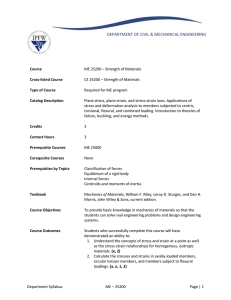

Structures 30 (2021) 294–304 Contents lists available at ScienceDirect Structures journal homepage: www.elsevier.com/locate/structures Flexural behaviour of cover plated CFS built-up beams composed of lipped channels: Comparison of test and design strengths M. Anbarasu a, M. Adil Dar b, Ahmad Fayeq Ghowsi c, A.R. Dar d, * a Department of Civil Engineering, Government College of Engineering, Salem, Tamil Nadu 636011, India Department of Civil and Environmental Engineering, National University of Singapore, 1 Engineering Drive 2, 117576, Singapore c Department of Civil Engineering, Indian Institute of Technology Delhi, New Delhi 110016, India d Department of Civil Engineering, National Institute of Technology Srinagar, J&K 190006, India b A R T I C L E I N F O A B S T R A C T Keywords: Cold-formed steel Beams Built-up section Experiment Flexural strength Built-up members are efficient in developing adequate resistance against large load demands, and their efficiency largely depends on how adequately the built-up sections are designed. This paper discusses the flexural behaviour of cover plated cold-formed steel (CFS) built-up beams made up of lipped channels. Lipped channels were placed at an adequate distance in the back-to-back arrangement and were connected at the flanges with self-drilling screws by means of cover plates, on both the tension as well as the compression faces. Simply supported end conditions were adopted in all the specimens. Both three-point loading as well as four-point loading was considered to study the influence of moment gradient and constant moment loading of theses built-up beam specimens. The sectional compactness of the channel section and the aspect ratio of the built-up section were varied to assess the behavioural effect in the specimens with respect to the variations incorporated. This study deals with the tests conducted to generate the test data. Prior to the testing of the specimens, tensile coupon tests were carried out as per the relevant standards to acquire the actual material properties of the steel used for the specimen fabrication. Both the European code as well as the North American Standards were used for developing the theoretical strengths and were compared with the test results. 1. Introduction Cold-formed steel (CFS) sections are being used extensively in the primary framing elements of the structural systems, as they offer numerous favourable features like light-weight construction, fast/ convenient installation, design flexibility with respect to availability of large variety of cross-sectional shapes and sizes, and many more. To overcome the limitation of the inherent local buckling instability in CFS sections, many successful research attempts have delivered effective solutions to the same [1,16,17,21–27]. Built-up members are gaining popularity in the construction sector, particularly in CFS building segment, which is mainly due to the com­ bination of the favourable features in both CFS as well as in the adoption of built-up members. Built-up members allow the cross-sectional strength to be utilized in an effective manner, resulting in the efficient utilization of steel, as a constructional material. The past research on built-up flexural members has indicated immense potential in their application. The web stiffening of the channel sections constructing the flexural built-up members improved their bending strength by delaying the local buckling failure [3,5,6,9]. The improvement in the stability of the web resulted in the strength enhancement of such improved built-up sections. However, the flexural stresses in the beams are always maximum at the top compression flange particularly under four-point loading. Therefore, the improvement in the flexural strength of such improved built-up sections was not substantial [4,6,30,31] and needed to be addressed differently. Many researchers attempted to address this problem by working on the stiffening of the flange elements. Their research identified that stiffening of the flange and around the flange region enhances the flexural strength of the built-up beams [7,15,28,29]. Furthermore, the stiffening of the flange improves the performance of these beam sections under cyclic loading as well [18–20]. All the measures to stiffen the individual elements improved their local buckling resistance by a reasonable margin only, as the thickness of the plate element (that could increase the sectional compactness/flat width-to-thickness ratio) could not be increased through these approaches. Also, the intermittent stiffening operation * Corresponding author. E-mail address: abdulrashid@nitsri.net (A.R. Dar). https://doi.org/10.1016/j.istruc.2020.12.088 Received 23 August 2020; Received in revised form 24 November 2020; Accepted 21 December 2020 Available online 23 January 2021 2352-0124/© 2021 Institution of Structural Engineers. Published by Elsevier Ltd. All rights reserved. M. Anbarasu et al. Structures 30 (2021) 294–304 Fig. 1. Details of the cross-section. requires more efforts, quality workmanship to attain the desired per­ formance levels. Since easy fabrication is one of the key features of CFS construction, there is a need to develop an easy and convenient fix to the local buckling resistance enhancement of the compression flange of the builtup beam section that is more susceptible to local buckling. Reinforcing the compression flange of the beam section by additional plates (also the addition of cover plates) increase its flexural strength by improving the local buckling strength (due to reduction in the compression flange plate slenderness). It also improves the sectional modulus of the built-up section. Very limited research work has been carried out on this type of strengthening approach, which is mostly numerical [11–13]. This clearly indicates the need for more research (particularly experimental ones) on these types beam configurations. Given the capital required for buying a cold-rolling machine that can fabricate complex geometries of the sectional profiles and time required for the fabrication of such built-up members, a simple cross-sectional geometry (cover plated CFS built-up beams), with a simple fabrication process would substantially improve the buckling resistance of these beam sections, and thereby enhance the quality of CFS construction at a much lower cost. This can boost the practice of safe, economical and durable construction, particularly in the developing countries. With this aim in consideration, the authors have made an attempt to bring out built-up flexural members (as shown in Fig. 1) that can perform better than the conventionally adopted built-up beams, i.e., two channels with their webs in contact, screwed through their webs. This paper presents the flexural behaviour of cover plated simply supported CFS built-up beams made up of lipped channels. Lipped channels were placed at an adequate distance in the back-to-back arrangement and were connected at the flanges with self-drilling screws by means of cover plates, on both the tension as well as the compression faces. To study the influence of moment gradient and constant moment loading of theses built-up beam specimens, both three-point loading and four-point loading were considered. The sectional compactness of the channel section as well as the aspect ratio of the built-up section was varied to evaluate the behavioural effect in the specimen. Lastly, the European code as well as the North American Standards were used for developing the theoretical strengths and were compared with the test results. Fig. 2. Plates welded at the ends to avoid warping failure. 2.1. Preparation of the test specimens Six specimens were prepared to complete the experimental compo­ nent of this investigation. Each specimen comprised of two lipped channel sections that were placed at an adequate distance in the back-toback arrangement. The channels as well as the cover plates were cut from the steel sheets using a shearing machine. The cold forming of lipped channels was carried out using a press brake that was based on hydraulic operations. The corner radius at the flange-web junction and at the flange-lip junction was 2 mm. Once the various components of the built-up section were cut and cold-formed, the channels were connected at the flanges with self-drilling screws of 6.4 mm diameter, by means of cover plates (of thickness 1.6 mm), on both the tension as well as the compression faces. The screws were connected at mid-point of the flanges along the length of the beams at a spacing of 85 mm. Near the supports the longitudinal spacing was reduced to avoid bearing failure. At the end of the specimens, a plate of size equal to the width and depth of the section was welded at the flange ends and the mid-point of the cover plates, as shown in Fig. 2. The nominal thickness of this plate was 1.6 mm. The reason behind the incorporation of these plates was to prevent warping of the cross-section. Additional plates were welded to the top cover plate to reduce the stress concentration and ensure more uniform distribution of forces, as shown in Fig. 3. Since one of the ob­ jectives of this investigation was to study the influence of moment gradient and constant moment loading of theses built-up beam speci­ mens, both three-point loading as well as four-point loading were considered accordingly. This resulted in the specimens being catego­ rized into two groups, first the three-point loading group, and second the 2. Experimental investigation This section presents the various details of the experimental inves­ tigation, and is given in the sub-sections below. 295 M. Anbarasu et al. Structures 30 (2021) 294–304 Fig. 3. Location of the loading plates to avoid punching failure. Fig. 4. Tensile coupons prepared for the material testing. four-point loading group. In the three-point loading group, the crosssectional aspect ratio (B/D) was varied at 1.25, 1.5 and 1.75, with constant width of the built-up section, while as the span was fixed at 1.2 m. In the four-point loading group, the sectional compactness of the built-up section (that was governed by the slender web element of the channel section) was varied as 50, 60 and 70, with a constant crosssectional aspect ratio of 1.5, while the span was fixed at 2.4 m. Three values of sectional compactness were considered based on the limiting value of sectional compactness being 60, proposed by the current stan­ dards [2,10]. The other two values were considered in such a way that one value higher than the limited value, and the other lower than the one. In both these cases, the moment span was fixed at 1.2 m. The specimens were labelled such that each detail indicates the specimen parameter affecting its behaviour, e.g., in the specimen 3PL-140-112-15, 3PL represents three-point loading, 140 indicates the depth of the built- up section in mm, 112 indicates the width of the built-up section in mm and 15 represents the depth of the lip in mm. 2.2. Coupon testing for material property assessment IS 1608 – 2005 [14] was referred for obtaining the details regarding the preparation of the tensile coupons, and three coupon specimens were prepared as per the recommendation of the material testing stan­ dard, as shown in Fig. 4. Since the corner radius was small and press braking operation was adopted for cold-rolling, the coupon specimens were extracted longitudinally from the steel sheet. A similar procedure has been adopted previously [4,8]. The material testing was carried out in the Structural Engineering Laboratory of Government College of En­ gineering Salem. The flange region of the coupon was clamped between the upper and lower clamp of the Computerized Universal Testing 296 M. Anbarasu et al. Structures 30 (2021) 294–304 of CFS members. Accordingly, the geometric imperfections were measured and noted, prior to the testing of specimens. The imperfections were noted along the midpoint of the bottom cover plate and the web to get these values in two orthogonal directions (both longitudinal as well as transverse), as shown in Fig. 6. Table 1 presents the magnitudes of imperfections noted. An optical theodolite along with a calibrated dig­ ital vernier caliper were used for the measuring the imperfections. The maximum amplitude of the measured geometric imperfection at the mid-span in the two said orthogonal directions viz., δ1 & δ2 were noted as 1/2894 mm and 1/2913 mm, respectively. These imperfections belonged to specimen 3PL-168-112-15. The minimum amplitude of the measured imperfections at the same location and in the same directions, belonged to the specimens 4PL-168-112-15 and 3PL-196-112-15, and were noted as 1/3495 and 1/3724 respectively. Fig. 5. Typical stress vs. strain plot obtained from the material testing. 2.4. Test setup and loading A heavy-duty loading frame of 50 Tonnes capacity (as shown in Fig. 7) was used for the testing of the specimens. Both four-point loading tests as well as three-point loading tests were performed under the same loading set-up. For transferring the single point load from the hydraulic jack to the two loading points in the four-point loading, a rigid spreader beam was used. Simply supported end conditions were considered for the testing both these loading type specimens. To measure the vertical displacement under the loading points as well as at the mid-point of the beam specimens, LVDTs were used. The loading was applied by means of a hydraulic jack and the loading was applied slowly, until the failure. Width of loading plate and the bearing plate was 100 mm. 2.5. Test results and discussion Fig. 8a shows the load vs. displacement plots of the three-point loading group specimens. The specimen 3P-140-112-15 carried a peak load of 18.75kN, and the corresponding displacement was noted as 2.81 mm. Predominant local buckling of the flange under and around the loading point was observed, as shown in Fig. 9. However, minor local buckling of the web portion near to the flange-web junction was also noted. In specimen 3P-168-112-15, an ultimate load of 22.01kN against the corresponding displacement of 2.17 mm was noted. Local bucking failure like the previous case was observed, as shown in Fig. 10. Since the web depth in this case was higher than the previous case, the involvement of the web buckling was relatively higher. The specimen 3P-196-112-15 resisted a maximum load of 26.30kN, with the corre­ sponding displacement being 1.57 mm. Local buckling of both flange and web was observed, as shown in Fig. 11. Clearly the web depth influenced the involvement of the web buckling in the observed failure modes. Also, the post peak branch of the plots got steeper, as the web depth increased. The load vs. displacement curves of the four-point loading group specimens are presented in Fig. 8b. The ultimate load resisted by the specimen 4P-120-80-15 was 11.48kN, with the corresponding displacement of 12.32 mm. The displacements noted in four-point loading cases were higher than the three-point loading cases, mainly due to larger span in the former cases. The displacements in the fourpoint loading cases were nearly double of that of in the three-point loading cases. Local buckling in the compression region of the built-up section within the moment zone, prominent in the cover plate, in be­ tween the fasteners was noted, as shown in Fig. 12. In the specimen 4P144-96-15, a peak load with the corresponding displacement of 16.63kN and 10.29 mm was noted. Like the previous case, local bucking halfwave lengths between the fasteners within moment zone was again observed, as shown in Fig. 13. Since the depth of the built-up section was higher, higher bending stresses were experienced, resulting in higher degree of local buckling failure being observed. The maximum load carried by the specimen 4P-168-112-15 was noted as 21kN, with the corresponding displacement of 9.52 mm. The local buckling of the cover Fig. 6. Details of the geometric imperfection measurement. Table 1 Geometric imperfections measured. Specimen 3PL-140–112-15 3PL-168–112-15 3PL-196–112-15 δ1/L δ2/L Specimen δ1/L δ2/L 1/3213 1/3367 4PL-120–80-15 1/3004 1/3325 1/2894 1/2913 4PL-144–96-15 1/3457 1/3337 1/3212 1/3724 4PL-168–112-15 1/3495 1/3215 Machine. The coupons were loaded until their fracture. The load vs. axial elongation data obtained from the test was used to determine the stress and strain data for the data plotting, as shown in Fig. 5. The average values of the Young’s Modulus, yield stress, peak stress and elongation obtained were 215GPa, 250 MPa, 364.33 MPa and 23.75% respectively. 2.3. Geometric imperfections CFS sections due to their low wall thickness are susceptible to geo­ metric imperfections. Therefore, the measurement of these imperfec­ tions is important as they influence the local as well as global behaviour 297 M. Anbarasu et al. Structures 30 (2021) 294–304 Fig. 7. Test set-up details (Four-point loading case). Fig. 8. Load vs. displacement plots. Fig. 9. Local buckling failure in 3P-140-112-15. 298 M. Anbarasu et al. Structures 30 (2021) 294–304 Fig. 10. Local buckling failure in 3P-168-112-15. Fig. 11. Local buckling failure in 3P-196-112-15. Fig. 12. Local buckling failure in 4P-120-80-15. Fig. 13. Local buckling failure in 4P-144-96-15. plate, as observed in the previous two cases was observed in this case as well. It was further noted that the magnitude of the local buckling in between the fasteners within the moment zone was large and dropped post the moment zone (within the shear zone), as shown in Fig. 14. The magnitude of the local buckling wave between the fasteners was higher due to constant moment within the moment zone. In the four-point loading group specimens, a small deviation in the stiffness of the load vs. displacement plots was observed, at around a displacement of approximately 7 mm. This may be due to the formation of multiple local buckling waves between the fasteners on the compression side cover plate. Fig. 15 shows the three-point loaded specimens after failure. role in governing its stability. It primarily controls the out-of-plane displacement in flexural members. In the three-point loading cases, on varying the aspect ratio from 1.25 to 1.5, the flexural strength changed from 11.25kNm to 13.21 kNm, which resulted in a flexural strength improvement of 17.42% as shown in Fig. 16a. On varying the aspect ratio further from 1.5 to 1.75, the flexural strength changed to 15.78kNm, with a flexural strength improvement of 19.45%. The improvement in the flexural strengths due to the variation in the aspect ratio attributes to the increase in the width of the flexural members, that improved their second moment of area, and thus improved their flexural strengths. The percentage improvement in the flexural strength was slightly higher in the latter case (when the aspect ratio was 1.75), as the second moment of area was higher in that case. Also, the sectional compactness in both these cases were constant. 2.5.1. Effect of aspect ratio on the flexural strength The cross-sectional aspect ratio of the flexural member plays a vital 299 M. Anbarasu et al. Structures 30 (2021) 294–304 Fig. 14. Local buckling failure in 4P-168-112-15. Fig. 15. Failed specimens of three-point loading cases. Fig. 16. Effect on the flexural strength of the specimens. 2.5.2. Effect of sectional compactness on the flexural strength The sectional compactness is a key parameter that significantly in­ fluences the behaviour in thin-walled members. It controls their local buckling response, which mainly dominates the performance of such members. In the four-point loading cases, on varying the sectional compactness of the channel section from 50 to 60, the flexural strength changed from 6.89kNm to 9.98kNm, that resulted in a flexural strength enhancement of 44.84%, as shown in Fig. 16b. This enhancement in flexural strength despite a small reduction in the sectional compactness was primarily due to the increase in the depth of the beam cross-section, that substantially improves its second moment of area, which drastically enhances the flexural performance of these members. Also, the local buckling occurs under compressive stresses, which occurs above the neutral axis. This makes only half of the cross-section effective for the local buckling effect. On varying the sectional compactness further from 60 to 70, the flexural strength changed to 12.6kNm, with a flexural strength improvement of 26.25%. The reason behind this improvement is the same as was in the previous case. However, the percentage improvement in the flexural strength in the former case (when sectional compactness was changed from 50 to 60) was about 1.75 times that of in the latter case, and was mainly as the sectional compactness limit (60) proposed by the current codes was exceeded. 2.5.3. Effect of aspect ratio on the stiffness characteristics Stiffness characteristics are important features in structural mem­ bers, particularly in flexural members, essentially from serviceability 300 M. Anbarasu et al. Structures 30 (2021) 294–304 Fig. 17. Effect on the stiffness characteristics of the specimens. improvement in the stiffness in the latter case (when sectional compactness was changed from 60 to 670) was about 1.3 times that of in the former case. Furthermore, the stiffness of three-point loading cases was substantially higher than the four-point loading cases, primarily due to smaller beam spans in the former cases. 2.5.5. Strength-to-weight ratio performance The strength-to-weight ratio performance of CFS members is gener­ ally higher than the hot-rolled steel members, and for these reasons the former is preferred over the latter, in moderately loaded structures. One of the primary objectives in the CFS research is to improve the efficiency of CFS sections by adopting different means to achieve the same. Fig. 18 shows the strength-to-weight comparison of different specimens. The strength-to-weight ratio performance of the three-point loading cases was better than the four-point loading cases, and was therefore, mainly due to higher stiffness that was achieved due to lower beam spans, that enabled them to carry higher loads. In the three-point loading cases, on varying the aspect ratio from 1.25 to 1.5, the strength-to-weight ratio changed from 1.04kNm/kg to 1.13 kNm/kg, which resulted in an improvement of 8.65% as shown in Fig. 18. On varying the aspect ratio further from 1.5 to 1.75, the strength-to-weight ratio changed to 1.26kNm/kg, with an improvement of 11.5%. The reason behind this percentage enhancement and the order of enhancement is the same as that of behind the flexural strength enhancement. In the four-point loading cases, on varying the sectional compactness of the channel section from 50 to 60, the strength-to-weight ratio changed from 0.37kNm/kg to 0.48kNm/kg, that resulted in a perfor­ mance enhancement of 29.73%. On varying the sectional compactness further from 60 to 70, the strength-to-weight ratio changed to 0.54kNm/ kg, with an improvement of 12.5%. The reason behind this percentage enhancement and the order of enhancement is the same as that of behind the flexural strength enhancement. Fig. 18. Effect on the strength-to-weight ratio of the specimens. consideration. The stiffnesses of the specimens were obtained as the ratio of the load resisted by them until their linear part of the load vs. displacement plots, to their corresponding displacements. In the threepoint loading cases, on varying the aspect ratio from 1.25 to 1.5, the stiffness changed from 8.72kN/mm to 11.44 kN/mm, which resulted in an improvement of 31.19% as shown in Fig. 17a. On varying the aspect ratio further from 1.5 to 1.75, the stiffness changed to 19.14kN/mm, with an improvement of 67.30%. The improvement in the stiffness due to the variation in the aspect ratio attributes to the increase in the width of the flexural members, that improved their stability, and thus improved their stiffness characteristics. The percentage improvement in the stiffness was more than double in the latter case (when the aspect ratio was 1.75), as the second moment of area was higher in that case. 2.5.4. Effect of sectional compactness on the stiffness characteristics In the four-point loading cases, on varying the sectional compactness of the channel section from 50 to 60, the stiffness changed from 1.43kN/ mm to 1.95kN/mm, that resulted in a strength enhancement of 36.36%, as shown in Fig. 17b. This enhancement in flexural strength despite a small reduction in the sectional compactness was primarily due to the increase in the depth of the beam cross-section, that substantially im­ proves its second moment of area, which drastically enhances the stiff­ ness characteristics of these members. On varying the sectional compactness further from 60 to 70, the stiffness changed to 2.88kN/mm, with an improvement of 47.69%. The reason behind this improvement is the same as was in the previous case. However, the percentage 3. Design strengths The comparison of the test strengths with the ones computed using the current standards on CFS members was one of the key objectives of this study. Accordingly, the design strengths of these built-up beams were quantified for the same. Both American Standards as well as Eu­ ropean Standards were adopted. In the European Standard, the versatile Effective Width Method was adopted, as that has been accepted worldwide with good reliability. However, in the North American Standard, the recently developed Direct Strength Method was imple­ mented, as the sections were open sections and were prismatic as well. 301 M. Anbarasu et al. Structures 30 (2021) 294–304 The primary design equations used in these standards are given below. 3.3. For distortional buckling 3.1. Design equations specified in AISI-S100-16 [2] (Direct strength Method) The elastic distortional buckling moment resistance (Mcrd) shall be determined as follows: Mcrd = Sf *Fcrd The procedure for the design strength determination of flexural members is presented below: For lateral torsional buckling of doubly symmetric sections (open cross-section); Fcre Cb *π2 *E*d*Iyc = )2 ( Sf * Ky *Ly Where Fcrd = β (1) For λd > 0.673 [ )0.5 ]( )0.5 ( Mcrd Mcrd Mnd = 1 − 0.15 My My My (3) My = Sfy *Fy 3.4. Design equations specified in EN1993-1-3 (effective width method) (4) The critical elastic moment of the beam cross-section shall be determined using the following equations, Mcr = Cb √̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅ ( )̅ √ 2 EI √ π 2 EI y π W √( (13) )2 GJ + (LKW )2 LKy Where, Sf is the elastic cross-sectional modulus of the gross-section, with reference to the extreme compression fibre, Fcrl is the local buck­ ling stress at compression fibre (extreme), and is given by (5) Where EIy, EIw and GJ are the flexural rigidity, warping rigidity and torsional rigidity respectively, about the major axis. The factors ky and kw are conservatively taken as unity. Also the constant Cb is considered as unity. √̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅ 3 Kσ = 0.5 + 0.83 (bp,c /bpl )2 √̅̅̅̅̅ f b /t λp = σyb = p √̅̅̅̅ Where, K is the plate buckling coefficient which is given in the Ap­ pendix 1 of the AISI [2], E = Young’s modulus of steel, t is the wall thickness of the element, µ is the Poisson’s ratio of steel, w is the flat width of the element. The nominal flexural resistance (Mnl) that considers the local buckling and global buckling interaction shall be determined by using the following equations: For λl ≤ 0.776 Mnl = Mne For λl > 0.776 [ ( )0.4 ]( )0.4 Mcrl Mcrl Mnl = 1 − 0.15 Mne Mne Mne (12) Sfy is the section modulus (elastic) of gross cross-section, relative to the extreme fibre in the first yielding. The beam’s local buckling moment resistance (Mcrl) shall be gov­ erned by the lowest buckling stress among the cross-sectional elements, with reference to the extreme compression fibre, as follows: π2 *E ( t )2 12(1 − μ2 ) w (11) Where √̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅ λd = My /Mcrd 3.2. For local buckling Fcrl = K (9) (10) Mnd = My Where, Mcre is the critical lateral-torsional buckling moment resistance, My is the yield moment resistance, Mp is the plastic moment resistance, Zf is the plastic modulus of the beam cross-section. Mcrl = Sf *Fcrl Kφfe + Kφwe + Kφ Kφfg + Kφwg β is conservatively considered as unity; Kфfe is the rotational stiffness provided to the flange-web junction by the flange, Kфwe is the rotational stiffness provided to the flange-web junction by the web, Kф is the rotational stiffness to the flange-web junction provided by any restraining element like brace, panel, sheathing, Kфfg is the geometric rotational stiffness demand of flange from the flange-web junction, Kфwg is the geometric rotational stiffness demand of the web from the flange/web junction. The nominal flexural resistance (Mnd,) shall be determined as follows: For λd ≤ 0.673 Where, Fcre is the elastic buckling stress, Cb is the constant that is conservatively considered as unity, d is the sectional depth, Iyc is the second moment of area of the full cross-section’s compression region about the centroidal axis, E = Young’s modulus of steel, Ky = effective length factor, Ly = unbraced member length for flexure about y axis. The nominal strength [resistance], Mne, considering inelastic flex­ ural reserve capacity is given by For Mcre > 2.78My , √̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅ ̅ / ) My Mcre − 0.23 ( Mne = Mp − Mp − My (2) 0.36 For 2.78My > Mcre > 0.56My , ( ) 10 10My Mne = My 1 − 9 36Mcre (8) cr 28.4ε kσ λp,b − 0.055(3+Ψ) ρ= (6) λp,b 2 Mrd Mb,Rd = χltγm1 = χlt Wy fy γm1 (7) (14) In which χlt is defined as follows: If λlt ≤0.4, χ lt = 1.0 If λlt >0.4, χ lt = 1.0/(φLT+(φ2LT + λ2LT )0.5)Where, φLT = 0.5(1+ɑ(λlt -0.2) + λ2LT ) λ2LT =(Wy fy /Mcr)0.5Where, Wy is the appropriate elastic sectional modulus depending on its class, Wel for class 3 and effective section Where √̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅ λl = Mne /Mcrl Mne is the nominal flexural resistance for lateral-torsional buckling, Mcrl is the critical local buckling moment resistance. 302 M. Anbarasu et al. Structures 30 (2021) 294–304 and the aspect ratio of the built-up section were varied to assess the behavioural effect in the specimens with respect to the variations incorporated. Both the European code as well as the North American Standards were used for developing the theoretical strengths and were compared with the test results. Some prominent results are given below: Table 2 Comparison of test results and FEA results. Specimen Test PuTest 3P-140-11218.75 15 3P-168-11222.01 15 3P-196-11226.3 15 4P-120-8011.48 15 4P-144-9616.63 15 4P-168-11221 15 Mean Standard deviation FEA MtTest/ W MtTest PuFEA MtFEA MtTest/ MtFEA 11.25 19.53 11.72 0.96 1.04 13.211 23.35 14.01 0.94 1.13 15.78 27.54 16.52 0.96 1.26 6.89 12.35 7.41 0.93 0.37 9.98 17.35 10.41 0.96 0.48 22.09 13.25 0.95 0.54 12.6 • Both the aspect ratio (by varying the transverse spacing between channels at constant depth) as well as the sectional compactness of the channel sections (by varying the sectional depth at aspect ratio) influence the flexural behaviour of cover plated CFS built-up beams. • The sectional compactness effects the flexural strength more than the aspect ratio. However, the influence of the sectional compactness is dominant provided the sectional compactness doesn’t exceed the limiting value recommended by the current codes. • The stiffness characteristics are affected by both the variation in the aspect ratio as well as the sectional compactness, and this relation­ ship is proportional. • Local buckling in the compression zone was the primary mode of failure observed in the cover plated CFS beam specimens, and was noted near the loading points. • The aspect ratio influences the stiffness characteristics more compared to the sectional compactness. This is primarily due to involvement of local buckling behaviour on the sectional compact­ ness of the built-up section that controls the structural behaviour of thin-walled members. • Both the strength as well as the stiffness in three-point loading cases were higher than that of the four-point loading cases. This behaviour was observed mainly due to the moment gradient in the former cases and constant moment in the latter cases. The stiffness was higher in the three-point loading cases, primarily due to smaller spans. • The strength-to-weight ratio in the three-point loading cases was higher than the four-point loading cases, and again attributed to 0.95 0.01 modulus Weff, for class 4 cross-sections, fy is the yield strength of steel, √̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅ kσ is the relative buckling factor, ε is the ratio 235/fyb with fyb in N/ mm2, Ψ is the stress ratio, t is the sectional thickness, σcr is the elastic critical buckling stress of the plate element. The comparison of the test strengths with the strengths predicted by the current codes are given in Table 2 and Fig. 19. Both Table 3 and Fig. 19 indicates that both current codes are unconservative in pre­ dicting the flexural strengths of the cover plated CFS beams comprising of lipped channel sections. One of the reasons behind such an uncon­ servative prediction may be that the role of the transverse spacing be­ tween the two lipped channel sections could not be considered in the design. Also, the interaction of the cover plate with the flange was not accounted for in the design strengths quantified as per the current codes. Both these reasons behind the unconservative design strength pre­ dictions need to be assessed individually and collectively. Furthermore, the extent of un-conservativeness was higher in the European code, as their design approach is different from that of the North American Standard. Table 3 Comparison of test strengths and design strengths. 4. Conclusions This study discussed the flexural behaviour of cover plated CFS builtup simply supported beams made up of lipped channels, under both three-point as well as four-point loading. The influence of moment gradient and constant moment loading on theses built-up beam speci­ mens was investigated. The sectional compactness of the channel section Specimen Test EC3 [10] NAS Test/EC3 Test/NAS 3P-140-112-15 3P-168-112-15 3P-196-112-15 4P-120-80-15 4P-144-96-15 4P-168-112-15 Mean Standard deviation 11.25 13.21 15.78 6.89 9.98 12.6 12.34 16.72 20.39 8.46 12.25 16.72 11.41 14.06 18.24 7.45 10.27 13.44 0.91 0.79 0.77 0.81 0.81 0.75 0.81 0.06 0.99 0.94 0.87 0.92 0.97 0.94 0.94 0.04 Fig. 19. Effect on the stiffness characteristics of the specimens. 303 M. Anbarasu et al. Structures 30 (2021) 294–304 larger flexural strengths and smaller spans in the former cases compared to the latter one. • Both the European code as well as the North American Specification over predicted the strengths of these beam specimens and was so as the transverse spacing is not accounted for in the design strength approach. [11] Faridmehr I, Osman MH, Tahir MM, Azimi M, Gholami M. Behaviour and design of cold-formed steel C-sections with cover plates under bending. Int J Steel Struct 2016;16(2):587–600. [12] Faridmehr I, Tahir MM, Osman MH, Nejad AF, Hodjati R. An experimental investigation of stiffened cold-formed C-channels in pure bending and primarily shear conditions. Thin-Walled Struct 2015;96:39–48. [13] Ghannam M. Bending moment capacity of cold-formed steel built-up beams. Int J Steel Struct 2019;19(2):660–71. [14] IS 1608-2005. Indian standard – metallic materials – tensile testing at ambient temperature, Bureau of Indian Standards, New Delhi, India 2005. [15] Muftah F, Sani MSHM, Kamal MMM. Flexural strength behaviour of bolted built-up cold-formed steel beam with outstand and extended stiffener. Int J Steel Struct 2019;19(3):719–32. [16] Obst M, Rodak M, Paczos P. Limit load of cold formed thin-walled nonstandard channel beams. J Theor Appl Mech 2016;54(4):1369–77. [17] Paczos P, Wasilewicz P. Experimental investigations of buckling of lipped, coldformed thin-walled beams with I –section. Thin-Walled Struct 2009;47:1354–62. [18] Serror MH, Ghareeb A, Mourad S. Numerical study on buckling of steel web plates with openings. Steel Compos Struct 2016;22(6):1417–43. [19] Serror MH, Hassan E, Mourad S. Experimental study on the rotation capacity of cold-formed steel beams. J Constr Steel Res 2016;121:216–28. [20] Serror MH, Soliman EG, Hassan AF. Numerical study on the rotation capacity of CFRP strengthened cold formed steel beams. Steel Compos Struct 2017;23(4): 385–97. [21] Szymczak CK, Kujawa M. Buckling and initial post-local buckling behaviour of cold-formed channel member flang. Thin-Walled Struct 2019;137:177–84. [22] Usefi N, Sharafi P, Ronagh H. Numerical models for lateral behaviour analysis of cold-formed steel framed walls: state of the art, evaluation and challenges. Thin Walled Struct 2019;138:252–85. [23] Valsa IT, Sharada BH, Manjulavani K, Merchant MZI. Flexural behaviour of coldformed steel-concrete composite beams. Steel Compos Struct 2013;14(2):105–20. [24] Yang Y, Lui EM. Behavior and design of steel I-beams with inclined stiffeners. Steel Compos Struct 2012;12(3):183–205. [25] Siahaan R, Keerthan P, Mahendren M. Section moment capacity design rules for rivet fastened rectangular hollow flange channel beams. Thin-Walled Struct 2018; 127:781–97. [26] Grenda M, Paczos P. Experimental and numerical study of local stability of nonstandard thin-walled channel beams. J Theor Appl Mech 2019;57(3):549–62. [27] Magnucki K, Paczos P, Kasprzak J. Elastic buckling of cold-formed thin-walled channel beams with drop flanges. J Struct Eng-ASCE 2010;136(7):886–96. [28] Yu J, Becquea J, Hajirasoulihaa I, Mojtabaei SM, Lim JBP. Development of optimum cold-formed steel sections for maximum energy dissipation in uniaxial bending. Eng Struct 2018;161:55–67. [29] Sani MSHM, Muftah F, Ismail MI. Testing and analysis of cold-formed steel channel section with notch. Int J Geomate 2018;14(43):42–9. [30] Wang L, Young B. Behavior of cold-formed steel built-up sections with intermediate stiffeners under bending. I: tests and numerical validation. J Struct Eng-ASCE 2016;142(3). https://doi.org/10.1061/(ASCE)ST.1943-541X.0001428. [31] Wang L, Young B. Behavior of cold-formed steel built-up sections with intermediate stiffeners under bending. II: parametric study and design. J Struct Eng-ASCE 2010; 142(3). https://doi.org/10.1061/(ASCE)ST.1943-541X.0001427. The authors are currently working on the parametric study on the similar configuration to develop a large pool of data for the development of reliable design equations. Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. References [1] Abu-Sena ABB, Abdelfattah FA, Soliman MS, Saleh MSR. An experimentally verified new approach for web crippling design of cold-formed steel Z-Sections. J Constr Steel Res 2020;164:105813. [2] AISI S-100, North American specification for the design of cold-formed steel structural members, AISI Standard, Washington, DC, 2016. [3] Anbarasu M. Simulation of flexural behaviour and design of cold-formed steel closed built-up beams composed of two sigma sections for local buckling. Eng Struct 2019;191:549–62. [4] Dar MA, Dar AR, Yusuf M, Raju J. Experimental study on innovative sections for cold formed steel beams. Steel Compos Struct 2015;19(6):1599–610. [5] Dar MA, Subramanian N, Dar AR, Majid M, Haseeb M, Tahoor M. Structural efficiency of various strengthening schemes for cold-formed steel beams: effect of global imperfections. Steel Compos Struct 2019;30(4):393–403. [6] Dar MA, Subramanian N, Rather AI, Dar A, Lim JBP, Anbarasu M, et al. Effect of angle stiffeners on the flexural strength and stiffness of cold-formed steel beams. Steel Compos Struct 2019;33(2):225–43. [7] Dar MA, Subramanian N, Dar AR, Anbarasu M, Lim JB, Mir A. Behaviour of partly stiffened cold-formed steel built-up beams: experimental investigation and numerical validation. Adv Struct Eng 2019;22(1):172–86. [8] Dar MA, Subramanian N, Mir A, Dar AR, Anbaasu M, Lim JBP. Efficient crosssectional profiling of built up CFS beams for improved flexural performance. Steel Compos Struct 2020;34(3):333–45. [9] Divahar R, Joanna PS. Numerical simulation and experimental investigation on static behavior of cold formed steel beam with trapezoidally corrugated web by varying depth-thickness ratio. Asian J Civil Eng 2018;19(2):121–37. [10] EC3.Eurocode3. Design of steel structures. Part1-3: General rules – Supplementary rules for cold-formed members and sheeting. BS EN1993-1-3, Brussels 2006: European Committee for Standardization. 304