 =ω 3 ṁa3

(4-2)

With the assumption of no heat transfer leaving the mixing box, the energy balance is:

ṁa1 ( ha1+ ω 1 hg1 ) + ṁa2 ( ha2 +ω 2 h g2 )= ṁa3 ( ha3+ ω 3 hg3 )

(4-3)

where we have used equation (1-11) for the enthalpy of the mixture. If the inlet conditions of both

inputs are known, then equations (4-1) through (4-3) can be solved to determine ṁa3 , ω 3 ,and

ha3+ ω 3 hg3 – which can be used to determine T 3 . It can be shown that the solutions to these equations

are:

T 3=

www.SlaythePE.com

T 2+T 1 ( ṁa1 / ṁa2 )

1+( ṁa1 / ṁa2 )

23

(4-4)

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

h3=

ω 3=

h2 +h1 ( ṁa1 / ṁa2 )

(4-5)

1+( ṁa1 / ṁa2 )

ω 2+ω 1 ( ṁa1 / ṁa2 )

1+( ṁa1 / ṁa2 )

(4-6)

and if v 2≈v1 we get:

T 3≈

T 2+T 1 ( CFM1 /CFM 2 )

1+( CFM 1 /CFM 2 )

; h3≈

h2 +h1 ( CFM 1 /CFM 2 )

1+ ( CFM 1 /CFM 2 )

; ω 3≈

ω 2+ ω 1 ( CFM1 /CFM 2 )

1+( CFM 1 /CFM 2 )

(4-7)

Another way to quickly determine the resulting conditions of the mixing of two moist air streams is the

graphical approach using a psychrometric chart. Locate points 1 and 2 on a psychrometric chart, and

draw a straight line between them (as shown in Figure 4-2).

1

L12

L13

3

2

Figure 4-2: Adiabatic mixing of two moist air streams – graphical representation on psychrometric chart

Then, use a ruler to measure the distance between points 1 and 2, L12 . Then, it can be shown that point

3 will be on the line connecting 1 and 2, and the distance between 1 and 3 is given by:

L13=L 12

(

) (

ma2

CFM 2

≈ L12

ma1+ma2

CFM1 +CFM 2

)

(4-8)

Note that in the limiting case when CFM 2 ≫CFM 1 ⇒ L 13 → L12 which means point 3 will be very close

to point 2. In the other extreme, if CFM 2 ≪CFM 1 ⇒ L 13 → 0 which means point 3 will be very close to

point 1.

www.SlaythePE.com

24

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

PROBLEMS:

04-01. Air at 40°F dry bulb and 35°F wet bulb is mixed with air at 100°F dry bulb and 77°F wet bulb in

the ratio of 2 lb of cool air to 1 lb of warm air. Determine the humidity ratio of the mixed air.

04-02. During an air-conditioning process, 900 cfm of conditioned air at 65°F and 30 percent relative

humidity is mixed adiabatically with 300 cfm of outdoor air at 80°F and 90 percent relative humidity at

a pressure of 1 atm. Determine (a) the temperature, (b) the specific humidity, and (c) the relative

humidity of the mixture.

04-03.* In a mixing process of two streams of air, 10,000 cfm of air at 75°F and 45% rh is mixed with

hot air at 98°F and 40% rh. The desired humidity ratio of the resulting mixture is 0.01 lbm/lbm. Under

these conditions, the flow rate (cfm) of hot air into the mixing box must be most nearly:

(A) 1,200

(C) 7,500

(B) 3,300

(D) 30,000

04-04.* In a mixing process of two streams of air, 10,000 cfm of air at 75°F and 50% rh mix with 4,000

cfm of air at 98°F dry-bulb and 78°F wet-bulb temperature. The dew point temperature (°F) of the

resulting mixture is most nearly:

(A) 58

(C) 72

(B) 61

(D) 80

04-05.* A room is being maintained at 75°F and 50% rh. The outdoor air conditions are 40°F and 50%

rh at this time. Return air from the room is cooled and dehumidified by mixing it with fresh ventilation

air from the outside. The total air flow to the room is 60% outdoor and 40% return air by mass. The

humidity ratio (lbm-H20/lbm-air) of the mixed air going to the room is most nearly:

www.SlaythePE.com

(A) 0.0025

(C) 0.0067

(B) 0.0052

(D) 0.014

25

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

This page was intentionally left blank

www.SlaythePE.com

26

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

SECTION 05: Cooling with Dehumidification and Heating with Humidification

Cooling with Dehumidification:

The cooling process with dehumidifying is illustrated schematically and on the psychrometric chart in

Fig. 5-1.

h1

h2

ADP

x

Refrigerant or chilled fluid

ω =const

Warm

humid air

1

ṁ a

1

2

Cooling coil

2

Cooled & dehumidified

air

Condensate line

ṁ cond

T1

T adp T 2

Figure 5-1: Cooling with dehumidification

Warm, humid air enters the cooling section at state 1 at a mass flow rate ṁa . As it passes through the

cooling coils, its temperature decreases and its relative humidity increases at constant specific

humidity. If the cooling section is sufficiently long, air reaches its dew point (state x, saturated air).

Further cooling of air results in the condensation of part of the moisture in the air. The condensate

leaves at a mass flow rate ṁcond . Air remains saturated during the entire condensation process, which

follows a line of 100 percent relative humidity until the final state is reached. In a “perfect”

refrigeration coil, the final state is saturated air at the apparatus dew point temperature, T adp which is

the average surface temperature on the outside of the cooling coil. In reality, some air passes through

without ever contacting the fins of the coil. The actual exit state, 2, is the result of the adiabatic mixing

of the air at that bypasses the coil (and thus is at condition 1) and the air that is cooled to T adp . See the

left side of Figure 5-1. The bypass factor (BF) is defined as the equivalent fraction of air that bypasses

the cooling coil while the remaining portion of the air is completely cooled to the apparatus dew-point

temperature. It can be shown that:

www.SlaythePE.com

27

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

BF=

T 2−T adp

T 1−T adp

(5-1)

The location of the outlet condition, 2, can be found by drawing a line from the inlet condition, point 1,

on the psychrometric chart to ADP, as shown in Figure 5-1, and then calculating the outlet dry bulb

temperature by rearranging Equation 5-1 to solve for T 2 using Equation 5-2. Point 2 will be located on

the line connecting 1 and ADP.

T 2=T adp+BF ( T 1 −T adp )

(5-2)

The total heat removed from the air (and absorbed by the fluid in the coil) is known as the coil load

Q̇ coil and is obtained from an energy balance on the cooling section:

Q̇ coil = ṁa ( h1 −h2 ) − ṁcond hcond

(5-3)

where it is typically assumed that the condensate leaves the cooling section at the apparatus dew point

temperature, hence hcond =h f (T adp) and from a water mass balance:

ṁcond = ṁa ( ω 1 − ω 2)

(5-4)

In HVAC calculations, it is typical to neglect the enthalpy of the condensate in equation (5-3) so the

coil load is obtained as:

Q̇ coil≈ ṁa ( h1−h 2 )

60 min

CFM×

1h

≈

( h1−h2 )

3

v [ft /lbm]

∣

∣

and using the specific volume at standard conditions (dry air at 68°F and 14.7 psia) of 13.3 ft 3/lbm the

above equation becomes:

Q̇ coil≈4.5 CFM ( h1 −h2 )

(5-5)

(Note: If standard conditions are specified as 70°F and 50% RH, replace 4.5 with 4.44.)

Point 2 has a lower temperature than point 1 but also a lower moisture content. As discussed in section

3, the heat transfer associated with the change in dry bulb temperature is known as the sensible heat.

The latent heat is the heat transfer associated with the phase change of the water.

Q̇ lat = ṁcond h fg

which in view of equation (5-4) becomes:

Q̇ lat = ṁa ( ω 1− ω 2) h fg

www.SlaythePE.com

28

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

and using the specific volume at standard conditions (dry air at 68°F and 14.7 psia) of 13.3 ft 3/lbm the

above equation becomes:

∣601min

h ∣

h

CFM×

fg ( ω 1 − ω 2 )

3

v [ft /lbm ]

CFM ( 60 )

≈

( 1,076 ) ( ω 1− ω 2 )

13.33

Q̇ lat≈

In the equation above, 1,076 (Btu/lbm) is the approximate energy content of the superheated water

vapor at 75°F (1094.7 Btu/lb), less the energy content of water 50°F (18.07 Btu/lb). This difference is

rounded up to 1,076. A temperature of 75°F is a common design condition for an occupied space and

50°F is normal condensate temperature from cooling and dehumidifying coils. Combining the

constants, the latent heat gain is:

Q̇ lat≈4,840 CFM ( ω 1− ω 2 )

(5-6)

(Note: If standard conditions are specified as 70°F and 50% RH, replace 4,840 with 4,680.)

The sensible heat factor (SHF), also called the sensible heat ratio (SHR), is the ratio of the sensible

heat for a process to the summation of the sensible and latent heat for the process:

SHR=

Q̇ sens

Q̇sens

=

Q̇sens +Q̇ lat Q̇ total

(5-7)

For a cooling coil, the sensible heat ratio can be found by applying equation (3-1) to find sensible

cooling, equation (5-5) to find the total cooling, and equation (5-7) to find SHR.

There are a couple of ways to graphically determine the SHR with a psychrometric chart. The first one

is to “break down” the cooling process into two imaginary processes as shown in Figure 5-2: process 11' in which there is no cooling but only dehumidification followed by process 1'-2 in which there is no

dehumidification but only cooling. The enthalpies of states 1, 1' and 2 are read from the enthalpy scale.

The sensible heat is (h1'−h2 ) the latent heat is (h1−h1' ) , and the total coil heat is (h1−h 2) . Therefore

SHR is calculated as SHR=(h1'−h2 )/(h1−h2) . The other graphical way to determine SHR is to use the

SHR protractor that some psychrometric charts have on the upper left corner. You draw a line parallel

to the process line 1-2 through the center of the protractor and use the SHR scale on the protractor to

read the value of SHR.

www.SlaythePE.com

29

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

h1

Parallel to 1-2

h1'

SHR scale

h2

total

sens.

1

1'

2

Figure 5-2: Calculation of Sensible Heat Ratio (SHR)

Heating with Humidification:

Injecting steam into a moist air stream to raise the humidity ratio of the moist air is a frequent airconditioning process (Figure 5-3). This is typically done in a humidification step after simple heating.

If the mixing is adiabatic, the following equations apply:

ṁ a1 , T 1, ω 1

1

Mixing

Chamber

2

ṁ a2 , T 2, ω 2

Humidifier

Perfect Insulation

ṁ steam , h steam

Figure 5-3: Adiabatic mixing of moist air with steam.

When steam is introduced in the humidification section, this will result in humidification with heating (

T 2>T 1 , ω 2> ω 1 ), as shown in Figure 5-4.

www.SlaythePE.com

30

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

2

1

Figure 5-4: Adiabatic mixing of moist air with steam – graphical representation on psychrometric chart.

The mass flow of steam injected into the air is obtained from a mass balance for water:

ṁsteam = ṁa ( ω 2 − ω 1 )

PROBLEMS

05-01. In a cooling and dehumidification coil, 71,000 cfm of air at 80°F dry bulb, 60% rh, and standard

atmospheric pressure, are conditioned to 57°F dry bulb and 90% relative humidity. Calculate the

following:

(a) cooling capacity of the air-conditioning unit, in Btu/h and in tons of refrigeration

(b) rate of water (condensate) removal from the unit

(c) coil sensible heat load, in Btu/h

(d) coil latent heat load, in Btu/h

(e) the dew point of the air leaving the conditioner

(f) the apparatus dew point

(g) the coil bypass factor

www.SlaythePE.com

31

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

05-02*. Air enters a 1-ft-diameter cooling section at 14.7 psia, 90°F, and 60% rh at 600 ft/min. The air

is cooled by passing it over a cooling coil through which chilled water flows. The chilled water

experiences a temperature rise of 14°F and the air leaves the cooling section saturated at 70°F. The

required flow rate of chilled water (gpm) is most nearly:

(A) 1.5

Chilled water, Δ T =14 °F

(B) 2.2

Cooling coil

(C) 12

Air, 600 fpm

90°F

60% r.h.

(D) 120

D=1 ft

70°F

saturated

1

2

05-03*. A quantity of 1,600 cfm of air at 14.7 psia, 80°F dry-bulb and 67°F wet-bulb flows through a

cooling coil with a 0.12 bypass factor and a 45°F apparatus dew point. Under these conditions, the wet

bulb temperature (°F) of the air leaving the coil is most nearly:

(A) 47

(C) 49

(B) 48

(D) 50

05-04*. Air flowing at a rate of 1,600 cfm at 78°F, 65°F w.b. enters a cooling unit with a total capacity

of 60,000 Btu/h and a sensible heat ratio of 0.75. The amount of water (gallons per hour) expected to

drain through the condensate line is most nearly:

(A) 2

(C) 6

(B) 4

(D) 8

05-05*. An air-conditioning system is to take in outdoor air at 50°F and 30 percent relative humidity at

a steady rate of 1,600 cfm and to condition it to 77°F and 60 percent relative humidity. The outdoor air

is first heated to 72°F in the heating section and then humidified by the injection of hot steam in the

humidifying section. Assuming the entire process takes place at a pressure of 14.7 psia, the mass flow

rate of the steam (pounds per hour) required in the humidifying section is most nearly:

www.SlaythePE.com

(A) 17

(C) 89

(B) 72

(D) 95

32

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

SECTION 06: Evaporative Cooling

Cooling in a hot dry climate (e.g., the southwest United States) can be accomplished by evaporative

cooling. This consists of either spraying liquid water into air, or forcing air through a soaked pad that is

kept replenished with water. This is the principle of operation of the so-called swamp coolers popular

in the southwestern states. In extremely dry climates, evaporative cooling of air has the added benefit

of conditioning the air with more moisture. Because of the low humidity of the air entering the

evaporative cooler, part of the injected water evaporates. The energy required for this phase change of

the water is taken from the air, which manifests in a reduction of air temperature. It can be shown that

the evaporative cooling process takes place at nearly constant wet-bulb temperature. Therefore, during

evaporative cooling, the wet-bulb temperature of the air remains constant but the dry-bulb temperature

drops as the humidity rises. Since the constant wet-bulb temperature lines almost coincide with the

constant-enthalpy lines, the enthalpy of the airstream can also be assumed to remain constant.

Therefore, when air is cooled evaporatively all the way to saturation, it is said to have undergone

adiabatic saturation.

Evaporative coolers have a continuously recirculated water stream. It can be shown that during steady

state operation, this water reaches an equilibrium temperature that equals the entering air wet-bulb

temperature. The evaporative cooling process is schematically shown on a psychrometric chart in

Figure 6-1. The process 1-2 follows a line of constant wet-bulb temperature.

2'

2

T w.b., 1

1

T2

T1

T 2'=T w.b., 1

Figure 6-1: Evaporative Cooling

www.SlaythePE.com

33

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

Note from Figure 6-1 that the lowest air temperature that can be theoretically achieved corresponds to

state 2', that is when the air at the exit of the cooler is saturated air. The lowest temperature

theoretically achievable by evaporative cooling is therefore the wet-bulb temperature of the incoming

air.

PROBLEMS

06-01. Air enters an evaporative (or swamp) cooler at 14.7 psi, 95°F, and 20 percent relative humidity,

and it exits at 80 percent relative humidity. Determine the exit temperature of the air.

06-02. What is the lowest temperature that air can attain in an evaporative cooler if it enters at 1 atm,

95°F, and 40 percent relative humidity?

06-03*. Saturated air at 40°F is first preheated and then saturated adiabatically. This saturated air is

then heated to a final condition of 105°F and 28% rh. The temperature (°F) to which the air must

initially be heated in the preheat coil is most nearly:

(A) 65

(C) 101

(B) 95

(D) 105

06-04*. Air at 1 atm, 60°F, and 60 percent relative humidity is first heated to 85°F in a heating section

and then passed through an evaporative cooler where its temperature drops to 77°F. The exit relative

humidity (%) is most nearly:

(A) 26

(C) 60

(B) 42

(D) 100

06-05*. Air enters an evaporative cooler at 14.7 psia, 90°F, and 20 percent relative humidity at a rate of

9,800 cfm, and it leaves with a relative humidity of 90 percent. The required rate of water supply to the

evaporative cooler (gallons per minute) is most nearly:

www.SlaythePE.com

(A) 0.067

(C) 4.2

(B) 0.5

(D) 8.5

34

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

SECTION 07: Wet Cooling Towers

Large-scale applications such as power plants, large commercial air-conditioning systems, and some

industrial sites generate large quantities of waste heat that is often rejected to cooling water from

nearby lakes or rivers. In some cases, however, the cooling water supply is limited or excessive thermal

pollution to a water body is undesirable. In such cases, the waste heat must be rejected to the

atmosphere, with cooling water recirculating and serving as a means of transport for heat between the

source and the sink (the atmosphere). Cooling towers provide a common way to achieve this.

A wet cooling tower is essentially a semi-enclosed evaporative cooler. An induced-draft wet cooling

tower is shown schematically in Figure 7-1.

Air out

Warm water

from process

Air in

Basin

Cooled water

to process

Make-up

water in

Pump

Figure 7-1: Induced-Draft Wet Cooling Tower

Note that – unlike in an evaporative cooler – the water in a cooling tower is supplied at a temperature

higher than the dry-bulb temperature of the incoming air. Air is drawn into the tower from the sides

and leaves through the top. Warm water is pumped to the top of the tower and is sprayed into this

airstream. The purpose of spraying is to expose a large surface area of water to the air. As the water

droplets fall under the influence of gravity, a small fraction of water (usually a few percent) evaporates

and cools the remaining water. The temperature and the moisture content of the air increase during this

process. Inside the tower, some designs use a series of solid structures known as packing or fill to

promote both the maximum contact surface and the maximum contact time between air and water. The

cooled water collects at the bottom of the tower in the basin and is pumped back to the process.

www.SlaythePE.com

35

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

Makeup water must be added to the cycle to replace the water lost by evaporation and drift, which is

circulating water lost from the tower as liquid droplets entrained in the exhaust air stream. To minimize

water carried away by the air, drift eliminators (baffles or similar elements designed to remove

entrained liquid water from the exhaust air) are installed in the wet cooling towers above the spray

section. The amount of makeup water is essentially equal to the moisture gained by the air; that is, air

mass flow rate times the increase in specific humidity.

The air circulation in the cooling tower described above is provided by a fan, and therefore it is

classified as a mechanical-draft cooling tower. The schematic of Figure 7-1 shows the fan located in

the exiting air stream drawing air through the tower; this is called induced draft. Conversely, if the fan

is located in the ambient air stream entering the tower thus blowing the air through the tower, this is

known as forced draft. Another type of cooling tower is the natural-draft cooling tower. The air in

the tower has a high water-vapor content, and thus it is lighter than the outside air. Therefore, the light

air in the tower rises, and the heavier outside air fills the vacant space, creating an airflow from the

bottom of the tower to the top – a “stack” effect. The flow rate of air is controlled by the conditions of

the atmospheric air. Natural-draft cooling towers do not require any external power to induce the air,

but they cost more to build than mechanical-draft cooling towers and are significantly taller. The

natural-draft cooling towers are hyperbolic in profile but this profile is for structural integrity reasons,

not for any thermodynamic or fluid dynamics reason.

The cooling tower range is the difference between the hot water temperature and the cold water

temperature. Similarly as evaporative coolers, the lowest temperature to which water can be cooled by

evaporation is the wet-bulb temperature of the incoming air. The approach is the difference between

the cold water temperature and the wet-bulb temperature of the incoming air. The tower cooling

efficiency is based on the water temperatures. It is defined as the ratio of the actual water temperature

drop over the theoretical maximum water temperature drop:

η CT =

T w,in −T w,out

T w,in −T wet bulb, in

(7-1)

The heat load is the total heat to be removed from the water by the cooling tower per unit time:

Q̇ CT = ṁ w c p ,w ( T w,in −T w,out )

(7-2)

Cooling tower problems are typically solved by performing energy and mass balances on the tower.

Referring to the tower in Figure 7-2, we can write down a mass balance for water as follows:

www.SlaythePE.com

36

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

86 °F

air, out 100% r.h.

2

3

Warm

water in 95 °F

68 °F

60% r.h.

1 air, in

4

5

Cool

water out

Make-up

water

Figure 7-2. Schematic of a wet cooling tower

of water = Rate of water

[ Rate

mass flow in ] [ mass flow out ]

(7-3)

ṁ3+ ṁ 4+ ṁair ω 1= ṁair ω 2 + ṁ5

Therefore, the rate of make-up water ṁ 4 required can be obtained as:

ṁmakeup = ṁ4 = ṁ air ( ω 2 − ω 1 )+ ṁ5 − ṁ3 = ṁair ( ω 2− ω 1 )

(7-4)

Now we will consider the energy balance. Although there is some mechanical work (power) consumed

by the fan(s), this energy interaction is typically neglected when performing an energy balance on

cooling towers, so we have:

at which = Rate at which

[ Rate

energy enters ] [ energy exits ]

ṁair h1 + ṁ3 h3 + ṁ4 h4= ṁair h2+ ṁ5 h5

Now, assuming the make-up water is at a temperature not too different than that of the cooled water,

we set h 4 =h 5 . Therefore: ṁair (h2 −h1 )= ṁ3 h3−( ṁ5− ṁ4 ) h5 . Combining this expression with the water

mass balance of equation (7-4) we obtain:

ṁair [(h2−h1 )−( ω 2− ω 1)h5 ]= ṁ3 (h3 −h5)

= ṁw c p ,w ( T w,in −T w,out )

(7-5)

and we recognize the right hand side of equation (7-5) as the tower heat load.

www.SlaythePE.com

37

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

PROBLEMS

07-01*. A cooling tower cools water by passing it through a stream of 1,400 cfm of air at 85°F dry bulb

and 78°F wet bulb entering the tower and leaving it saturated at 95°F. The water enters the tower at

110°F with a flow rate of 10 gpm. Under these conditions, the temperature (°F) of the water leaving the

tower is most nearly:

(A) 78

(B) 86

(C) 95

(D) 99

07-02*. The cooling water from the condenser of a power plant enters a wet cooling tower at 110°F at a

rate of 720 gpm. Water is cooled to 80°F in the cooling tower by air that enters the tower at 1 atm,

76°F, and 60 percent relative humidity and leaves saturated at 95°F. Under these conditions, the

volume flow rate of air (cfm) entering the tower is most nearly:

(A) 66,900

(B) 71,000

(C) 78,600

(D) 87,400

07-03*. A cooling tower with a cooling efficiency of 57% is being considered for the heat rejection

needs of a large commercial HVAC system. The water must leave the tower at 77°F. The air flow

through the tower is 263,000 cfm entering at 68°F, 50% rh and exiting at 90°F, 98% rh. Under these

conditions, the water flow (gpm) entering the tower is most nearly:

(A)

475

(B)

950

(C) 2,000

(D) 2,600

www.SlaythePE.com

38

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

07-04*. A cooling tower operates with a heat load of 600,000 Btu/hour. The air will enter the tower at

68°F, 30% rh and will be discharged as saturated air at 95°F, while the water will be cooled down to

70°F. Under these conditions, the water flow (gallons per hour) required as makeup water is most

nearly:

(A)

58

(B) 230

(C) 480

(D) 3,300

07-05.* Water enters a cooling tower at a rate of 30 gpm and 95°F. The cooling efficiency of the tower

is 75%. The air enters the tower at 60°F, 30% rh. Under these conditions, the cooling tower heat load

(Btu per hour) is most nearly:

(A)

9,250

(B) 66,600

(C) 395,000

(D) 555,100

www.SlaythePE.com

39

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

This page was intentionally left blank

www.SlaythePE.com

40

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

SECTION 08: Basic HVAC System Calculations

A single conditioner serving a single temperature control zone is the simplest form of an all-air HVAC

system. The unit may be installed remote from, or within, the space it serves, and it may operate either

with or without distributing ductwork. Well-designed systems can maintain temperature and humidity

closely and efficiently.

A single-zone system is one which responds to only one set of space conditions. Its use is limited to

situations where variations occur approximately uniformly throughout the zone served or where the

load is stable. Single-zone systems are used in such applications as small department stores, small

individual shops in a shopping center, individual classrooms for a small school, and computer rooms.

A rooftop unit complete with a refrigeration system serving an individual space is an example of a

single-zone system. The refrigeration system, however, may be remote and serving several single zone

units in a larger installation.

A schematic of the single-zone central unit is shown in Figure 8-1.

Return air

Exhaust air

Return Fan

Return air

(from room)

Optional section

Supply air

(to room)

Outside air

Supply Fan

Pre-heat coil (optional)

Cooling

coil

Humidifier (optional)

Reheat coil (optional)

Figure 8-1: Single-Duct System

Several strategies of control can be employed on a single-zone system. These strategies include on-off

operation, varying the quantity of cooling medium providing reheat, using face and bypass dampers, or

a combination of these. A single-duct system with a reheat coil satisfies variations in load by providing

independent sources of heating and cooling. Humidity control completely responsive to space needs is

possible when a humidifier is included in the system. Since control is directly from space temperature

www.SlaythePE.com

41

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

and humidity, close regulation of the system conditions may be achieved. Generally, a return air fan is

needed if the total resistance of the return air system (grilles and ductwork) exceeds about 0.25 in.

water gage.

The basic equations for individual rooms (zones) are the same for all single-path systems. Air supplied

to each room must be adequate to take care of each room’s peak load conditions whether or not it

occurs simultaneously in all rooms. The peak may be governed by sensible or latent room cooling

loads, heating loads, outdoor air requirements, air motion, or exhaust.

If qsens, summer is the room's peak summer sensible load, then the summer room supply air volume

required to satisfy this peak sensible load is:

CFM sens, summer =

qsens, summer

1.1×( T r −T s )

(8-1)

where T r is the room (or return) air temperature and T s is the supply air temperature required to satisfy

the summer peak load.

If qlat, summer is the room's peak summer latent load, then the summer room supply air volume required to

satisfy this peak latent load is:

CFM lat, summer =

qlat, summer

4,840×( ω r − ω s )

(8-2)

where ω r is the room (or return) air humidity ratio and ω s is the supply air humidity ratio required to

satisfy the summer peak load.

If qsens, winter is the room's peak winter sensible load (less any auxiliary heat), then the winter room

supply air volume required to satisfy this peak sensible load is:

q

CFM sens, winter = sens, winter

1.1×( T s −T r )

(8-3)

where T r is the room (or return) air temperature and T s is the supply air temperature required to satisfy

the winter peak load.

If qlat, winter is the room's peak winter latent load, then the winter room supply air volume required to

satisfy this peak latent load is:

CFM lat, winter =

www.SlaythePE.com

qlat, winter

4,840× ( ω s −ω r )

42

(8-4)

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

where ω r is the room (or return) air humidity ratio and ω s is the supply air humidity ratio required to

satisfy the winter peak load.

In some instances, the air volume required for ventilation purposes might be larger than that required

by sensible or latent loads. There are three basic categories of ventilation air volume requirements:

1. Outdoor air requirements dictate the supply volume to a room as determined by an actual

quantity of outdoor air required CFM oa req and the ratio of the system's total outdoor air to its

total supply air, X o :

CFM ventilation =

CFM oa req

Xo

2. Exhaust air requirements in applications in which the air discharged to the outside (exhaust air)

exceeds the volume required to satisfy any loads. Then the supply air must match the exhaust

air requirement and serve as makeup for exhaust flow out of the room.

CFM ventilation =CFM exhaust

3. Air movement requirements in some applications might be larger than the volume required to

satisfy any loads. In these cases, the supply air volume has to be chosen to satisfy these air

movement requirements, which are expressed either in terms of air changes per hour (ACH) or

as proportional to the room floor area.

3

CFM ventilation =(Room volume in ft )×ACH/60 , or CFM ventilation=K (Room floor area )

Both ACH and K are empirical values that vary according to designers’ experiences and local

building code requirements.

EXAMPLE 8-1:

Consider a space which is designed to have a summer inside temperature of 75°F and relative humidity

of 50% and a winter inside temperature of 72°F and relative humidity of 25%. The summer supply air

conditions are 55°F, 90% rh, while the winter supply air temperature is 110°F with a humidity ratio of

0.0065 lb/lb. The summer design loads are qsens, summer =18,000 Btu /h and qlat, summer =3,000 Btu /h and

the winter design loads are qsens, winter =20,000 Btu / h and qlat, winter =2,500 Btu / h .The outdoor air

requirement is 120 cfm and the ratio of outdoor air to total supply air is 0.35. Determine the required

supply air in CFM to satisfy summer, winter, and ventilation conditions.

www.SlaythePE.com

43

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

Solution:

CFM sens, summer =

CFM lat, summer =

CFM ventilation=

18,000

=818cfm

1.1× ( 75−55 )

CFM sens, winter =

20,000

=479 cfm

1.1×( 110−72 )

3,000

2,500

=620 cfm CFM lat, winter =

=225 cfm

4,840×( 0.0093−0.0083 )

4,840× ( 0.0065−0.0042 )

CFM oa req 120

=

=343cfm

Xo

0.35

In order to satisfy all design parameters, the design volume flow rate should be selected as the

maximum flow requirement of 818 cfm. This is what is required for the summer sensible design load.

All of the other design parameters will be satisfied with this volume flow but would require some form

of control to maintain temperature, relative humidity, and outside ventilation air quality.

The operation of a single path system is illustrated in Figure 8-2. Each state point is shown with

corresponding nomenclature in the cycle diagram and in the summer and winter representations on the

psychrometric chart of Figure 8-3. In Figure 8-2, the red arrows represent heat loads. Each change in

temperature or humidity ratio is a result of sensible or latent heat loss or gain. Here we describe the

flow paths in a typical single-duct, single-zone system. In this illustration all return air is assumed to

pass from the room through a hung-ceiling return air plenum.

Roof

CFMEXH

CFMR

Tr

CFMr

Return Fan

Tr

CFMR

TRP

Trd

CFMS

CFMO

TO

CFMs

Tm

CFMS

TCC

THC

TSF

Supply Fan

Cooling

coil

plenum

lights

Ts

CFMR

Troom

window

CFMexf

room

occupants

Heating coil

equipment

Floor

Figure 8-2: Single-Duct, Single-Zone Cycle Diagram

www.SlaythePE.com

44

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

In Figure 8-2, supply air leaves the supply fan discharge at a rate CFM s and at temperature T sf in the

summer mode. This air absorbs transmitted supply duct heat and supply air fan velocity pressure

energy, thus raising the temperature to T s . The air enters the room where it absorbs room sensible and

latent heat qsens and qlat along the room sensible heat factor (SHF) line s-R, thus reaching the desired

room state, T room and ω room . Room (internal) sensible loads which determine CFM s consist of (for

example): (1) ceiling transmission from the hung ceiling above the room, and floor transmission from

the floor deck below, (2) direct light heat emissions to the room, (3) transmissions from other surfaces

such as walls, windows, etc., (4) appliance heat and occupancy heat, and (5) infiltration loads (not

shown). Additional loads in the plenum space move the conditions from “room” to “RP” and the

volume of air in the return system CFM R is CFM s minus the volume lost by exfiltration CFM exf . The

return air picks up return duct transmissions and return fan heat gains so it reaches the intake plenum

entrance at T r . Mixing of outdoor air, CFM o at state “o”, with final return air occurs along process line

r-o to mixture state “m”. Total system air flowing at rate CFM s passes through the cooling coil (process

line m-cc), terminating in state cc. The temperature rise through the supply fan results in T sf which

completes the cycle. Note that there may be more loads and flow rates (for example duct leakage) not

mentioned in this discussion.

o

summer

R

cc

m

rp r

sf s

R

m

hc

r

s sf

o

Figure 8-3: Single-Duct, Single-Zone Psychrometric Chart

www.SlaythePE.com

45

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

Consider the simplified single-duct system of Figure 8-4 shown operating in cooling (summer) mode.

With respect to the control volume defined by the imaginary red dashed line we notice the following

heat transfer interactions (shown as red arrows): the coil load, which is heat (sensible and latent)

removed from the supply air by the cooling coil, and the space load which is heat (sensible and latent)

absorbed by the air as it flows through the conditioned space.

x

Q̇ space

r

ṁ a, x

Conditioner

r

Fan

o

ṁ a, o

ṁ w, space

s

m

Space

c

Q̇ coil

ṁ cond

Condensate

Figure 8-4: Thermal and Moisture Loads for a Single-Duct, Single-Zone System

Also, the water mass flow rates (blue arrows) are: the condensate removed by dehumidification in the

conditioner and the space moisture load, which is water vapor added to the air as it flows through the

conditioned space.

The outdoor air at state “o” enters the control volume at a mass flow rate ṁa , o and is discharged at the

exhaust at state “x” (which is assumed for simplicity to be identical to “r”) at a mass flow rate ṁa , x . If

we neglect any building infiltration and exfiltration, the steady-state mass balance for air in the red

control volume requires that: ṁa , o= ṁa , x .

The energy balance requires that the rate at which energy enters the control volume equals the rate at

which energy leaves the control volume. Thus:

ṁ a , o ho + Q̇ space = ṁ a , x h r +Q̇ coil + ṁ cond hcond

⇒ Q̇ coil =Q̇ space + ṁ a , o ( ho−hr ) − ṁ cond hcond

and if we neglect the condensate enthalpy,

Q̇ coil =Q̇space + ṁa , o ( h o−hr )

(8-5)

We note then, that the coil size has to exceed the space load by at least the term underlined in equation

www.SlaythePE.com

46

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

8-5. This underlined term is the amount of energy that is required to take the outdoor air from the

outdoor condition “o” to the room condition, “r” and it is known as the load due to outdoor air.

Outdoor air that flows through a building is often used to dilute and remove indoor air contaminants.

However, the energy required to condition this outdoor air can be a significant portion of the total

space-conditioning load. The magnitude of the outdoor airflow into the building must be known for

proper sizing of the HVAC equipment and evaluation of energy consumption.

Air exchange of outdoor air with the air already in a building can be divided into two broad

classifications: ventilation and infiltration. Ventilation is the intentional introduction of air from the

outside into a building; it is further subdivided into natural ventilation and forced ventilation. Natural

ventilation is the intentional flow of air through open windows, doors, grilles, and other planned

building envelope penetrations, and it is driven by natural and/or artificially produced pressure

differentials. Forced ventilation is the intentional movement of air into and out of a building using

fans and intake and exhaust vents; it is also called mechanical ventilation. Infiltration is the

uncontrolled flow of outdoor air into a building through cracks and other unintentional openings and

through the normal use of exterior doors for entrance and egress. Infiltration is also known as air

leakage into a building. Exfiltration is the leakage of indoor air out of a building. Like natural

ventilation, infiltration and exfiltration are driven by natural and/or artificial pressure differences.

PROBLEMS

08-01: Consider an air-conditioned space with a summer sensible design load of 100,000 Btu/h, and a

summer design latent load of 20,000 Btu/h. The space is maintained at 75°F and 55% rh. Conditioned

air leaves the apparatus (and enters the room) at 58°F. The outdoor air is at 96°F, 77°F wet bulb, and is

20% of total flow to the conditioning apparatus.

Complete the following table where o, r, m, and s refer to outdoor, return, mix (r+o) and supply.

Point

T(°F)

o

96

r

75

ϕ

T wb (°F)

h (Btu/lbm)

ω (lbm/lbm) v a (ft3/h)

ṁ (lbm/h)

CFM

SCFM

77

55

m

s

58

www.SlaythePE.com

47

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

08-02. Determine the size of the required cooling unit in Btu/h and tons for the system of problem 0801.

08-03. For the system of problem 08-01; what percent of the required cooling is for sensible cooling,

and what percent is for dehumidification?

08-04. For the system of problem 08-01; what percent of the required cooling is due to the outdoor air

load?

08-05*. A room is to be maintained at 76°F and 40% rh. Supply air at 39°F is to absorb 100,000 Btu of

sensible heat and 35 lbm of moisture per hour. Assume the moisture has an enthalpy of 1100 Btu/lbm.

The required mass flow rate of air (lbm of dry air per hour) is most nearly:

(A) 1,230

(B) 2,457

(C) 11,100

(D) 16,500

08-06*. Moist air enters a chamber at 40°F dry-bulb and 36°F wet-bulb temperature at a rate of 3,000

scfm. In passing through the chamber, the air absorbs sensible heat at a rate of 116,000 Btu/h and picks

up 83 lbm/h of saturated steam at 230°F. The relative humidity (%) of the leaving air is most nearly:

(A) 5

(B) 10

(C) 30

(D) 50

www.SlaythePE.com

48

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

08-07*. In an auditorium, a sensible-heat load of 350,000 Btu and 1,000,000 grains of moisture must be

removed per hour. The room must be maintained at a temperature not to exceed 77°F, and a relative

humidity not to exceed 55%,. Air is supplied to the auditorium at 67°F. Under these conditions, the

dew-point (°F) of the supplied air is most nearly:

(A) 55

(B) 59

(C) 65

(D) 67

08-08*. A flow rate of 30,000 lbm/h of conditioned air at 60°F and 85% rh is added to a space that has

a sensible load of 120,000 Btu/h and a latent load of 30,000 Btu/h. A mixture of 50% return air and

50% outdoor air at 98°F dry bulb and 77°F wet bulb enters the air conditioner. The required size (tons)

of the cooling coil is most nearly:

(A) 10

(B) 12.5

(C) 17

(D) 27

www.SlaythePE.com

49

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

This page was intentionally left blank

www.SlaythePE.com

50

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION

SECTION 09: Answers

01-01.

a) Use equation (1-5):

ω

( ω +0.622

)p

0.1

=(

×14.7 psia

0.1+0.622 )

pv=

=0.3462 psia

b) The dew-point is the saturation temperature corresponding to p v =0.3462 psia , so from the steam

tables, T dp =T sat (0.3462 psia)=68.6 °F

c) Use equation (1-6):

ϕ=

pv

pg

where p g = psat @ T =0.4302 psia . Thus, ϕ =0.3462/0.4302=0.805=80.5% .

d) Use equation (1-9) μ = ω / ω s where ω s is found by setting ϕ =1 in equation (1-8):

ω s=

0.622 p g 0.622×0.4302 psia

=

=0.01875

p− p g

( 14.7−0.4302 ) psia

Therefore μ = ω / ω s =0.015/0.01875=0.8=80 % .

e) Use equation (1-12):

h=0.24T + ω ( 1,061+0.444T )=34.42 Btu /lbm

f) Use equation (1-13):

(

)

Ra T

ω

1+

p

0.622

3

psia ft

0.3704

×( 75+459.67 ) °R

3

lbm °R

0.015

ft

=

× 1+

=13.8

14.7 psia

0.622

lbm

v=

(

www.SlaythePE.com

51

)

Copyright © 2018. All rights reserved.

LICENSED EXCLUSIVELY TO WILLIAM OFORI-ATTA – NO UNAUTHORIZED DISTRIBUTION