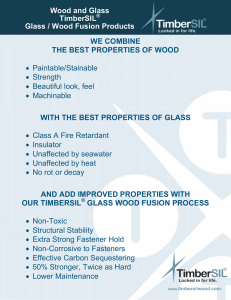

The Architecture Reference + Specification Book The Architecture Reference + Specification Book Everything Architects Need to Know Every Day Julia McMorrough Contents Introduction 6 1 Materials 2 Structures and Systems 3 Standards 106 4 Compendium 232 8 Index About the Author 56 266 272 Measure and Drawing 106 1: Wood 10 2: Masonry and Concrete 24 3: Metals 36 4: Finishes 44 5: Structural Systems 58 6: Mechanical Systems 72 7: Electrical Systems 78 8: Plumbing and Fire Protection Systems 84 9: Building Enclosure Systems 88 10: Measurement and Geometry 108 11: Architectural Drawing Types 120 12: Architectural Documents 132 13: Hand Drawing 148 14: Computer Standards and Guidelines 154 Proportion and Form 162 15: The Human Scale 164 16: Residential Spaces 172 17: Form and Organization 182 18: Architectural Elements 186 Codes and Guidelines 196 19: Building Codes 198 20: ADA and Accessibility 206 21: Parking 218 22: Stairs 222 23: Doors 226 24: Timeline 234 25: Glossary 242 26: Resources 252 i. INTRODUCTION ARCHITECTURAL DESIGN is a complex activity that involves multiple levels of knowledge, communication, and production, even on a small project. Architects often speak their own language, both in terminology and through conventions of drawings, models, and diagrams. Moreover, to make a piece of architecture requires following countless rules of which an able practitioner must remain ever knowledgeable: building codes, human dimensions, drawing standards, material properties, and relevant technologies. Familiarity with so many issues comes with schooling and long years of experience, but even the most seasoned architect must avail him- or herself of a vast and exhaustive array of resources, from code books to graphic standards, from materials libraries to manufacturers’ catalogs. 6 The Architecture Reference + Speciication Book is a unique compilation of essential information for architects, students of architecture, and anyone contemplating an architectural project. Included here are the tables, charts, diagrams, dimensions, standards, codes, and general data that many architects need on a daily basis. This book is not a replacement for other sources that architects might consult regularly, but rather a handy “irst-stop” reference that is always at the ready, on a desk or in a bag. Part 1, “Materials,” provides a detailed catalog of the most common building materials—wood, masonry, concrete, metals—as well as various interior inishes. Parts 2 and 3, “Structures and Systems,” and “Standards,” address the major aspects of undertaking an architectural project. Topics include basic measurements and geometry, architectural drawing types and conventions, architectural elements, the human scale, parking, building codes, accessibility, structural and mechanical systems, and building components. Part 4, “Compendium,” brings together a glossary and a timeline of key moments in the history of architecture. Finally, because such a compact book cannot possibly contain everything, a directory of resources offers an extensive guide to the most helpful publications, organizations, and websites. For every project, architects must take into account an endless number of external forces, not least of which are the codes and standards of design and construction. But these codes and standards should certainly not be viewed as limiting: Knowledge of them and their creative use can, in fact, liberate and empower. 7 MATERIALS 8 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 1. During the design process architects often use a foam board model as a quick way to realize and study a form or space. Frequently, the building’s materials may not yet have been chosen or inalized, and there is a seductive simplicity to the foam (or wood or cardboard) model at this point: anything is still possible. Aside from the overarching impact of the project’s budget, numerous factors inluence the selection of materials for a building’s structure, skin, and inishes. Some materials are more readily available in certain regions, or the local building trades may be more comfortable with speciic construction practices. Other materials have very long lead times, and for some projects, time constraints may rule these out. Also, different climates have different material needs, and the building’s program, size, and code requirements bear on the appropriateness of materials and methods of construction. A basic sampling of common materials found in many buildings is presented here. Space limitations do not allow for discussion of other more innovative materials, but increasingly, for reasons of practicality, cost, or environmental concerns, architects are looking to less standard sources for building materials (textiles, plastics, and aerogels) or to unconventional uses for common products (concrete roof tiles, acrylic “glass blocks,” and recycled cotton fabric insulation). 9 01 Chapter 1: Wood Lightweight, strong, and durable, wood is an ideal construction material with many uses. The two major classifications—soft wood and hard wood—do not necessarily indicate relative hardness, softness, strength, or durability. COMMON WOOD TERMS Board foot: Unit of measurement for wood quantities, equivalent to 12” x 12” x 1” (305 x 305 x 25.5). Book-matched: Result of resawing thick lumber into thinner boards, opening the two halves like a book, and gluing the boards together along the edge to create a panel with a mirrored grain pattern. Dimensional stability: Ability of a section of wood to resist changes in volume at luctuating moisture levels. Low dimensional stability produces expansion in humid environments and contraction in dry ones. Early growth/Late growth: In regions of little climatic change, trees tend to grow at a fairly consistent rate and have little variation in texture. In regions of seasonal climatic change, however, trees grow at different rates, depending on the season. Variations in growth contribute to the color and texture of the growth rings in the tree. Figure: Patterns on a wood surface produced by growth rings, rays, knots, and irregular grains. Descriptors include interlocked, curly, tiger, wavy, and iddleback, among others. iddleback swirl Burl: Irregular grain pattern that results from an unusual growth on the tree. Cathedral grain: V-shaped grain pattern running the length of the board. Check: Separation of the wood ibers running with the grain that do not go through the whole cross section. Occurs as a result of tension and stress caused by wood movement during the drying process. 10 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK bird’s-eye crotch Grain: Size, alignment, and appearance of wood ibers in a piece of lumber. 01 Gum pocket: Excessive accumulation of resin or gum in certain areas of the wood. Movement in performance: See dimensional stability. Hardness: Ability of wood to resist indentation. See Janka hardness test. Plainsawn: Lumber cut with less than a 30-degree angle between the face of the board and the wood’s growth ring. Hardwood: Wood from deciduous trees (which lose their leaves in the winter months). Oak and walnut constitute 50 percent of all hardwood production. Heartwood: Harder, nonliving innermost layers of a tree. It is generally darker, denser, more durable, and less permeable than the surrounding sapwood. Good all-heartwood lumber may be dificult to obtain, and, depending on the species, it is common to ind boards with both heartwood and sapwood combined. Plywood: Large sheet of wood made up of several layers of veneer that are glued together so that the grain of each layer lies perpendicular to the grain of the previous layer. There are always an odd number of layers, enabling the grain direction of both faces to run parallel to one another. Pressure-treated lumber: Wood products that are treated with chemical preservatives to prevent decay brought on by fungi and to resist attack from insects and microorganisms. Under pressure, the preservatives are forced deep into the cellular structure of the wood. sapwood heartwood cambium phloem outer bark Quartersawn: Lumber cut with a 60- to 90degree angle between the face of the board and the wood’s growth rings. Janka hardness test: Test that measures the pounds of force required to drive a 0.444” (11 mm) -diameter steel ball to half its depth into a piece of wood. Moisture content: Percentage that represents a board’s ratio of water weight to the weight of oven-dried wood. Wood 11 01 01 Riftsawn: Lumber cut with a 30- to 60degree angle between the face of the board and the wood’s growth rings. SOFTWOOD LUMBER Lumber Standards* Rough Lumber Sawed, trimmed, and edged lumber whose faces are rough and show marks. Surfaced (Dressed) Lumber Rough lumber that has been smoothed by a surfacing machine. Sapwood: Living outer layers of a tree, between the outer bark and the thin formative layers of the cambium and phloem, on the one side, and the heartwood, on the other. These layers contain the sap-conducting tubes. Generally lighter in color, less durable, less dense, and more permeable than heartwood, sapwood darkens with age and becomes heartwood. Sapwood and heartwood together make up the xylem of the tree. Softwood: Wood from coniferous (evergreen) trees. Split: Separation of wood ibers from one face through to the next. Occurs most often at the ends of boards. Stain: Substance used to change the color of wood. Straight grain: Wood ibers that run parallel to the axis of a piece of lumber. Stud: 2” x 4” and 2” x 6” dimension lumber used for load-bearing and stud walls. Texture: Describes the size and distribution of wood ibers: coarse, ine, or even. Warp: Bowing, cupping, and twisting distortion in lumber that occurs after it has been planed, usually during the drying process. 12 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK S1S: Surfaced one side S1E: Surfaced one edge S2S: Surfaced two sides S2E: Surfaced two edges S1S1E: Surfaced one side and one edge S1S2E: Surfaced one side and two edges S2S1E: Surfaced two sides and one edge S4S: Surfaced four sides Worked Lumber Surfaced lumber that has been matched, patterned, shiplapped, or any combination of these. Shop and Factory Lumber Millwork lumber for use in door jambs, moldings, and window frames. Yard (Structural) Lumber Lumber used for house framing, concrete forms, and sheathing. Boards: No more than 1” (25) thick and 4”–12” (102–305) wide Planks: Over 1” (25) thick and 6” (152) wide Timbers: Width and thickness both greater than 5” (127) *From U.S. Department of Commerce American Lumber Standards of Softwood Lumbers 01 Softwood Lumber Sizes Nominal Size1 inches Actual Size, Dry2 inches (mm) Actual Size, Green3 inches (mm) 1 3/4 (19) 25/32 (20) 11/4 1 (25) 11/32 (26) 11/2 11/4 (32) 19/32 (33) 2 11/2 (38) 19/16 (40) 21/2 2 (51) 21/16 (52) 3 2 1/2 (64) 2 9/16 (65) 31/2 3 (76) 3 1/16 (78) 4 31/2 (89) 3 9/16 (90) 41/2 4 (102) 41/16 (103) 5 41/2 (114) 4 5/8 (117) 6 51/2 (140) 5 9/16 (143) 7 61/2 (165) 6 5/8 (168) 8 71/4 (184) 71/2 (190) 9 81/4 (210) 81/2 (216) 10 91/4 (235) 91/2 (241) 11 101/4 (260) 101/2 (267) 12 111/4 (286) 111/2 (292) 14 131/4 (337) 131/2 (343) 16 151/4 (387) 151/2 (394) 1 Nominal dimensions are approximate dimensions assigned to pieces of lumber and other materials as a convenience in referring to the piece. 2 Dry lumber is deined as having a moisture content of less than 19 percent. 3 Green (unseasoned) lumber is deined as having a moisture content of greater than 19 percent. Softwood grading is based on the appearance, strength, and stiffness of the lumber. Numerous associations nationwide establish their own grading standards, though they must all conform to the U.S. Department of Commerce American Lumber Standards. Grading is often dificult to understand, and because it deals with both strength analysis and visual analysis, there is an allowable 5 percent variation below a given grade. Wood 13 01 Dimensional Variations of a 2X6 Stud 2” 1 1/2” 6” 5 1/2” 2X6 Old Growth Typically, older growth wood is denser, stronger, and more dimensionally stable. Before aggressive logging, older growth trees grew more slowly, as they competed for sunlight in more densely forested conditions, resulting in more rings per inch. 14 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 2X6 Farmed Wood By contrast, farmed wood grows bigger faster, due to more aggressive watering, fertilizing, and exposure to sunlight. More rapid growing results in less dense wood. 01 1 5/8” 1 3/4” 5 1/2” 6” Laminated Veneer Lumber (LVL) - Farmed & Glued Commonly referred to by its proprietary name of Microllam (Weyerhauser), LVL lumber is made of thin sheets of wood sandwiched and glued together, much like plywood, though resulting in heavy and dense wood members that resist warping and shrinkage, and are designed to carry signiicant loads. Metal Stud Though more expensive than wood framing members, steel studs offer more strength and dimensional stability. Wood 15 01 HARDWOOD Board Feet Most lumber is measured and sold in board feet (one board foot equals 144 cubic inches), calculated as follows: thickness x face width x length 144 Hardwood Lumber Grades First and Second (FAS): Best grade, normally required for a natural or stained inish. Boards must be at least 6” wide, 8’–16’ long, and 83.3 percent clear on the worst face. Select, No. 1 Common: Boards must be a minimum 3” wide, 4’–16’ long, and 66.66 percent clear on the worst face. 1x2 1 board foot = 1” x 2” x 72” Select, No. 2 Common Select, No. 3 Common 2x4 1 board foot = 2” x 4” x 18” Hardwood Lumber Thicknesses 4x8 1 board foot = 4” x 8” x 4 1/2” Quarter* 6 x 12 1 board foot = 6” x 12” x 2” 8 x 16 1 board foot = 8” x 16” x 11/8” Surfaced 1 Side (S1S) Surfaced 2 Sides (S2S) 3/8” (10) 1/4” (6) 3/16” (5) 1/2” (13) 3/8” (10) 5/16” (8) 5/8” (16) 1/2” (13) 7/16” (11) Rough Dimension 3/4” (19) 5/8” (16) 9/16” (14) 4/4 1” (25) 7/8” (22) 13/16” (21) 5/4 1 1/4” (32) 1 1/8” (29) 1 1/16” (27) 6/4 1 1/2” (38) 1 3/8” (35) 1 5/16” (33) 8/4 2” (51) 1 13/16” (46) 1 3/4” (44) 3” (76) 2 13/16” (71) 2 3/4” (70) 4” (102) 3 13/16” (97) 3 3/4” (95) 12/4 16/4 *Hardwood thickness is often referred to in “quarters:” 4/4 equals 1” (25), 6/4 is 1 1/2” (38), and so on. 16 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 01 01 PLYWOOD Exposure Durability Exterior: Fully waterproof glue and minimum C-grade veneers - suitable for applications permanently exposed to the weather. Exposure 1: Fully waterproof glue and minimum D-grade veneers - suitable for applications with some exposure to weather. Exposure 2: Glue of intermediate moisture resistance suitable for applications of intermittent high humidity. Plywood quality is rated by the American Plywood Association (APA) and is generally graded by the quality of the veneer on both front and back sides of the panel (A-B, C-D, and so on). Veneer grades describe appearance according to natural unrepaired growth characteristics and the size and number of repairs allowed during manufacture. Interior: Protected indoor applications only. Typical Plywood Construction Veneer Grades N Premium grade available by special order. Select, all heartwood or all sapwood with a smooth surface and free of open defects. No more than six repairs, wood only, matched for grain and color, and parallel to the grain, allowed per 4’ x 8’ panel. Best for natural inish. A Smooth and paintable. Permits no more than eighteen neatly made repairs of boat, sled, or router type, and parallel to the grain. Used for natural inish in less demanding applications. B Solid surface that allows shims, circular repair plugs, and tight knots limited to 1” across grain, with minor splits permitted. C Plugged Improved C veneer with splits up to 1/8” width and knotholes and borer holes up to 1/4” x 1/2”. Some broken grain is permitted, and synthetic repairs are allowed. C Tight knots and knotholes up to 11/2” permitted if total width of knots and knotholes is within speciied limits. Synthetic or wood repairs allowed. Discoloration and sanding defects that do not impair strength, limited splits, and stitching all permitted. Lowest exterior use grade. D 3-layer (3 ply) 3-layer (4 ply) 5-layer (5 ply) Knots and knotholes up to to 21/2” across grain and 1/2” larger within speciied limits permitted. Limited splits and stitching also permitted. Use restricted to Interior, Exposure 1, and Exposure 2 panels. 5-layer (6 ply) Wo o d 17 01 WOOD TYPES AND CHARACTERISTICS ASH white Fraxinus Americana Hardness H Principal Finish Uses trim, cabinetry Creamy white to Color light brown Paint n/a Transp. excellent BIRCH Betula alleghaniensis Hardness H trim, paneling, Principal Finish Uses cabinetry Color Paint White to dark red excellent Transp. good BUTTERNUT Juglans cinerea Hardness M trim, paneling, Principal Finish Uses cabinetry Color Paint pale brown n/a Transp. excellent CEDAR western red Thuja plicata Hardness S trim, exterior & Principal Finish Uses interior paneling Reddish brown Color nearly white Paint 18 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK n/a Transp. good 01 S=soft; M=medium; H=hard; VH=very hard; n/a=not normally used Finishes: Painted and Transparent CHESTNUT Castanea dentate Hardness M trim, paneling Principal Finish Uses Grayish brown Color Paint n/a Transp. excellent MAHOGANY Hond. Sweitenia macrophylla Hardness M trim, frames, panelPrincipal Finish Uses ing, cabinetry Color Paint Rich golden brown n/a Transp. excellent MAPLE Acer saccharum Hardness VH trim, paneling, Principal Finish Uses cabinetry White to reddish Color brown Paint excellent Transp. good OAK English brown Quercus robur Hardness H veneered paneling, Principal Finish Uses cabinetry Color Paint Leathery brown n/a Transp. excellent Wood 19 01 WOOD TYPES AND CHARACTERISTICS OAK red Quercus rubra Hardness H trim, paneling, Principal Finish Uses cabinetry Color Paint Reddish tan to brown n/a Transp. excellent OAK white Quercus alba Hardness H trim, paneling, Principal Finish Uses cabinetry Color Paint Grayish tan n/a Transp. excellent PECAN Carya species Hardness H trim, paneling, Principal Finish Uses cabinetry Reddish brown w/ Color brown stripes Paint n/a Transp. good PINE east. or north. white Pinus strobes Hardness S trim, frames, Principal Finish Uses paneling, cabinetry Creamy white to Color pink Paint 20 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK good Transp. good 01 S=soft; M=medium; H=hard; VH=very hard; n/a=not normally used Finishes: Painted and Transparent ROSEWOOD Dalbergia nigra Hardness VH veneered paneling, Principal Finish Uses cabinetry Mixed red/brown/ Color black Paint n/a Transp. excellent TEAK Tectona grandis Hardness H trim, paneling, Principal Finish Uses cabinetry Tawny yellow to dark Color brown Paint n/a Transp. excellent WALNUT Juglans Hardness H trim, paneling, Principal Finish Uses cabinetry Color Paint Chocolate brown n/a Transp. excellent ZEBRAWOOD Brachystegea leuryana Hardness H trim, paneling, Principal Finish Uses cabinetry Gold streaks on Color dark brown Paint n/a Transp. excellent Wood 21 01 WOOD JOINERY ve roo G nd Edge Joints tt le p Sim Bu ea gu nt Joi Ton n tte ack Ba B n tte Ba et Fill End Joints p ipla Sh arf p La Sc lice d are Sp ap lf L u Ha lice Fin Sq r ge Sp Right-Angle Joints (Miters) Plain 22 Wood Spline THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Quirk Tongue and Groove Shoulder 01 Right-Angle Joints Right-Angle Joints (Mortise and Tenon) Butt Joint Half Blind Right-Angle Joints (Dovetail) Ship Rabbet Blind Right-Angle Joints (Lap) Dovetail Dado Dado Dado and Rabbet Middle Lap End Lap Miter Half Lap Wood 23 02 Chapter 2: Masonry and Concrete Masonry Masonry building has become quicker, stronger, and more efficient than in the past, but the basic principles of construction have changed very little since ancient times. Masonry units include bricks, stones, and concrete blocks, and because they all come from the earth, they are suitable for use as foundations, pavers, and walls embedded in the earth. The strength and durability of most masonry makes it ideal to resist fire and decay from water and air. BRICKS The small scale of a single brick makes it a lexible material for use in walls, loors, and even ceilings. Brick production, in which the clay is ired at very high temperatures, gives brick excellent ire-resistive qualities. Brick Grades (Building and Facing) SW: Severe weathering (where water may collect) MW: Moderate weathering NW: Negligible weathering Brick Types (Facing) course (horizontal layer of brick or other masonry unit plus mortar) FBS: General use in exposed exterior and interior walls; most common type and default choice if architect does not specify head joint bed joint face brick (brick on exposed surface of a wall, selected for its appearance and durability) wythe (vertical layer of brick or other masonry unit) 24 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK FBX: Special use in exposed exterior and interior walls, where a higher degree of mechanical perfection, narrower color range, and minimal variation in size are required FBA: Special use in exposed exterior and interior walls, where nonuniformity in size, color, and texture are desired 02 Brick Manufacturing Winning (Mining) and storage: Clays are mined and enough raw material is stored for several days’ use to allow continuous operation in any weather. The three principal types of clay are surface clays, shales, and ire clays. Preparation: Clay is crushed and pulverized. Forming Processes Stiff mud process (extrusion process): Clay is mixed with minimal amounts of water and then “pugged” (thoroughly mixed). Air pockets are removed from the clay as it is passed through a vacuum. Then it is extruded through a rectangular die and pushed across a cutting table where it is sliced into bricks by cutter wires. Extrusion Soft mud process (molding process): Moist clay is pressed into rectangular molds. Water or sand are used as media to prevent the clay from sticking to the molds. Water-struck bricks have a smooth surface, produced when the molds have been dipped into water before being illed; sand-struck, or sand-mold, bricks have a matte-textured surface, produced by dusting the molds with sand before forming the brick. Molding Dry-press process: Clay is mixed with a minimum of water and machine-pressed into steel molds. Drying Process Firing Process Molded bricks are placed in a low-temperature kiln and dried for one to two days. In periodic kilns, bricks are loaded, ired, cooled, and unloaded. In continuous tunnel kilns, bricks ride through a tunnel on railcars, where they are ired the entire time at various temperatures and emerge at the end fully burned. Firing can take from 40 to 150 hours. Water-smoking and dehydration: Remaining water is removed from the clay. Oxidation and vitrification: Temperatures reach up to 1,800º F (982ºC) and 2,400ºF (1,316ºC), for these respective processes, Flashing: Fire is regulated to produce color variations in the brick. Bricks may also be glazed, either during the initial iring or in a special additional iring. Masonr y and Concrete 25 02 BRICK UNITS Comparative Proportions Standard Engineer Economy Norman Nominal brick dimensions are derived from combining actual brick dimensions (length, thickness, and height) with their respective mortar joints. Typical mortar joints are 3/8” (10) and 1/2” (13). Roman Utility SCR T H L Standard Sizes Unit Type Joint Thickness in. (mm) Standard Modular 3/8 (10) Norman 3/8 (9.5) Nominal T in. (mm) Nominal H in. (mm) Nominal L in. (mm) 3C = 8 (203) 4 (102) 2 2/3 (68) 8 (203) 3 5/8 (92) 3 1/2 (89) 2 1/4 (57) 2 3/16 (56) 11 5/8 (295) 11 1/2 (292) 3C = 8 (203) 4 (102) 2 2/3 (68) 12 (305) 3 5/8 (92) 3 1/2 (89) 1 5/8 (41) 1 1/2 (38) 11 5/8 (295) 11 1/2 (292) 2C = 4 (102) 4 (102) 2 (51) 12 (305) 3 5/8 (92) 3 1/2 (89) 2 13/16 (71) 2 11/16 (68) 7 5/8 (194) 7 1/2 (191) 5C = 16 (406) 4 (102) 3 1/5 (81) 8 (203) 3 5/8 (92) 3 1/2 (89) 3 5/8 (92) 3 1/2 (89) 7 5/8 (194) 7 1/2 (191 1C = 4 (102) 4 (102) 4 (102) 8 (203) 3 5/8 (92) 3 1/2 (89) 3 5/8 (92) 3 1/2 (89) 11 5/8 (295) 11 1/2 (292) 1C = 4 (102) 4 (102) 4 (102) 12 (305) 1/2 (12.7) 1/2 (12.7) 5 1/2 (140) 2 1/8 (54) 11 1/2 (292) 3C = 8 (203) 6 (152) 2 2/3 (68) 12 (305) 3/8 (9.5) 3/8 (9.5) Economy 3/8 (9.5) 1/2 (12.7) 1/2 (12.7) 26 Vertical Coursing = (C) in. (mm) 7 5/8 (194) 7 1/2 (191) Engineer Modular SCR Brick Length = L in. (mm) 2 1/4 (57) 2 3/16 (56) 1/2 (12.7) Utility Brick Height = H in. (mm) 3 5/8 (92) 3 1/2 (89) 1/2 (13) 1/2 (12.7) Roman Brick Thickness = T in. (mm) 3/8 (9.5) THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 02 Orientations Bond Types Preferred SI Dimensions for Masonry Nominal Height (H) x Length (L) Vertical Coursing (C) 50 x 300 mm [2C = 100] 67 x 200 mm 67 x 300 mm [3C = 200] 75 x 200 mm 75 x 300 mm [4C = 300] 80 x 200 mm 80 x 300 mm [5C = 400] 100 x 200 mm 100 x 300 mm 100 x 400 mm [1C = 100] 133 x 200 mm 133 x 300 mm 133 x 400 mm [3C = 400] 150 x 300 mm 150 x 400 mm [2C = 300] 200 x 200 mm 200 x 300 mm 200 x 400 mm [1C = 200] 300 x 300 mm [1C = 300] Rowlock Running Bond Header Flemish Monk Bond Sailor 1/3 Running Bond Soldier Stack Bond Stretcher Acceptable Length Substitutions for Flexibility 200 mm (100 mm) 300 mm (100 mm, 150 mm, 200 mm, 250 mm) 400 mm Common Bond Shiner (100 mm, 200 mm, 300 mm) Flemish Bond Masonr y and Concrete 27 02 9’-4” (2 845) 42 83 8’-8” (2 642) 39 64 14’-0” (4 267) 63 20 62 4’-0” (1 219) 18 61 13’-4” (4 064) 60 17 59 3’-4” (1 016) 15 58 12’-8” (3 861) 57 14 56 2’-8” (813) 12 55 12’-0” (3 658) 54 11 53 2’-0” (610) 9 52 11’-4” (3 454) 51 8 50 1’-4” (406) 6 49 10’-8” (3 251) 48 5 28 14’-8” (4 470) 65 4’-8” (1 422) 21 4 67 66 23 7 15’-4” (4 674) 68 5’-4” (1 626) 24 10 70 69 26 13 16’-0” (4 877) 71 6’-0” (1 829) 27 16 73 72 29 19 16’-8” (5 080) 74 6’-8” (2 032) 30 22 76 75 32 25 17’-4” (5 283) 77 7’-4” (2 235) 33 28 79 78 35 31 18’-0” (5 486) 80 8’-0” (2 438) 36 34 82 81 38 37 18’-8” (5 690) 84 41 40 no. of courses no. of courses Standard Modular Brick Coursing 47 8” (203) 46 3 45 2 44 1 43 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 10’-0” (3 048) 9’-4” (2 845) 02 Colors Mortar Mortar adheres masonry units together, cushions them while mediating their surface irregularities, and provides a watertight seal. Composed of portland cement, hydrated lime, an inert aggregate (generally sand), and water, there are four basic types of mortar: M: High strength (masonry below grade, or subjected to severe frost or to high lateral or compressive loads) Bricks come in numerous textures and patterns, and both bricks and mortar are available in almost endless varieties of color (especially if either is custom produced). Coordination of brick and mortar colors can be an effective way to achieve different qualities within one brick type and color. Matching mortar to brick color, for example, produces a more monolithic look for the wall. Similarly, darker mortars can make a wall feel darker overall, and lighter mortars can make it feel lighter. Full-scale mockups are helpful for testing color combinations. S: Medium-high strength (masonry subjected to normal compressive loads, but requiring high lexural bond strength) N: Medium strength (masonry above grade, for general use) O: Medium-low strength (masonry in non-load-bearing interior walls and partitions) Mortar Joints concave v-shaped lush struck weathered raked Masonr y and Concrete 29 02 CONCRETE MASONRY UNITS CMUs (also called concrete blocks) are available as bricks, large hollow stretcher units, and large solid units. The cores of hollow units can receive grout and reinforcing steel, making them a common element in masonry bearing-wall construction, either alone or as a backup for other cladding material. Like bricks, CMUs have nominal dimensions and accommodate mortar joints; 8” (203) nominal block heights correspond to three brick courses. Typical Standard Sizes (W x H x L) 4” Block H 4x8x8 (102 x 203 x 203) 4 x 8 x 16 (102 x 203 x 406) 3 5/8 x 7 5/8 x 15 5/8 (92 x 194 x 397) L nominal Other Shapes 3 5/8 x 7 5/8 x 7 5/8 (92 x 194 x 194) W 6” Block 6 x 8 x 16 (152 x 203 x 406) 6x8x8 (152 x 203 x 203) 5 5/8 x 7 5/8 x 15 5/8 (143 x 194 x 397) 5 5/8 x 7 5/8 x 7 5/8 (143 x 194 x 194) Screen Brick 8” Block 8 x 8 x 16 (203 x 203 x 406) 8x8x8 (203 x 203 x 203) 7 5/8 x 7 5/8 x 15 5/8 (194 x 194 x 3 97) 7 5/8 x 7 5/8 x 75/8 (194 x 194 x 194) Solid Block 10” Block 10 x 8 x16 (254 x 203 x 406) 10 x 8 x 8 (254 x 203 x 203) 9 5/8 x 7 5/8 x 15 5/8 (244 x 194 x 397) 9 5/8 x 7 5/8 x 7 5/8 (244 x 194 x 194) Corner Block 12” Block 12 x 8 x 16 (305 x 203 x 406) 12 x 8 x 8 (305 x 203 x 203) 11 5/8 x 7 5/8 x 15 5/8 (295 x 194 x 397) 11 5/8 x 7 5/8 x 7 5/8 (295 x 194 x 194) Bond Beam All sizes may also be 4” (102) high and 8” (203), 12” (305), or 24” (610) long. 30 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 02 CMU Production Decorative CMUs To produce CMUs, a stiff concrete mixture is placed into molds and vibrated. The wet blocks are then removed from the molds and steam cured. Concrete blocks are easily produced in many different shapes, surface textures, and colors, allowing for a variety of wall surfaces. Numerous standard decorative units exist and units may be custom designed. Fire-resistance ratings for CMUs vary depending on the aggregate type used in the concrete and the size of the block. CMU Grades Split Face N: General use above and below grade S: Use above grade only; good where wall is not exposed to weather; if used on exterior, wall must have weatherprotective coating CMU Types Ribbed Face I: Moisture-controlled, for use where shrinkage of units would cause cracking II: Not moisture-controlled Scored Face CMU Weights Fluted Face Normal: Made from concrete weighing more than 125 lb. per cu. ft. (pcf) (2 000 kg/m3) Medium: Made from concrete weighing 105–25 pcf (1 680–2 000 kg/m3) Light: Made from concrete weighing 105 pcf (1 680 kg/m3) or less Masonr y and Concrete 31 02 CONCRETE Concrete comprises a mixture of aggregate (sand and gravel), portland cement, and water. Because these elements are found almost everywhere, concrete is employed as a construction material throughout the world. When combined correctly with steel reinforcing, concrete becomes virtually indestructible structurally and is generally not susceptible to burning or rotting. It can be shaped into almost any form. COMPOSITION Aggregate: Mixture of sand and gravel. Gravel sizes can range from dust to 2 1/2” but should not exceed one-quarter of the thickness of the unit being poured (that is, for a 4” slab, gravel should not be greater than 1”). Rounded fragments are preferred. Larger gravel yields more costeffective concrete and fewer problems from shrinkage. Types of Portland Cement There is no universal international standard for portland cement. The United States uses the ASTM C-150 Standard Speciication for Portland Cement, as do a number of other countries. Type I: Normal; for general use Type IA: Normal, air-entraining Portland cement: Chemical combination of lime, silicon, aluminum, iron, small amounts of other ingredients, and gypsum, which is added in the inal grinding process. Exact ingredients vary by region, based on local availability. Type II: Moderately sulfate resistant; ideal for use in bridges and pilings; also used when heat build-up is an issue There are ive basic types of portland cement. Type III: Quick hardening with high early strength; used mostly in winter and for rush jobs Type IIA: Moderately sulfate resistant, air-entraining Type IIIA: High early strength, air-entraining Water: Clean and impurity free. Air: Millions of tiny air bubbles in the mixture make up a fourth component of some mixes of concrete. Air makes the concrete lighter and more able to withstand the effects of freezing and thawing, thus useful in cold climates. 32 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Type IV: Slow hardening and low heat producing; used when the amount and rate of heat generation must be minimized Type V: Highly sulfate resistant; used in high water and soils with high alkali content 02 SITECAST CONCRETE FRAMING Sitecast concrete is concrete that is cast into forms on the building site. It can be cast into any shape for which a form can be made; however, the work and time involved in building formwork, reinforcing and pouring the concrete, waiting for the concrete to cure, and dismantling the formwork makes sitecast concrete slower to erect than precast concrete or structural steel. Concrete Casting edge form concrete welded wire mesh moisture barrier crushed stone Slab on Grade plywood formwork studs walers form tie Cast concrete uses welded wire mesh or reinforcing steel bars (rebar) to prevent cracking or uneven settling and to supply rigidity. Rebar commonly ranges in size from #3 to #18 (diameter in eighths of an inch), and its size, spacing, and number are determined by the sizes and natures of the columns, slabs, and beams. Casting loor slabs, slabs on grade, plates, walls, columns, beams, and girders all involves the use of formwork, which is often plywood but can also be metal or iberboard. Standardization of column and beam sizes within a project helps to mitigate the cost of the formwork, which can be reused. To hold formwork together during pour and curing, form ties are inserted through holes in the formwork and secured in place with fasteners; the protruding ends are snapped off after formwork comes down. bracing reinforcing bars concrete Poured concrete must have regular control joints designed into walls and slabs, either as part of the form or tooled onto the surface before the concrete has cured. A control joint is a line of discon tinuity acting as a plane of weakness where movement or cracking can occur in response to forces, relieving potential cracking elsewhere. Wall Masonr y and Concrete 33 02 PLACING AND CURING As concrete is poured and placed, care must be taken to ensure that it is not subjected to excessive vibration or sudden vertical drops, which could cause segregation of the materials (course aggregate to the bottom, water and cement to the top). For this reason, vertical transportation should be done with drop chutes. If the concrete must travel excessive distances from the mixer to the formwork, it should be pumped through hoses, not transported in the formwork. Concrete cures by hydration, as a binding chemical combination of the cement and water; it must be kept moist during this period, generally twenty-eight days, before it is adequately cured. Surfaces may be kept moist by spraying them with water or a curing compound or by covering them with moistureresistant sheets. Admixtures Other ingredients may be added to concrete for various desired effects. Fibrous admixtures: Short glass, steel, or polypropylene ibers that act as reinforcing. Fly ash: Improves workability of wet concrete while also increasing strength and sulfate resistance, and decreases permeability, temperature rises, and needed water. Pozzolans: Improve workability, reduce internal temperatures while curing, and reduce reactivity caused by sulfates. Retarding admixtures: Promote slower curing and allow more time for working with wet concrete. Silica fume: Produces extremely high strength concrete with very low permeability. Super-plasticizers: High-range waterreducing admixtures that turn stiff concrete into lowing liquid for placing in dificult sites. Water-reducing admixtures: Allow for more workability with less water in the mix. Accelerating admixtures: Promote faster curing (may be used in cold weather, when curing is slowed down). Air-entraining admixtures: Increase workability of wet concrete, aid in reducing freeze-thaw damage, and may produce lightweight, thermal-insulated concrete. Blast furnace slag: Similar to ly ash in effect. Reinforcing Steel Without reinforcing, concrete would have few or no structural uses. Fortunately, steel and concrete are chemically compatible and have a similar rate of dimensional change due to temperature. Coloring agents: Dyes and pigments. Corrosion inhibitors: Reduce corrosion of reinforcing steel. #8 Re-bar #3 Re-bar 34 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 02 FINISHES Concrete can be inished in a variety of ways, allowing it to be used on virtually any surface in almost any kind of space. As cast: Concrete remains as it is after removal of forms and often bears the imprint of wood grain from the plywood. Blasted: Various degrees of sandblasting smooth the surface while exposing successive levels of cement, sand, and aggregate. Chemically retarded: Chemicals are applied to the surface to expose the aggregate. Mechanically fractured: Tooling, hammering, jackhammering, and scaling produce varied aggregate-exposing effects. Polished: Heavy-duty polishing machines polish the surface to a high gloss, with or without polishing compounds. Sealed: Acrylic resin helps protect concrete from spalling (chipping or laking caused by improper drainage or venting and freeze/thaw damage), dusting, eflorescence (whitening caused by water leeching soluble salts out of concrete and depositing them on the surface), stains, deicing salts, and abrasion. Reinforcing bars: Bars come in the following sizes: 3, 4, 5, 6, 7, 8, 9, 10, 11, 14, 18. Nominal diameters of #8 and lower are the bar number in eighths of an inch; that is, #3 is 3/8” (9.52). Nominal diameters of #9 and higher are slightly larger. Color Colored concrete provides numerous design opportunities, It is generally achieved in one of two ways: Integral coloring: Color is added to the wet concrete or mixed in at the jobsite— in either case, the color is distributed throughout the concrete. Because so much concrete is involved, colors are limited to earth tones and pastels. Once cured, the surface is sealed, which provides protection and a sheen that enhances the color. Dry-shake color hardeners: Color hardeners are broadcast onto freshly placed concrete and troweled into the surface. The hardeners produce a dense and durable surface. Because the color is concentrated on top of the concrete, more vibrant and intense tones are possible. Sealers applied after curing further accentuate the richness of the color. As in all natural materials, variations in color outcome will occur. The base color of the cement determines the ranges possible. Welded wire fabric: Reinforcing steel is formed into a grid of wires or round bars 2”–12” (51–305) on center. Lighter styles are used in slabs on grade and some precast elements; heavier styles may be used in walls and structural slabs. Masonr y and Concrete 35 03 03 Chapter 3: Metals Metals play an enormous role in almost every component of many projects and building types, from structural steel to sheet-metal ductwork, from drywall partition studs to oxides used as paint pigments. Metals of most varieties occur in nature as oxide ores, which can be mined and worked to extract and reine the metals, separating them from other elements and impurities. Metals fall under two broad categories: ferrous (containing iron) and nonferrous. Ferrous metals are generally stronger, more abundant, and easier to reine, but they have a tendency to rust. Nonferrous metals tend to be easier to work and most form their own thin oxide layers that protect them from corrosion. MODIFYING METAL PROPERTIES Most metals in their chemically pure and natural form are not very strong. To be suitable for construction and other functions, their properties must be altered, which can be done in several ways, often dependent on the proposed use of the metal. Alloys Metals are mixed with other elements, usually other metals, to create an alloy. For example, iron mixed with small amounts of carbon produces steel. Generally, the alloy is stronger than its primary metal ingredient. In addition to improved strength and workability, alloys provide self-protecting oxide layers. 36 Cold-Worked Metals At room temperature, metals are rolled thin, beaten, or drawn, making them stronger but more brittle by altering their crystalline structures. Cold-worked metals may be reversed by annealing. Cold rolling: Metal is squeezed between rollers. Drawing: Drawing metal through increasingly smaller oriices produces the wires and cables used to prestress concrete, which have ive times the structural strength of steel. Coated Metals Heat-Treated Metals Anodizing: A thin oxide layer of controlled color and consistency is electrolytically added to aluminum to improve its surface appearance. Tempering: Steel is heated at a moderate rate and slowly cooled, producing a harder and stronger metal. Electroplating: Chromium and cadmium are coated onto steel to protect it from oxidation and improve its appearance. Annealing: Steel and sometimes aluminum alloys are heated to very high temperatures and cooled slowly, softening the metal so that it is easier to work. Galvanizing: Steel is coated with zinc to protect it against corrosion. THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Other coatings: Coatings can include paints, lacquers, powders, luoropolymers, and porcelain enamel. 03 FABRICATION TECHNIQUES Casting: Molten metal is poured into a shaped mold. The metal produced is weak but can be made into many shapes, such as faucets or hardware. Casting Drawing: Wires are produced by pulling metal through increasingly smaller holes. Extrusion: Heated (but not molten) metal is squeezed through a die, producing a long metal piece with a shaped proile. Drawing Forging: Metal is heated until lexible and then bent into a desired shape. This process improves structural performance by imparting a grain orientation onto the metal. Grinding: Machines grind and polish metal to create lat, inished surfaces. Extrusion Forging Machining: Material is cut away to achieve a desired shape. Processes include drilling, milling (with a rotating wheel), lathing (for cylindrical shapes), sawing, shearing, and punching. Sheet metal is cut with shears and folded on brakes. Rolling: Metal is squeezed between rollers. Hot rolling, unlike cold, does not increase the strength of metal. Stamping: Sheet metal is squeezed between matching dies to give it shape and texture. Grinding Joining Metals Machining Rolling Welding: In this high-temperature fusion, a gas lame or electric arc melts two metals and allows the point of connection to low together with additional molten metal from a welding rod. Welded connections are as strong as the metals they join and can be used for structural work. Brazing and soldering: In these lowertemperature processes, the two metals are not themselves melted but joined with the solder of a metal with a lower melting point: Brass or bronze are used in brazing, lead-tin alloy is used in soldering. Too weak for structural connections, brazing and soldering are used for plumbing pipes and rooing. Mechanical methods: Metals can also be drilled or punched with holes, through which screws, bolts, or rivets are inserted. Stamping Interlocking and folding: Sheet metal can be joined by such connections. Metals 37 03 METAL TYPES Ferrous Cast iron: Very brittle with high compressive strength and ability to absorb vibrations; ideal for gratings and stair components but too brittle for structural work. Malleable iron: Produced by casting, reheating, and slowly cooling to improve workability; similar to cast iron in use. Mild steel: Ordinary structural steel with a low carbon content. Stainless steel: Produced by alloying with other metals, primarily chromium or nickel for corrosion resistance and molybdenum when maximum resistance is required (in sea water, for example). Though harder to form and machine than mild steel, its uses are many, including lashing, coping, fasteners, anchors, hardware, and inishes that can range from matte to mirror polish. Steel: Iron with low amounts of carbon (carbon increases strength, but decreases ductility and welding capabilities); used for structural components, studs, joists, and fasteners, and in decorative work. Wrought iron: Soft and easily worked, with high corrosion resistance, making it ideal for use below grade. Most often cast or worked into bars, pipes, or sheets, and fashioned for ornamental purposes. Other metals like steel have virtually replaced it today. Steel Alloys Aluminum Alloy Series Aluminum: Hardens surfaces Chromium and cadmium: Resists corrosion Copper: Resists atmospheric corrosion Manganese: Increases hardness and helps to resist wear Molybdenum: Often combined with other alloys, increases corrosion resistance and raises tensile strength Nickel: Increases tensile strength and resists corrosion Silicon: Increases strength and resists oxidation Sulfur: Allows for free machining of mild steels Titanium: Prevents intergranular corrosion in stainless steel Tungsten: With vanadium and cobalt, increases hardness and resists abrasions 38 THE ARCHICTECTURE REFERENCE + SPECIFICATION BOOK Wrought Series 1000 Alloying Element Cast Series Alloying Element pure aluminum 100.0 2000 copper 200.0 copper 3000 manganese 300.0 silicon plus copper and/ or magnesium pure aluminum 4000 silicon 400.0 silicon 5000 magnesium 500.0 magnesium 6000 magnesium and silicon 600.0 unused series 7000 zinc 700.0 zinc 8000 other elements 800.0 tin 900.0 other elements 1st digit is series no.; 2nd is modiication of alloy; 3rd/4th are arbitrary identiiers 1st digit is series no.; 2nd/3rd are arbitrary identiiers; no. after decimal is casting if 0, ingot if 1 or 2 03 Nonferrous Aluminum: When pure, it resists corrosion well, but is soft and lacks strength; with alloys, it can achieve various levels of strength and stiffness, at one-third the density of steel, and can be hot- or cold-rolled, cast, drawn, extruded, forged, or stamped. Sheets or foil, when polished to a mirror inish, have extremely high levels of light and heat relectivity. Its uses include curtain wall components, ductwork, lashing, rooing, window and door frames, grills, siding, hardware, wiring, and coatings for other metals. Aluminum powder may be added to metallic paints and its oxide acts as an abrasive in sandpaper. Brass: Alloy of copper, zinc, and other metals; can be polished to a high luster and is mostly used for weather stripping, ornamental work, and inish hardware. Bronze: Alloy of copper and tin that resists corrosion; used for weather stripping, hardware, and ornamental work. Cadmium: Similar to zinc; usually electroplated onto steel. Chromium: Very hard and will not corrode in air; like nickel, often used as an alloy to achieve a bright polish and is excellent for plating. Copper: Ductile and corrosion-, impact-, and fatigue-resistant; it has high thermal and electrical conductivity, and can be cast, drawn, extruded, hot-, or cold-rolled. Widely employed as an alloy with other metals, it can also be used for electrical wiring, lashing, rooing, and piping. Lead: Extremely dense, corrosion resistant, limp, soft, and easy to work; most often combined with alloys to improve hardness and strength. Foil or sheets are ideal for waterprooing, blocking sound and vibrations, and shielding against radiation. Can also be used as rooing and lashing, or to coat copper sheets (lead-coated copper) for rooing and lashing. High toxicity of vapors and dust have made its use less common. Magnesium: Strong and lightweight; as an alloy, serves to increase strength and corrosion resistance in aluminum. Often used in aircraft, but too expensive for most construction. Tin: Soft and ductile; used in terneplate (80 percent lead, 20 percent tin) for plating steel. Titanium: Low density and high strength; used in numerous alloys and its oxide has replaced lead in many paints. Zinc: Corrosion resistant in water and air, but very brittle and low in strength. Primarily used in galvanizing steel to keep it from rusting; also electroplated onto other metals as an alloy. Other functions include lashing, rooing, hardware, and die-casting. Metals 39 03 GALVANIC ACTION GAUGES AND Galvanic action is corrosion that occurs between metals under the following conditions: There exist two electrochemically dissimilar metals, an electrically conductive path between the two metals, and a conductive path for metal ions to move from the less noble metal to the more noble one. A good understanding of the material compatibilities in the galvanic series will minimize corrosion in design. The galvanic series lists metals from least noble (anodic, or most reactive to corrosion) to most noble (cathodic, or least reactive to corrosion). Generally, the farther apart two metals are on the list, the greater the corrosion of the less noble one. Therefore, combinations of metals that will be in electrical contact should be selected from groups as close together in the series as possible. Note that the ranking of metals may differ, based on variations in alloy composition and nonuniform conditions. When specifying and detailing metals, always consult the manufacturer of the metal product. Anode + Galvanic Series Magnesium, magnesium alloys Zinc, zinc alloys and plates Zinc (hot-dipped), galvanized steel Aluminum (non-silicon cast alloys), cadmium Aluminum (wrought alloys, silicon cast) Iron (wrought, malleable), plain carbon and lowalloy steel Aluminum (wrought alloys —2000 series) Lead (solid, plated), lead alloys Tin plate, tin-lead solder The series listed here is for general information only and does not consider the anodic index of any metals. The anodic index (V) of each metal determines more precisely its compatibility thresholds with other metals. Accurate anodic index numbers should be obtained from the speciic metal manufacturer. MILS Sheet metal thicknesses have long been expressed in terms of gauge (ga.), an antiquated term based on weight (originally for reasons of taxation) and not a reference to the precise thickness of a sheet. Thus, a sheet of mild steel and one of galvanized steel may have the same gauge but different thicknesses. As the gauge number increases, the sheet becomes thinner; sheets thicker than 1/4” (6), or about 3-gauge, are referred to as plates. Most steel manufacturers are adapting to mils. This straightforward system allows the actual thickness of the sheet to deine its mil designation. Chromium plate High brasses and bronzes Brasses and bronzes Copper, low brasses and bronzes, silver solder, copper-nickel alloys Silver Gold, platinum - Cathode Nickel, titanium alloys, monel 40 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK There is no equation for a strict translation from gauge to mil thickness; however—for reference purposes only—many common mil sizes may be associated with speciic gauge sizes. 03 Gauge Reference Chart Mil (µm) 118 97 33 mil is considered the thinnest material allowable for structural cold-formed steel framing 68 54 43 30 | 33 20-gauge material often comes in the following two thicknesses: 30 mil for nonstructural drywall studs; 33 mil for structural studs 18 mil is considered the thinnest material allowable for nonstructural, cold-formed steel framing 27 18 Gauge Standard Steel (ga.) in. 3 0.2391 4 5 (mm) Galvanized Steel in. (mm) Aluminum in. (mm) (6.073) 0.2294 (5.827) 0.2242 (5.695) 0.2043 (5.189) 0.2092 (5.314) 0.1819 (4.620) 6 0.1943 (4.935) 0.1620 (4.115) 7 0.1793 (4.554) 0.1443 (3.665) 8 0.1644 (4.176) 0.1285 (3.264) 9 0.1495 (3.797) 0.1532 (3.891) 0.1144 (2.906) 10 0.1345 (3.416) 0.1382 (3.510) 0.1019 (2.588) 11 0.1196 (3.030) 0.1233 (3.132) 0.0907 (2.304) 12 0.1046 (2.657) 0.1084 (2.753) 0.0808 (2.052) 13 0.0897 (2.278) 0.0934 (2.372) 0.0720 (1.829) 14 0.0747 (1.879) 0.0785 (1.994) 0.0641 (1.628) 15 0.0673 (1.709) 0.0710 (1.803) 0.0571 (1.450) 16 0.0598 (1.519) 0.0635 (1.613) 0.0508 (1.290) 17 0.0538 (1.367) 0.0575 (1.461) 0.0453 (1.151) 18 0.0478 (1.214) 0.0516 (1.311) 0.0403 (1.024) 19 0.0418 (1.062) 0.0456 (1.158) 0.0359 (0.912) 20 0.0359 (0.912) 0.0396 (1.006) 0.0320 (0.813) 21 0.0329 (0.836) 0.0366 (0.930) 0.0285 (0.724) 22 0.0299 (0.759) 0.0336 (0.853) 0.0253 (0.643) 23 0.0269 (0.683) 0.0306 (0.777) 0.0226 (0.574) 24 0.0239 (0.607) 0.0276 (0.701) 0.0201 (0.511) 25 0.0209 (0.531) 0.0247 (0.627) 0.0179 (0.455) 26 0.0179 (0.455) 0.0217 (0.551) 0.0159 (0.404) 27 0.0164 (0.417) 0.0202 (0.513) 0.0142 (0.361) 28 0.0149 (0.378) 0.0187 (0.475) 0.0126 (0.320) 29 0.0135 (0.343) 0.0172 (0.437) 0.0113 (0.287) 30 0.0120 (0.305) 0.0157 (0.399) 0.0100 (0.254) 31 0.0105 (0.267) 0.0142 (0.361) 0.0089 (0.226) 32 0.0097 (0.246) 0.0134 (0.340) 0.0080 (0.203) 33 0.0090 (0.229) 0.0071 (0.180) 34 0.0082 (0.208) 0.0063 (0.160) 35 0.0075 (0.191) 0.0056 (0.142) 36 0.0067 (0.170) Metals 41 03 LIGHT-GAUGE FRAMING Metal studs are generally made of cold-rolled corrosion-resistant steel in standard sizes. They work in both load-bearing and non-load-bearing capacities and as loor and roof framing elements. Studs are spaced 16” (406) or 24” (610) OC inside top and bottom tracks. Metal studs with gypsum sheathing provide greatly reduced combustibility, and can be built taller than wood stud walls. Knockouts or punchouts are provided at regular intervals to allow for bridging between studs or for the passing through of electrical conduit or plumbing. depth lange knockout F = furring channels (for applying inished wall materials to concrete or masonry) T = track sections S = stud or joist U = cold-rolled (C-shapes with lange stiffeners) channel (without lange stiffeners) The Steel Stud Manufacturers Association (SSMA) designations for light-gauge steel framing members are written as follows: web depth (in 1/100”) + S, T, U, or F designation + lange width (in 1/100”) + minimum base metal thickness (in mils). Thus, a 250S 162-33 member is a 21/2” (250/100”) stud with a flange of 15/8” (162/100”), at 33 mils. Common Metal Stud Sizes Non-load-bearing Studs depths: 15/8” (41), 2 1/2” (64), 3 5/8” (92), 4” (102), 6” (152) gauges [mils]; 25 [18], 22 [27], 20 [30] Non-load-bearing Curtain Wall Studs depths: 21/2” (64), 3 5/8” (92), 4” (102), 6” (152) gauges [mils]: 20 [30], 18 [43], 16 [54], 14 [68] lange: 1 3/8” (35) Structural C-Studs depths: 21/2” (64), 3 5/8” (92), 4” (102), 6” (152), 8” (203), 10” (254), 12” (305) gauges [mils]: 20 [33], 18 [43], 16 [54], 14 [68] lange: 1 5/8” (41) Structural Stud/Joist depths: 21/2” (64), 3 5/8” (92), 4” (102), 6” (152), 8” (203), 10” (254), 12” (305) gauges [mils]: 20 [33], 18 [43], 16 [54], 14 [68] lange: 2” (51) 42 THE ARCHICTECTURE REFERENCE + SPECIFICATION BOOK 03 Sheet Thickness (actual size) 210 mils 97 mils 33 mils 18 mils Metal Roofing Seams Flat Seam Standing Seam Batten Seam Forms and Sheets Ribbed Decking Corrugated Perforated Expanded Metals 43 04 Chapter 4: Finishes Interior inishes encompass all CEILINGS materials and surfaces that can be seen or touched. The choice of materials and the methods of construction should be based on WALL SYSTEMS the function of the space, the anticipated volume of trafic, acoustical effects, ire-resistance ratings, and aesthetic appearance. FINISH CARPENTRY 44 THE ARCHICTECTURE REFERENCE + SPECIFICATION BOOK 04 FINISH CARPENTRY FINISH FLOORING Finishes 45 04 WALL SYSTEMS Gypsum Board Gypsum board goes by many names: gypsum wallboard (GWB), drywall, plasterboard, and Sheetrock (a trademarked brand name). Gypsum board is a less expensive alternative to plaster, because it requires less labor, time, and skill to install, but it still provides excellent ire-resistance and sound control. Gypsum, a naturally occurring mineral, is formulated chemically when combined with water, starch, and other elements into a slurry and placed between paper faces to become gypsum board. When gypsum board is exposed to ire, the water is released as steam, providing a ire barrier until the water is completely eliminated (calcination). When the gypsum is completely calcined, its residue still acts as an insulating barrier to lames, preventing the structural members behind it from igniting. Panel Types Customary Sizes Panel sizes may vary depending on the type of board, though generally they fall in the following range: 4’ (1 220) wide by 8’ (2 439) to 16’ (4 877) high. Widths of 2’ (610) and 2’-6” (762) and heights of 6’ (1 829) may also be available for certain preinished boards and core boards. Backing board: Used as a base layer when multiple layers are needed, improving ire resistance and sound control. Coreboard: Thicker boards, 1” (25.4) and 2” (50.8), used to enclose vent shafts, emergency egress stairs, elevator shafts, and other vertical chases. Foil-backed: Can work as a vapor barrier in exterior wall assemblies and as a thermal insulator. Prefinished: Covered in a variety of inishes such as paint, paper, or plastic ilm for installation without further inishing. Regular: Used for most applications. Type X: Short glass ibers in the core hold the calcined gypsum residue in place for increased ire resistance protection ratings. SI Preferred Sizes Standard panel size is 1 200 x 2 400 mm. Other acceptable increments are 600 mm, 800 mm, and 900 mm. 46 THE ARCHICTECTURE REFERENCE + SPECIFICATION BOOK Water-resistant (green board): Waterresistant board with a water-repellent paper facing (colored light green to distinguish it from other walls) and a moisture-resistant core (also available in type X); used as base for tiles and other nonabsorbent materials in wet locations. 04 Board Thicknesses Edge Types Square 1/4” (6.4) backing board, some acoustic work 5/16” (8) used for manufactured housing 3/8” (9.5) used in double-layer inishes 1/2” (12.7) used for stud spacings up to 24” (610), most common thickness 5/8” (16) used when additional ire resistance or structural stiffness are required Rounded Beveled Tongue and Groove Tapered Rounded Taper 1” (25.4) coreboard used for shaft walls Finishes 47 04 GWB Partition Wall Installation Gypsum wallboard is placed over wood studs using nails or screws and over metal studs using screws. The orientation of the boards may differ based on the height of the wall, whether it is double-layer construction, and other factors. Generally, it is best to minimize end joints between boards (boards have inished paper only on the face, back, and long edges, which themselves are inished in a variety of edge types), because these joints are more dificult to inish. If two or more layers of board are to be installed, joints between the layers should be staggered for added strength. ceiling channel stiffener channels shaftliner (for shaft wall construction) metal stud base GWB layer tape and joint compound face GWB layer tape and joint compound base loor channel 48 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Joints are inished with joint compound and tape, usually in the following manner: A layer of joint compound is troweled into a tapered edge joint, then iber-reinforcing mesh tape is applied; for some tapered edge joints, joint compound is forced through the tape to ill the V-shaped trough. After drying overnight, more joint compound is applied to completely smooth the joint, making it lush with the surrounding wall. Individual board manufacturers may suggest adding more layers of joint compound. Nail or screw holes are also illed, and the whole wall receives a inal light sanding before painting. 04 Common GWB Partition Assemblies Fireprooing at Steel Structural Members 3 5/8” STC: 40–44: (1 layer 3/8” GWB on either side of 15/8” metal studs; face layers of 1/2” GWB) 1-HR intumescent latex paint FIRE RATING metal lath and plaster enclosure 4 7/8” STC: 40–44: (1 layer 5/8” type X GWB on either side of 3 5/8” metal studs) 1-HR FIRE RATING spray-on ireprooing 5 1/2” STC: 45–49: (1 layer 5/8” type X GWB on either side of 35/8” metal studs; one face layer 5/8” GWB applied with laminating compound; 31/2” glass iber insulation in cavity) 1-HR FIRE RATING 6 1/4” STC: 55–59: (2 layers 5/8” type X GWB on either side of 3 5/8” metal studs; one face layer 1/4” GWB applied with laminating compound; 11/2” glass iber insulation in cavity) sheet-metal enclosure with loose insulating ill reinforced concrete encasement 2-HR FIRE RATING multiple layers of GWB enclosure Finishes 49 04 PLASTER Today most plaster has a gypsum base. Gypsum is calcined and then ground into a ine powder. When mixed once again with water, it rehydrates and returns to its original state, expanding as it hardens into a plaster that possesses excellent ire-resistive qualities. This formulation can be mixed with an aggregate and applied by hand or by machine directly to masonry walls or to a lath system. Lath Assemblies Plaster Types Plaster over Metal Lath Gauging plaster: Mixed with lime putty for accelerated setting and reduced cracking; may be mixed with inish lime to make a highquality inish coat. Three-Coat Plaster metal lath: expanded metal or mesh (steel) scratch coat: troweled on roughly and scratched to create a scored surface for the next coat brown coat: applied over the lath and hardened scratch coat; leveled with a long straightedge Gypsum plaster: Used with sand or lightweight aggregate. finish coat: very thin (1/16”) outer layer that may be smoothed or textured. High-strength basecoat: Used under high-strength inish coats. Keenes cement: High-strength with a very strong and crack-resistant inish. Total thickness of all three layers is roughly 5/8” (16) and provides good ire resistance and durability. Plaster over Gypsum Lath Molding plaster: Fast-setting for molding ornaments and cornices. Stucco: Portland cement–lime plaster; used on exterior walls or where moisture is present. With wood fiber or perlite aggregate: Lightweight with good ire resistance. 50 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Two- or Three-Coat Plaster gypsum lath: hardened gypsum plaster core with an outer sheet of absorbent paper to adhere to the plaster and water-resistant inner layers to protect the core; comes in 16” x 48” (406 x 1 219) boards in 3/8” (10) and 1/2” (13) thicknesses. brown coat finish coat If gypsum is attached to studs, it is rigid enough to require only two coats of plaster; solid plaster walls (plaster on either side of gypsum, with no studs) require three coats. Total thickness of the plaster on one side is 1/2” (13). 04 Veneer Plaster Veneer plaster is a less expensive and less labor-intensive plaster system. The special veneer base works much like a standard gypsum board wall system and is inished smooth and lat to provide the best surface for the very dense veneer plaster. The plaster is applied in two coats in quick succession; the second coat, called a skim coat, dries almost immediately. The total plaster thickness is about 1/8” (3). TRIM SHAPES Ceiling Moldings crown bed Plaster over Masonry Plaster can be applied directly to brick, concrete block, poured concrete, and stone walls. Walls should be dampened irst to keep the plaster from dehydrating during application. Generally, three coats will be needed, totaling 5/8” (16) in plaster thickness, though the roughness of the masonry surface will dictate the thickness in many cases. Where the masonry or other wall is unsuitable for direct plaster application (if moisture or condensation are present or if an air space is required for insulation), plaster and lath are applied over furring channels attached to the wall. cove quarter-round General Moldings picture rail chair rail Wall Assemblies Plaster and lath assemblies can be applied to truss studs, steel studs, or wood studs, in addition to furring strips. Solid plaster walls of roughly 2” (51) thick are sometimes used where space is at a premium. They generally consist of plaster on either side of expanded metal mesh or gypsum lath, supported at the loor and ceiling by metal runners. panel molding for wainscoting Baseboards Wood lath is rarely used today in favor of cheaper and more durable lath types. Finishes 51 04 FINISH FLOORING Floors receive regular wear and abuse, from feet, furniture, dirt, and water. Floor inish materials should be carefully chosen based on the function of the space and the amount of trafic they must endure. A wide array of inish loor types and methods of installation exist, of which the small sampling shown here represents the most common residential and commercial applications. Wood Wood offers a variety of widths and thicknesses, as well as methods of installation. Almost any wood can be made into strip looring, though oak, pecan, and maple are the most common. Thicker boards should be installed in areas of heavier use. strip looring 15# felts board subloor Carpet Wool, nylon, polypropylene, and polyester account for most carpet ibers, with nylon the most widely used. Construction types include velvet, Axminster, Wilton, tufted, knitted, locked, needlepunched, and fusion-bonded. Installation methods include stretch-in (using staples), direct glue down, and double glue down. Ceramic Tile and Quarry Tile For thick-set installation, tiles are laid on ±1” (25) portland cement mortar. For thin-set installation, tiles are laid on ±1/8” (3) dry-set mortar, latex– portland cement mortar, organic adhesive, or modiied epoxy emulsion mortar. tile carpet bond coat backing cushion subloor mortar bed with cleavage membrane concrete or wood subloor Terrazzo Resilient Flooring Vinyl sheet, homogeneous vinyl tile, vinyl composition tile (VCT), cork tile, rubber tile, and linoleum are the common types. The looring, either ±1/8” (3) thick sheets or tiles, is glued to a concrete or wood subloor. Most types can be installed to include a seamless integral cove base. looring Terrazzo is a poured or precast material composed of stone chips and a cement matrix (epoxy, polyester, polyacrylate, latex, or electrically conductive). Appearance types vary from Standard (small chip sizes) to Venetian (large chips with small chips between), Palladiana (large random marble slabs with small chips between) to Rustic (uniform texture with suppressed matrix to expose chips). ±1/2” (13) terrazzo adhesive underbed subloor concrete slab 52 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 04 CEILINGS Attached Ceilings Gypsum board, plaster, metal, and other materials can be attached directly to joists, rafters, and concrete slabs. Attached ceilings are constructed in a similar manner to wall systems. Common Panel Sizes in. (mm) Suspended Ceilings Suspended ceiling systems can support almost any material, although gypsum board, plaster, or ibrous board panels are most common. Regular grids of sheet metal cee channels suspended from the structure above with hanger wires support the gypsum board and plaster. The space between the structure above and the suspended ceiling, called the plenum, provides a zone for ductwork, piping, conduit, and other equipment. 12 x 12 12 x 24 24 x 24 24 x 48 24 x 60 20 x 60 30 x 60 60 x 60 48 x 48 (305 x 305) (305 x 610) (610 x 610) (610 x 1 219) (610 x 1 524) (508 x 1 524) (762 x 1 524) (1 524 x 1 524) (1 219 x 1 219) Fibrous panels known as acoustic ceiling tiles (ACT) are lightweight boards made of mineral or glass ibers that are highly sound absorptive. They are easily laid into an exposed, recessed, or concealed grid of lightgauge metal tees suspended with hanger wires. Good ACT has a very high noise reduction coeficient (NRC), meaning that it absorbs the majority of the sound that reaches it. The NRC for gypsum and plaster, by contrast, is very low. Lightweight panels, however, tend to pass the sound through, which limits acoustical privacy in spaces with a shared plenum. Composite panels with acoustic material laminated to a substrate can alleviate this problem. Acoustical panels may involve other materials such as perforated metal, Mylar, and tectum. Ceiling tiles can be easily removed, allowing access to the plenum area for maintenance of equipment and systems. structure hanger wire main runner cross tee ceiling panel Finishes 53 04 FINISH CARPENTRY The wood interior inish components of a building are called millwork, and their installation is known as inish carpentry. Wood used for millwork encompasses various arrangements of solid and veneer wood, but in general it is of a higher quality than that used for framing. Millwork related to cabinetry and its assembly is called casework. Common Countertops Plastic Laminate Plastic laminate counters may come postformed, with the laminate already glued to a particle board platform, complete with a backsplash and bull-nosed front edge. It is also possible to apply p-lam as thin sheets—generally 1/16” (1.6) thick—using a contact adhesive. Decorative plastic laminates have a top sheet of paper printed with wood-grain patterns or other images. Stone Solid stone countertops of granite, soapstone, marble, or slate (typically resting on a thin-set bed of cement) are durable and resistant to most common kitchen or bathroom wear and tear. Substrates are generally two layers of plywood or particle board. The thickness of the stone varies based on type, but is in the general range of 3/4”–15/16” (19–33). Grouted stone tiles offer a lighter, less expensive alternative. Solid Surface The general composition of solid surface is polymer (acrylic-based resin or unsaturated polyester resin), aluminum trihydrate iller, pigment (colorant), and a catalyst. Solid surface materials are nonporous, homogeneous (maintaining the same appearance all the way through), strong, and have UV stability and surface hardness. They resist water, impacts, chemicals, stains, and high temperatures. Moreover, solid surface can be repaired by being sanded and polished back to its original inish. Solid surface materials are highly versatile and come in a wide variety of colors, textures, patterns, and translucencies. 54 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 04 Wood-based Board Types wood veneer MDF veneer plywood core plywood core wood veneer MDF veneer Veneer core hardwood plywood: VC is common plywood (typically, ir) with a inished wood grain surface veneer; it is relatively lightweight and easy to handle. Medium- and high-density overlay plywood: MDO and HDO are generally common plywood with an MDF surface, resulting in panels that weigh less than full MDF but have smoother and more stable surfaces than VC. wood veneer wood veneer HDP core MDF core wood veneer wood veneer High-density plywood: HDP has more plies and fewer voids than common plywood. Its strength and stability make it useful for cabinetry, and it typically comes in birch (Baltic) or maple (Appleby). Medium-density iber core hardwood plywood: MDF is produced by heat-pressing a mixture of ine wood dust and a binder into panels. Paint-grade blank sheets can be used as they are or with a veneer skin, while dyed MDF has a consistent color from face to core. Though ideal for use in cabinetry and shelving, full MDF is very heavy. veneer, gen’l paper with melamine resin PBC core PBC core veneer, gen’l paper with melamine resin Particle board core plywood: PBC produced by heat-pressing a coarse wood dust and a binder into panels, which are lower in weight than full MDF, due to the coarser dust. As the surface is rougher and less consistent, it is an ideal substrate for many other products. Melamine: Melamine consists of a particle board core with a thermally fused, resin-saturated paper inish. Though the name refers to the resin in the paper liner, and not the paper or board, the entire product is commonly referred to as melamine. Melamine is ideal for use in cabinetry and comes in a wide variety of colors. MDF can also be used as the substrate. Finishes 55 05 STRUCTURES AND SYSTEMS 56 56 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 2. 05 A single person rarely designs all aspects of a building. Numerous teams of professionals are needed to create the systems that make a building stand and function well. Coordination of these systems begins early and may continue even after the building is occupied. During design, the building is an ever-changing organism, growing and shrinking to accommodate more systems as they are shaped and sized, designed and reined, requiring continual communication between the architect and the consulting trades. Many decisions cannot be made until speciic systems are in place. For example, the materials, structure, occupancy, and layout of a building must be known before a preliminary code analysis can be attempted. This analysis may yield new information, such as the need for wider egress stairs, more exit corridors, or further provisions for sprinkler systems. The accommodation of larger stairs and more corridors will affect the arrangement of spaces—or it may generate an overall change to the size of the building, which could, in turn, require less expensive cladding materials—and more sprinklers might entail more plumbing requirements. This give-and-take process continues throughout design, resulting in a (usually) happy coexistence of systems, spaces, and materials. Structural Systems 57 57 05 Chapter 5: Structural Systems Structural elements of a building—its walls, frame, and foundation—hold it up (or keep it down) by resisting gravity (vertical forces) and lateral (horizontal) loads such as winds and earthquakes. The primary components of a building’s structural system are its foundation system and framing system. The type selected for either is contingent on many factors, including the building’s use, desired height, soil conditions of the site, local building codes, and available materials. Elements of a building’s structure cannot be removed without compromising its strength and stability. STRUCTURAL TERMINOLOGY Loads All stresses acting on a building’s structure, no matter how complex, can be reduced to either tension or compression. In basic terms, a building’s structure must press up with the same force that the weight of the building is pressing down, which includes all ixed dead loads and varying live loads. Tension is a pulling and stretching force. Compression is a pressing, pushing, or squeezing force. Dead loads: Fixed, static loads made up of the building’s own structure, skin, equipment, and other ixed elements. Live loads: Moving or transient loads such as occupants, furnishings, snow, ice, and rain. Wind loads: Pressure from wind that affects lateral loads as well as possible uplift forces on roofs or downward pressure. Other loads: Impact loads, shock waves, vibrations, and seismic loads. 58 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Arch: Structural device that supports vertical loads by translating them into axial forces. Axial force: System of internal forces whose outcome is a force acting along the longitudinal axis of a structural member or assembly. Beam: Horizontal linear element that spans an opening and is supported at both ends by walls or columns. Buttress: Vertical mass built against a wall to strengthen it and to resist the outward pressure of a vault. 05 Cantilever: Horizontal beam or slab that extends beyond its last point of support. Column: Upright structural member acting in compression. beam column Shear: System of internal forces whose outcome is a force acting perpendicular to the longitudinal axis of a structural member or assembly. Shoring: Temporary vertical or sloping supports. Slump test: Test in which wet concrete or plaster is placed in a metal cone-shaped mold of speciic dimensions and allowed to slump under its own weight after the cone is removed. The index of the material’s working consistency is determined by the distance between the height of the mold and the height of the slumped mixture. Dome: Arch rotated in plan to produce an inverted bowl-shaped form. Strain: Intensity of deformation at a point in an object. Girder: Horizontal beam, which is usually very large, that supports other beams. Stress: Intensity of internal force acting at a point in an object. Lintel: Beam used to span the opening in a wall left for a window or a doorway. The lintel supports and distributes the load of the wall above the opening. Vault: Extruded arch. vault Prestressing: Applying a compressive stress to a concrete structural member, either by pretensioning (pouring concrete around stretched steel strands, then releasing the external tensioning force on the strands once the concrete has cured) or posttensioning (tensioning high-strength steel tendons against a concrete structural member after the concrete has cured). Retaining wall: Wall used to mediate abrupt changes in ground elevation and to resist lateral soil pressures. groin vault Materials Structural framing elements may be made of wood, heavy timbers, concrete, masonry, steel, or a combination of these. Structural Systems 59 05 FOUNDATION SYSTEMS The selection of a foundation system depends on many factors, including the building size and height, the quality of the subsurface soil and groundwater conditions, construction methods, and environmental concerns. Superstructure The above-ground portion of a building, composed of a framing system and exterior cladding. Substructure The portion of a building below ground (which may be habitable). Foundation The below-ground elements of the building’s structural system that transfer the building’s loads into the soil. Shallow Foundation Deep Foundation Transfers the building’s load at the base of a column or bearing wall of the substructure. Transfers the building’s load at a point well below the substructure. Less expensive than deep foundations and commonly used when good soil conditions exist within a few stories below the substructure. 60 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Penetrates upper layers of incompetent soil to get to more competent soil or bedrock deeper down. 05 SHALLOW SYSTEMS DEEP SYSTEMS Footings Caissons Concrete footings may be in the form of a column pad, for distributing the load of a column, or a strip footing, which does the same for a bearing wall. To construct a caisson (also referred to as a “drilled pier”), a hole is drilled or dug (a process known as augering) through unsatisfactory soil beneath a building’s substructure, until rock, dense gravel, or irm clay is reached. If the caisson will rest on soil at the bottom, the hole is sometimes belled out to achieve a bearing area similar to a footing and the hole is then illed with concrete. Caissons may range from 18” (457) to 6’ (1 829) in diameter. Column Footing Strip Footing Slab on Grade Used for one- and two-story structures, this inexpensive foundation has thickened edges and rests as a continuous slab on the surface of the ground. Piles Piles are similar to caissons, but are driven into place, not drilled or poured. They may be made from concrete, steel, or timber, or a combination of these materials. Piles are driven closely together in clusters and then cut off and capped in groups of two to twentyive. The building’s columns rest on top of the pile caps. Load-bearing walls, where used, rest on reinforced-concrete grade beams that span between pile caps, transmitting the walls’ loads to the piles. Slab on Grade Mat Foundation In this foundation system (also known as raft foundation), the whole building rests on a large continuous footing. It is often used to resolve special soil or design conditions. “Floating” or “compensated” mat foundations are sometimes employed in situations with weak soil. The loating foundation is placed beneath the building to a point that the amount of soil removed is equal to the total weight of the building. grade beam pile cap cluster of four piles Structural Systems 61 05 WOOD LIGHT-FRAMING Wood light-frame construction uses a system of wood wall studs, loor joists, rafters, columns, and beams to create both structure and framework for applied interior and exterior inished surfaces. As a building material, wood is relatively inexpensive, versatile, and quick to erect. Typical spacing for studs and loor joists is 12” (305), 16” (406), or 24” (610) on center. These dimensions are compatible with typical wall, loor, and ceiling material unit dimensions, such as gypsum wallboard and plywood sheets. When complete SI conversion occurs in the United States, these building materials will undergo a change in unit size, and framing dimensions will shift to the metric planning grid used elsewhere in the world. Exterior wall sheathing is typically plywood, which acts as a base for stucco, siding, or even brick and stone façades; insulation is placed between the studs. The most common framing method is platform framing, in which, in multistory buildings, the levels are built one at a time, so that each loor acts as a platform on which the walls above can rest. In balloon framing, wall studs are continuous from sill to roof; the intermediate loor joists tie into a ribbon occurring at the loor line and attached to the studs. Balloon framing is more prevalent in older houses and is seldom used today. ridge beam rafter double header exterior sheathing double sill cripple stud sublooring loor joists wall studs sole plate header joist sill concrete foundation 62 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 05 HEAVY TIMBERS Heavy-timber construction uses speciically engineered woods of minimum dimensions to achieve greater structural strength and ire resistance than is possible with wood light-frame construction, while also taking advantage of the aesthetic beneits of exposed wood. To achieve high levels of ire resistance, construction details, fastenings, and wood treatment are closely regulated in heavy-timber construction. Decking Floor deck planking spans between loor beams; inished loor material is placed above the planking, running perpendicular to it. Planks should be a minimum 3” nominal (76) thick if splined or tongue-andgrooved together, or a minimum 4” nominal (102) if set on edge and spiked together. Flooring should be 1/2”–1” (13–25) thick. Floors Beams and girders may be sawn or glue-laminated. They should not be less than 6” wide x 10” deep nominal (152 x 254). Truss members must be a minimum 8” x 8” nominal (203 x 203). Decay Structural members must be preservatively treated or be from the heartwood of a naturally durable wood. girder beam Connections Connection types vary and can include metal hangers (shown here), metal angles, bolts and split rings, and bolts and shear plates, and for column anchorage, metal shoes (shown here), anchor straps, straps with shear plates and bolts, and angles with bolts, all on bearing plates. Columns Columns may be sawed or glue-laminated. Supporting loor loads, must be a minimum 8” wide x 8” deep nominal (203 x 203). Supporting roof and ceiling loads, must be a minimum 6” wide x 8” deep nominal (152 x 203). Structural Systems 63 05 Concrete Floor and Roof Systems Different systems, in order of increasing load capacity, spans, and cost, are one-way solid slab (spans across parallel lines of support), two-way lat plate (uses no beams, dropped plate, or column capitals, but rather, reinforcing of various stresses), two-way lat slab (uses column capitals and/or drop panels instead of beams), one-way joist, wafle slab, one-way beam and slab, and two-way beam and slab. Two-way systems tend to be square in proportion and are supported on four sides; one-way systems have a 1:>1.5 proportion and are supported on two sides. Two-way Flat Plate One-way Ribbed Slab (joist) Flat Beam and Slab 64 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Two-way Flat Slab Two-way Wafle Slab One-way Beam and Slab 05 Moment Frame Rigid framework resists lateral forces Braced Frame Internal structure braces light frame Tube Exterior walls contribute to structural stability Structural Systems 65 05 05 PRECAST CONCRETE FRAMING 4’-0” (1 219) 4” (102) 6” (152) 8” (203) Slab Detail topping Solid Flat Slab welded wire fabric 6” (152) 8” (203) 10” (254) 12” (305) 4’-0” (1 219) Hollow Core Slab prestressing strands Slab Detail optional topping Type A: 8’-0” (2 438) Type B: 10’-0” (3 048) 2” (51) 3’-4” (1 016) Type D 4’-0” (1 219) Type E 4’-0” (1 219) Type F varies 12” (305)– 32” (813) Type A: 4’-0” (1 219) Type B: 5’-0” (1 524) Stemmed Deck, Double Tee (DT) optional topping Type C: 8’–0” (2 438) Type D: 10’–0” (3 048) 1 1/2” (38) varies 20” (508)– 48” (1 219) Type C 4” (102) 6” (152) 8” (203) 10” (254) 1’-4” (406) 1’-8” (508) 2’-0” (508) 2’-0” (610) 6” (152) 8” (203) 10” (254) 12” (305) Type B 4” (102) 6” (152) 8” (203) 10” (254) 12” (305) 4’-0” (1 219) 6” (152) 8” (203) 10” (254) 12” (305) Type A 4” (102) 6” (152) 8” (203) 10” (254) 12” (305) 4’-0” (1 219) 6” (152) 8” (203) 12” (305) 15” (381) Hollow Core Slab Types 8” (203) Stemmed Deck, Single Tee (ST) 66 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 05 05 Hollow Slab Framing System Beam-to-Column Connection Slab-to-Bearing Wall Connection hollow core slab precast column rectangular beam precast bearing wall Stemmed Deck DT Framing System stemmed deck (double tee) Deck to-Bearing Wall Connection Beam-to-Column Connection precast column with corbel inverted tee beam precast bearing wall Structural Systems 67 05 STEEL FRAMING Structural Steel Shape Designations Shape Description W Wide-lange hot-rolled, doubly symmetric wide-lange shapes used as beams and columns HP Wide-lange hot-rolled, wide-lange shapes whose langes and webs are of the same nominal thickness and whose depth and width are essentially the same; often used as bearing piles S American Standard beam hot-rolled, doubly symmetric shapes produced in accordance with AASM* dimensional standards; generally being superseded by wide-lange beams, which are more structurally eficient M Miscellaneous doubly symmetrical shapes that cannot be classiied as W or HP shapes L Angle equal leg and unequal leg angles C American Standard channel hot-rolled channels produced in accordance with AASM dimensional standards MC Channel hot-rolled channels from miscellaneous shape WT Structural tee hot-rolled tees cut or split from W shapes ST Structural tee hot-rolled tees cut or split from S shapes MT Structural tee hot-rolled tees cut or split from M shapes TU Tube hollow structural steel members shaped like a square or rectangle; used as beams or columns, or in bracing *AASM: Association of American Steel Manufacturers 68 68 THE REFERENCE++SPECIFICATION SPECIFICATIONBOOK BOOK THE ARCHICTECTURE ARCHITECTURE REFERENCE 05 Steel Shape Examples tf (lange thickness) Wide-lange W8X67 k tw (web thickness) 8 = nominal depth (in.); 67 = weight per foot of length (lb.) T d (depth) k k1 bf (lange width) Wide-lange HP12X84 American Standard S8X18.4 Miscellaneous M10X8 12 = nominal depth (in.); 84 = weight per foot of length (lb.) 8 = nominal depth (in.); 18.4 = weight per foot of length (lb.) 10 = nominal depth (in.); 8 = weight per foot of length (lb.) Structural Tees WT25X95 Angle L6X4X7/8 Channel MC7X22.7 6 and 4 = nominal depths of legs (in.); 7/8 = nominal thickness of legs (in.) 7 = nominal depth (in.); 22.7 = weight per foot of length (lb.) ST15X3.75 Tube TU2X2X1/8 StructuralSystems Systems Structural 69 69 05 TRUSS DESIGN Steel-Frame Connections Steel is proportionally light in weight relative to its strength and can be erected quickly but precisely. Steel-frame construction uses a combination of structural steel shapes that act as columns, beams, girders, lintels, trusses, and numerous means of connection. The integrity and strength of steel connections are just as important as the steel shapes themselves, because a failed connection results in a failed system. Steel-frame connections include angles, plates, and tees for transitioning between members being joined. Heel Conditions Light Wood Connections that join only the web of the beam to the column are called framed connections; they can transmit all the vertical (shear) forces from the beam to the column. If the langes of the beam are also connected to the column, it is then capable of transmitting bending moment from beam to column. Heavy Wood Framed Connection: Shear connection with beam web bolted to column lange using connecting angles. Welded Moment Connection: Moment connection between beam and column using groove welds at beam web and lange. Cold-rolled Steel Channel Welded Steel 70 70 THE REFERENCE++SPECIFICATION SPECIFICATIONBOOK BOOK THE ARCHICTECTURE ARCHITECTURE REFERENCE 05 A truss is a structural framework of triangular units for supporting loads over long spans. The framework of the structural members reduces nonaxial forces to a set of axial forces in the members themselves. panel length top chord web overall height bottom chord heel bottom chord length Truss Types Belgian Flat Pratt Warren Pitched Howe Fink Flat Howe Scissors Bowstring Pitched Pratt Modiied Bowstring Structural Systems 71 06 Chapter 6: Mechanical Systems A building’s mechanical systems involve control of heat, ventilation, air-conditioning, refrigeration, plumbing, ire protection, and noise reduction, all of which must be integrated with the architectural, structural, and electrical design. ENERGY DISTRIBUTION SYSTEMS All-air Systems: Conditioned air is circulated to and from spaces by central fans that direct it through runs of ductwork. Air and Water Systems: Conditioned air is ducted to each space, and chilled and heated water are piped to each space to modify the temperature of the air at each outlet. All-water Systems: No ductwork is used, and air is circulated within each space, not from a central source. Chilled and heated water are furnished to each space. Because water piping is much smaller than ductwork for air, all-water systems are very compact. Air duct: Pipe that carries warm and cold air to rooms and back to a furnace or airconditioning system. Louver: Opening with horizontal slats that permit passage of air, but not rain, sunlight, or view, into a structure. ASHRAE: American Society of Heating, Refrigerating, and Air-Conditioning Engineers. Plenum: Chamber that serves as a distribution area for heating or cooling systems, usually found between a false ceiling and the actual ceiling. Cavity wall: Hollow wall formed with two layers of masonry, providing an insulating air space between. Chase wall: Cavity wall containing electrical runs or plumbing pipes in its cavity. Closed loop: Evaporator side of chiller system, closed to the atmosphere. Dry bulb: Ambient outside temperature. Furnace: Device that generates heated air, and is powered by natural gas, fuel oil, or electricity. Most often used in small commercial or residential applications. Heat pump: A device that warms or cools by transfering thermal energy from a heat source to a heat sink. HVAC: Heating, ventilating, and air-conditioning. IAQ: Indoor Air Quality 72 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Open loop: Condenser/tower side of chiller system; open to the atmosphere. Radiant heat: Heating system that uses coils of electricity, hot water, or steam pipes embedded in loors, ceilings, or walls to heat rooms. Shaft: Enclosed vertical space (usually with ire-resistive walls) containing all vertical runs of pipes, ducts, and elevators. Variable air volume (VAV): Air-handling system that conditions air to a constant temperature and varies airlow to ensure thermal comfort. Wet bulb: Combination of outside air temperature and relative humidity; higher relative humidity makes it more dificult for a cooling tower to evaporate water into the atmosphere. 06 HVAC SYSTEMS The systems for accomplishing heating, ventilation, and air conditioning of indoor spaces vary considerably, based on factors including building type and program, cost, climate, and building size. The basic principals and components of heating, cooling, and circulating are similar across all systems. Cooling tower: Open recirculating system where heat exchange occurs by evaporation. COOLING TOWER Air handling unit (AHU): Equipment including a fan or blower, heating and/or cooling coils, regulator controls, condensate drain pans, and air ilters. AHU BOILER CHILLER Boiler: Tank where the heat produced from the combustion of fuels (natural gas, fuel oil, wood, or coal) generates hot water or steam for use in heating. Chiller: Heat exchanger (evaporator, condenser, and compressor system) that uses air, a refrigerant, water, and evaporation to transfer heat and produce air-conditioning. Mechanical Systems 73 06 MECHANICAL DISTRIBUTION TYPES FAN COIL UNITS Fan coil units (FCUs) contain cooling or heating coils and a fan. Typically, hot or chilled water is piped to the unit from a central boiler and chiller. Air from the room is drawn into the unit (return air) and blown over the coil by a fan. The air is then heated or cooled and discharged (supply air) to the room. FCUs may be vertical or horizontal, mounted on walls, ceilings, or freestanding. 2-Pipe: System has one supply and one return pipe. Must be changed over from hot to cold with change in seasons. Chiller Supply air 4-Pipe: System has hot supply, hot return, cold supply, and cold return pipes, allowing the system to change between heating and cooling at any time. Return air Boiler Piping Fan Coil Unit Horizontal Console Floor-mounted, often at exterior wall Vertical Stack May be concealed within wall system, or freestanding Vertical Stack — ducted May be concealed within wall system, or freestanding Horizontal FCU Ceiling-hung, may be within sofit or exposed 74 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 06 FORCED AIR DUCT SYSTEM A duct system distributes heated, cooled, and fresh air throughout the building, while also iltering and dehumidifying the air. HYDRONIC SYSTEMS Hydronic systems provide heating, but typically not cooling. Hot water is circulated through tubing, from the central heat source to radiators throughout the space to be heated. The radiators may be wall-mounted or loor-mounted. Tubes may also be designed into loor systems, providing consistent radiant heat. Heat sources may include boilers, water heaters, and solar power. Main supply Branch Return: (Register/Grille) Supply: (Register/Diffuser) Main return Plenum Heating element Cooling element Blower fan Coolant lines Condensor Unit Pad-mounted, outdoor Drain to stack Filter FORCED AIR FURNACE — Typical residential heating and cooling system Mechanical Systems 75 06 06 SUSTAINABLE DESIGN The issue of sustainable design shines a brighter and brighter light on architecture’s need to grow, learn, and adapt to a changing world. By nature, architecture is subject to inertia: Buildings take years to design and realize, and architects, engineers, and contractors take years to train. This process once ensured painstaking attention to detail and craftsmanship that resulted in a building that could last forever. Today architecture must too often bend to economic pressures to build quickly and inexpensively. Technological and engineering advances allow for such economy, though often at the risk of producing disposable buildings, ultimately unable to stand the test of time and frequently at odds with the well-being of the environment. Sustainable design proposes using systems that meet present needs without compromising those of future generations. Architects, for their part, are increasingly compelled to understand and implement such new systems and methods as they envision ways in which buildings may work with the environment and the living world. The result is a built world that enhances instead of diminishes its surroundings and resources. LEED DESIGN The LEED (Leadership in Energy and Environmental Design) Green Building Rating System is a voluntary, nationally recognized standard for developing high-performance, sustainable buildings. LEED was developed by the U.S. Green Building Council (USGBC), comprising members from all walks of the building community. LEED’s progressive levels of certiication—Certiied, Silver, Gold, and Platinum—relect various levels of building performance and sustainability. Projects wishing for certiication must register and submit documentation for review by LEED. Among LEED’s primary goals is to establish a common standard of measuring sustainability and to promote integrated design practices while raising awareness of the beneits of “green building.” A green building is one that uses energy in an eficient and ecologically aware way and that minimizes negative impact on the health of its users. 76 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK DECLARATION OF INTERDEPENDENCE In 1993 the Union Internationale des Architectes (UIA) and the AIA signed a “Declaration of Interdependence for a Sustainable Future,” which made commitment to environmental and social sustainability a core issue of practice and professional responsibility. In addition to bringing the existing built environment up to established sustainability standards, it also stresses the importance of developing and reining practices, procedures, products, services, and standards to enable implementation of sustainable design, as well as educating all members of the building community, clients, and the general public about the beneits of and need for sustainable approaches to design. Similarly, a coalition of architects, landscape architects, and engineers formed the Interprofessional Council on Environmental Design (ICED) as a multidisciplinary partnership committed to the common goal of sustainability. 06 06 TERMINOLOGY Adaptive reuse: Changing a building’s function in response to the changing needs of its users. Black water: Waste water from toilets, kitchen sinks, and dishwashers. Brownfields: Abandoned or underused industrial and commercial sites where environmental contamination hampers redevelopment. Chlorofluorocarbons (CFCs): Chemical compounds used as refrigerants and in aerosol and believed to be responsible for depleting the ozone layer. Conservative disassembly: Counterproposal to destructive demolition of buildings (where most of the building’s material is crushed into waste) that promotes varying levels of salvaging materials from a building before it is demolished. Embodied energy: All of the energy consumed by all of the processes associated with the production of a building, including transportation. Gray water: Wastewater from baths, showers, washers, and lavatories, which might be appropriate for irrigation or other uses not requiring clean water. Hydrochlorofluorocarbons (HCFC): Alternative to CFCs, with shorter atmospheric lifetimes that deliver less reactive chlorine to the ozone layer, though alternatives to both are still being sought. GUIDELINES Hydronic heating: In-loor hot-water heating system where hot water is pumped through a thermal mass loor that absorbs the heat, evenly radiating it over time. Life cycle analysis (LCA): Quantiiable assessment of all stages in the life cycle of a product system (resource extraction, manufacturing, onsite construction, occupancy/ maintenance, demolition, and recycling/reuse/disposal) used to determine the impact of the material or system via four phases: initiation, inventory analysis, impact assessment, and improvement assessment. Passive solar: Technology of heating and cooling a building naturally, through the use of energy-eficient materials and proper site placement. Photovoltaics: Solar panels used to harness the sun’s energy into electricity that can be stored in batteries and used to power an electrical system. Renewable: Resource that comes into being through a relatively quick natural process. Upstream/downstream: Cause-and-effect example that what one does upstream affects what happens downstream. Design for energy eficiency through the use of high levels of insulation and high-performance windows. Design buildings with renewable energy sources such as passive solar heating, daylighting, and natural cooling, whenever possible. Design for standard sizes to minimize material waste. Avoid materials containing CFCs and HCFCs. Use salvaged or recycled building materials such as heavy timbers, millwork, and plumbing ixtures. When possible, use locally produced materials to cut down on transportation costs and pollution. Use materials with low embodied energy. Rules of thumb: lumber, brick, concrete, and iberglass have relatively low embodied energies, whereas timber, ceramics, and steel are higher, and glass, plastic and aluminum are very high. Often a higher embodied energy level can be justiied if it contributes to lower operating energy, such as when large amounts of thermal mass can signiicantly reduce heating and cooling needs in well-insulated passive solar buildings. Avoid off-gassing materials with high levels of VOCs. Reduce energy and water consumption. Minimize external pollution and environmental impact. Reduce resource depletion. Minimize internal pollution and negative effects on health. Volatile organic compound (VOC): Highly evaporative, carbon-based chemical substance producing noxious fumes and found in many paints, caulks, stains, and adhesives. Mechanical Systems Mechanical Systems 77 77 07 Chapter 7: Electrical Systems Lighting has a tremendous effect on the manner in which a space will be experienced and perceived. Architects often work closely with lighting designers, who provide expertise on the technical aspects and effects of lighting and how they can best serve the design and function of a space. Lighting designers provide lighting speciications for the project and coordinate much of their design information with the electrical drawings and relected ceiling plans. LIGHTING TERMINOLOGY Ambient lighting: General lighting for an entire space. Ampere (amp): Unit of measuring electrical current, equal to one coulomb per second. Baffle: Opaque or translucent element that controls the distribution of light at certain angles. Ballast: Device that provides starting voltage for a luorescent or HID lamp, then limits and regulates the current in the lamp during operation. Bulb: Decorative glass or plastic housing that diffuses light distribution. Candela: SI unit of the luminous intensity of a light source in a speciic direction. Also called candle. Candlepower (CP): Measure (in candelas) of the luminous intensity of a light source in a speciic direction. Coefficient of utilization (CU): Ratio of a luminaire’s lumens on a surface to the lamp’s production of lumens. Color rendering index (CRI): Scale of 1 to 100 determining a light source’s effect on the color appearance of an object, compared to the color appearance under a reference light source. A rating of 1 indicates maximum color shift and 100 indicates no color shift. 78 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Color temperature: Speciication of the color appearance of a light source, measured in Kelvins. Color temperatures below 3,200K may be considered warm and those above 4,000K may be considered cool. Compact fluorescent: Small luorescent lamp used as an alternative to incandescent light. Known also as twin-tube, PL, CFL, or BIAX. Daylight compensation: Energy-saving photocell-controlled dimming system that reduces the output of lamps in the presence of daylight. Diffuser: Translucent piece of plastic or glass that shields a ixture’s light source, scattering and diffusing the transmitted light. Direct glare: Glare resulting from direct view of light source. Downlight: Ceiling ixture that can be fully recessed, semirecessed, or ceiling mounted, in which most of the light is directed downward. Variously called a can, high-hat, or recessed downlight. Electroluminescent: Lighting technology that provides uniform brightness and long lamp life while consuming very little energy, making it ideal for use in exit signs. Energy: Electric power unit, measured in kilowatt hours (kwh). Fluorescent: Tube illed with argon, krypton, or another inert gas. An electrical current applied to the gas produces an arc of ultraviolet radiation that causes the phosphors inside the lamp wall to radiate visible light. 07 Foot-candle (FC): English unit of measuring the light level on a surface, equal to one lumen per square foot. Lux (LX): Metric unit of illuminance measure. One lux = 0.093 foot-candles; one foot-candle = 10.76 lux. High-intensity discharge (HID): Mercury vapor, metal halide, high-pressure sodium, and low-pressure sodium light sources. Nadir: Reference direction directly below (0 degrees) a luminaire. High output (HO): Lamp or ballast that operates at high currents and produces more light. IALD: International Association of Lighting Designers. IESNA: Illuminating Engineering Society of North America. Illuminance: Luminous lux per unit area on a surface at any given point. Commonly called light level, it is expressed in foot-candles or lux. Incandescent: Bulb that contains a conductive wire ilament through which current lows. This is the most common type of light source. Lamp: Light-producing component inside a bulb. Opaque: Of material, transmitting no visible light. Optics: Components of a light ixture— relectors, refractors, lenses, louvers, and so on; or, the light-emitting performance of a luminaire. Reflectance: Ratio of light relected from a surface to the light incident on the surface. (The relectance of a dark carpet is 20 percent and that of a clean white wall is 50 to 60 percent.) Reflector: Element of a luminaire that shrouds the lamps, redirecting some of the light they emit. Refractor: Element of a luminaire that redirects light output by bending the waves of light. Lay-in troffer: Fluorescent ixture that lays into a ceiling grid. Room cavity ratio (RCR): Ratio of room dimensions used to determine how light will interact with the room’s surfaces. Light-emitting diode (LED): Semiconductor diode that emits light when voltage is applied to it; used in electronic displays such as signage. T12 lamp: Industry standard designation for a luorescent lamp that is 12/8” in diameter. T8 and T10 are similarly named. Lens: Transparent or translucent element that alters the directional characteristics of light as it passes through. Lumen: Unit of measuring the total light output of a lamp. Luminaire: Complete lighting unit (also called a ixture) consisting of lamp(s) and the parts required to distribute the light, hold the lamps, and connect them to a power source. Luminance: Luminous intensity per unit area of a surface. It is expressed in candelas (metric) or footlamberts (customary). Translucent: Of material, transmitting some visible light. Transparent: Of material, transmitting most visible light incident on it. Troffer: Recessed luorescent ixture (from trough plus coffer). Ultraviolet (UV): Invisible radiation of shorter wavelength and higher frequency than visible violet light. Underwriters’ Laboratories (UL): Independent organization that tests products for public safety. Electrical Systems 79 07 LIGHT FIXTURES AND TYPES recessed luorescent troffer track lighting luorescent ixture in a cove (provides indirect light source) loor lamp table lamp 80 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 07 semirecessed downlight recessed downlight recessed wall washer (provides even level of illumination on a wall) pendant wall sconce desk lamp (provides task lighting) Electrical Systems 81 07 COMMON BULB TYPES Fluorescent lamps are long, sealed glass tubes, coated inside with a phosphor powder. Fluorescent bulbs contain mercury, which is converted from a liquid to a gas by the energy produced by electrodes at either end. T2 Fluorescent bulbs come in a variety of lengths, diameters, 2/8” dia. T5 wattages, and starting methods. (1/4”) Lengths are in increments of 12” 5/8” dia. (commonly 48”), and diameters are noted by 1/8” modules. T12 bulbs, which are typically 40 watts, T8 have begun to 8/8” dia. be phased out in the U.S., per (1”) the Department T12 of Energy, in favor of more 12/8” dia. eficient T8 and (1-1/2”) T5 lamps. Contact pins Mercury Electrode Glass tube (sealed) Phosphor coating (internal) 82 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 07 Bulbs are typically identified by a letter or letters that indicate its type or shape, and a number that indicates the greatest diameter of the bulb in 1/8”. CFL (Compact Fluorescent Lamp) Incandescent The A-series incandescent light bulb has long been the ‘classic’ multipurpose bulb type. The most common size is the A19 (2-3/8” dia.) CFLs are luorescent lights designed to replace incandescent bulbs - many screw into the same ixtures, and the luorescent tube has been folded and curved to it the same volume as a typical incandescent bulb. CFLs use less power and last longer than incandescent, though their mercury content makes safe disposal dificult. MR (Multi-faceted Reflector) PAR (Parabolic Aluminized Reflector) The inside surface of MR lamps is faceted and covered in a relective coating. The light is produced by a single-ended quartz halogen ilament capsule. PARs contain the light bulb, relector, and lens within one unit, allowing them to shape and concentrate light for speciic tasks and settings. The light is a sealed beam incandescent. Sizes vary, and include PAR 16 (2” dia.), PAR 30 (3-3/4” dia.), PAR 38 (4-3/4” dia.), and PAR 64 (8” dia.) Common sizes are MR16 (2” dia.), MR11 (1-3/8” dia.) and MR8 (1” dia.) Electrical Systems 83 08 Chapter 8: Plumbing and Fire Protection vent stack (through roof) shower supply tub supply tub drain si nk tub trap col rs nk to ply ld tw ate up co ho si rs ho tt o dw ate up ply waste Common Bathroom Pipe Layout 84 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 08 PIPES SUPPLY Water Supply: white plastic (PVC) 1/2” - 1” dia. Water or Gas Supply: copper 1/2” - 1” dia. Water Supply: galvanized iron 1/2” - 1” dia. Gas Supply: black iron 1/2” - 1” dia. DRAIN Drain and Vent: black plastic 1-1/2” + dia. Drain and Vent: cast iron 1-1/2” + dia. Plumbing and Fire Protection 85 08 Fire Protection Systems Limitations on building area and height may be lessened when ire-protection systems such as automatic sprinklers are in place. Active ire-protection systems are deined by IBC 202 as “approved devices, equipment and systems or combinations of systems used to detect a ire, activate an alarm, extinguish or control a ire, control or manage smoke and products of a ire, or any combination thereof.” They are meant to work in conjunction with the building’s passive systems (ire-resistive construction) to provide necessary protection for the occupants of any building type. Higher levels of stringency in one system might mean lessened requirements in the other, though neither should be compromised for the sake of cost or convenience. The IBC requires active systems for buildings above certain sizes and occupant loads, regardless of the type of construction. IBC Section 903 establishes these requirements based on use groups and ire areas (“the aggregate loor area enclosed and bounded by ire walls, ire barriers, exterior walls, or ireresistance-rated horizontal assemblies of a building”). Alternative ire-extinguishing systems may be used when necessary, in compliance with IBC 904. Examples of reasons to use alternative systems might include libraries and museums or telecommunications facilities, whose contents would sustain water damage from standard water sprinkler systems. Until recently, Halon 1301 gas was widely preferred as a ire-suppression option; however, it has proven to be harmful to the ozone layer and is being replaced by other options. reserve tank wa te rm ain Sprinkler Distribution Diagram 86 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 08 Sprinkler Head Distribution Types Concealed Pendant Sprinkler head is recessed in ceiling and covered with a decorative cap, which falls off once ambient air temperatures reach a temperature of 20˚F prior to sprinkler activation. Water sprays downward in a circular pattern. Pendant Hangs from ceiling and sprays water downward. Side Wall When mounting sprinklers to ceiling is not possible, they may be mounted to walls. Two delectors spray water out and back toward the wall. Actuation Methods Fusible Link: two pieces of metal are fused by a heat-sensitive metal alloy, which, when it reaches its melting point, causes the two metals to separate and activate the sprinkler. Upright Mounted atop supply pipe, upright sprinkler heads are used in locations where ceiling mounting is not possible, or obstructions prevent adequate coverage (such as mechanical or storage rooms). Glass Bulb: a glass bulb illed with liquid expands and bursts when it has reached a suficient temperature, causing the pip cap to fall away and actuate the sprinkler. The color of liquid indicates the temperature range that will cause the liquid to expand. Response Temperatures (per National Fire Protection Association 13) classiication ordinary sprinkler activation temp. 135°F - 170°F glass bulb color Orange (135°F) fusible link color Black; no color Red (155°F) intermediate 175°F - 225°F Yellow (175°F) White Green (200°F) high 250°F - 300°F Blue Blue extra high 325°F - 375°F Purple Red very extra high 400°F - 475°F Black Green ultra high 500°F - 575°F Black Orange Plumbing and Fire Protection 87 09 1 2 Chapter 9: Enclosure Systems 3 A building’s enclosure systems serve many functions. Not only must they separate and protect interior from exterior, they must still allow the inside and outside to have a relationship that contributes to the most effective means of moisture, thermal, and ventilation control, all while presenting the building’s public face. 4 5 6 7 8 9 1 10 11 12 13 14 2 15 3 4 16 17 Roof Forms 18 19 20 Flat 21 Pitched Hip Hip Gable 22 23 24 25 Mansard Barrel Vault Gambrel Gambrel Pyramidal Sawtooth Shed Butterly 26 27 28 29 30 88 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 09 FLASHING Flashing is used in several locations of a building’s exterior to move water away and into the drainage system quickly and eficiently. Flashing is commonly thin sheet metal (copper, aluminum, stainless steel, or painted galvanized steel) or other impervious material such as rubber. Material choices often depend on whether the lashing will be exposed (metals are preferred) or concealed, and with which other materials it is likely to come into contact. 1. Roof Flashing is wrapped around protruding objects such as chimneys and vents to keep water from settling into joints and seams. back cap lashing (folds into mortar joint) (brick chimney) side cap lashing (folds into mortar joint) 2. Wall Flashing may prevent water from entering a wall, or may divert water that has entered a wall cavity. saddle or cricket ice/water barrier beneath 3. Sill Interruptions in a wall, such as doors and windows, are vulnerable to water penetration. building paper open-weave mesh 4. Base Gravity helps water escape walls down the sloped surfaces of the lashing, and out through weep holes. lashing weep hole (with open-weave mesh inserted into joint) Enclosure Systems 89 09 1 2 ROOF SYSTEM TYPES: STEEP SLOPES 3 4 5 6 Tiles: (clay or concrete) sit on top of a weatherprooing underlayment (typically asphalt-saturated non-perforated organic rooing felts) 7 8 9 10 11 Shingles and Shakes: (asphalt, slate, wood, synthetic) sit on top of a weatherprooing underlayment (typically asphalt-saturated non-perforated organic rooing felts) 12 13 14 15 16 17 Metal: architectural metal panels sit on top of a weather-prooing underlayment (typically asphaltsaturated nonperforated organic rooing felts) 18 19 20 12 21 12 22 Steep slope 23 Low slope 24 12 25 Flat 4 12 26 27 28 29 30 90 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 2 09 ROOF SYSTEM TYPES: LOW & FLAT SLOPES Structural metal panel: over weather-prooing underlayment Single-ply membranes: thermoplastic or thermoset membranes are factory-made. Methods of installing include fullyadhered, mechanicallyfastened, or held down with a ballast material. Shown here, the membrane is fully adhered to the insulation, which itself is mechanically fastened to the substrate. Polymer-modiied bitumen sheet membranes (MB): composed of multiple layers, and most often fully-adhered as a two-ply system. SPF (Spray polyurethane foam board): base layer is a rigid, spray foam insulation, on top of which is a spray-applied elastomeric weather-proof coating. Sand or mineral granules may be added to this layer for reasons of durability and aesthetic concerns. Built-up roof (BUR): bitumen (asphalt, coal tar, or cold-applied adhesive) and reinforcing fabrics (rooing felts) are applied in alternating layers to create the membrane. Sometimes referred to as ‘tar and gravel’ roofs. Gravel or other minerals may be added on top. Enclosure Systems 91 09 1 STONE 2 As a building material, stone may be used in two different manners: as a masonry unit laid with mortar, similar to brick or concrete blocks, or as a thin, non-load-bearing veneer facing attached to a backup wall and structural frame. Stone colors, textures, and patterns are highly varied, as are the design and detailing of unit masonry and cladding systems. 3 4 5 SEDIMENTARY ROCK (rock deposited as a result of natural action or wind) 6 limestone 7 8 9 10 11 sandstone 12 13 14 15 Limestone: Colors limited mostly to white, buff, and gray. Very porous and wet when quarried, though after air seasoning, quarry sap evaporates and stone becomes harder. Suitable for wall and loor surfaces, but does not accept a polish. Sandstone: Colors range from buff to chocolate brown to red. Suitable for most building applications, but also does not accept a high polish. Stone masonry includes rubble stone (irregular quarried fragments), dimension stone (quarried and cut into rectangular forms called cut stone when large and ashlar when small), and lagstone (thin slabs of paving stone, irregular or cut). Masonry Patterns IGNEOUS ROCK (rock deposited in a molten state) 16 17 granite 18 19 Granite: Wide range of grains and colors including gray, black, brown, red, pink, buff, and green. Nonporous and very hard. Suitable for use in the ground and with exposure to weather. Comes in many textures and may be highly polished. Random (Uncoursed) Rubble 20 Coursed Rubble 21 METAMORPHIC ROCK (sedimentary or igneous rock transformed into another rock type by heat or pressure) 22 23 slate 24 25 26 27 marble 28 29 Slate: Colors range from red and brown to grayish-green to purple and black. Sheetlike nature makes it ideal for paving, rooing, and veneer panels. Marble: Highly varied in both color and streaking patterns. Color range includes white, black, blue, green, red, and pink, and all tones between. Suitable for use as a building stone but is most often highly polished and used as a veneer panel. Coursed Ashlar 30 92 Random (Uncoursed) Ashlar THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 09 MASONRY BEARING WALLS Brick, concrete block, and stone walls built as load-bearing walls will have many different characteristics, depending on whether or not they are reinforced, use more than one masonry unit type (composite wall), or are solid or cavity walls. Common Wall Configurations Reinforcing Reinforcing masonry allows the entire wall system to be thinner and taller. Double-wythe brick wall with concrete and steel reinforcing between Composite Walls Composite masonry walls employ a concrete block backup with brick or stone veneer on the exterior wythe, with the two layers bonded with steel horizontal reinforcing. Masonry ties join wythes of masonry together or to supporting wood, concrete, or steel backup structures. Anchors connect masonry units to the supporting structure. Cavity Walls Cavity walls have an inner and outer wythe of masonry units, separated by an air space of a minimum 2” (51). Masonry ties hold the two wythes together. If rain penetrates the outer wythe, it runs down the inner surface of the outer wythe and is collected at the base with lashing materials that divert it back to the outside through weep holes. Brick wall on CMU backup (CMUs may or may not be reinforced), tied together with Z-ties Brick and CMU cavity wall (CMU wall is reinforced) cavity wall tie brick cmu lashing Stone veneer on CMU backup, tied together with adjustable stone ties weep hole Enclosure Systems 93 09 1 2 3 4 EXTERIOR WALLS Common conigurations are shown here, though the combinations of backup systems and exterior cladding systems are interchangeable in many cases, with changes to fastening systems dependent on the type of material being attached to speciic structural elements. 5 6 7 8 9 Wood stud wall Wood studs with batt insulation between; exterior sheathing with weather-resistive barrier; exterior-grade plywood panels (sealed) 10 11 12 13 14 15 SIP (Structural Insulated Panel) Wall SIP (insulated foam-core with OSB skin, either side); weather-resistive barrier; exterior siding Metal stud wall Metal studs with batt insulation between; exterior sheathing with weather-resistive barrier; aluminum composite material (ACM) 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 94 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 09 The outer skin of a building is the vertical envelope that separates interior from exterior, and must effectively keep out water and contribute effectively to maintaining the desired interior climate. Most wall constructions include structural elements, insulation, water barriers, and an exterior cladding material. Depending on many factors, including the building’s size and height, backup materials such as CMUs, concrete, and stud systems may be load-bearing, or act as inill within a structural frame. Composite wall Reinforced CMU backup; rigid insulation; 1” min. airspace; brick (or other masonry) tied to CMUs UHPC Concrete wall Poured-in-place or pre-cast concrete wall; ultra high performance concrete (UHPC) pre-cast panels (textured) Stucco wall Concrete or masonry wall; two layers stucco Enclosure Systems 95 09 1 2 WINDOWS AND GLAZING 3 4 5 6 Caulk: Sealant that ills a void. Condensation: Process in which water vapor from the air, coming into contact with a cold surface like glass, condenses and forms a foggy effect. 7 8 9 10 Convection: Transfer of heat by air movement. Desiccant: Porous crystalline substance used in the air space of insulating glass units to absorb moisture and solvent vapors from the air. 11 12 13 14 15 16 Dew point: Calculated temperature at which water vapor will condense. Dual-sealed units: Sealed insulating glass units with a primary seal and a secondary outer seal. Emissivity: Relative ability of a surface to absorb and emit energy in the form of radiation. 18 Gas-filled units: Insulating glass units with a gas instead of air in the air space, used to decrease the thermal conductivity U value. 19 Glaze: To it a window frame with glass. 20 Grille: Decorative grid installed on or between glass lites, meant to look like a muntin bar, but without actually dividing the glass. 17 21 22 23 24 25 26 27 Light (or lite): Unit of glass in a window or door, enclosed by the sash or muntin bars. Sometimes spelled lite to avoid confusion with visible light; also called a pane. Mullion: Horizontal or vertical member holding together two adjacent lites of glass or sash. Muntin bar: Strip that separates panes of glass in a sash. Passive solar gain: Solar heat that is captured naturally as it passes through a material. R-value: Measure of the overall resistance to heat transmission due only to the difference in air temperature on either side of the material. See U-value. Radiation: Process by which heat is emitted from a body through open space, as in sunlight. Sash: Frame that holds glass lites and into which glass products are glazed. Shading coefficient: Relative measurement of the total amount of solar energy that enters a building space through its glass, as the ratio of the solar heat gain through a speciic glass product to the solar heat gain through a lite of 1/8” (3) clear glass. Glass of 1/8” (3) thickness is given a value of 1.0. The lower the shading coeficient number, the lower the amount of solar heat transmitted. Tempered glass: Specially heat-treated high-strength safety glass. Thermal performance: Ability of a glass unit to perform as a barrier to the transfer of heat. Total solar energy: Total solar spectrum composed of UV, visible, and near infrared wavelengths. U-value: Measure of thermal conductance; the reciprocal of R-value. Ultraviolet (UV): Type of radiation in wavelengths shorter than those of visible light and longer than those of X rays. Visible light: Portion of solar energy detected by the human eye as light. 28 29 30 96 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 09 WINDOW TYPES Fixed Double-hung Sliding Awning Single-hung Casement Hopper Sliding Doors Skylight French Doors Terrace Door Roof Window Enclosure Systems 97 09 1 Window Sizing 2 A typical chart from a window manufacturer’s catalog depicts stock sizes and types of windows (in feet and inches). Mas Opg (masonry opening) is the opening that must be provided for a brick, block, or stone wall; Rgh Opg (rough opening) is the opening required for typical stud walls; Sash Opg (sash opening) is the size of the window itself; and Glass Size is the size of the glass. 3 4 5 6 7 8 9 10 11 Mas Opg Rgh Opg Sash Opg Glass Size 12 13 head 2’-8 1/2” 2’-6 3/8” 2’-4” 24” decorative grille 14 3’-6 1/2” 3’-5 3/4” 3’-2” 16” 16 17 meeting rail 18 19 lite/pane 20 21 22 sash 23 4’-2 1/2” 4’-1 3/4” 3’-10” 20” 24 25 26 27 Double-hung Window 28 29 30 98 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK rough opening double layer of glass 15 09 Punched opening Window wall Window system ‘rests’ on loor Curtain wall Window system slides past loor and is anchored to structure Curtain wall Spandrel panel covers edge of loor Enclosure Systems 99 09 1 2 WINDOW CONSIDERATIONS 3 4 casement interior screen 5 6 7 casement + fixed interior screen 8 slider exterior screen or interior screen double hung exterior screen fixed no screen (space above windows ideal for window treatments) 9 10 11 12 13 14 15 (no wall space for window treatments if windows end at ceiling) 16 17 18 19 20 21 22 fixed tempered (begins below 24” AFF) 23 24 25 fixed max. size 72 sf. for single insulated unit (typ.) 26 27 28 29 Interior 30 100 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK hoppers tempered or solid if under 24” AFF (check local codes) 09 Exterior Enclosure Systems 101 09 1 2 3 4 5 6 7 GLASS AND GLAZING Most architectural glass comprises three major raw materials that are found naturally: silica, lime, and sodium carbonate. Secondary materials may be added to facilitate the glass-making process or to give the glass special properties, which can be broken into three basic categories. Soda-lime glass accounts for the majority of commercially produced glass. Used for bottles, glassware, and windows, its composition of silica, soda, and lime does not give it good resistance to sudden thermal changes, especially high temperatures, or to chemical corrosion. Lead glass contains about 20 percent lead oxide, and its soft surface makes it ideal for decorative cutting and engraving, though it does not withstand sudden temperature changes. Borosilicate glass, which refers to any silicate glass with a composition of at least 5 percent boric oxide, has greater resistance to thermal changes and chemical corrosion. 8 9 10 11 12 13 14 15 16 17 18 Glass Production The most common lat glass is loat glass, in which properly weighed and mixed soda lime glass, silica sand, calcium, oxide, soda and magnesium are melted in a 2,732°F (1,500°C) furnace. The highly viscous molten glass is loated across a bath of molten tin in a continuous ribbon. Because the tin is very luid, the two materials do not mix, creating a perfectly lat surface between them. By the time the glass has left the molten tin, it has cooled enough to proceed to a lehr, where it is annealed, that is, cooled slowly under controlled conditions. 19 20 21 22 23 Glass may also be rolled, a process by which semimolten glass is squeezed between metal rollers to form a ribbon with predeined thicknesses and patterned surfaces. This process is used mostly for patterned and cast-glass production. Nominal Thickness Actual Range 3/32” single 0.085”–0.101” (2.16–2.57) strength laminate 0.102”–0.114” (2.59–2.90) 1/8” double 0.115”–0.134” (2.92–3.40) strength 5/32” 0.149”–0.165” (3.78–4.19) 3/16” 0.180”–0.199” (4.57–5.05) 7/32” 0.200”–0.218” (5.08–5.54) 1/4” 0.219”–0.244” (5.56–6.20) 5/16” 0.292”–0.332” (7.42–8.43) 3/8” 0.355”–0.406” (9.02–10.31) 1/2” 0.469”–0.531” (11.91–13.49) 5/8” 0.595”–0.656” (15.09–16.66) 3/4” 0.719”–0.781” (18.26–19.84) 1” 0.969”–1.031” (24.61–26.19) 11/4” 1.125”–1.375” (28.58–34.93) 24 25 26 27 Glass Thickness Sheet size, wind, and other loads determine the required glass thickness for any particular window. 28 29 30 102 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 09 GLASS FORMS Glass Block: Glass blocks are considered to be masonry units. Typical units are made by fusing together two hollow halves, with a vacuum inside. Solid blocks, called glass bricks, are impact resistant but can be seen through. Solar control units may have coatings or inserts. Glass block walls are constructed in a similar fashion to other masonry walls, with mortar, metal anchors, and ties; they can be applied to interiors or exteriors. Customary Sizes 4 1/2” x 4 1/2” 5 3/4” x 5 3/4” (nominal 6” x 6”) 7 1/2” x 7 1/2” 7 3/4” x 7 3/4” (nominal 8” x 8”) 9 1/2” x 9 1/2” 11 3/4” x 11 3/4” (nominal 12” x 12”) 3 3/4” x 7 3/4” (nominal 4” x 8”) 5 3/4” x 7 3/4” (nominal 6” x 8”) 9 1/2” x 4 1/2” thickness: 3”– 4” Preferred SI Sizes 115 x 115 mm 190 x 190 mm 240 x 240 mm 300 x 300 mm 240 x 115 mm thickness: 80–100 mm Cast or Channel Glass: U-shaped linear glass channels are selfsupporting and contained within an extruded metal perimeter frame. One or two interlocking layers may be used, creating varying levels of strength, sound and thermal insulation, and translucence. Glass thicknesses are roughly 1/4” (6–7); channel widths range from 9” (230) to 19” (485), with heights varying depending on widths and wind loads. Cast glass can be employed vertically or horizontally, internally or externally, and as a curved surface. The glass itself can be made with wires, tints, and other qualities. Double layers of channels provide a natural air space that can be illed with aerogel, a lattice-work of glass strands with small pores, which results in an insulating substance that is 5 percent solid and 95 percent air. Enclosure Systems 103 09 1 2 3 4 5 6 7 8 9 10 11 GLASS TYPES Insulating Glass: Two or more panes of glass enclose a hermetically sealed air space and are separated by a desiccantilled spacer that absorbs the internal moisture of the air space. The multiple layers of glass and air space of these insulating glass units (IGUs) drastically reduce heat rates. Low-E or other coatings may be used on one or more of the glass surfaces to further improve thermal performance. Argon and sulfur hexaluoride gases may ill the space between glass sheets for even further eficiency as well as reduced sound transmission. Standard overall thickness for a double-glazed IGU is 1” (25.4), with 1/4” (6) thick glass and a 1/2” (13) air space. Numbers in bubbles represent glass surface numbers, beginning with 1 on the exterior face. 2 4 air space 1 3 spacer exterior interior 12 13 14 15 16 Reflective Glass: Ordinary loat glass (clear or tinted) is coated with metal or metal oxide to reduce solar heat. The coating also produces a one-way mirror effect, generally with the mirror on the exterior. Shading coeficients depend on the density of the metallic coating and range from about 0.31 to 0.70. 17 18 Low-E Glass: Low emissivity is clear loat glass with a microscopically thin metal oxide coating that reduces U-value by suppressing radiative heat low and blocking short wave radiation to impede heat gain. At the same time, it provides for light transmission, low relection, and reduced heat transfer. Generally, Low-E glass can be cut, laminated, or tempered. It is produced in soft-coat (vacuum or sputter coated) or hard-coat (pyrolitic) versions. 19 20 21 22 23 24 25 26 Body-Tinted Glass: Chemical elements added to the molten glass mixture produce a variety of colors. The visible light transmitted depends on the color and ranges from about 14 percent for very dark colors to 75 percent for light colors. (Clear glass has about an 85 percent light transmission.) Shading coeficients range from 0.50 to 0.75, meaning that they transmit 50 to 75 percent of the solar energy that would be transmitted by doublestrength clear glass. Colorant Glass Colors Cadmium sulide yellow Carbon and sulfur brown, amber Cerium yellow Chromium green, pink, yellow Cobalt blue, green, pink Copper blue, green, red Iron blue, brown, green Manganese purple 27 Nickel purple, yellow 28 Selenium pink, red Titanium brown, purple Vanadium blue, gray, green 29 30 104 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 09 09 Safety Glass Specialty and Decorative Glasses Tempered Glass: Annealed glass is cut and edged before being reheated at about 1,200°F (650°C). If the glass is cooled rapidly, it is considered to be fully tempered; the glass can be up to four times as strong as annealed glass, and, when broken, it shatters into small, square-edged granules instead of into sharp shards. If cooled slowly, the glass is twice as strong as annealed glass, and the broken pieces are more linear but tend to stay in the frame. The slower process is also much less expensive. Tempered glass is ideal for loor-to-ceiling glass, glass doors, walls of squash courts, and walls exposed to heavy winds and intense temperatures. Photovoltaic Glass: Solar cells are embedded in special resin between panes of glass. Each cell is electrically connected to the other cells, converting solar energy into an electrical current. Chemically Strengthened Glass: Glass is covered by a chemical solution that produces a higher mechanical resistance, giving the glass similar properties to thermal-strengthened (tempered) glass. Laminated Glass: Interlayers of plastic or resin are sandwiched between two sheets of glass and the layers are bonded together under heat and pressure. When the glass breaks, the laminate interlayer holds the fragments together, making it ideal for use in overhead glazing, stair railings, and store fronts. Security glass (bullet-proof) is made of multiple layers of glass and vinyl, in many thicknesses. Wired Glass: A wire mesh is sandwiched between two ribbons of semimolten glass, which are squeezed together through a pair of metal rollers. When the glass breaks, the wire holds it in place. Wire glass is often acceptable for windows in ire doors and walls. X-ray Protection Glass: Used primarily in medical or other radiology rooms, X-ray glass has high levels of lead oxide that reduce ionizing radiation. X-ray glass can be laminated and used in single- or double-glazed units. Electrically Heated Glass: Polyvinyl butyral (PVB) ilms are pressed between two or more sheets of glass. Electrically conductive wires heat the glass, making it useful in areas of high moisture content or with extreme differences between indoor and outdoor temperatures. Self-cleaning Glass: Float glass is given a photocatalytic coating on the exterior that reacts to ultraviolet rays to break down organic dirt. Hydrophilic properties also cause rain to low down the glass as a sheet, washing away the dirt. Enameled/Screen-printed Glass: Special mineral pigments are deposited on one face of the glass surface before tempering or annealing. A variety of colors and patterns may be applied for decorative purposes. Enameled glass can also be used as a solar-ray conductor. Sand-blasted Glass: A translucent surface is produced by spraying sand at high velocity over the surface of the glass, which may be done in decorative patterns or in varying depths and translucencies, depending on the force and type of sand. Acid-etched Glass: One side of loat glass is acid-etched, giving a smoother inish than achieved by sand-blasting. Antireflective Glass: Float glass is given a coating that relects very small amounts of light. Enclosure Systems 105 STANDARDS 3. MEASURE AND DRAWING For an architect’s ideas to evolve into fully considered designs, they require constant evaluation, investigation, and experimentation. Scribbled notes and sketches are quickly put to the test as real scales and measures are applied; lat plans grow into volumes, and spaces are examined inside and out. To become built form, ideas must be communicated to the various groups involved in the design process, and so the architect embarks on a cycle of production and presentation. For presentation to the client whose building this will become, communication can take the form of sketches, cardboard models, computer models, and digital animations—whatever is needed to ensure that the design is understood. In preparing such materials, the architect often discovers new aspects of the design that prompt further study and presentation. For construction, the architect prepares documents to certain standards. Technical measured drawings describe everything necessary to erect the building. Depending on the size of the project, many other parties will also be involved, from structural and mechanical engineers to electrical engineers and lighting designers. Each of these trades also produces construction documents speciic to their work and coordinated with the entire set. In every case, these drawings and written speciications must be clear and precise to ensure a wellbuilt structure. 10 Chapter 10: Measurement and Geometry The two primary measurement systems used in the world today are the metric system, also known as the Système International d’Unités and commonly abbreviated to SI in all languages, and the U.S. customary units system, referred to in the United States as English units or standard units. The latter is an irregular system based on imperial units once used in the United Kingdom and the British Commonwealth. The metric system has become the universally accepted system of units in science, trade, and commerce. In the United States, however, where the Metric Conversion Act of 1975 established SI as the preferred system of weights and measures for trade and commerce, federal laws have yet to mandate SI as the oficial system, making its use still primarily voluntary. Several U.S. agencies, including the American National Metric Council (ANMC) and the United States Metric Association (USMA), are working to establish SI as the oficial measurement system, a process known as metrication. Though the architectural, engineering, and building trades have been slow to make a full transition, nearly all federally funded building projects are now required to be in SI units. UNITS OF MEASURE: CUSTOMARY UNIT DATA Customary units may be shown in a number of ways, including as fractions (11/2”) or as decimals (1.5” or 0.125’), depending on the more common usage for a particular situation. It should be noted that, though not the case here, exponents can be used with abbreviations that designate area or volume; for example, 100 ft.2 for area or 100 ft.3 for volume. Linear Equivalents Customary Unit of Measure Relation to Other Customary Units inch (in. or “) 1/12 foot (ft. or ‘) 12 in. 1/3 yd. yard (yd.) 36 in. 3 ft. rod (rd.), pole, or perch chain furlong mile (mi.), statute mile (mi.), nautical 108 108 Area Equivalents ft. 16 1/2 ft. 5 1/2 yd. 4 rd. 22 yd. Customary Unit of Measure square inch (sq. in.) 0.007 (1/142) sq. ft. square foot (sq. ft.) 144 sq. in. square yard (sq. yd.) 1,296 sq. in. 9 sq. ft. square pole 30 1/4 sq. yd. 220 yd. or 40 rd. or 10 chains or 1/8 mi. 5,280 ft. or 1,760 yd. or 8 furlongs 2,025 yd. THE ARCHITECTURE ARCHITECTURE REFERENCE REFERENCE ++ SPECIFICATION SPECIFICATION BOOK BOOK THE Relation to Other Customary Units acre 43,560 sq. ft. 40 rd. (1 furlong) x 4 rd. (1 chain) square mile (sq. mi.) 640 acres 10 Fraction to Decimal Equivalents Fraction Decimal 1/32 0.03125 1/16 0.0625 3/32 0.0938 METRIC CONVERSION Conversion Factors for Length Customary Metric 1 in. 25.4 mm 1/ 8 0.1250 1 ft. 0.304 8 m or 304.8 mm 5/32 0.1563 1 yd. 0.914 4 m 3/16 0.1875 1 mi. 1.609 344 km 7/32 0.2188 1/ 4 0.2500 9/32 0.2813 5/16 0.3125 11/32 0.3438 3/ 8 13/32 7/16 15/32 Customary Metric 1 sq. in. 645.16 mm2 0.3750 1 sq. ft. 0.092 903 m2 0.4063 1 sq. yd. 0.836 127 m2 0.4375 1 acre 0.404 686 ha or 4 046.86 m2 1 sq. mi. 2.590 00 km2 0.4688 1/ 2 0.5000 17/32 0.5313 9/16 0.5625 19/32 0.5938 5/8 0.6250 Metric 21/32 Conversion Factors for Length Customary 0.6563 1 micrometer (µm) 0.0000394 in. or 0.03937 mils 11/16 0.6875 1 mm 0.0393701 in. 23/32 0.7188 1m 3.28084 ft. or 1.09361 yd. 3/ 4 0.7500 1 km 0.621371 mi. 25/32 0.7813 13/16 0.8125 27/32 0.8438 7/ 8 0.8750 Metric Customary 29/32 0.9063 1 mm2 0.001550 sq. in. 15/16 0.9375 31/32 0.9688 1/ 1 1.0000 Conversion Factors for Area 1m 2 10.7639 sq. ft. or 1.19599 sq. yd. 1 ha 1 km 2.47105 acres 2 0.368102 sq. mi. Measurement and Geometr y 109 10 UNITS OF MEASURE: SI METRIC UNIT DATA The General Conference on Weights and Measures (abbreviated to CGPM from the French Conférence Générale des Poids et Mesures), which meets every four years concerning issues related to the use of the metric system, has established speciic rules for use, type style, and punctuation of metric units. The National Institute of Standards and Technology (NIST)—formerly the National Bureau of Standards (NBS)—determines metric usage in the United States. Millimeters are the preferred unit for dimensioning buildings, with no symbol necessary if they are used consistently. Meters and kilometers are reserved for larger dimensions such as land surveying and transportation. Unit names and symbols employ standard, lowercase type, except for symbols derived from proper names (for example, N for newton). Another exception is L for liter, to avoid confusing the lowercase l with the numeral 1. Preixes describing multiples and submultiples are also lowercase, except for M, G, and T (mega-, giga-, and tera-), which are capitalized in symbol form to avoid confusion with unit symbols, but which maintain the lowercase standard when spelled out. No space is left between the preix and the letter for the unit name (mm for millimeter and mL for milliliter). A space is left between the numeral and the unit name or symbol; for example, 300 mm. Linear Metric Equivalents Millimeters (mm) Centimeters (cm) Decimeters (dm) Meters (m) Decameters (dam) 1 0.1 0.01 0.001 10 1 0.1 0.01 Hectometers (hm) Kilometers (km) 0.000 1 0.000 01 0.000 001 0.001 0.000 1 0.000 01 100 10 1 0.1 0.01 0.001 0.000 1 1 000 100 10 1 0.1 0.01 0.001 10 000 1 000 100 10 1 0.1 0.01 100 000 10 000 1 000 100 10 1 0.1 1 000 000 100 000 10 000 1 000 100 10 1 Area Metric Equivalents Square Millimeters (mm2) Square Centimeters (cm2) Square Decimeters (dm2) Ares Hectares (ha) 1 0.0 1 0.001 0.000 001 100 1 0.01 0.000 1 0.000 001 10 000 100 1 0.01 0.000 1 0.000 001 1 000 000 110 Square Meters (m2) Square Kilometers (km2) 10 000 100 1 0.01 0.000 1 0.000 001 1 000 000 10 000 100 1 0.01 0.000 1 1 000 000 10 000 100 1 0.01 1 000 000 10 000 100 1 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 10 Although the United States and Canada mark the decimal with a point, other countries use a comma (for example: 5,00 vs. 5.00). For this reason, commas should not be used to separate groups of digits. Instead, the digits should be separated into groups of three, both to the left and the right of the decimal point, with a space between each group of three digits (for example, 1,000,000 is written as 1 000 000). This convention for metric units is used throughout the book. Units with Compound Names Physical Quantity Unit Symbol Area in Metrics Area square meter m2 Volume cubic meter m3 Density kilogram per cubic meter kg/m3 Velocity meter per second m/s SI metric units for area, like volume, are derived from the base units for length. They are expressed as powers of the base unit: for example, square meter = m2 = 106 mm2. Angular velocity radian per second rad/s Acceleration meter per second squared m/s2 Angular acceleration radian per second squared rad/s2 Volume rate of flow cubic meter per second m3/s Moment of inertia kilogram meter squared kg m2 Moment of force newton meter Nm Intensity of heat flow watt per square meter W/m2 Thermal conductivity watt per meter kelvin W/m K Luminance candela per square meter cd/m2 The square centimeter is not a recommended unit for construction and should be converted to square millimeters. The hectare is acceptable only in the measurement of land and water. When area is expressed by linear dimensions, such as 50 x 100 mm, the width is written irst and the depth or height second. SOFT AND HARD CONVERSIONS Conversions of customary and SI units can be either “soft” or “hard.” In a soft conversion, 12 inches equals 305 millimeters (already rounded up from 304.8). In a hard conversion of this same number, 12 inches would equal 300 millimeters, which makes for a cleaner and more rational equivalency. This is the ultimate goal of total metrication within the building trades. The process, however, is an extensive one, which will require many building products whose planning grid is in customary units to undergo a hard metric conversion of their own, making 6 inches equal 150 millimeters (instead of 152) and 24 inches equal 600 millimeters (instead of 610). Thus, to conform to a rational metric grid, the actual sizes of standard products such as drywall, bricks, and ceiling tiles will need to change. Every attempt has been made in this book to represent accurately the relationship between customary and SI units. Except where noted, soft conversions are used throughout and, due to constraints of space, are usually written as follows: 1’-6” (457). Measurement and Geometr y 111 10 METRIC CONVERSION Feet and Meters Scale Inches and Millimeters Scale (1:1) 152.4 mm 6” 304.8 mm 12” 150 mm ➔ 300 mm 11 13/16” 140 mm 130 mm 5” 290 mm 127.0 mm 11” 120 mm 4” 100 mm 260 mm 101.6 mm 250 mm 240 mm 80 mm 9” 76.2 mm 70 mm 50 mm 8” 50.8 mm 203.2 mm 200 mm 7 7/8” 190 mm 30 mm 25.4 mm 7” 20 mm 180 mm 160 mm 6” 150 mm THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 177.8 mm 170 mm 10 mm 112 228.6 mm 210 mm 40 mm 1” 230 mm 220 mm 60 mm 2” 254.0 mm 10” 90 mm 3” 279.4 mm 270 mm 110 mm 3 15/16” 280 mm 152.4 mm 10 165’ 82.0’ 25 m 50 m 164.0’ 160’ 80’ 45.7 m 150’ 70’ 45 m 147.6’ 20 m 65.6’ 140’ 60’ 131.2’ 40 m 15.2 m 50’ 130’ 15 m 49.2’ 40’ 120’ 35 m 32.8’ 10 m 114.8’ 110’ 30’ 30.5 m 20’ 100’ 30 m 96.4’ 16.4’ 5m 15’ 10’ 90’ 5’ 25 m 82.0’ 0 0 Feet Inches 1 12 2 24 3 36 4 48 5 60 6 72 7 84 8 96 9 108 10 120 11 132 12 144 13 156 14 168 15 180 16 192 17 204 18 216 19 228 20 240 21 252 22 264 23 276 24 288 25 300 26 312 27 324 28 336 29 348 30 360 31 372 32 384 33 396 34 408 35 420 80’ Measurement and Geometr y 113 10 SLOPES AND PERCENTAGE GRADE Note: Entries in blue indicate frequently used slopes. Slopes gentler than 1:20 do not require handrails; 1:12 is the maximum ADA-approved slope for ramps and 1:8 is the maximum code-approved slope for ramps (non-ADA). Degrees 114 Gradient % Grade Degrees Gradient % Grade Degrees Gradient % Grade 0.1 1:573.0 0.2 23.0 1:2.4 42.4 57.0 1: 0.6 154.0 0.2 1:286.5 0.3 24.0 1:2.2 44.5 58.0 1: 0.6 160.0 0.3 1:191.0 0.5 25.0 1:2.1 46.6 59.0 1: 0.6 166.4 0.4 1:143.2 0.7 26.0 1:2.1 48.8 60.0 1: 0.6 173.2 0.5 1:114.6 0.9 27.0 1:2.0 51.0 61.0 1: 0.6 180.4 0.6 1:95.5 1.0 28.0 1:1.9 53.2 62.0 1: 0.5 188.1 0.7 1:81.8 1.2 29.0 1:1.8 55.4 63.0 1: 0.5 196.2 0.8 1:71.6 1.4 30.0 1:1.7 57.7 64.0 1: 0.5 205.0 0.9 1:63.7 1.6 31.0 1:1.7 60.1 65.0 1: 0.5 214.5 1.0 1:57.3 1.7 32.0 1:1.6 62.5 66.0 1: 0.4 224.6 2.0 1:28.6 3.5 33.0 1:1.5 64.9 67.0 1: 0.4 235.6 2.86 1:20.0 5.0 34.0 1:1.5 67.5 68.0 1: 0.4 247.5 3.0 1:19.1 5.2 35.0 1:1.4 70.0 69.0 1: 0.4 260.5 4.0 1:14.3 7.0 36.0 1:1.4 72.7 70.0 1: 0.4 274.7 4.76 1:12.0 8.3 37.0 1:1.3 75.4 71.0 1: 0.3 290.4 5.0 1:11.4 8.7 38.0 1:1.3 78.1 72.0 1: 0.3 307.8 6.0 1:9.5 10.5 39.0 1:1.2 81.0 73.0 1: 0.3 327.1 7.0 1:8.1 12.3 40.0 1:1.2 83.9 74.0 1: 0.3 348.7 7.13 1:8.0 12.5 41.0 1:1.2 86.9 75.0 1: 0.3 373.2 8.0 1:7.1 14.1 42.0 1:1.1 90.0 76.0 1: 0.2 401.1 9.0 1:6.3 15.8 43.0 1:1.1 93.3 77.0 1: 0.2 433.1 10.0 1:5.7 17.6 44.0 1:1.0 96.6 78.0 1: 0.2 470.5 11.0 1:5.1 19.4 45.0 1:1.0 100.0 79.0 1: 0.2 514.5 12.0 1:4.7 21.3 46.0 1:1.0 103.6 80.0 1: 0.2 567.1 13.0 1:4.3 23.1 47.0 1: 0.9 107.2 81.0 1: 0.2 631.4 14.0 1:4.0 24.9 48.0 1: 0.9 111.1 82.0 1: 0.1 711.5 15.0 1:3.7 26.8 49.0 1: 0.9 115.0 83.0 1: 0.1 814.4 16.0 1:3.5 28.7 50.0 1: 0.8 119.2 84.0 1: 0.1 951.4 17.0 1:3.3 30.6 51.0 1: 0.8 123.5 85.0 1: 0.1 1,143.0 18.0 1:3.1 32.5 52.0 1: 0.8 128.0 86.0 1: 0.1 1,430.1 19.0 1:2.9 34.4 53.0 1: 0.8 132.7 87.0 1: 0.1 1,908.1 20.0 1:2.7 36.4 54.0 1: 0.7 137.6 88.0 1: 0.0 2,863.6 21.0 1:2.6 38.4 55.0 1: 0.7 142.8 89.0 1: 0.0 5,729.0 22.0 1:2.5 40.4 56.0 1: 0.7 148.3 90.0 1: 0.0 ∞ THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 10 Calculating Slope Degrees: Slope = Vertical Rise Distance (V) = tangent m Horizontal Distance (H) Slope Angle = tangent m Calculating Gradient: = 1 unit in Vertical Distance (V) = 100 x Tangent (Slope) or 100 x V/H 90° Calculating % Grade: Horizontal Distance (H) 45 ° 60 ° ∞ 0% 10 % Vertical Distance (V) 90 % 80 ° 30 % 70 % 60 50% 40% 30% 20% 10% 1 2 3 4 5 6 7 8 9 10 12 15 20 Horizontal Distance (H) Measurement and Geometr y 115 10 PLANE FIGURE FORMULAS Rectangle Equilateral Triangle (all sides equal) a cc a b h a area = ab perimeter = 2(a+b) a2 + b2 = c2 a area = a2! 3 = 0.433 a2 4 perimeter = 3a Parallelogram a h = 2 !3 = 0.866a Triangle b a h h U area = ah = ab sinU perimeter = 2(a+b) b bh area = 2 perimeter = sum of length of all sides Trapezium Trapezoid (irregular quadrilateral) b c d b h h e a h1 g f a area = (a+b) h 2 perimeter = sum of length of sides area = (h + h1) g + eh + fh1 2 perimeter = sum of length of all sides Quadrilateral or h dd22 U d1 2 b h 3 area = bh2 + bh3 2 2 area = d1d2 sinU 2 116 116 THE THE ARCHITECTURE ARCHITECTURE REFERENCE REFERENCE ++ SPECIFICATION SPECIFICATION BOOK BOOK (Divide igure into two triangles and add their areas together.) 10 VOLUMES Regular Polygons (all sides equal) a Prism or Cylinder (right or oblique, regular or irregular) volume = area of base x altitude R r Altitude (h) = distance between parallel bases, measured perpendicular to the bases. When bases are not parallel, then altitude = perpendicular distance from one base to the center U of the other. h n = number of sides nR2 sin 2U nar area = = nr2 tan U = 2 2 perimeter = n a h Polygon Sides Pyramid or Cone (right or oblique, regular or irregular) Area Triangle (equilateral) 3 0.4330 a2 Square 4 1.0000 a2 Pentagon 5 1.7205 a2 Hexagon 6 2.5981 a 2 Heptagon 7 3.6339 a2 Octagon 8 4.8284 a2 Nonagon 9 6.1818 a2 Decagon 10 7.6942 a2 Undecagon 11 9.3656 a2 Dodecagon 12 11.1962 a2 h volume = area of base x 1/3 altitude Altitude (h) = h distance from base to apex, measured perpendicular to base. h h Measurement and Geometr y 117 10 CIRCLE c a m circumference = 2 p r = p d = 3.14159 d U 2 area = pr2 = p d = 0.78539d2 4 p length of arc a = U 180 r = 0.017453 U r r 2 r= d m2 + c /4 c/2 = 2m sin 1/2U c = 2!2 mr – m2 = 2 r sin 1/2U a = arc r = radius d = diameter c = cord m = distance U = degrees p = 3.14159 2 2 m = r +_ !r – c 4 use + if arc >_ 180˚ use – if arc < 180˚ D A C U A C r U B Sector of Circle arc length AC = prU 180 pU r2 360 or area ABCA = arc length AC x r 2 118 118 2 3 B area ABCA = r 1 Segment of Circle Circular Zone area ACDA = pU – sinU r2 x 2 180 area 2 = circle area – area 1 – area 3 r = radius U = degrees A, B, C, D = points p = 3.14159 1 = segment 2 = zone 3 = segment 1 THE THE ARCHITECTURE ARCHITECTURE REFERENCE REFERENCE ++ SPECIFICATION SPECIFICATION BOOK BOOK 2 10 ELLIPSE A perimeter (approximate) = p [1.5 (x + y) – !x y] B y (Assume point G is the center point of the ellipse, with x,y coordinates of 0,0, and point B coordinates of Bx and By.) G [BG-22-MS.live] d area ABFEA = (Bx x By) + ab sin-1 (Bx /a) F E x D DOUBLE-CURVED SOLIDS Sphere Ellipsoid volume = R 4 p R3 3 surface = 4 p R2 a Segment of Sphere C volume = b R p b2 (3R–b) 3 (sector – cone) b surface = 2 p R b c volume = Sector of Sphere p abc 6 surface = no simple equation C volume = b R 2p R2 b 3 surface = p R(4b + C) 2 (segment + cone) Measurement Measurements and Geometr 119 y 119 11 Chapter 11: Architectural Drawing Types An architect uses eight basic drawing types within the drawing set to most completely describe the design of a building. PLAN View of the horizontal planes of the building, showing their relationship to each other. A plan is a horizontal section, typically depicting the building as though cut approximately 3’-0” (915) from its loor. SECTION View of a vertical cut through the building’s components. A section acts as a vertical plan and often contains elevational information, such as doors and windows. This information is shown with a lighter line weight than the section cuts. 120 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 11 ELEVATION View of the vertical planes of the building, showing their relationship to each other. An elevation is viewed perpendicularly from a selected plane. THREE-DIMENSIONAL REPRESENTATIONS Perspectives (not scaled), axonometrics, and isometrics describe the building or space in a way that conventional plans, elevations, and sections cannot. Perspectives are particularly effective in producing a view that would actually be experienced by being in the space designed. Architectural Drawing Types 121 11 READING THE DRAWING SET Drawing Symbols Symbols and reference markers are necessary for navigating the drawing set. They tell whoever is looking at a drawing where to go to ind out more information about certain elements. DET SHT DET SHT building section wall or detail section DET SHT detail section (nondirectional) DET SHT partition type north arrow column grid and bubbles enlarged detail reference DET SHT centerline FIRST FLOOR EL. elevation target drawing label DET SHT DET SHT First Floor Plan exterior elevation graphic scale interior elevation break line OFFICE room name and room number ceiling height revision cloud and number window number spot elevation align note door number 122 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK ALIGN 11 Floor Plans Overall building plans are usually drawn at a scale that enables one to see the whole plan. Most elements of the overall plan are keyed to other drawings in the set, as in the case of larger-scale plans, details, sections, and elevations. Some information may be keyed and cross-referenced among multiple drawings. Keys shown on the plan below reappear on the drawings to follow. CARPORT DRIVEWAY BENCH KITCHEN PATIO LIVING POOL BATH BED ROOM PATIO BED ROOM First Floor Plan Architectural Drawing Types 123 11 Building Elevations Building elevations depict the exterior conditions of the building, describing materials and important vertical dimensions. In instances where a drawing is too large to it on a standard sheet, it must be broken apart and continued on the same sheet or another sheet, requiring the use of match lines for alignment. T.O. ROOF FIRST FLOOR POOL PRECAST CONC. PANELS West Elevation T.O. ROOF FIRST FLOOR POOL East Elevation 124 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK PRECAST CONC. PANELS MATCH LINE MATCH LINE MATCH LINE T.O. ROOF MATCH LINE 11 FIRST FLOOR POOL MATCH LINE MATCH LINE North Elevation (Partial) CHANNEL GLASS PRECAST CONC. PANELS MATCH LINE MATCH LINE PRECAST CONC. PANELS North Elevation (Partial) EXTERIOR BUILDING ELEVATIONS Architectural Drawing Types 125 11 Doors and most windows do not appear on an RCP, but their headers do. Reflected Ceiling Plans Relected ceiling plans (RCPs) may be thought of as upside-down loor plans, for they are literally a plan of the ceiling. They are used to describe light ixture placement and types, ceiling heights and materials, and anything else found on the ceiling plane. RCPs employ standard keys and symbols as well as some speciic to the ceiling plan. Site information is not present on an RCP (unless it happens overhead). KITCHEN Light ixtures often bear tags that refer to their descriptions in the lighting speciications. return-air diffuser CARPORT 2 x 4 luorescent GWB supply-air diffuser 2 x 2 recessed luorescent Elevation markers call out the height and material of the ceiling planes. LIVING smoke detector luorescent pendant BATH WOOD SOFFIT smoke detector w/ audible device decorative pendant ADA light/ speaker BED ROOM ceiling-mounted exit sign wall-mounted exit sign recessed wall washer PLYWOOD recessed downlight BED ROOM ceiling sprinkler head wall sconce wall sprinkler head Mylar-coated ACT 126 ACT THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Relected Ceiling Plan 11 Interior Elevations Interior elevations are drawn at a larger scale than the overall building plans, allowing for more details, notes, and dimensions to be represented. Keyed from the building plan, interior elevations are, in turn, keyed to other, larger-scale views, such as section and plan details of cabinetry construction and wall sections. PLYWOOD PANELS CHANNEL GLASS WALL BOOKSHELVES SLIDING DOOR ON SSTL TRACK HARDWOOD SHELVING/ROOM DIVIDER UNITS CURTAIN ON TRACK Bedroom Details Details are drawn at scales such as 1 1/2” = 1’-0”, 3”= 1’-0”, 6”= 1’-0”, and sometimes even at full scale, and are keyed from and to numerous other drawings. PLYWOOD PANELS SLIDING DOOR ON SSTL TRACK HARDWOOD SHELVING/ROOM DIVIDER UNITS Bedroom Shelving Architectural Drawing Types 127 11 THREE-DIMENSIONAL DRAWINGS Paraline Drawings Paraline drawings are projected pictorial representations of the three-dimensional qualities of an object. These drawings can be classiied as orthographic projections, with a rotated plan view and a tilted side view. They are also commonly referred to as axonometric or axiometric drawings. Unlike in perspective drawings, the projection lines in a paraline drawing remain parallel instead of converging to a point on the horizon. side side back plan Unfolded Object front Oblique Isometric In an oblique drawing, one face (either plan or elevation) is drawn directly on the picture plane. Projected lines are drawn at a 30- or 45-degree angle to the picture plane. The length of the projecting lines is determined as shown in the diagrams opposite. An isometric drawing is a special type of dimetric drawing, where all axes of the object are simultaneously rotated away from the picture plane and kept at the same angle (30 degrees) of projection. All legs are equally distorted in length and maintain an exact 1:1:1 proportion. Dimetric A dimetric drawing is similar to an oblique drawing, except that the object is rotated so that only one corner touches the picture plane. 128 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Trimetric A trimetric drawing is similar to a dimetric drawing, except that the plan of the object is rotated so that the two exposed sides are not at equal angles to the picture plane. 11 A A A 30° 45° 45° 30° A A A 30º Oblique 45º Oblique A A 15° 15° A A 45° A 45° 30° A 15º Dimetric 45º Dimetric A A 30° Isometric (30º Dimetric) 30° A A 60° 30° 30° A A Trimetric Architectural Drawing Types 129 11 Two-Point Common Method Perspective Station Point (SP): Locates the ixed position of the viewer. Picture Plane (PP): Flat, two-dimensional surface that records the projected perspective image and aligns perpendicular to the viewer’s center of vision. The picture plane is the only true-size plane in the perspective ield: Objects behind the picture plane project to its surface smaller than true scale, whereas those between the viewer and the picture plane project to its surface larger than true scale. Measuring Line (ML): Located on the picture plane, the measuring line is the only true-scale line in a perspective drawing. Most commonly, this is a vertical line from which can be projected the key vertical dimensions of the object. Horizon Line (HL): Lies at the intersection of the picture plane and a horizontal plane through the eye of the viewer. Vanishing Point: Point at which parallel lines appear to meet in perspective. The left (vpL) and right (vpR) vanishing points for an object are determined by the points at which a set of lines originating from the station point and parallel to the object lines intersect the picture plane. Ground Line (GL): Lies at the intersection of the picture plane and the ground plane. pl an PP ML SP HL vpL GL elevation 130 130 THE THEARCHITECTURE ARCHITECTUREREFERENCE REFERENCE++SPECIFICATION SPECIFICATIONBOOK BOOK vpR 11 One-Point Common Method Perspective One-point perspectives use a single vanishing point, and all edges and planes that are perpendicular to the picture plane vanish toward this point. To locate this point (C), draw a vertical line from the station point to the horizon line. Building edges that are parallel to the picture plane appear as parallel lines in perspective, with no vanishing point. PP SP Picture Frame Projections occurring in front of the picture frame will appear distorted. As the station point moves closer to the picture plane, the ield of vision decreases. As the station point moves farther from the picture plane, the ield of vision increases. HL C GL Basic GeometrArchitectural y and Drawing Projections Drawing Types 131 131 12 Chapter 12: Architectural Documents THE PRACTICE OF ARCHITECTURE To speak an architectural language is to do many things: It could involve the art of form and style or the more prosaic aspects of contract administration. Architecture and its practice move, sometimes with effort, among realms not only of art, science, and engineering, but also of business, economics, and sociology. All professional groups speak their own language to some extent. To their written and spoken language architects add drawings and symbols, organizing them into accepted standards of presentation and legibility. As with good manners, the point of these standards is not to complicate but to ease communication and interaction. Most countries have a governing body in architectural practice—in the United States it is the American Institute of Architects (AIA)—which oversees ethics and professional conduct and establishes guidelines for issues ranging from project delivery schedules to contracts and legal documents. The architect who has complete mastery of every aspect of the multiple personalities of architectural practice may be rare. However, all responsible practicing architects are compelled to understand the business of the profession, because the art of architecture depends on the practice of getting it built. COMMON PROJECT TERMS Addendum: Written information that clariies or modiies the bidding documents, often issued during the bidding process. Alternate: Additional design or material options added to the construction documents and/or speciications to obtain multiple possible cost estimates for a project. “Add-alternates” imply added material and cost; “deduct-alternates” imply removal of certain elements to lower the project cost, as necessary. ANSI: American National Standards Institute. 132 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK As-built drawings: Contract drawings that have been marked up to relect any changes to a project during construction, differentiating them from the bid documents. Also known as record drawings. Bid: Offer of a proposal or a price. When a project is “put out to bid,” contractors are asked to submit their estimates as to the time and the cost of a project. Building permit: Written document issued by the appropriate government authority permitting the construction of a speciic project in accordance with the drawings and speciications that the authority has approved. 12 Certificate of occupancy: Document issued by the appropriate local governmental agency, stating that a building or property meets local standards for occupancy and is in compliance with public health and building codes. Change order: Written document between and signed by the owner and the contractor authorizing a change in the work, or an adjustment in the contract sum or length of time. Architects and engineers may also sign a change order, but only if authorized (in writing) by the owner to do so. Charrette: Intensive design process for solving an architectural problem quickly; often undertaken by students of architecture, but also employed by professionals in various stages of the design process. The instructors of the École des Beaux Arts in Paris would use a charrette, French for “small wooden cart,” for collecting the design work of the students after such a process. Construction cost: Direct contractor costs for labor, material, equipment, and services, as well as overhead and proit. Excluded from construction cost are fees for architects, engineers, consultants, costs of land, or any other items that, by deinition of the contract, are the responsibility of the owner. Construction management: Organization and direction of the labor force, materials, and equipment to build the project as designed by the architect. Construction management contract: Written agreement giving responsibility for coordination and accomplishment of overall project planning, design, and construction to a construction management irm or individual, called the construction manager (CM). Consultant: Professional hired by the owner or architect to provide information and to advise the project in the area of his or her expertise. Contract administration: Contractual duties and responsibilities of the architect and engineer during a project’s construction. Contract over- (or under-) run: Difference between the original contract price and the inal completed cost, including all change order adjustments. Contractor: Licensed individual or company that agrees to perform the work as speciied, with the appropriate labor, equipment, and materials. Date of substantial completion: Date certiied by the architect when the work is to be completed. Design-build construction: Arrangement wherein a contractor bids or negotiates to provide design and construction services for the entire project. Estimating: Calculation of the amount of material, labor, and equipment needed to complete a given project. Fast-track construction: Method of construction management in which construction work begins before completion of the construction documents, resulting in a continuous design-construction situation. FF&E: Moveable furniture, ixtures, or equipment that do not require permanent connection to the structure or utilities of a building. Architectural Documents 133 12 Field order: Written order calling for a clariication or minor change in the construction work and not involving any adjustment to the terms of the contract. Project directory: Written list of names and addresses of all parties involved in a project, including the owner, architect, engineer, and contractor. General contractor: Licensed individual or company with prime responsibility for the work. Project manager: Qualiied individual or irm authorized by the owner to be responsible for coordinating time, equipment, money, tasks, and people for all or portions of a project. Indirect cost: Expenses that are not chargeable to a speciic project or task, such as overhead. Inspection list: List prepared by the owner or authorized owner’s representative of work items requiring correction or completion by the contractor; generally done at the end of construction. Also called a punch list. NIBS: National Institute of Building Sciences. Owner-architect agreement: Written contract between the architect and client for professional architectural services. Parti: Central idea governing and organizing a work of architecture, from the French partir “to depart with the intention of going somewhere.” Program: Desired list of spaces, rooms, and elements, as well as their sizes, for use in designing the building. Progress schedule: Line diagram showing proposed and actual starting and completion times in a project. Project cost: All costs for a speciic project, including those for land, professionals, construction, furnishings, ixtures, equipment, inancing, and any other project-related expenses. 134 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Project manual: Detailed written speciications describing acceptable construction materials and methods. Request for Information (RFI): Written request from a contractor to the owner or architect for clariication of the contract documents. Request for Proposal (RFP): Written request to a contractor, architect, or subcontractor for an estimate or cost proposal. Schedule: Plan for performing work; also, a chart or table within the drawing set. Scheme: Chart, diagram, or outline of a system being proposed. Scope of work: Written range of view or action for a speciic project. Shop drawings: Drawings, diagrams, schedules, and other data specially prepared by the contractor or a subcontractor, subsubcontractor, manufacturer, supplier, or distributor to illustrate some portion of the work being done. These drawings show the speciic way in which the particular contractor or shop intends to furnish, fabricate, assemble, or install its products. The architect is obligated by the owner-architect agreement to review and approve these drawings or to take other appropriate action. 12 Site: Location of a structure or group of structures. Soft costs: Expenses in addition to the direct construction cost, including architectural and engineering fees, permits, legal and inancing fees, construction interest and operating expenses, leasing and real estate commissions, advertising and promotion, and supervision. Soft costs and construction costs add up to the project cost. Zoning: Restrictions of areas or regions of land within speciic areas based on permitted building size, character, and uses as established by governing urban authorities. Zoning permit: Document issued by a governing urban authority that permits land to be used for a speciic purpose. Standards of professional practice: Listing of minimum acceptable ethical principals and practices adopted by qualiied and recognized professional organizations to guide their members in the conduct of speciic professional practice. Structural systems: Load-bearing assembly of beams and columns on a foundation. Subcontractor: Specialized contractor who is subordinate to the prime or main contractor. Substitution: Proposed replacement or alternate for a material or process of equivalent cost and quality. Tenant improvements (TIs): Interior improvements of a project after the building envelope is complete. Time and materials (T&M): Written agreement wherein payment is based on actual costs for labor, equipment, materials, and services rendered, in addition to overhead. Value engineering (VE): Process of analyzing the cost versus the value of alternative materials, equipment, and systems, usually in the interest of achieving the lowest total cost for a project. Architectural Documents 135 12 ISO (International Organization for Standardization)—based on one square meter Architectural ANSI (American National Standards Institute) COMMON PAPER SIZES 136 SHEET FOLDING Paper Size Inches Millimeters ANSI-A 8 1/2 x 11 216 x 279 ANSI-B 11 x 17 279 x 432 ANSI-C 17 x 22 432 x 559 ANSI-D 22 x 34 559 x 864 ANSI-E 34 x 44 864 x 1 118 Paper Size Inches Millimeters Arch-A 9 x 12 229 x 305 Arch-B 12 x 18 305 x 457 Arch-C 18 x 24 457 x 610 Arch-D 24 x 36 610 x 914 Arch-E 36 x 48 914 x 1 219 Paper Size Inches Millimeters 4A0 66 1/4 x 93 3/8 1 682 x 2 378 2A0 46 3/4 x 66 1/4 1 189 x 1 682 A0 33 1/8 x 46 3/4 841 x 1 189 A1 23 3/8 x 33 1/8 594 x 841 A2 16 1/2 x 23 3/8 420 x 594 A3 11 3/4 x 16 1/2 297 x 420 A4 8 1/4 x 11 3/4 210 x 297 Paper Size Inches Millimeters B0 39 3/8 x 55 5/8 1 000 x 1 414 B1 27 7/8 x 39 3/8 707 x 1 000 B2 19 5/8 x 27 7/8 500 x 707 B3 13 7/8 x 19 5/8 353 x 500 B4 9 7/8 x 13 7/8 250 x 353 Paper Size Inches Millimeters C0 36 1/8 x 51 917 x 1 297 C1 25 1/2 x 36 1/8 648 x 917 C2 18 x 25 1/2 458 x 648 C3 12 3/4 x 18 324 x 458 C4 9 x 12 1/2 229 x 324 MATERIALS, STRUCTURES, AND STANDARDS Individual sheets that must be folded (for reasons of ile storage or mailing) should be folded in a logical and consistent manner that allows the title and sheet number information to be visible in the bottom-right corner of the folded sheet. Large numbers of sheets are best bound into sets and rolled for shipping or laid lat for storage. 12 DRAWING SHEET LAYOUT AND SET ASSEMBLY In the NIBS Standard sheet layout (in accordance with the National CAD Standard), drawings within a sheet are numbered by coordinate system modules as described below. The graphic or text information modules are known as drawing blocks and their numbers are established by the coordinates for the bottom-left corner of their module. This system enables new drawing blocks to be added to a sheet without having to renumber the existing blocks, saving considerable time once drawings begin to be keyed to other drawings and schedules. note block (when needed) This edge is bound with staples or post binding and covered with paper or tape. D2 E5 A1 The title block may run vertically along the right edge or horizontally along the bottom edge, but the location of the sheet number and title remains in the bottom-right corner, enabling a quick glimpse of all sheets when lipping through the set. Architectural Documents 137 12 DRAWING SET ORDER Typical Order for Disciplines Standards for the order of disciplines in the drawing set may vary within different ofices. The order below is recommended by the Uniform Drawing System (UDS) to minimize confusion among the many trades that will use the set. Note that most projects will not contain all the disciplines listed here, and others might have need for additional, project-speciic disciplines. Cover Sheet Index Sheet(s) H Hazardous Materials C Civil L Landscape S Structural A Architectural I Interiors Q Equipment F Fire Protection P Plumbing M Mechanical E Electrical T Telecommunications R 138 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Resource 12 Typical Order for Sheets within the Architecture Discipline A-0: General A-001 Notes and Symbols A-1: Architectural Floor Plans A-101 A-102 A-103 A-104 A-105 A-106 A-107 First-Floor Plan Second-Floor Plan Third-Floor Plan First-Floor RCP Second-Floor RCP Third-Floor RCP Roof Plan A-2: Architectural Elevations A-201 A-202 A-203 Exterior Elevations Exterior Elevations Interior Elevations A-3: Architectural Sections A-301 A-302 A-303 Building Sections Building Sections Wall Sections A-4: Large-Scale Views A-401 A-402 A-403 Enlarged Toilet Plans Enlarged Plans Stair and Elevator Plans and Sections A-5: Architectural Details A-501 A-502 A-503 A-504 Exterior Details Exterior Details Interior Details Interior Details A-6: Schedules and Diagrams A-601 A-602 A-603 Partition Types Room Finish Schedule Door and Window Schedules Architectural Documents 139 12 DRAWING SET ABBREVIATIONS When all drawings were done by hand, architectural lettering—an art form of its own—could be tedious and time-consuming. As a result, architects and draftspersons abbreviated words. Though many standards were created, they have not always been consistent and historically have led to interpretive errors by contractors. CAD technology makes much shorter work of text production and arrangement and enables less frequent use of abbreviations. If space dictates that abbreviations must be used, omit spaces or periods and capitalize all letters. Though variations still exist, the following is a widely accepted list. ACT: acoustical ceiling tile ADD: additional ADJ: adjustable AFF: above inish loor ALUM: aluminum APPX: approximately BD: board BIT: bituminous BLDG: building BLK: block BLKG: blocking BM: beam BOT: bottom BC: brick course BUR: built-up rooing CB: catch basin CBD: chalkboard CI: cast iron CIP: cast-in-place CJ: control joint CMU: concrete masonry unit CEM: cement CLG: ceiling CLR: clearance CLO: closet COL: column COMP: compressible CONC: concrete CONST: construction CONT: continuous 140 CPT: carpet CRS: courses CT: ceramic tile CUB: column utility box DF: drinking fountain DET: detail DIA: diameter DN: down DR: door DWG: drawing EA: each ENC: enclosure EJ: expansion joint EL: elevation or electrical ELEV: elevator EQ: equal EQUIP: equipment ERD: emergency roof drain EWC: electric water cooler EXIST: existing EXP: expansion EXT: exterior FE: ire extinguisher FEC: ire extinguisher cabinet FHC: ire hose cabinet FD: loor drain THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK FDN: foundation FFT: inished loor transition FIN: inish FLR: loor FLUOR: luorescent FOC: face of concrete FOF: face of inish FOM: face of masonry FTG: footing FIXT: ixture FR: ire-rated FT: feet FUB: loor utility box GA: gauge GALV: galvanized GC: general contractor GL: glass GWB: gypsum wallboard GYP: gypsum HC: hollow core or handicap accessible HDW: hardware HM: hollow metal HORIZ: horizontal HP: high point HGT: height HTR: heater HVAC: heating, ventilating, and air conditioning 12 IN: inch INCAN: incandescent INCL: including INS: insulation INT: interior JAN: janitor JC: janitor’s closet JT: joint LP: low point LAM: laminated LAV: lavatory LINO: linoleum LTG: lighting MAT: material MO: masonry opening MAX: maximum MECH: mechanical MEMB: member MFR: manufacturer MIN: minimum MISC: miscellaneous MTL: metal NIC: not in contract NTS: not to scale NO: number OC: on center OD: outside diameter or overlow drain OHD: overhead door OHG: overhead grille OPNG: opening OPP: opposite OPPH: opposite hand PC: precast PGL: plate glass PTN: partition PL: plate PLAM: plastic laminate PLUM: plumber PTD: painted PT: paint PVC: polyvinyl chloride QT: quarry tile QTY: quantity R: radius or riser RA: return air RD: roof drain REG: register RO: rough opening REINF: reinforcing REQD: required RM: room REV: revision or reverse RSL: resilient looring SC: solid core SECT: section SHT: sheet SIM: similar SPEC: speciications STD: standard SSTL: stainless steel STL: steel SUSP: suspended SQ: square STRUC: structural STOR: storage STA: station T: tread TBD: tackboard TD: trench drain THK: thickness TEL: telephone TO: top of TOC: top of concrete TOF: top of footing TOR: top of rail TOS: top of steel TRT: treated TOW: top of wall TYP: typical UNO: unless noted otherwise VCT: vinyl composition tile VERT: vertical VIF: verify in ield VP: veneer plaster VWC: vinyl wall covering W/: with WD: wood WC: water closet WF: wide lange WPR: waterprooing W/O: without WWF: welded wire fabric WDW: window WUB: wall utility box &: and <: angle “: inch ‘: foot @: at CL: centerline [ : channel #: number Ø: diameter Architectural Documents 141 12 PROJECT TIMELINE Pre-design Even before beginning the actual design of a project, the architect may be asked to perform the following tasks, alone or in conjunction with other consultants: site selection and evaluation, environmental analysis, community participation, feasi-bility studies, programming, cost analysis, and conceptual design. It is not unusual for the architect to do many of these services as a (paid or unpaid) marketing effort, in anticipation of varies The information presented here is a generalization of the phases and events within a typical architectural project. It does not attempt to account for all project sizes and client types. The length of each phase is a rough estimation for a normal, medium-sized project, but the timeframes can vary wildly. The expectations and duration of any of these phases are subject to the stipulations of the project’s ownerarchitect agreement. being awarded the project. Competitions: Firms or individuals submit a design for a speciied program and site, for which a winner is chosen. Competitions vary in form—they may be paid or unpaid, open or invited—and do not always result in a project being built. Requests for Qualiications (RFQs): A potential client asks architects to submit their qualiications, sometimes to a speciied format. Requests for Proposal (RFPs): Similar to RFQs, though often irms are speciically asked to supply information about other relevant projects they have completed. Proposals may include a wide variety of information types, including proposed budget and schedule, and sometimes may require a design for the project. Interviews: A potential client will want to meet the architect, sometimes with his or her prospective consultants. At this meeting, the design team may be asked to present a proposal for the project in question. 142 MATERIALS, STRUCTURES, AND STANDARDS Major design ideas are proposed and explored, including alternate schemes. Drawings produced in this phase include site plan, plans, elevations, and sections suficient for cost estimation. SD often requires multiple presentations to the client for review and approval and can encompass the production of perspectives, renderings, and models to describe the design concept. DD Design Development The detailed development of the design (as established in SD) results in a drawing set suitable for a more accurate cost estimate. Coordination with consultants is key in this phase to identify and address potential problems before the design has proceeded too far. Presentations to the client turn more to these issues of coordination and cost control and take into account more speciic feedback about the nature of rooms and spaces. The design is documented inside and out, including construction details, interior elevations, schedules, and speciications, all of which will be further reined in the CD phase. 6 months In the competitive environment of architecture, procuring a project can be more time- and labor-intensive than getting it built. Marketing takes many forms, but common modes of obtaining work are: 3 months SD Schematic Design Marketing 12 CD Construction Documents The CD set is the oficial documentation of the project and is distributed to contractors for bids as well as to the building department and other oficials for all necessary permits. The architect is responsible for assisting the client in this process. 9 months The “working drawing” phase of the project, in which every aspect of the design is drawn to scale and appropriately speciied, is time- and energyintensive, and project teams usually grow larger to accommodate the work involved. The design of the project must be well established by this point, and most owner-architect agreements stipulate that any requests for major design changes made after DD must be part of an “Additional Services” agreement, to make up for the time it has taken to document the project to date. A CD set contains, at a minimum, a site plan, loor plans, relected ceiling plans, exterior and interior building elevations, building sections, wall sections depicting construction detailing, interior details, door and window schedules, equipment schedules (if applicable), inishes schedules, and written speciications, as well as the drawings of engineers and other consultants. CA Construction Administration Marketing duration durationofofconstruction construction Though the project is under construction, the architect must still maintain control over its outcome, both through regular site visits, in which construction quality is observed for its conformance with the CD set, and by overseeing solutions to unanticipated problems as they arise. The architect must review shop drawings, change orders, and requests for information from the contractor, always acting in the best interest of the client and the budget. At the end of construction, the architect prepares the punch list and assists in obtaining a Certiicate of Occupancy. Once completed, the project is photographed and documented. The architect may submit it for publication in any number of professional magazines, include it in the irm’s brochure, or post it on the irm’s website. It now serves as a marketing tool for obtaining more projects, and the process continues. Architectural Documents 143 12 SPECIFICATIONS Architectural speciications act as written instructions to the contractor and all parties involved in the construction of a building. Speciications are part of the construction document set, usually as a separate project manual. They provide detailed descriptions of the acceptable construction materials for all aspects of a building, from the type and color of paint to the type and method of structural ireprooing. Speciication writing is time-consuming and exacting work; it is most often undertaken by speciication writers or architects who specialize in the writing of speciications. Certiied spec writers list the sufix CCS (Certiied Construction Speciier) after their name. A wellwritten set of specs is imperative to keep a project safe and on budget and to ensure that the needs of both architect and owner have been met. CSI MASTERFORMAT SYSTEM The Construction Speciications Institute (CSI) was established in 1948 to bring order to the post–World War II building boom. CSI governs standardization of speciication writing and formatting, and its Project Resource Manual (formerly the Manual of Practice, or MOP) is the industry reference. Spec writers might avail themselves of prewritten master guide specs that serve as a basis for many projects, or they might begin a set of specs entirely from scratch. The CSI MasterFormat system has become the standard formatting system for nonresidential building projects in the United States and Canada. It consists of a list of numbers and titles that organize the information contained in the speciication project manual. Division Numbering 0 0 0 0 0 0 Level One Level Two (division number) 144 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Level Three .0 0 Level Four (separated by a decimal point; used only when the amount of detail warrants further classiication) 12 MasterSpec Sample Section Pro Forma SECTION NUMBER SECTION TITLE PART 1 - GENERAL 1.01 Summary 1.02 Price and Payment Procedures 1.03 References 1.04 Administrative Requirements 1.05 Submittals 1.06 Quality Assurance 1.07 Delivery, Storage, and Handling 1.08 Warranty PART 2 - PRODUCTS 2.01 Manufacturig 2.02 Manufacturers and Products 2.03 Materials 2.04 Finishes 2.05 Accessories PART 3 - INSTALLATION 3.01 Examination 3.02 Preparation 3.03 Erection 3.04 Field Quality Control 3.05 Adjusting 3.06 Cleaning Architectural Drawing Types 145 12 CSI MasterFormat Division Titles Reserved divisions provide space for future development and expansion, and CSI recommends that users not appropriate these divisions for their own use. PROCUREMENT AND CONTRACTING REQUIREMENTS GROUP 00—Procurement and Contracting SPECIFICATIONS GROUP General Requirements 01—General Requirements Facility Construction 02—Existing Conditions 03—Concrete 04—Masonry 05—Metals 06—Wood, Plastics, and Composites 07—Thermal and Moisture Protection 08—Openings 09—Finishes 10—Specialties 11—Equipment 12—Furnishings 13—Special Construction 14—Conveying Equipment 15—Reserved for future expansion 16—Reserved for future expansion 17—Reserved for future expansion 18—Reserved for future expansion 19—Reserved for future expansion 146 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 12 Facility Services 20—Reserved 21—Fire Suppression 22—Plumbing 23—Heating, Ventilating, and Air-Conditioning 24—Reserved 25—Integrated Automation 26—Electrical 27—Communications 28—Electronic Safety and Security 29—Reserved for future expansion Site and Infrastructure 30—Reserved for future expansion 31—Earthwork 32—Exterior Improvements 33—Utilities 34—Transportation 35—Waterway and Marine Construction 36—Reserved 37—Reserved 38—Reserved 39—Reserved Process Equipment 40—Process Integration 41—Material Processing and Handling Equipment 42—Process Heating, Cooling, and Drying Equipment 43—Process Gas and Liquid Handling, Puriication and Storage Equipment 44—Pollution and Waste Control Equipment 45—Industry-Speciic Manufacturing Equipment 46—Water and Wastewater Equipment 47—Reserved for future expansion 48—Electrical Power Generation 49—Reserved for future expansion Architectural Documents 147 13 Chapter 13: Hand Drawing Though rapidly being replaced by computer-aided drafting, hand drafting continues to be used by some practitioners, and its principles can still be applied to computer drawing. The practice of hand drafting employs a number of key instruments. WORK SURFACE 45°/90° triangle T-square drafting surface 30°/60°/90° triangle parallel bar 148 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 13 PAPERS AND BOARDS Paper Type Qualities Format Best Uses Use for Overlay Tracing paper white, buff or yellow; inexpensive Rolls in multiple sizes (12”, 18”, 24”, 36”, 48”); pads sketch overlay; layouts yes Vellum oil-treated to achieve transparency rolls, sheets, and pads pencil and technical pen work; overlay work yes Mylar (drafting ilm) nonabsorbent polyester ilm (1- and 2-sided) rolls and sheets pencil and tech. pen work; ideal for archival work yes Bond and drawing papers variety of weights, textures, and colors rolls and sheets smooth best for pens; textured best for pencils no Illustration board high-quality white rag afixed to board large-scale sheet sizes inished work in watercolor, pencil, chalk, or pen no Chip board variety of plies; mostly gray large-scale sheet sizes model making; some dry mounting no Foam board polystyrene foam between paper liners; white/black large-scale boards; 1/8”, 3/16”, 1/4”, 1/2” thick model making; dry-mounting sheets no translucent paper and ilm sheets boards Hand Drawing 149 13 DRAFTING SUPPLIES 1. Drafting brush: Implement used to brush away erasures and drafting powder. 2. Drafting powder: Finely ground white compound that prevents dust, dirt, and smudges from being ground into the drafting media. 1 3. French curve: Template used as guide to draw smoothly most desired curvatures. 2 4. X-Acto knife: Cutting tool used in model making and in Letratone application. 5. Erasing shield: Device used to erase speciic lines and areas without affecting others. 3 4 6. Adjustable triangle: Tool used alone or in combination with other triangles to achieve any angle. 7. Template: Pattern guides available in a wide variety of types (lettering, toilets, people) and scales. 6 5 8. Compass: Hinge-legged instrument that accommodates a pen or pencil to describe precise circles or circular arcs. 7 8 150 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 13 Triangular Architect’s Scale (1:1) With the exception of perspectives and some other three-dimensional representations, most architectural drawings are made “to scale.” Simply put, a loor plan or elevation, too large to be represented at full scale (1”=1”), must be reduced to it on a sheet of paper. To do so, a standard architect’s scale is employed. A representation made at a quarter-inch scale (1/4”=1’-0”), for instance, indicates that a distance of a quarter-inch on the drawing equals one foot in reality. The three sides of a triangular architect’s scale provide a total of eleven scales, which are written as follows: 1/16”=1’-0” 3/32”=1’-0” 1/8”=1’-0” 3/16”=1’-0” 1/4”=1’-0” 3/8”=1’-0” 1/2”=1’-0” 3/4”=1’-0” 1”=1’-0” 1 1/2”=1’-0” 3”=1’-0” Engineer’s scales are often used for larger-scale drawings such as site plans; they follow the same principle as architect’s scales but with larger increments of ten (1”=10’, 1”=50’, 1”=100’, and so forth). Scales are also available in metric units. Hand Drawing 151 13 PENCILS Harder leads contain more clay, whereas softer leads contain more graphite. Lead holders employ a pushbutton that advances the 2 mm lead, which comes in a wide array of hardnesses, colors, and nonphoto blue (does not appear on reproductions). Leads are sharpened in lead pointers or with simple emery paper or sandpaper blocks. Pencil Hardness Range Grade 9H Weight and Use very hard and dense ideal range for guidelines and underlay work 8H 7H 6H 5H 4H 2H medium-hard H medium F medium, general purpose HB medium-soft, bold line work best range for inished drawings 3H 2B 152 lead reills for lead holder clutch lead holder wood pencil 3B THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 4B 5B 6B very soft range for bold lines and shading, less suitable for drafting purposes B 13 TECHNICAL INK PENS Technical pens, which use an ink low–regulating wire with a tubular point (the pen nib), can produce very precise line widths. Depending on the pen type, the ink may come in a prepackaged cartridge or the barrel of the pen may be illed with ink as needed. The iner the pen nib, the more fragile and prone to clogging it is. All nibs require cleaning and maintenance to keep them in working order. Ink should be waterproof, nonfading, and opaque. Ink pens can be used on most paper types and are ideal for vellum and Mylar; they can even be erased from Mylar ilm with a nonabrasive drafting eraser or electric eraser. Technical Pen Line Weights pen nib 7 2.0 6 1.4 4 1.2 3 1/2 1.0 3 .80 2 1/2 .70 technical pen body 2 .60 1 .50 0 .35 00 .30 3x0 .25 4x0 .18 6x0 .13 Hand Drawing 153 14 Chapter 14: Computer Standards and Guidelines Building design and construction involves enormous amounts of information in need of organization and dissemination among numerous groups of interested and active parties. The introduction of computers into this process has understandably changed the way in which buildings are conceived, designed, and documented. Truly, many things can now be done faster and with more ease, but computers have given rise to new issues involving management of computer iles, quality standards for deliverable materials, and the constant need to stay current with rapidly evolving technologies. The prospect of documenting computer standards and guidelines as static and absolute is therefore neither productive nor possible—the only thing that is certain is that things will change. With this in mind, this chapter focuses on guidelines affecting AutoCAD, at this printing still the de facto industry standard for construction document production. COMPUTER PROGRAMS Architectural production can be divided into two major groups: contract document deliverables and general presentation materials. Deliverables are usually understood as the construction document set composed of the basic two-dimensional drawing types (plan, section, elevation, details, and schedules) that describe the building suficiently for the contractors to build it. The computer programs used to produce a standard set of deliverables are primarily drafting programs. In essence, they provide eficient, precise, and easily modiiable mechanical drawings. AutoCAD remains the drafting program of choice for most architects and engineers. Though it does have three-dimensional capabilities and can also accommodate rendering plug-ins, for high-quality presentation drawings, AutoCAD is still most valued for its precision as a versatile drafting program. 154 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Presentation materials can include standard plan, section, and elevation drawings as well as physical three-dimensional models, computer renderings, and animations. Computer modeling and rendering programs are numerous and varied, depending on the desired output. Predictably, the more sophisticated the intended product, the more expensive the tool. Modeling programs are not limited to production output. Many are employed extensively to design complex forms that would simply be impossible otherwise. Increasingly, architecture is taking advantage of programs developed for use in other ields, such as the automotive industry, aerospace engineering, video game development, and animated ilm production. 14 AUTOCAD TERMS drawing. Examples include building grids and site information. Also called X-Ref. Aspect ratio: Ratio of display width to height. Block: Grouping of one or more objects combined to form a single object. On creation, blocks are given a name and an insertion point. CAD: Computer-aided design or computeraided drafting. Also CADD, for computer-aided design and drafting. Command line: Text area reserved for keyboard input, messages, and prompts. Coordinates: X, y, and z location relevant to a model’s origin (0,0,0). Crosshairs: Type of cursor. Cursor: Active object on a video display that enables the user to place graphic information or text. Drawing file: Electronic representation of a building or object. Drawing web format (DWF): Compressed ile format that is created from a DWG ile, ideal for publishing and viewing on the Web. DWG: File format for saving vector graphics from within AutoCAD. Drawing interchange format (DXF): ASCII or binary ile format of an AutoCAD drawing, for exporting AutoCAD drawings to other applications or importing those from other applications into AutoCAD. Entity: Geometric element or piece of data in a CAD drawing, such as a line, a point, a circle, a polyline, a symbol, or a piece of text. Explode: Disassemble complex objects such as blocks and polylines. Layer: Entity used for classiication in a CAD drawing, whose properties allow for manipulation and lexibility of information in the drawing. Model: In AutoCAD, a two- or threedimensional representation of an object; or a three-dimensional replica of a design, whether physical or digital. Model space: One of two primary spaces in which AutoCAD entities exist. Model space is a three-dimensional coordinate space in which both two-dimensional and three-dimensional drafting and design are done at full (1:1) scale. Paper space: Other primary AutoCAD space. Used for creating a inished printable or plottable layout; usually contains a title block. Polyline: Object made up of one or more connected segments or arcs, treated as a single object. Sheet file: Print- or plot-ready electronic representation of a presentation sheet, containing a view or views of the model, text, symbols, and a title block. User coordinate system (UCS): System that deines the orientation of x, y, and z in threedimensional space. UCS icons: Keys that indicate the direction of x, y, and z planes, as well as whether the user is in paper space or model space. paper space icon model space icon Viewport: Bounded area that displays some portion of the model space of a drawing. Window: Drawing area, including the command line and surrounding menus. External reference: File or drawing that is used as background in another drawing but cannot be edited, except in its original Computer Standards and G uidelines 155 14 AUTOCAD WINDOWS Active Model Space Model may be edited in model space. Tilemode = 1 (on) All drawing done in model space should be at 1:1. UCS icon Active Paper Space Title block or other non–model space information may be edited in the paper space viewport. Tilemode = 0 (off). When tilemode is off, viewports are objects that can be moved and resized. UCS icon Paper Space with Active Model Space Viewport To enter the viewport, type ms at command line; note the model space icon. Tilemode = 0 (off) Paper space scales (XP) may be set by zooming while in this mode. Editing of the model is possible though not encouraged. 156 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 14 EXTERNAL REFERENCES External reference (X-Ref) drawings contain architectural information common to multiple sheet iles. Typically, these drawings are loor plans that can serve many purposes; each has its own sheet ile. For example, the same plan model can be used for loor plans, relected ceiling plans, and large-scale plans. The following diagram describes the interaction between X-Ref drawings and sheet iles. X-Ref Model Files X-Ref drawing attached to other X-Ref drawings Floor Plan A-FP-01 Structural Grid X-GRID X-GRID and A-FP-01 are both used as X-Refs in other iles to create sheet iles. Sheet iles before X-Refs: contain sheet-speciic text, dimensions, and symbols Sheet Files Enlarged Kitchen Plan A-401 Sheet iles with X-Refs First-Floor Plan A-101 Computer Standards and G uidelines 157 14 MODEL SPACE AND PAPER SPACE SCALES All AutoCAD models and drawings, from detailed wall sections to expansive site plans, are drawn in model space at full scale (1:1). Paper space is used to set up print- and plot-worthy sheets (often with the use of a title block) that enable the information in model space to be printed to a speciic and accurate scale. Such a system allows the architect considerable lexibility when designing and drawing, because one drawing can be used at many different scales and for many different purposes and need not be drawn “to scale.” viewport zoom: 1/48XP (1/4”=1’-0”) 158 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK viewport viewport paper space title blocks A simple way to envision the relationship between model and paper space is to think of the paper space title block as an actual piece of paper, with a hole cut out (the viewport). Through this hole model space is visible. Using XP factors (see following page), the model in the viewport is scaled in relation to the paper space title block. viewport zoom: 1/24XP (1/2”=1’-0”) 14 AutoCAD Text Scale Chart (in inches) Desired Text Height DWG Scale Scale Factor XP Factor 1/16” 3/32” 1/8” 3/16” 1/4” 5/16” 3/8” 1/2” 3/4” 1” Full 1 1 .0625 .09375 .125 .1875 .25 .3125 .375 .5 .75 1 6”=1’ .5 1/2 .125 .1875 .25 .375 .5 .625 .75 1 1.5 2 3”=1’ .25 1/4 .25 .375 .5 .75 1 1.25 1.5 2 3 4 11/2”=1’ .125 1/8 .5 .75 1 1.5 2 2.5 3 4 6 8 1”=1’ .08333 1/12 .75 1.125 1.5 2.25 3 3.75 4.5 6 9 12 3/4”=1’ .0625 1/16 1 1.5 2 3 4 5 6 8 12 16 1/2”=1’ .04167 1/24 1.5 2.25 3 4.5 6 7.5 9 12 18 24 3/8”=1’ .03125 1/32 2 3 4 6 8 10 12 16 24 32 1/4”=1’ .02083 1/48 3 4.5 6 9 12 15 18 24 36 48 3/16”=1’ .015625 1/64 4 6 8 12 16 20 24 32 48 64 1/8”=1’ .01042 1/96 6 9 12 18 24 30 36 48 72 96 1/16”=1’ .005208 1/192 12 18 24 36 48 60 72 96 144 192 1”=10’ .0083 1/120 7.5 11.25 15 22.5 30 37.5 45 60 90 120 1”=20’ .004167 1/240 15 22.5 30 45 60 75 90 120 180 240 1”=30’ .002778 1/360 22.5 33.75 45 67.5 90 112.5 135 180 270 360 Using This Chart Because all work done in AutoCAD models should be at 1:1, text and labels must be adjusted to appropriate sizes based on the scale at which they will be printed. For example: if a detail drawing will be printed at 3”=1’-0”, and the desired height of the text when printed is 1/8”, the text in the model must be set to 0.5”. If the same drawing will be printed at 1/4” = 1’- 0”, and that text also needs to be 1/8” high, any text related to the 1/4” scale output would be set to 6” in the model. Many clients, including government agencies, will require a minimum text size for legibility. Using Paper Space Scales (XP) The XP scale is the relationship between the desired plotted scale and the sheet of paper on which it will be plotted. With hand drafting, one would typically use an architect’s or engineer’s scale to assist in correctly making a drawing “to scale.” On such a scale, if using 1/4” = 1’-0”, 1’ is shown on the scale as 1/4” in length; 2’ are shown as 1/2”, and so on. In reality, the scale has already done much of the calculation necessary to draw at the desired scale. To describe this process accurately, one could say that, for the drawing to it on a certain sheet of paper, the drawing has been made at 1/48th its full scale (if 1/4”=1 2 ”, 1/4 x 1/12 =X, therefore X = 1 / 48 ). In AutoCAD the process is much the same. To set the scale of a viewport while inside the viewport (ms) in paper space, zoom to 1/48XP (also equal to 0.02083XP). XP literally means “times paper space.” This action will zoom the viewport window to 1/4” =1’-0” in relation to the paper space title block, which is printed at 1:1. Computer Standards and Guidelines 159 14 AUTOCAD FILE-NAMING CONVENTIONS File types have a direct bearing on the format of the ile and the manner in which it should be named. File types include models, details, sheets, schedules, text, databases, symbols, borders, and title blocks. The ile- and layer-naming system discussed here follows the AIA CAD Guidelines, as established by the U.S. National CAD Standard. Model Files A building model ile is an electronic representation of the building. Models may be two- or threedimensional and are created at a true 1:1 scale. All geometry in a model ile contains a three-dimensional coordinate (x, y, z). In two-dimensional drawings, the z coordinate is 0. Sheet Files The electronic sheet ile contains one or more views of one or more model iles, as well as text, symbols, and, often, a border or title block. The title block generally contains graphic and text information common to all other sheets in a project or section. 160 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Level 1 Discipline Designators Both ile names and layer names are classiied by discipline. The discipline code is a twocharacter ield in which the second character is either a hyphen or a modiier deined by the user. A B C D E F G H I L M O P Q R S T V W X Z Architectural Geotechnical Civil Process Electrical Fire Protection General Hazardous Materials Interiors Landscape Mechanical Operations Plumbing Equipment Resource Structural Telecommunications Survey/Mapping Distributed Energy Other Disciplines Contractor/Shop Drawings 14 Standard Model File Identification Model File Types FP SP DP QP XP EL SC DT SH 3D DG Floor Plans Site Plans Demolition Plans Equipment Plans Existing Plans Elevations Sections Details Schedules Three-Dimensional Drawings Diagrams A A A U U U U discipline designator (same as for sheet ile naming) A A A U U U U hyphen (serves as a placeholder and makes name more readable) A A A U U U U model ile type deined by user (optional alphanumeric modiiers) Examples: A-FP-01 (Architectural Floor Plan, Level 1) P-DP-010 (Plumbing Demolition Plan, Level 1) Standard Sheet Identification Sheet Type Designators 0 General 1 Plans 2 Elevations 3 Sections 4 Large-scale Views 5 Details 6 Schedules and Diagrams 7 User Deined 8 User Deined 9 Three-Dimensional Drawings A A N N N U U U discipline designator (discipline character plus optional modiier character) A A N N N U U U N N U U U sheet type designator A A N sheet sequence numbers deined by user (optional alphanumeric modiiers) Examples: A-103 (Architectural Plan, Level 3) AD206 (Architectural Demolition Elevation, Level 6) Computer Standards and G uidelines 161 STANDARDS 162 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 3. PROPORTION AND FORM Since most architecture, even that designed for a large-scale use (such as an airplane hangar or an elephant barn), requires some human interface, our own bodies serve as useful reference points for inhabiting space. Similarly, no matter how complicated structures may be, most are reducible to the point, line, or plane that evolved into the more complex combinations of forms and spaces that constitute a design. Throughout history, architects have devised and employed ordering and proportioning systems for architecture based on the logics of harmonics, arithmetic, geometry, and the human body, often producing a visual and physical order that is apparent to the observer even if the organizing logic is not known or understood. Daily life brings us into contact with endless numbers of systems of arrangement and order, much of it centered on how our bodies and our cars (extensions of our bodies) use and navigate our immediate surroundings and share them with others. The standards presented here describe the basic clearances demanded of an assortment of programs that architects regularly encounter. They do not propose speciic designs, but give a better understanding of how different bodies occupy different spaces. 163 15 164 MATERIALS, STRUCTURES, AND STANDARDS Chapter 15: The Human Scale The scale of the human body informs almost every aspect of architectural design. The dimensions in this chapter represent an average range (the lower number denotes the 2.5th percentile, while the upper number denotes the 97.5th percentile). 19.4 495 16.0 405 15.1 385 12.4 315 75.0 1 905 64 .6 1 640 eye 15.3 390 13.6 345 70.3 1 785 60.6 1 540 shoulder 59.7 1 515 51.0 1 295 19.2 485 16.7 425 center of gravity pelvis 40.5 1 030 34.3 870 18.1 460 15.3 390 knee 22.4 19.0 570 480 4.7 4.2 120 105 17.7 450 14.8 375 ankle Adult Male Figure 164 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 15 On the drawings below, the gray bars indicate inches and the blue bars indicate millimeters. 17.7 450 14.4 365 13.7 350 11.2 285 70.4 1 790 60.6 1 540 eye 14.5 370 12.8 325 66.0 1 675 56.6 1 440 shoulder 55.9 1 415 47.8 1 215 18.0 455 15.7 400 center of gravity pelvis 37.9 32.1 960 815 16.7 425 14.0 355 knee 21.2 18.1 535 460 16.2 410 13.6 345 ankle 5.0 4.5 125 115 Adult Female Figure The Human Sc ale 165 MATERIALS, STRUCTURES, AND STANDARDS ACCESSIBLE DESIGN DIMENSIONS 6” (152) 18” (457) 26” (660) 42” (1 067) 43” –51” (1 092–1 295) eye lap 19” (483) toe 8” (203) 27” (686) 30” (762) seat 36” (914) 15 166 Overall Dimensions for Adult Wheelchairs 166 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 15 Architects must equally be familiar with the dimensions of those with special needs, speciically the constraints posed by wheelchair use. Design to accommodate wheelchairs and other special needs is increasingly the rule rather than the exception, particularly as the concept of universal design gains more prominence. Universal design suggests making all elements and spaces accessible to and usable by all people to the greatest extent possible—a goal that, through thoughtful planning and design, need not add to the cost of production. shelving depth 9”–12” (230–305) high shelf reach 48.5”–67.7” (1 230–720) work clearance 15 - 20 (380 - 510) reach to back 42” (1 075) minimum workspace width 42” (1 065) toe space 7” (180) toe clearance 10” (255) lowest shelf 10.7” (270) workspace 21” (535) counter height 32” (810) low shelf (reach to back) 18” (455) eye switches and phone dial height 42”–48” (1 065–220) highest shelves: reach to front 45.5” (1 155) Side Approach Work Station Clearances The Human Scale 167 MATERIALS, STRUCTURES, AND STANDARDS SEATED DIMENSIONS 12” (305) 54” (1 372) switches 42”–48” (1 065–220) 24”–30” (610–760) knee well 20”–24” (510–610) Work Station Clearances 168 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 14.4”–18.5” (365–470) 24” (610) toe space 4” (102) 25”–31.5” (635–800) wall outlets 18” (457) 4” (102) 15 168 15 30” (750) 35” (875) 35” (875) 25” (625) 25” (625) 39” (1 000) 35” (875) 38” (950) 35” (875) 12” (300) 35” (875) 73” (1 875) Lounging Position General Space Considerations The Human Scale 169 MATERIALS, STRUCTURES, AND STANDARDS 8” (203) 4” (102) 12” (305) 4” (102) Masonry 16” (406) 6” (152) 6” (152) 10” (254) 8” (203) 8” (203) 12” (305) 15 170 Wood Proportions of Materials 170 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Masonry 15 48” (1 220) 96” (2 440) 48” (1 220) Plywood 60” (1 524) Plywood Gypsum Wall Board 96” (2 440) 60” (1 524) Proportions of Materials The Human Sc ale 171 16 Chapter 16: Residential Spaces KITCHENS 5’-6” (1 676) avg. 18” (457) 30” (762) Typical Dimensions 36” (914) 32” (813) avg. 30” (762) avg. The total distance of all three sides of the work triangle should average between 12 lineal feet (3 660) and 22 lineal feet (6 705). work triangle work triangle Storage guidelines: minimum 18 sq. ft. (1.67 m2) basic storage, plus 6 sq. ft. (0.56 m2) per person served. 5’-0” (1 524) min. Typical Layout Types U-shape L-shape 172 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 16 Cabinetry Components upper cabinets adjustable shelves backsplash 12” (305) drawer adjustable shelves 25” (635) door base Appliances Many appliances have become modular in width, and it within a 3” system (ex. 9”, 12”, 15”, 18”, 21”, 24”...48”) line of work work triangle 4’-0” (1 219) min. Single Wall Parallel Walls Residential Spaces 173 16 BATHROOMS General Guidelines Minimum ceiling height = 6’-8” (2 032) (Subject to Local Codes) 18”(457) 18”(457) Minimum ventilation should be a window of at least 3 sq. ft. (0.28 m2), of which 50 percent is operable, or a mechanical ventilation system of at least 50 cu. ft. per minute (cfm) ducted to the outside. Wall area above a tub or shower pan should be covered in a waterproof material to a height of not less than 72” (1 829) AFF. 36” (914) min. 30”(762) Minimum clear opening at door = 32” (813). Door swing should not interfere with other doors (including cabinets) or the safe use of ixtures and cabinets. 174 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Vanity height = 32”–43” (813–1 092), as it suits the user 16 Lighting In addition to general lighting, task lighting should be installed at each functional area of the bathroom, and at least one light must be provided that is controlled by a wall switch located at the entry. Any light ixture installed at a tub or shower must be marked as suitable for damp/wet locations. 2’-6” (762) 4’-0” (1 219) 4’-6” (1 372) 5’-0” (1 524) Electrical Outlets All electrical receptacles should be protected by GFCI (groundfault circuit interrupter) protectors, and at least one GFCI receptacle should be installed within 36” (914) of the outside edge of the lavatory. No receptacles of any kind should be installed in a shower or bathtub space, nor should switches be installed in wet locations in tub and shower spaces (unless installed as part of a UL-listed tub or shower assembly). 6’-3” (1 905) 7’-0” (2 134) 5’-0” (1 524) Floors Bathroom loors and tub and shower loors should have slip-resistant surfaces. Typical Arrangements 7’-6” (2 286) 5’-0” (1 524) Glazing Tempered glass or an approved equal should be used in the following conditions: shower doors or other glass in tub or shower enclosures; tub or shower surrounds with glass windows or walls that are less than 60” (1 524) above any standing surface; and any glazing such as windows or doors whose bottom edge is less than 18” (458) AFF. 8’-0” (2 438) Residential Spaces 175 16 HABITABLE ROOMS 75” (1 905) 28” (711) In most residential projects, sleeping rooms should have at least one means of egress to the exterior, which can be in the form of an operable window of not less than 3.3 sq. ft. (0.307 m2), and with a minimum clear opening of 20” x 24” (508 x 610), with a sill height no higher than 44” (1 118). 5’-0” (1 524) Crib Ceiling height should not be less than 7’-6” (2 286) for at least 50 percent of the required area; 50 percent may be sloped to a minimum height of 5’ (1 524). 7’-6” (2 286) 52” (1 321) Beds (mattress sizes) Twin 39” (991) Table Size (in.) Maximum Seats 24 x 48 4 Full 30 x 48 4 (2 wch.) (Double) 30 x 60 6 (4 wch.) 36 x 72 6 (6 wch.) 80” (2 032) 54” (1 372) Queen 8 (6 wch.) 2 36 x 36 4 42 x 42 4 (2 wch.) 48 x 48 8 (2 wch.) 54 x 54 8 (4 wch.) 30 dia. 2 36 dia. 4 42 dia. 4–5 48 dia. 6 (2 wch.) 54 dia. 6 (4 wch.) 80” (2 032) 60” (1 524) 36 x 84 30 x 30 24”–40” (varies) 4’-0” –10’-0” (varies) 18” x 18” (457 x 457), typical 36” (914) wch. = wheelchair King in. 24 30 36 42 48 54 60 72 84 mm 610 762 914 1 067 1 219 1 372 1 524 1 829 2 134 76” (1 930) 176 28”–42” (varies) 75” (1 905) Seating THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 16 Each dwelling should have at least one room not less than 120 sq. ft. (11.15 m2). Closets Habitable rooms (except bathrooms and kitchens) should have an area greater than or equal to 70 sq. ft. (6.51 m2), with no less than 7’-0” (2 134) in any direction. Kitchens may be a minimum of 50 sq. ft. (4.65 m2). Garages A minimum clearance of 2’-6” (762) for circulation should be maintained between the vehicle and other vehicles, walls, or equipment. 21’-10” (6 655) avg. 5’-2”–5’-10” (1 575–779) 5’-10”–6’-4” (1 779–930) 22”–30” (559–762) clear inside depth 48”–72” (1 219–829) of hanging space per person 12” (305) = 6 suits, 12 shirts, 8 dresses, or 6 pairs of pants 11’-2” (3 404) avg. for one car 19’-10” (6 045) avg. for two cars 8’ (2 438) min. door clearance 9’ (2 743) recommended 16’ (4 877) min. required for single door of two-car garage Residential Spaces 177 16 EATING 1-person: 2’-0”–2’-6” (610–762) Seating Types 2-person: 3’-6”–4’-6” (1 067–372) 2’-0”–2’-6” (610–762) 1’-6” (457) Booth tables may be 2” (51) shorter than bench seats, and with rounded corners to facilitate getting in and out of the booth. 2’-6” (762) 3’-0”–4’-0” (914–1 219) Booths 0–4” (0–102) 1’-6” 5’-0”–6’-2” (1 524–880) (457) Tables customer zone 1’-6”–2’-0” (457–610) 2’-6” (762) Tables with widespread bases (shown here) are more practical for sitting down and getting up than four-legged tables. 1’-6” (457) Chair seat dimensions average 1’-2”–1’-6” (356–457). customer zone 1’-6”–2’-0” (457–610) 2’-4”–3’-2” (711–965) Bars and Counters 2’-6”–3’-0” (762–914) 178 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 3’-0”–3’-6” (914–1 067) 5’-0”–5’-9” (1 524–753) 2’-6” (762) Counter stools should average ten per server. 2’-6”–2’-10” (762–864) 6”–7” (152–179) 3’-6”–3’-9” (1 067–143) 1’-6”–2’-0” (457–610) 2’-0”–2’-6” (610–762) 16 Seating Clearances 19” (483) Clear loor area for wheelchairs is 30” x 48” (762 x 1 219), of which 19” (483) may be used for required under-table knee space. At least 5 percent (but not less than 1) of tables must be accessible. 36” (914) required for all accessible routes service aisle 6” (152) no passage 30”–42” (762–1 067); 36” (914) minimum required for accessible aisle 18” (457) limited passage service aisle service aisle 30” (762) service aisle bar Residential Spaces 179 16 PUBLIC SEATING Typical Chair Widths Chair widths typically run 18”–24” (457–610); the ideal width is 21” (533). Accessible spaces of 36” x 60” (914 x 1 524) should be open, on level ground, and provided as follows: Total Seating Wheelchair Spaces 4–25 1 26–50 2 51–300 4 301–500 6 500+ 6 (+1 per each additional 100 seats) Plumb Line Clearance The distance between an unoccupied chair in the up position and the back of the chair in front of it. Local codes should be consulted for minimum clearances. Row Spacing Row spacing, like tread, runs 32”–40” (813–1 016) and higher. Also, 1 percent of all ixed seats (but not less than one) must have removable or folding armrests on the aisle side and must be identiied with appropriate signage. Closer spacing may cause uncomfortable conditions for the seated person, as well as dificulty for anyone trying to pass in front of a seated person. Conversely, whereas wider spacing of rows provides more comfort while sitting and passing in front of seated persons, too wide a spacing may make the audience feel overly spread out. In addition, the wider spacing may encourage some people to try to squeeze through when exiting, causing a jam that could be dangerous in the event of an emergency. An ideal spacing that accounts for all of these factors is 36” (914). row spacing (= tread) plumb line clearance pitch row spacing (= tread) 180 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 17” (432) 6” (152) 8.5” (216) 20” (508) max. 16 OFFICE WORKSPACES Flexible Workspaces Many companies produce lexible ofice furniture and workspace modules, in a wide variety of styles and inishes. These diagrams are for general layout purposes only and to illustrate a range of possibilities for ofice privacy, interaction, and space allocation. 8’-0” (2 438) 30”(762) 30”(762) 8’-0” (2 438) 24” (610) 30”(762) Various arrangements of four 8’ x 8’ (2 438 x 2 438) workspaces, allowing for a wide range of levels of interaction. The primary advantage of lexible ofice furniture is precisely its ability to adjust to changing staff levels, changing personnel type, and even shifts in the nature of work being performed in the space. Residential Spaces 181 16 17 Chapter 17: Form and Organization PRIMARY ELEMENTS The primary elements of form are points, lines, planes, and volumes, each growing from the other. A point is a position in space and the prime generator of form. A line is a point extended; its properties are length, position, and direction. A plane is a line extended; its properties are width and length, shape, surface, orientation, and position. A volume is a plane extended; its properties are length, width, and depth, form and space, surface, orientation, and position. PRIMARY SHAPES Square Triangle Circle PLATONIC SOLIDS Cube 182 Pyramid THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Cone Cylinder Sphere 16 17 POLYHEDRA Icosahedron (20-sided Solid) Geodesic Sphere A geometric polyhedron is a threedimensional solid made up of a collection of polygons, usually joined at the edges. Geodesic Dome Geodesic spheres and domes are designed by illing each face of a solid, such as an icosahedron, with a regular pattern of triangles, bulged out so that their vertices are not coplanar but are in the surface of the sphere instead. As a structural concept, the subpattern of triangles form geodesics that distribute stresses across the structure. BOOLEAN OPERATIONS Joining together or subtracting of one solid from one or more sets of solids. Union Extraction Intersection RULED SURFACES A ruled surface, which is the surface generated by connecting line segments between corresponding points, can take many forms. Hyperboloid of Revolution Hyperbolic Paraboloid Conoid A hyperbolic paraboloid is a doubly ruled surface generated by two meshes of lines that are skewed from each other but appear parallel when viewed in plan. The saddle point is found at its center. Form Residential and Organization Spaces 183 17 THE GOLDEN SECTION The properties of proportion of the golden section have been employed by architects, artists, mathematicians, and musicians since the ancient Greeks recognized its proportional ordering in the human body. Even today many believe it to contain mystical qualities, whose unique mathematical and geometrical relationships create a harmonic condition that is nature’s aesthetically “perfect” balance between symmetry and asymmetry. Constructing a Golden Rectangle C A 1. Create a square and locate the midpoint of one side. B C A 4. Line AB is the long leg of the golden rectangle. 2. Draw a line from the midpoint to a corner that does not share a line with the midpoint. 5. A golden rectangle has been added to the original square, and together they also form a larger golden rectangle. 3. This is the radius of a circle with its center at the midpoint; the point where the circle and the line AC intersect becomes point B. 6. The process can be repeated ininitely, creating proportionally larger or smaller series of squares and rectangles. C A In mathematics, the golden section is the ratio of the two divisions of a line such that the smaller is to the larger as the larger is to the sum of the two. In addition to its many uses in the arts and music, there are practical uses for the mathematical integrity of the golden section in its proportions as related to structure. 184 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK B Calculating the Golden Mean AC/CB = AB/AC (a unique characteristic) If AB = 1, let AC = x x= !5 –1 = 0.61803398 . . . (ininite). 2 Therefore: the ratio of AC to AB is approximately 61.8%; the inverse (1/61.8) is 1.61803398 . . . B 17 THE FIBONACCI SEQUENCE The Fibonacci Sequence is a recursive series of numbers, where each number in the sequence is the sum of the two numbers preceding it. A simple sequence beginning with 0 follows: 0 , 1 , 1 , 2 , 3 , 5 , 8 , 13 , 21 , 34 , 55 … Any two adjacent numbers in the sequence may be divided, the lower number by the higher number (for example, 34/55), to achieve a very close approximation of the golden section (in this case, 0.6181818 . . . ). The higher the numbers, the more accurate the answer will be (for example: 377/610 = 0.6180327 . . . ). REGULATING LINES The guiding lines that indicate the proportional and alignment relationships in drawings, such as those depicting the golden rectangle, are known as regulating lines. They are used, for instance, both to determine and to illustrate proportional relationships in a design. Rectangles whose diagonals are either perpendicular or parallel to each other have similar proportions (even if they are not golden rectangles), and the use of such lines is a common proportional ordering tool. axis intersection at perpendicular lines tangent to arc parallel lines Residential Spaces 185 18 Chapter 18: Architectural Elements CLASSICAL ELEMENTS Classical architecture typically refers to the styles of both ancient Greece and Rome, which are based around the ixed columnar proportions and ornamentation of the classical orders. Both Greek and Roman classicism have been the bases of revivals throughout history, and the ideals behind their form and proportion continue to have resonance today. Parthenon, Athens, Greece 448–32 B.C.E. peripteros: single row of columns surrounding building pronaos: vestibule opisthodomos: cella (naos): shrine room at center of temple 186 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK enclosed section at the rear of the temple 18 pediment tympanium acroterion cornice frieze triglyph metope architrave capital tenia guttae regula shaft shaft (maximum entasis at 2/5 height of column) stylobate stereobate Entasis: Slight convex curvature of classical columns, used to counteract the optical illusion of concavity produced by straight lines. Other adjustments, such as reclining the columns slightly away from the vertical and making the end columns larger and closer together, also produce a more pleasing visual effect. Caryatid: Sculpted female igure used as a column to support an entablature. Other forms include atlantes or telamones (male caryatids), canephorae (females with baskets on their heads), herms (three-quarter-height igures), and terms (pedestals that taper upward, terminating in a sculptured human or animal). Architectural Elements 187 18 CLASSICAL ORDERS 13/4 dia. simplest; derived from Etruscan temples entablature Doric Ionic Greek (no base) and Roman characterized by volutes on its capital 2 dia. Tuscan 2 1/4 dia. Elements of the classical orders are distinguished by their unique proportioning system based on the shaft diameter of the columns, from which pedestal, shaft, and entablature heights are derived. Using a common shaft diameter, the ive orders are shown here in their proportional relationship to each other. 7 dia. 8 dia. 9 dia. capital shaft 1 dia. 188 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 3 dia. 22/3 dia. pedestal 21/3 dia. base 18 Composite Corinthian frieze entablature 2 1/2 dia. 10 dia. base shaft capital architrave 2 1/2 dia. 10 dia. cornice Roman combination of Ionic and Corinthian orders Greek and Roman, luted or not; characterized by acanthus leaves on its capital plinth pedestal 31/3 dia. 31/3 dia. dado or die plinth Architectural ArchitecturalElements Elements 189 18 GOTHIC ELEMENTS wooden roof inial pinnacle clerestory crocket aisle main arcade tritorium lying buttress buttress pier nave aisle Rheims Cathedral, France 1212–1300 aisle nave chapel apse transept chapel Typical Plan 190 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 18 ARCHES 6 1 2 3 4 5 6 7 8 9 10 3 abutment voussoirs keystone intrados (sofit) extrados crown haunch span springing line center 7 1 5 2 4 9 10 8 Semicircular Segmental Semicircular Stilted Jack Tudor (Four-centered) Pointed Saracenic (Gothic) Ogee Three-centered Architectural ArchitecturalElements Elements 191 18 parapet cornice dentils louver (mechanical) drip mold mullion muntin curtain wall spandrel quoin band base (piano nobile) rustication 192 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 18 MODERNISM Architectural modernism opposed following the forms and styles of the past in favor of embracing contemporary technology and opportunities. Industrialization and innovative methods of using iron, steel, and concrete for structural systems opened up new and lexible ways to design buildings that no longer depended on heavy masonry bearing walls. Swiss architect Le Corbusier (1887–1965) developed the Domino House system (1914), in which he separated building structure from enclosure, freeing up both plan and façade. Le Corbusier’s ive points are supports (pilotis), roof gardens, free plans, horizontal windows, and free design of the façade. His 1929 Villa Savoye (which he dubbed a “machine for living”) in Poissy, France, illustrates all ive points clearly. roof terrace free façade ribbon windows open plan pilotis Architectural Elements 193 18 CANONICAL ARCHITECTURAL PUBLICATIONS MARCUS VITRUVIUS POLLIO (c. 80 BCE - c. 15 BCE) was a Roman architect, engineer, and writer, whose De Architectura (in English, Ten Books on Architecture) was written around 15 BCE and dedicated to Emperor Augustus. The books provide explanation and insight into the architecture, engineering and city planning of classical antiquity, though it was not until the Renaissance that they were re-discovered and ultimately published in 1486. Vitruvius proposed firmitas, utilitas, and venustas as three elements forming the basis for architecture: irmness (structural stability and integrity) commodity (eficient and functional spatial arrangement) delight (pleasing proportion and beauty) Book 1: Education of the architect; principals of architecture; city planning Book 2: Materials for building; origin of the dwelling house Book 3: Symmetry and proportion; temples; architectural orders Book 4: Temples; origins of the three orders (continuation of Book 3) Book 5: Civic buildings (Forum, Basilica, Senate); theater design Book 6: Domestic buildings Book 7: Stucco; plasterwork; colors Book 8: Water; aqueducts and cisterns Book 9: Zodiac; planets; astrology Book 10: Machines and instruments LEON BATTISTA ALBERTI (1401-1472) De Re Aedificatoria (On the Art of Building), written between 1443-1452, became the irst printed book on architecture with its publication in 1485 (followed by the publication of Vitruvius’s Ten Books inally in 1486). 1. Lineaments 2. Materials 3. Construction 4. Public Works 5. Works of Individuals 6. Ornament 7. Ornament to Sacred Buildings 8. Ornament to Public Secular Buildings 9. Ornament to Private Buildings 10. Restoration of Buildings 194 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 18 ANDREA PALLADIO (1508-1580) LE CORBUSIER (1887-1965) I quattro libri dell’architettura (The Four Books of Architecture) Oeuvre Complète (Complete Works in Eight Volumes) A Renaissance architect, Palladio’s highly illustrated treatise includes his own designs and the ancient Roman inspirations for his and other work of the Renaissance. Published regularly throughout the proliic working life (and beyond) of Swiss architect Le Corbusier, the Oeuvre Complète comprises over 1700 pages. Contained within is a comprehensive collection of his sketches, drawings, projects both built and unbuilt, texts and manifestos, paintings, and sculptures. Book 1 - buidling materials and techniques; the orders of architecture Book 2 - private houses Book 3 - streets, bridges, piazzas Book 4 - reproductions of ancient Roman temple designs volume 1: 1910-1929 volume 2: 1929-1934 volume 3: 1934-1938 volume 4: 1938-1946 volume 5: 1946-1952 volume 6: 1952-1957 volume 7: 1957-1965 volume 8: 1965-1969 (last works) SEBASTIANO SERLIO (1475-1554) I sette libri dell’architettura (Seven Books of Architecture) also known as: Tutte l’opere d’architettura et prospetiva (All the works on architecture and perspective) 1. On Geometry 2. On Perspective 3. On Antiquities 4. On the Five Styles of Buildings 5. On Temples 6. On Habitations 7. On Situations With the irst of the books published in 1537, Serlio’s books were highly illustrated, and written in Italian, in order to appeal to architects and builders of the day - in contrast to Alberti’s books, which were written in Latin and did not focus on illustration. Many of Serlio’s books were published long after his death. Architectural Elements 195 STANDARDS 3. CODES AND GUIDELINES Codes, laws, and regulations can carry with them a certain off-putting suggestion of bureaucratic obfuscation. To run afoul of them would never be recommended, but attempts to understand them can be frustrating. Certainly, there exist standards that appear senseless or unnecessarily restrictive, but as the world changes and populations expand, the built environment is subject to an increasing number of forces that dictate its use and forms. As we open doors, turn on lights, and navigate stairs, we all experience irsthand standards within design practice. Ideally, codes and standards allow us to use buildings safely. Constraints brought by code restrictions may also provide an opportunity to let good design solve dificult problems. As the very real design needs of people with disabilities receive oficial and widespread acknowledgment and the concept of accessibility becomes more naturally integrated with architecture—for younger designers this is the norm—it can be dificult to imagine how recently it was viewed as an impediment to good design. Acceptance of the aesthetic possibilities of sustainable design is even more recent. In fact, new standards that accommodate all types of users and a growing recognition of architecture’s responsibility to the environment and its future can provide fresh takes on old forms and strong incentives to try new processes. 19 Chapter 19: Building Codes The fundamental purpose of building codes is to protect the health, safety, and welfare of all people through the construction of safe buildings and environments. Building practices have long been regulated in various ways, and regulations have existed in America since the early colonies, but it was the 1871 Chicago ire that emphasized the need for effective and enforceable building codes. In the early years since, most building codes in the United States were written and administered by local city, county, or state jurisdictions, eventually producing three major model codes: the National Codes of the Building Oficials and Code Administrators International (BOCA), the Uniform Codes of the International Conference of Building Oficials (ICBO), and Standard Codes of the Southern Building Code Congress International (SBCCI). With a few exceptions, each of the ifty states has adopted one of these models for its primary building code, in addition to supplemental codes for ire, mechanical, electrical, plumbing, and residential. INTERNATIONAL BUILDING CODE In 1997 the International Code Council (ICC) enlisted representatives from BOCA, ICBO, and SBCCI (the three founding arms of the ICC) to create a comprehensive and internationally available model construction code that would combine the considerable scope of the existing model codes. The irst International Building Code (IBC) was established in 2000, and with it, the development of the National Codes, Uniform Codes, and Standard Codes was discontinued. Currently, most U.S. states have adopted or are making efforts to adopt the IBC as their primary building code, though the process continues to differ for each state. Some have adopted the IBC but have not yet made it effective, others have adopted it on a statewide level, and still others have let their local city and county governments decide. The same has been true for the supplemental codes. The current status of the applicable codes for any given state or local jurisdiction should be veriied with local building departments or by visiting the ICC website at www.iccsafe.org. Any code information cited in this book is from the IBC, unless stated otherwise. NOTE OF DISCLAIMER The code information contained in this chapter is for general information only and is here to provide the reader with an introductory overview of the purposes and organization of building codes. It is not intended to replace any codes discussed, to present interpretations or analyses of said codes, or to address any speciic project. It also does not try to address all aspects of any one code in such a small number of pages; rather, the information touches on topics of general interest to most users of this book. All attempts have been made to present information as accurately as possible, with the understanding that code content may change after the book’s publication. 198 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 19 To address a changing world, the IBC codes are evolving through continual review by almost any party that comes in contact with them, including code enforcing oficials, various code development committees, and design professionals. Changes occur, for instance, to address new materials, emerging technologies, and shifts in use types. They even occur to clarify interpretations of language and the intent of the codes as written. As a result, the IBC has been designed to be updated every three years. The 2012 edition, for example, exhibits the 2009 code with ICCapproved changes included. For any project, the applicable codes must be interpreted by the appropriate Authority Having Jurisdiction (AHJ), which could include, among others, local building and ire oficials. The use and interpretation of codes can be daunting, and differences of interpretation may occur among designers and building oficials. For this reason, it is beneicial to a project to establish contact with the local building department early enough in the design process to address any questions of interpretation. Numerous publications offer explanations and interpretations of many aspects of code use, though they should always be used in conjunction with the code itself, and not as a substitute. In addition, licensed code consultants can provide further clariication of codes or offer a general review of projects, especially large and complex ones, with an eye to code compliance. Even with the help of consultants and the interpretations of others, architects must make every effort to familiarize themselves with pertinent codes, which puts them in a position of greater authority when issues of interpretation do arise. It is never recommended to memorize passages of the code, however, because these will change over time and memory may fail. What is important is to have a thorough working knowledge of the table of contents and to be able to navigate the code with a conident eficiency that, like all aspects of the practice of architecture, comes with experience. OTHER CODES Within any one jurisdiction, a complex variety of codes may still be in use, even if the IBC has been adopted as the primary code. Local building departments must always be consulted for a complete breakdown of what codes are to be addressed for any given project. In addition, federal laws such as the Americans with Disabilities Act and the Federal Fair Housing Act must be followed. All codes are structured around protection of human life and of property, including both prevention and reaction. Code analysis is performed based on the following sets of data: Occupancy Type Construction Type Building or Floor Area Building Height Exits and Egress Building Separations and Shafts Fire Protection Fire Extinguishing Systems Engineering Requirements B uilding Co des 199 19 OCCUPANCY TYPE AND USE GROUPS A building’s use and occupancy are primary criteria for determining many aspects of how codes will affect a building, including the height, area, and type of construction allowed. Within each occupancy use group are further subdivisions. It is not unusual for a building to fall under more than one category of occupancy type, which is known as a mixed-use occupancy. It may then be handled either as a “separated use,” by providing complete ire separation between occupancies, or as a “nonseparated use,” by subjecting each occupancy type to the most stringent requirements for its respective use group. Occupancy Use Groups A B E F H I M R S U Assembly Business Educational Factory and Industrial High Hazard Institutional Mercantile Residential Storage Utility and Miscellaneous In addition, other building types exist which do not fall into the above categories, and/ or contain elements requiring additional code requirements. Group B: Business Most ofice buildings fall into this category, including their storage areas (unless they exceed the amount of hazardous materials allowable, in which case they become Use Group H). Also included are educational facilities after grade 12 (colleges and universities), outpatient clinics and doctors’ ofices, and research laboratories. Any assembly area, including a lecture hall, may fall into Group A and should be treated as such. Group E: Educational More than 6 people, for classes up to the 12th grade Group A: Assembly (50 or more occupants) Daycare facilities for ive or more children over age 21/2 (daycare in a dwelling unit for fewer than 5 people is classiied as R-3) A-1: Assembly areas usually with ixed seats, usually for viewing movies or performances (may or may not have a stage) A-2: Assembly areas involving serving and consumption of food and drink, as in a restaurant or bar. Loose seating and possible patron alcohol impairment are key factors in this group. A-3: Other assembly groups that don’t it A-1 or A-2. May include houses of worship, art galleries, and libraries. A-4: Assembly areas for indoor sporting events. A-5: Assembly areas for outdoor sporting events. 200 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Group F: Factory and Industrial F-1: Moderate-hazard factory occupancy that has established that the relative hazards of fabrication operations do not put them in Group H (Hazardous) or in category F-2. F-2: Low-hazard factory industrial occupancy where the materials of manufacture are considered to be noncombustible. 19 Group H: High-Hazard Group R: Residential A range in high-hazard occupancies from H-1 to H-5, addressing the quantities and nature of use of the hazardous materials. R-1: Residences with sleeping units serving transient occupants. May include hotels and boarding houses. Group I: Institutional R-2: Permanent dwellings with more than two units. May include apartments, dormitories, and longer term boarding houses. I-1: More than 16 people in a 24-hour residential environment and under supervised conditions. May include group homes, assisted-living facilities, and halfway houses whose residents require custodial care, but are capable of self preservation. R-3: Permanent single-family or duplex residences. May also include care facilities for 5 or fewer people, boarding houses with 10 or fewer occupants, and (nontransient) congregate living facilities with 16 fewer occupants. Includes many residential occupancies not included in R-1, R-2, R-4, or I. I-2: More than 5 people in a 24-hour residential environment and under supervised conditions and receiving medical care. May include hospitals and nursing homes whose residents are unable to respond to emergency situations without the aid of staff members. I-3: More than 5 people in a 24-hour supervised environment under full-time restraint and security. Because of security measures, occupants cannot respond to emergencies without the aid of a staff member. May include prisons, detention centers, and mental hospitals, which may be further subdivided into ive categories based on the amount of freedom of movement of residents inside the facility. I-4: More than 5 people under supervised conditions or custodial care for less than 24 hours a day. May include care facilities for adults and children under the age of two, who are unable to respond to emergency situations without assistance from a staff member. Group M: Mercantile Department stores, drug stores, markets, gas stations, sales rooms, and retail or wholesale stores. R-4: Between 5 and 16 occupants of a residential care or assisted-living facility, in which the residents receive custodial care on a 24-hour basis, but are capable of self preservation. Types include alcohol and drug centers and social rehabilitation facilities. Group S: Storage S-1: Moderate-hazard storage occupancy for materials not considered hazardous enough for Group H but that do not qualify as S-2. S-2: Low-hazard storage occupancy for materials considered to be noncombustible. Group U: Utility and Miscellaneous Used for incidental buildings and nonbuildings (such as fences or retaining walls) that are generally not occupied for long periods of time and may serve a secondary function to other occupancies. This occupancy is seldom used and is not to be used for any building that is dificult to categorize. Building Codes 201 19 CONSTRUCTION TYPES AND FIRE RESISTANCE Construction types are categorized by their material content and the resistance to ire of the structural system. The IBC assigns ive broad categories to all buildings, based on the predominant materials in the building’s construction. These categories are I, II, III, IV, and V, with Type I being most ire resistive and Type V being least ire resistive. The ive types are divided into A and B categories, relecting the level of ire-resistance rating for each. Noncombustible materials, which are deined as being materials “of which no part will ignite and burn when subjected to ire,” typically include masonry and steel. Combustible materials, which may be assumed to be materials that fail to meet noncombustibility requirements, include wood and plastic. Types of Construction Noncombustible IA IB All building elements as listed in IBC Table 601 (structural frame, interior and exterior bearing walls, interior and exterior nonbearing walls, floor construction, and roof construction) are of noncombustible materials. IIA Noncombustible/Combustible IIB All building elements as listed in IBC Table 601 (structural frame, interior and exterior bearing walls, interior and exterior nonbearing walls, floor construction, and roof construction) are of noncombustible materials. Type IIB construction is not required to be fireresistance rated. IIIA IIIB Exterior walls must be of noncombustible materials and interior building elements may be of any material permitted by the code. Fire retardant–treated wood framing may be allowed in exterior wall assemblies of less than 2-hour rating, as long as they comply with IBC Section 2303.2. IV (Heavy Timber = HT) Exterior walls must be of noncombustible materials and interior building elements may be of solid or laminated wood without concealed spaces. Fire retardant–treated wood framing may be allowed in exterior wall assemblies of less than 2-hour rating, as long as they comply with IBC Section 2303.2. Combustible VA VB All building elements as defined by IBC Table 601 are of any materials permitted by the code. Fire-Resistance Ratings Fire-resistance ratings are measured in hours or fractions of an hour and relect the amount of time that a material or assembly of materials will resist ire exposure, as set forth in ASTM E119 (American Society for Testing and Materials Standard for Fire Tests of Building Constructions). When beginning design of a building, the initial code analysis must consider the desired occupancy and the desired height and area to determine the minimum allowable construction type for ire ratings. 202 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 19 Means of Egress Diagram An exit is an enclosed, protected way of travel from an exit access to an exit discharge. When the exit access is above or below the grade of the exit discharge, an enclosed stair or ramp is required. The number of means out of an occupied space are determined by size, occupancy type, and occupant load. An exit access leads an occupant from an occupied part of the building to an exit (commonly, this is a corridor). PU BL IC WA Y An exit discharge provides a means of moving from an exit to a public way. This is considered an unallowable dead-end corridor, unless a second means of egress is provided. Typically, dead-end corridors must not exceed 20' (6 069), though exceptions exist for certain occupancies and sprinklered conditions. Building Codes 203 19 MEANS OF EGRESS IBC 202 deines a means of egress as “a continuous and unobstructed path of vertical and horizontal egress travel from any occupied portion of a building or structure to a public way.” It consists of the exit access, the exit, and the exit discharge. Simply put, means of egress provide conditions for getting all occupants to a safe place (usually an outdoor public way) in the event of ire or other emergency. Required Egress Widths Sizes are determined by coordinating IBC Table 1004.1 (summarized on the following page) with the requirements below, taking whichever number is higher. Egress Doors In areas with an egress load of more than ifty occupants, or any Group H occupancy, exit access doors should swing in the direction of travel. If they swing into a required egress path, they may not reduce the required width by more than one half while swinging open, and once opened 180º, the door may not project into the required width more than 7” (178). Number of Means of Egress Per IBC Table 1015.1, occupancy spaces that require more than one means of egress are: A, B, E, F, M, and U, with occupant loads 50 and over H-1, H-2, H-3, with occupant loads over 3 H-4, H-5, I-1, I-2, I-3, I-4, and R, with occupant loads over 10 S with occupant loads 30 and over Any occupancy between 501 and 1,000 requires three exits, and occupancies over 1,000 require four. Exit Passageways Minimum passageway width is determined by IBC 1005.1 but must not be less than 44” (1 118), except for the following conditions: Within a dwelling unit or in an occupancy of less than ifty: 36” (914) Group E with a hundred or more capacity: 72” (1 829) Group I-2 areas with required bed movement: 96” (2 438) Egress Stairs Egress doors should be a minimum of 6’-8” (2 032) high, with a clear opening width determined by IBC 1008.1, but no less than 32” (813), measured from the face of the door to the stop when open. Maximum width of a swinging door leaf is 48” (1 219). 204 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Minimum width is determined by IBC 1005.1 but must not be less than 44” (1 118), except for passageways serving occupant loads of less than ifty, which must be no less than 36” (914). Ramps in an egress system should have a width no less than the corridors that serve them, and no less than 36” (914) between handrails.. 19 Determining Occupancy Loads The table at right may be used to establish occupant loads per area sizes, from which egress widths per occupant are calculated. Alternatively, occupant loads are determined by the actual number, if larger, of occupants for whom the space is designed or, in addition, for whom the space will serve as a means of egress. Maximum Floor Areas per Occupant (excerpted from IBC Table 1004.1.2) Type of Occupancy Floor Area per Occupant Assembly with fixed seats Occupant load for areas with fixed seats and aisles is determined by the number of seats, with one person for every 18” (457) of seating length; or one person for every 24” (610) in seating booths. Assembly without fixed seats chairs (concentrated): 7 sq. ft. (0.65 m2) net standing space: 5 sq. ft. (0.46 m2) net Required Egress Widths in Inches Per Occupant All Other Occupancies I-2 Institutional H-1, H-2, H-3, and H-4 Stairs 0.7 (no sprinkler system) 0.3 (with sprinkler system) 0.3 (with sprinkler system) Other Egress Components 0.4 (no sprinkler system) 0.2 (with sprinkler system) 0.2 (with sprinkler system) 0.3 (no sprinkler system) 0.2 (no sprinkler system) 0.2 (with sprinkler system) 0.15 (with sprinkler system) tables and chairs (unconcentrated): 15 sq. ft. (1.39 m2) net Business areas 100 sq. ft. (9.29 m2) gross Dormitories 50 sq. ft. (4.65 m2) gross Educational—classrooms 20 sq. ft. (1.86 m2) net Educational— shop and vocational areas 50 sq. ft. (4.65 m2) net Commercial kitchens 200 sq. ft. (18.58 m2) gross Library reading room 50 sq. ft. (4.65 m2) net Library stacks 100 sq. ft. (9.29 m2) gross Mercantile— basement or grade floor 30 sq. ft. (2.79 m2) gross Mercantile—floors other than basement or grade floor 60 sq. ft. (5.57 m2) gross Mercantile— storage, stock, and shipping 300 sq. ft. (27.87 m2) gross Parking garage 200 sq. ft. (18.58 m2) gross Residential 200 sq. ft. (18.58 m2) gross Net area is generally considered to be the actual occupied area and does not include unoccupied areas such as corridors, walls, stairways, or toilets. Gross area includes loor area within the inside perimeter of the exterior walls, as well as corridors, stairways, closets, interior partitions, columns, and other ixed features. Building Codes 205 20 Chapter 20: ADA and Accessibility The Americans with Disabilities Act (ADA) was passed by Congress in 1990 to protect and honor the civil rights of people with disabilities, including conditions affecting mobility, sight, hearing, stamina, speech, and learning disorders. Modeled on earlier landmark laws prohibiting discrimination based on race and gender, the ADA provides equal access for all people to housing, public accommodations, employment, government services, transportation, and telecommunications. Similar to building codes, accessibility guidelines and standards are continually subject to improvement and revision, and in 2010 the Department of Justice adopted a revised set of standards, published as the 2010 Standards for Accessible Design. Included among the revisions are accommodation for children, and ambulatory (in addition to wheelchair) accessibility. KEY TERMS AS DEFINED BY ADA Access aisle: Accessible pedestrian space between elements such as parking spaces, seating, or desks that provides clearances appropriate for use of the elements. Accessible: Of a site, building, facility, or portion thereof, in compliance with ADA guidelines. Accessible element: Element (telephone, controls, and the like) speciied by ADA guidelines as in compliance. Accessible route: Continuous unobstructed path connecting all accessible elements and spaces of a building or facility. Interior accessible routes may include corridors, loors, ramps, elevators, lifts, and clear loor space at ixtures. Exterior accessible routes may include parking access aisles, curb ramps, crosswalks at vehicular ways, walks, ramps, and lifts. Accessible space: Space that complies with ADA guidelines. Adaptability: Ability of certain building spaces and elements, such as kitchen counters, sinks, and grab bars, to be added or altered so as to accommodate the needs of individuals with or without disabilities or with different types or degrees of disability. 206 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Addition: Expansion, extension, or increase in the gross loor area of a building or facility. Administrative authority: Governmental agency that adopts or enforces regulations and guidelines for the design, construction, or alteration of buildings and facilities. Area of rescue assistance: Area that has direct access to an exit, where people who cannot use stairs may remain temporarily in safety to await further instructions or assistance during emergency evacuation. Assembly area: Room or space accommodating a group of individuals for recreational, educational, political, social, or amusement purposes, or for the consumption of food and drink. Automatic door: Door equipped with a poweroperated mechanism and controls that open and close the door automatically on receipt of a momentary actuating signal. The switch that begins the automatic cycle may be a photoelectric device, loor mat, or manual switch. See power-assisted door. 20 Building: Any structure used and intended for supporting or sheltering any use or occupancy. Circulation path: Exterior or interior way of passage from one place to another for pedestrians, including, but not limited to, walks, hallways, courtyards, stairways, and stair landings. Clear: Unobstructed. Clear floor space: Minimum unobstructed loor or ground space required to accommodate a single, stationary wheelchair and occupant. Common use: Describes interior and exterior rooms, spaces, or elements that are made available for the use of a restricted group of people (for example, the occupants of a homeless shelter, the occupants of an ofice building, or the guests of such occupants). Cross slope: Slope that is perpendicular to the direction of travel. Curb ramp: Short ramp cutting through a curb or built up to it. Detectable warning: Standardized surface feature built in or applied to a walking surface or other elements to warn visually impaired people of hazards on a circulation path. Elements: Architectural or mechanical component of a building, facility, space, or site (for example, a telephone, curb ramp, door, drinking fountain, seating, or water closet). Entrance: Any access point to a building or portion of a building or facility used for the purpose of entering. An entrance includes the approach walk, the vertical access leading to the entrance platform, the entrance platform itself, vestibules if provided, the entry door(s) or gate(s), and the hardware of the entry door(s) or gate(s). Marked crossing: Crosswalk or other identiied path intended for pedestrian use in crossing a vehicular way. Operable part: Part of a piece of equipment or appliance used to insert or withdraw objects, or to activate, deactivate, or adjust the equipment or appliance (for example, a coin slot, push button, or handle). Power-assisted door: Door used for human passage with a mechanism that helps to open the door, or relieves the opening resistance of a door, on the activation of a switch or a continued force applied to the door itself. Egress, means of: Continuous and unobstructed way of exit travel from any point in a building or facility to a public way. A means of egress comprises vertical and horizontal travel and may include intervening room spaces, doorways, hallways, corridors, passageways, balconies, ramps, stairs, enclosures, lobbies, horizontal exits, courts, and yards. An accessible means of egress is one that complies with ADA guidelines and does not include stairs, steps, or escalators. Areas of rescue assistance or evacuation elevators may be included as part of accessible means of egress. ADA and Accessibility 207 20 Public use: Describes interior or exterior rooms or spaces that are made available to the general public. Public use may be provided at a building or facility that is privately or publicly owned. Ramp: Walking surface that has a running slope greater than 1:20. SIGNAGE Elevator Control Panel Raised character and Braille designations - left of button button diameter 3/4” (19) Running slope: Slope that is parallel to the direction of travel. main entry loor Signage: Displayed verbal, symbolic, tactile, and pictorial information. door open door close emergency alarm emergency stop Space: Deinable area (for example, a room, toilet room, hall, assembly area, entrance, storage room, alcove, courtyard, or lobby). Tactile: Of an object, perceptible using the sense of touch. Text telephone: Machinery or equipment that employs interactive graphic (that is, typed) communications through the transmission of coded signals across the standard telephone network. Text telephones can include devices known as TDDs (telecommunication display devices or telecommunication devices for deaf persons) or computers. Walk: Exterior pathway with a prepared surface intended for pedestrian use, including general pedestrian areas such as plazas and courts. Emergency controls should be grouped at the bottom, with centerlines no less than 35” (889) AFF. Raised and Tactile Characters Characters should be raised 1/32” (0.8) and in uppercase with sans serif font. Characters shall not be italic, oblique, decorative or unusual. Characters must be accompanied by Grade 2 Braille. Raised characters must be a minimum of 5/8” (16) and maximum of 2” (51) high based on an uppercase I. Braille shall be positioned below the corresponding text, and shall be separated by 3/8” (10) minimum from any other tactile characters or raised borders. Tactile characters on signs shall be located 48” (1 220) min. AFF, measured from the baseline of the lowest character, and 60” (1 525) max. AFF, measured from the baseline of the highest tactile character. 208 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 20 Visual Characters ACCESSIBLE MEANS OF EGRESS Characters and background must be eggshell, matte, or another nonglare inish and must contrast with background (either light on dark or dark on light). Any space that is considered to be accessible must have at least one accessible means of egress. Characters may be uppercase or lowercase, or a combination of both, and shall not be italic, oblique, decorative or unusual. Minimum character height shall be determined by the horizontal viewing distance (per 2010 Standard 703). Pictograms Text descriptors (if any) must be placed directly below pictogram ield. Pictograms can be any size within a minimum ield of 6” (153) in height. Elevators that comply with ASME A17.1, Safety Code for Elevators and Escalators, may be allowed as part of an accessible egress route. Primarily, they must be equipped with standby power and emergency operation and signaling devices, and most must be accessed from an area of refuge. Areas of refuge, where those unable to use stairways remain temporarily in an evacuation, should be in an egress stairway or have direct access to one, or to an elevator with emergency power. Two-way communications systems should be provided in the area of refuge, connecting it to a central control point. One 30” x 48” (762 x 1 219) wheelchair space must be provided for every two hundred occupants of the space served. Generally these spaces are alcoves within an enclosed stair, because they must not reduce the egress width. Except in sprinklered buildings, accessible egress stairways should be a minimum of 48” (1 219) wide clear between handrails. This provides a space wide enough for two people to carry a disabled person down or up to safety. ADA and Accessibility 209 20 ACCESSIBLE PARKING SPACES The length of accessible parking spaces must be in accordance with local building codes. Accessible spaces should be marked by high-contrast painted lines or other high-contrast delineation. Access aisles should be a part of an accessible route to the building or facility entrance. Two accessible parking spaces may share a common access aisle. Access aisles should be marked clearly by means of diagonal stripes. parking space 96” (2 438) access aisle parking space 60” (1 524) 96” (2 438) for vans: 96” (2 438) Number of Accessible Spaces Required 210 1–25 1 26–50 2 51–75 3 76–100 4 101–150 5 151–200 6 201–300 7 301–400 8 401–500 9 501–1,000 2% of total 1,001 and over 20 plus 1 for each 100 over 1,000 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Surface slopes should not exceed 1:50 (2%) in any direction on accessible parking spaces and access aisles. Accessible parking spaces serving a particular building should be located on the shortest accessible route of travel from the adjacent parking to an accessible entrance. In buildings with multiple accessible entrances with adjacent parking, accessible parking spaces should be dispersed and located closest to the accessible entrances. 20 WHEELCHAIR SPACE ALLOWANCES Clear loor or ground space is deined as the minimum clear area required to accommodate a single, stationary wheelchair and occupant. This applies to both forward and parallel approaches to an element or object. Clear loor space may be part of the knee space required under objects such as sinks and counters. Wheelchair Passage Widths Clear Floor Space at Alcoves 30” (762) single wheelchair two wheelchairs 36” (914) 12” (305) 48” (1 219) 30” x 48” (762 x 1 219) clear floor space, typical 30” (762) 60” (1 524) x 32” (813) 48” (1 219) x # 24” (610) 36” (914) x # 15” (381) 12” (305) x 36” (914) 30” (762) or 36” (914) if x$ 24” (610) 60” (1 524) 60” (1 524) dia. min. 78” (1 981) preferred 48” (1 219) or 60” (1 524) if x$ 15” (381) x 60” (1 524) dia. min. ADA ADA and and Accessibility Accessibility 211 20 DOORS Maneuvering Clearances at Doors pull side 60” (1 524) Clear Doorway Width and Depth 18” (458) hinged door 60” (1 524) 12” (305) sliding door 32” (813) push side folding door 24” max. (610) Swinging Doors (front approaches) 48” (1 219) pull side 42” (1 067) 24” (610) 24” (610) push side Swinging Doors (latch-side approaches) 212 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 20 Two Hinged Doors in a Series Y X pull side 54” (1 372) 48” (1 219) 42” (1 067) push side If Y=60” (1 524 ), X =36” (914 ) If Y=54” (1 372), X =42” (1 067) Swinging Doors (hinge-side approaches) 54” (1 372) side 48” (1 219) 42” (1 067) 48” (1 219) front approach approach 42” (1 067) 24” (610) latch-side approach Sliding and Folding Doors ADA ADA and and Accessibility Accessibility 213 20 TOILETS AND BATHROOMS 56”-59” (1 420 - 1 499) Clear Floor Space at Water Closets - Adult Toilet Stalls 35” - 37” (890 - 940) Grab bars: 32” (813) 32” (813) 60” (1 524) End-of-Row Wheelchair Accessible Stall 214 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 17–19” (432–483) 12” 42” (305) (1 065) 33–36” (838–914) 16”-18” (406-457) non-circular cross sections shall have a crosssectional dimension of 2” (51) max, and a perimeter dimension between 4” and 4.8” (100 - 120) Ambulatory Accessible Stall 32” (813) 36” (914) 56” min. (1 422) Wheelchair Accessible Stall 54” min. (1 372) 17” -19” (432-482) circular cross section should be 11/4”–2” (32–51) in diameter, with a clearance of 11/2” (38) from wall. 42” (1 067) min. latch-side approach 48” (1 219) min. other approaches 16”-18” (406-457) 52” min. (1 321) 56” min. (1 420) wall-mtd. toilet 59” (1 499) floor-mtd. toilet 12” (305) 12” max. (305) 60” min. (1 524) 24” min. 12” max. (609) (305) 60” min. (1 524) 60” (1 525) Side-wall Elevation toilet paper dispenser mounting height: 15” (483) - 48” (1 220) 20 Lavatories 19” max. (483) 8” min. (203) 17” min. (432) 36” (914) A seat must be provided in shower stalls 36” x 36” (914 x 914), mounted 17”–19” (432–83) from the bathroom loor and extending from the back wall to a point within 3” (76) of the compartment entry. 36” (914) 30” min. (762) 60” min. (1 524) 36” x 48” (914 x 1 219) min. clear loor space Transfer Type 36” x 60” (914 x 1 524) min. clear loor space Fixed seats in 30” x 60” (762 x 1 524) shower stalls should be of a folding type mounted on the wall adjacent to the controls. Roll-in Type 15” (381) 30” x 60” (762 x 1 524) min. clear loor space seat head seat Bathtubs foot 40” max. (1 016) 6” max. (19) Showers fixed seat 27” min. (686) 9” min. (229) 30” x 48” (762 x 1 219) min. clear floor space 34” max. (864) 17” min. (432) 48” x 60” (1 219 x 1 524) min. clear loor space 12” max. 24” min. (305) (610) 30” x 75” (762 x 1 905) min. clear loor space 48” min. (1 219) 33-36” (838-914) 8”-10” (203-254) 12”max. (305) ADA ADA and and Accessibility Accessibility 215 20 ELEVATORS ” 54 2) 37 1 ( 60” (1 524) Call buttons must be a minimum 3/4” (19) in the smallest direction. 42” (1 067) Door jambs should have raised and Braille loor designation markings. 72” (1 829) Hall lantern ixtures at each hoistway entrance must indicate visibly and audibly which car is answering a call. (1 68 ” 72 7) 36 (91 ” 4) Typical Dimensions for off-centered door RAMPS The rise for any ramp run before landing shall be 30” (762) max. The minimum clear width of a ramp should be 36” (914), inside handrails. If a ramp has a rise greater than 6” (150) then it should have handrails on both sides. th ram g mi n. idt h ) c oje l pr nta rizo ing and el l lev 60” 5) 2 (1 5 un n (r tio ho THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK din pw Maximum slope is 1:12. 216 lan wid rise ing and el l ” v e l 60 5) 2 (1 5 = 20 STAIRS Handrails Nosings at wall: handrail returns to wall 11/4” –2” (32–51) dia. Risers should be sloped, or the underside of nosings should have an angle not less than 60º from the horizontal. at switchback: handrail is continuous 11/2” (38) min. from wall where no wall: handrail returns smoothly to the loor lush riser 11” (280) min. tread depth handrail extension at top of run = 12” (305) minimum angled nosing 7” (178) max. riser height rounded nosing g din th lan id n. h = w i m dt ir wi sta of 80” (2 032) Handrail Extension (min.)at Bottom of Run 27” (686) 34” –38” (864–965) tread depth ne ca rea na tio c ete d ADA ADA and and Accessibility Accessibility 217 21 Chapter 21: Parking Almost everywhere, parking is often a person’s irst and last interface with a building and should be designed with this in mind. Primarily, parking should be safe, eficient, well-marked, and able to accommodate users of all kinds. Because vehicle sizes luctuate, parking areas must be lexible enough to respond to future scenarios. General Guidelines PARKING LOTS Pavement striping should be 4” (102) wide, in white or yellow paint. Parking area surfaces should have a minimum slope of 2 percent (a quarter-inch per foot or 6 mm per 305 mm) for drainage purposes. 20’-0” to 24’-0”, typ. (6 096 to 7 315) 45º 60º 75º width stall 90º 8’-0” (2 438) stall length aisle Parking Stalls 218 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 20’-0” (6 096) Parallel Parking Lots are laid out with modules. One complete module includes one access aisle and the parking it serves on either side. The most common angle for parking is the 60º stall, which provides for ease of entering and exiting spaces while still allowing for an eficiently sized module. Stalls of 45º reduce the total number of parking spaces for a given area but do not require a wide access aisle. They are the only acceptable angle for a herringbone parking lot pattern. Stalls of 90º provide the most parking spaces for a given area, though they are unsuitable for in-and-out trafic, due to the higher degree of dificulty entering and exiting the stalls. They are ideal for all-day parking, such as for employees. 21 COMMON PARKING STALL LAYOUTS cross aisle (one-way): 14’ (4 267) cross aisle (two-way): 24’ (7 315) G H A B C D interlock interlocking module stall depth A B C D 45º 17.5’ (5 334) 12.0’ (3 658) 15.3’ (4 663) 42.6’ (12 984) 60º 19.0’ (5 791) 16.0’ (4 877) 17.5’ (5 334) 51.0’ (15 549) 75º 19.5’ (5 944) 23.0’ (7 010) 18.8’ (5 730) 61.0’ (18 593) 90º 18.5’ (5 639) 26.0’ (7 925) 18.5’ (5 639) 63.0’ (19 202) Recommended parking layouts and stall dimensions vary and are most often determined by local or state zoning provisions (which should always be consulted). Commonly accepted minimum stall sizes are 9' (2 743) x 18.5'–19.5' (5 639–944), though sizes and layouts should best accommodate their situation; for instance, stalls at hardware or grocery stores should be wide enough to accommodate easy loading and unloading of large packages, and may be up to 10' (3 048) wide. Compact car spaces may be as small as 7'-6" (2 286) x 15' (4 572) and should be well marked and logically grouped. Par king 219 21 Parking Lot Flows Two-way 90 Degrees One-way Angled Common Parking Space Allocations Hospital Auditorium/theater/stadium Restaurant Industrial Church Retail Ofice Shopping center Hotels/motel Senior high schools Elementary schools 1.2 per bed 0.3 per seat 0.3 per seat 0.6 per employee 0.3 per seat 4.0 per 1000’ gross loor area 3.3 per 1000’ gross loor area 5.5 per 1000’ gross leasable area 1.0 per room/0.5 per employee 0.2 per student/1.0 per staff member 1.0 per classroom Typical Car Length Classifications Pre-1975 Subcompact Compact Intermediate Standard 220 Post-1975 <100” (2 540) 101”–111” (2 565–819) 112”–118” (2 845–997) >119” (3 025) THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Small Medium Large <100” (2 540) 100”–112” (2 540–845) >112” (2 845) 21 PARKING GARAGES Ramp Design length ramp blend 7’-0” (2 134) minimum blend Straight Ramps Length Helical Ramps < 65’-0” (19 812) > 65’-0” (19 812) Blend length 10’-0” (3 048) 8’-0” (2 438) Blend slope 8% 6% Ramp slope 16% 12% width = 15’-0” (4 572) for counterclockwise travel width = 20’-0” (6 096) for clockwise travel slope = 12% maximum (4% in transverse direction) General Considerations e width op Express helical exit ramps are recommended to avoid congestion inside garage. 17’-0” (5 182) sl Parking garage stalls should be well-marked and use clear signage to direct drivers, especially in one-way trafic situations. Par king 221 22 Chapter 22: Stairs Stairs are a primary method of vertical circulation in most private residences and even in public places where elevators or escalators are present. In elevatored buildings, building codes will require a minimum number of enclosed exit stairs. Stair construction is typically of wood, metal, or concrete, or a combination of all three. STAIR TYPES Straight Run Stair Fire codes generally restrict the total rise of a straight stair to 12’-0” (3 658) before an intermediate landing is required. Landing depth should equal the stair width. L-shaped Stair with Landing L-shaped stairs may contain long or short legs, with a landing at any change in direction. U-shaped Stair with Landing U-shaped stairs, which switch back as they ascend, are useful in tight loor plans and as one component in a stacking multilevel circulation system (such as an egress stair core). 222 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 22 L-shaped Stair with Winders Winders may help to compress the area needed for a stair by adding angled treads where a landing might go in a typical L-shaped stair. Most winders do not comply with local codes. L-shaped Stair with Offset Winders Offset winder treads are more generous in proportion and, therefore, may comply with applicable codes. Spiral Stair Spiral stairs occupy a minimum amount of plan space and are often used in private residences. Most spiral stairs are not acceptable as egress stairs, except in residences and in spaces of ive or fewer occupants in 250 sq. ft. (23 m2) or less. Curved Stair Curved stairs follow the same layout principles of spiral stairs. Though with a suficient open center diameter, the treads may be dimensioned to legal code standards for egress. Stairs 223 22 STAIR COMPONENTS break line (entire run of stair cannot be seen in loor plan) arrow indicates direction of stair (one plan might have stairs going down and up) dashed lines indicate stair continues above break line UP total run of stair ceiling clearance: 6’-8” (2 032) min. guard rail height: 42” (1 067) min. total rise of stair handrail height: 34–38” (864–965) max. opening may allow an 8” (203) dia. sphere to pass through max. opening may allow a 4” (102) dia. sphere to pass through max. opening may allow a 6” (152) dia. sphere to pass through Plan and Elevation of Stair 224 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 22 riser: 6” (152) tread: 111/2” (292) riser: 5” (127) tread: 121/2” (318) Riser and Tread Dimensions Angle Riser inches (mm) Tread inches (mm) 22.00° 5 (127) 12 1/2 (318) 23.23° 5 1/4 (133) 12 1/4 (311) 24.63° 5 1/2 (140) 12 (305) 3/4 (146) 11 3/4 (299) 26.00° 5 27.55° 6 (152) 11 1/2 (292) 29.05° 6 1/4 (159) 11 1/4 (286) 30.58° 6 1/2 (165) 11 (279) 32.13° 6 3/4 (172) 10 3/4 (273) 33.68° 7 (178) 10 1/2 (267) 35.26° 7 1/4 10 1/4 (260) 36.87° 7 1/2 (191) 10 (254) 38.48° 7 3/4 (197) 9 3/4 (248) 40.13° 8 (203) 9 1/2 (241) 41.73° 8 1/4 (210) 9 1/4 (235) (184) 43.36° 8 1/2 (216) 9 (229) 45.00° 8 3/4 (222) 8 3/4 (222) 46.63° 9 (229) 8 1/2 (216) 48.27° 9 1/4 (235) 8 1/4 (210) 9 1/2 (241) 8 (203) 49.90° riser: 7” (178) tread: 101/2” (267) riser: 8” (203) tread: 91/2” (241) 46.63º 40.13º 33.68º 27.55º 22.00º TREADS AND RISERS riser: 9” (224) tread: 81/2” (216) General Guidelines The following are rules of thumb for calculating limits; always check appropriate local codes: riser x run = 72”–75” (1 829–905) riser + run = 17”–17 1/2” (432–45) 2(riser) + run = 24”–25” (610–35) exterior stairs: 2(riser) + run = 26” (660) Nonresidential: minimum width = 44” (1 120) maximum riser = 7 1/2” (191) minimum tread = 11” (279) Residential: minimum width = 36” (915) maximum riser = 8 1/4” (210) minimum tread = 9” (229) Blue band indicates preferred proportions for comfort and safety. Stairs 225 23 Chapter 23: Doors Interior and exterior doors may be of many combinations of wood, metal, and glass, and mounted in wood or metal frames. Interior doors may require various levels of ire ratings; exterior doors must be well constructed and tightly weather-stripped to avoid excessive leakage of air and moisture. Widths 2’-0” 2’-4” 2’-6” 2’-8” 2’-10” 3’-0” 3’-4” 3’-6” 3’-8” 3’-10” 4’-0” (610) (711) (762) (813) (864) (914) (1 016) (1 067) (1 118) (1 168) (1 219) Preferred SI Dimensions door frame single widths: 700 mm, 800 mm, 900 mm, 1 000 mm head jamb 5” (127) double widths: 1 200 mm, 1 500 mm, 1 800 mm st rik e equal heights: 2 100 mm, 2 200 mm, 2 400 mm lo ck Thicknesses ha 48” nd le 21/4” (54) equal 13/4” (44) (1 219) de ad 13/8” (35) (2 134) 7’-2” (2 184) 7’-10”* (2 388) 8’-0”* (2 438) 10” (254) (2 032) 7’-0” (914) 6’-8” 36” Heights *13/4” thick doors only side jamb 226 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 23 DOOR TYPES Flush Vision Panel Narrow Lite Glass Glass Louvered Louvered Glass and Louvered Fire Doors U.L. Label Rating Glazing Permitted: 1/4” (6.4) Wire Glass A 3 hour no glazing permitted B 11/2 C 3/4 D E hour 100 sq. in. (64 516 mm2) per leaf hour 1 296 sq. in. (836 179 mm2) per light; 54” (1 372) max. dimension 11/2 hour 3/4 hour no glazing permitted 720 sq. in. (464 544 mm2) per light; 54” (1 372) max. dimension Max. door size: 4’ x 10’ (1 219 x 3 048); door frame and hardware must have same rating as door; door must be self-latching and equipped with closers; louvers with fusible links are permitted for B and C label doors; no louver and glass light combinations are allowed. Doors 227 23 WOOD DOORS Flush Solid Core Flush Hollow Core Panel Used primarily for exterior conditions and wherever increased ire resistance, sound insulation, and dimensional stability are required. Lightweight and inexpensive, used primarily for interior applications, though may be used on the exterior if bonded with a waterproof adhesive. Low sound and heat insulation value. Supporting framework of rails and stiles may hold panels of wood, glass, or louvers. Makeup of doors minimizes dimensional changes brought on by luctuating moisture content of the wood. rail stile stile stile rail panel rail rail Door Elevation Door Elevation Door Elevation Detail Section Detail Section Detail Section face veneer face veneer panel cross banding cross banding solid core: continuous block, stile and rail, mineral composition, or particle board hollow core: mesh grid, ladder strips, honeycomb, or spiral blanks wood spacers edge strip edge strip 228 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK stile or rail 23 Typical Wood Door Framing head and side jamb should have similar proile to ensure continuous frame around doorway wall construction Head shim space casing or trim (exterior joints may require lashing and caulk) Jamb In the prehung method, shims help assure that the door and frame will it cleanly in the rough opening provided. The resulting gap between the frame and the wall inish is generally covered with a casing. Detailing of this condition may take many forms, depending on the desired result, though a common approach is shown at left. rabbeted door frame (interior frames may have applied stops) Wood Face Veneer Types Standard: 1/32” –1/16” (0.08–1.6), bonded to hardwood; crossband of 1/16” –1/10” (1.6–2.5). Economical and widely used; for all types of cores. Dificult to reinish or repair face damage. In the interest of speed and economy, many wood doors have been prehung (hinged and itted to their frames at the mill). When they arrive on site, the carpenter may tilt the frame into the rough opening, carefully plumbing the frame and shimming as necessary before nailing the frame in place. Wood Grades Sawn veneers: 1/8” (3.2), bonded to crossband. Easily reinished and repaired. Premium: For natural, clear, or stained inishes Sawn veneers: 1/4” (6.4), no crossband on stile and rail. Face depth allows for decorative grooves. Standard: For opaque (painted) inishes Doors 229 23 HOLLOW METAL DOORS Meeting Stiles top rail hinge stile lush or recessed panel rabbeted parallel bevel with z astragal bull nose vinyl or rubber astragal parallel bevel plate astragal v-bevel one-piece overlapping astragal center rail lock stile bottom rail Standard Double Rabbet Frame jamb depth rabbet 1 sofit throat opening rabbet 2 backbend frame head frame jamb backbend door meeting stiles face stop Jamb Depth 230 4 3/4” (121) 5 1/2” (140) 5 3/4” (146) 6 3/4” (171) 7 3/4” (197) Rabbet 1 19/16” (40) standard for 1 3/8” (35) door Rabbet 2 115/16” (49) standard for 1 3/4” (44) door 8 3/4” (222) 12 3/4” (324) Backbend 1/2” (13) 3/4” (19) 1/2” (13) 1/2” (13) 1/2” (13) 1/2” (13) 1/2” (13) Throat 33/4” (95) 4” (102) 4 3/4” (121) 5 3/4” (146) 6 3/4” (171) 7 3/4” (197) 11 3/4” (298) THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 23 FRAME ANCHORS Hollow Metal Door Gauges GRADE GAUGE Residential 20 and lighter Commercial 16 and 18 Institutional 12 and 14 High Security steel plate Standard Floor Knee Jambs are attached to the loor with powder-driven fasteners. Wood Stud Anchor Jambs are anchored to wood studs by nailing through holes in jamb inserts. Steel Channel Anchor Jambs are anchored to steel studs; sheet metal zees are welded to jambs, and receive screws driven through studs. Extended Frame with Base Anchor Floor-topping concrete is poured around the door frame. Masonry T Anchor Jambs are anchored to masonry walls: loose sheet metal tees are inserted into the frame and built into the mortar joints. OTHER CORES treated ibrous material formed into honeycomb anhydrous mineral, foam, or iber core kiln-dried structural wood core z-member or channel stiffeners (vertical, horizontal, or gridded) Doors 231 COMPENDIUM 232 232 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 4. The art of architecture is not easily quantiied or deined. It is certainly more than the sum of the systems and materials that give it shape, though architecture would not exist without the standardized procedures that erect its forms. The preceding chapters have provided the rudimentary tools for making buildings. It is in how architects use these tools to transform limitations into possibilities that allow them to navigate challenging situations and ultimately produce a better built environment. The breadth of practical information about basic systems and concepts that this book has so far touched on is also a way of describing the world of architecture to all its users. What follows is a broad overview of how these basic systems have become a history of our overlapping cultures. We live in the built world: Whether it is well-designed or poorly designed, it is the space and surface of our existence. By inhabiting architecture and moving around it, we have knowledge of it. To enhance our understanding, this book ends with a beginning: an introduction to a range of resources within the enormous, endless scope of architectural information and discussion. 233 233 3000 Chapter 24: Timeline B.C.E. 24 The history of architecture is a history of civilization. Buildings are artifacts intrinsically linked to the epoch and society of their creation, clearly expos- ANCIENT Great Sphinx of Giza (ca. 2500 B.C.E.) Egypt Great Pyramids of Giza (2570–2500 B.C.E.) Egypt • • ing the varied conditions of how they came to be. To understand a piece of architecture is to gain insight into • countless aspects of a place and a moment in time—geography, weather, social hierarchies, religious practices, and industrialization. And because architecture is rarely portable, it is virtually impossible to disengage a building from its origins. The luidity of history can make for unwieldy attempts to classify periods succinctly, and architectural styles and movements relect this dificulty: Though some styles may have come into sudden existence as the result of a speciic event, most evolve slowly and taper off gradually. The distillation of any history presents obvious limitations; therefore, many dates shown here are approximations, serving the overall purpose of this timeline, which is to illustrate relationships among movements. (Before Common Era) = B.C. C.E. (Common Era) = A.D. b. = before; c. = century; ca. = circa B.C.E. 234 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Stonehenge (ca. 2900–1400 B.C.E.) Salisbury Plain, England • • • 0 B.C.E. 1000 B.C.E. 2000 24 Hall at Karnak • Hypostyle ) (ca. 1300 B.C.E. Egypt Egyptian (ca. 3500–30 B.C.E.) Mortuary Temple • Mentuhotep ) (2061–2010 B.C.E. Deir el-Bahari, Egypt Temple of Ramses II • Great ) (ca. 1285–1225 B.C.E. Abu Simbel, Egypt El Castillo (850 C.E.) Chichen Itza, Yucatan, Mexico Greek (ca. 2000–31 B.C.E.) Palace at Knossos (1700–1380 B.C.E.) Knossos, Greece • Temple of Hera (460 B.C.E.) Paestum, Italy of the Rock • Dome ) (687–89 C.E. • Jerusalem Temple of Apollo (310 B.C.E.) Turkey Paeonis and Daphnis • Parthenon (448–432 )• Athens, Greece • • Temple of Paestum (ca. 530-460 B.C.E.) Paestum, Italy B.C.E. Stoa of Attalus (150 B.C.E.) Athens, Greece • Romanesque (500–1200 C.E.) of Caracalla • Baths ) (215 Rome, Italy • of Constantine • Arch ) (312–15 C.E. Pantheon (rebuilt 118–25 C.E.) Rome, Italy Roman C.E. (510 B.C.E.–476 C.E.) Pont du Gard Aqueduct (15 B.C.E.) Nîmes, France • • Rome, Italy (72–80 • Colosseum Rome, Italy C.E.) Ziggurat at Ur (ca. 2100 B.C.E.) Mesopotamia Etruscan (ca. 9th c.–50 B.C.E.) Byzantine (324–15th c.) Timeline 235 1200 1100 1000 24 MIDDLE AGES Mahadeva Temple • Kandariya (1025–50) Notre-Dame Cathedral (1163–1250) Paris, France Khajuraho, India • Cathedral • Chartres (1194–1220) Chartres, France Cathedral • Amiens (1220–47) Amiens, France Salisbury Cathedral (1220–60) Salisbury, England Cathedral (1110–81) • Worms Worms, Germany Romanesque (500–1200) Nuovo • S.(ca.Apollinaire 490) Ravenna, Italy Cathedral (1063–92) • Pisa and Baptistery (1153) Pisa, Italy Wat • Angkor (b. ca. 1120) Cambodia Vitale (526) • San Ravenna, Italy Mark (1042–85) • St.Venice, Italy Sophia (537) • Hagia Istanbul (Constantinople), Turkey 236 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Byzantine (324–12th c.) • • • 1500 1300 1400 24 College Chapel • King’s (1446–1515) Cambridge, England Gothic (ca. 1140–1500) • Cathedral • Strasbourg (begun 1277) Palais de Justice (1493–1508) Rouen, France Milan Cathedral (1387–1572) Milan, Italy • Alsace, France of Supreme Harmony • Hall (15th c.) Forbidden City, Beijing, China Duomo de S. Maria del Fiore (1377–1436) Florence, Italy Filippo Brunelleschi • Villa La Rotonda (1557) Vicenza, Italy Andrea Palladio Renaissance (1350–1600) Façade of S. Maria Novella (1458) Florence, Italy Leon Battista Alberti • Library • Laurentian (1524) • • San Lorenzo, Italy Michelangelo Palazzo Rucelai (1455–70) Florence, Italy Leon Battista Alberti S. Giorgio Maggiore (1566) Venice, Italy Andrea Palladio • of S. Pietro in Montorio • Tempietto (1502) Rome, Italy Donato Bramante Timeline 237 1700 1650 1600 24 PREMODERN Piazza of St. Peter’s • Colonnade (1656) of S. Susanna • Façade (1603) Rome, Italy Carlo Maderno Rome, Italy Gianlorenzo Bernini Karlskirche (b. 1656) Vienna, Austria Johann Fischer van Erlach • Carlo alle Quattro Fontane (b. 1634) Rome, Italy • S.Francesco Borromini Baroque (1600–1700) Renaissance (1350–1600) Hall • Wollaton (1580–88) Mahal • Taj (1630–53) Agra, India Emperor Shah Jahan Nottinghamshire, England Robert Smythson 238 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK • Chiswick House (1725–29) London, England Lord Burlington Spanish Steps (1723–25) Rome, Italy Francesco de Sanctis • 1850 1800 1750 24 Art Nouveau (1880–1902) “Panopticon” (1791) Jeremy Bentham Tassel House (1893) Brussels, Belgium Victor Horta • • Nationale • Bibliothèque (1858–68) Crystal Palace (1851) London, England Joseph Paxton Salt Works (1780) Chaux, France Claude-Nicolas Ledoux • Neoclassicism (1750–1880) Paris, France Henri Labrouste • (1819–21) • Schauspielhaus Berlin, Germany Karl Friedrich Schinkel of Virginia (1826) • University Charlottesville, Va., USA Thomas Jefferson (1771–82) • Monticello Charlottesville, Va., USA Boston Public Library (1887–95) Boston, Mass., USA McKim, Mead & White Thomas Jefferson • (1764–90) • Panthéon Paris, France Jacques Germain Souflot Houses of Parliament (1836–68) London, England Charles Barry • Georgian (1714–1830) • • Marshall Field Wholesale Store (1885–87) Chicago, Ill., USA H. H. Richardson of England • Bank (1788) London, England John Soane Rococo (1700–80) Timeline 239 • 1940 1920 1900 24 MODERN Art Nouveau • (1880–1902) • German Pavilion (Barcelona Pavilion) (1928; demolished 1930, rebuilt 1959) Milà (1906–10) • Casa Barcelona, Spain Barcelona, Spain Antoni Gaudí Ludwig Mies van der Rohe Savoye (1929) • Villa Poissy, France • Philip Speakman Webb Water (1937) • Falling Mill Run, Pa., USA • Frank Lloyd Wright • • Arts & Crafts (1860–1925) Art Deco (1920s–40s) State Building (1930) • Empire New York, N.Y., USA Shreve, Lamb & Harmon Internationale des Arts • Exposition Décoratifs et Industriels Modernes (1925) Paris, France 240 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK • Le Corbusier Einstein Tower (1921) Potsdam, Germany Erich Mendelsohn Ward Willits House (1902 Highland Park, Ill. USA Frank Lloyd Wright Bauhaus (1925) Dessau, Germany Walter Gropius House (1859–60) • Red Bexleyheath, England • (1929) New York, N.Y., USA (1900–45) • Eames House (1945) Paciic Palisades, Calif., USA Charles & Ray Eames Style Exhibition, • International MoMA Modernism Goldman & Salatsch Store (1910) Vienna, Austria Adolf Loos • 1960 1980 2000 24 Brutalism School (1954) • Hunstanton Norfolk, England (1950s–70s) Alison & Peter Smithson dello Sport • Palazzetto (1960) Rome, Italy Pier Luigi Nervi Late Modernism (1945–1975) • Kimbell Art Museum (1967–72) Fort Worth, Tex., USA Louis I. Kahn Seattle Public Library (2004) Seattle, Wash., USA Rem Koolhaas (OMA) Terminal (1962) • TWA New York, N.Y., USA to the Louvre (1983–89) • Addition Paris, France Eero Saarinen Center (1964) • Carpenter Cambridge, Mass., USA Le Corbusier House III (1969–70) Lakeville, Conn., USA Peter Eisenman • I. M. Pei Pompidou (1976) • Centre Paris, France • Renzo Piano & Richard Rogers Deconstructivism (1980-88) House (1949) • Glass New Canaan, Conn., USA de la Villette (1982–85) • Parc Paris, France Philip Johnson Bernard Tschumi Gehry House (1977–78) Santa Monica, Calif., USA Frank Gehry • Postmodernism Wexner Center for the Arts (1989) Columbus, Ohio, USA Peter Eisenman • Building (1982) • Portland Portland, Ore., USA Michael Graves (1960s–90s) Building (1978) • AT&T New York, N.Y., USA Philip Johnson & John Burgee Venturi House (1964) • Vanna Chestnut Hill, Pa., USA Robert Venturi Timeline 241 25 Chapter 25: Glossary AASM: Association of American Steel Manufacturers AGCA: Associated General Contractors of America AIA: American Institute of Architects AISC: American Institute of Steel Construction. AISI: American Iron and Steel Institute ANSI: American National Standards Institute APA: American Plywood Association ASHRAE: American Society of Heating, Refrigerating, and Air Conditioning Engineers ASTM: American Society for Testing and Materials CSI: Construction Speciications Institute IESNA: Illumination Engineering Society of North America ICC: International Code Council ICED: International Council on Environmental Design ISO: International Organization for Standardization NIBS: National Institute of Building Sciences ADA: Americans with Disabilities Act NFPA: National Fire Protection Association Adaptive reuse: Changing a building’s function in response to the changing needs of its users. RAIC: Royal Architecture Institute of Canada RIBA: Royal Institute of British Architects UIA: Union Internationale des Architectes UL: Underwriters’ Laboratory A Aalto, Alvar: (1898-1976) Finnish architect and designer; notable buildings include the Municipal Library in Viipuri, Finland, Paimio Sanatorium, and Baker House at MIT. Access flooring: Removable inish loor panels raised above the loor structure to allow installation of wiring and ductwork below. Accessible: Capable of being reached by all persons, regardless of levels of disability. Acoustical ceiling: System of ibrous removable tiles in the ceiling that absorb sound. LEED: Leadership in Energy & Environmental Design 242 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK AFF: Above inish loor. Aggregate: Particles such as sand, gravel, and stone used in concrete and plaster. Alberti, Leon Battista: (1404-1472) Italian architect, artist, and Renaissance humanist polymath; notable work includes the facade of the Santa Maria Novella in Florence, Italy, and numerous treatises on art and architecture, with scientiic study of perspective. Alloy: Substance made of two or more metals or a metal and another substance. Anchor bolt: Concreteembedded bolt that fastens a building frame to masonry or concrete. Annealed: Metal cooled under controlled conditions. Angle: L-shaped steel or aluminum structural section. 25 Arch: Structural device that supports vertical loads by translating them into axial forces. Band/banding: Continuous horizontal division on a wall created by different materials, colors, or textures. Arcade: Series of arches on columns or piers. Bar: Small rolled steel shape Area: Quantity expressing the size of a igure in a plane or surface. Atelier: Workshop or studio. Atrium: Open-roofed entrance court of a Roman dwelling; also, a manystoried court in a building, usually skylit. Bar joist: Truss type used for loor and roof support, with steel members on top and bottom and heavy wire or rod web lacing. Axial: Force, load, tension, or compression in a direction parallel to the long axis of a structural member. Base plate: Steel plate between a column and foundation that distributes the column’s load to the foundation. B Ballast: In rooing, a heavy material such as crushed stone installed over a roof membrane to minimize wind uplift; in lighting, a device that provides starting voltage for a luorescent or high-intensity discharge lamp, then regulates the current during operation. Bay: Rectangular area of a building deined at its four corners by adjacent columns; projecting portion of a façade. Balloon frame: Wood-frame construction in which vertical studs run from the sill to the eave instead of resting on intermediate loors. Bearing wall: Wall that supports loors or roofs. Baluster: Vertical member used to support a stair railing or a railing in a continuous banister. Balustrade: Railing system, usually around a balcony, that consists of balusters and a top rail. Beam: Horizontal linear element that spans an opening and is supported at both ends by walls or columns. Bed joint: Horizontal layer of mortar between units in a masonry wall. Bending moment: Force acting on a structure, causing it to curve. Blocking: Pieces of wood placed between joists, studs, or rafters to stabilize the structure or provide a nailing surface for inishes. Blueprint: Photographic print on specially coated paper; ideal for making precise and undistorted copies of large-scale drawings. Blueprint technology is rapidly being superseded by computer plotters and printers. Board foot: Unit of measuring lumber volume (nominally: 144 cu. in.). Bond beam: Top course of a masonry wall, illed with concrete and reinforcing steel, and used to support roof loads. Bramante, Donato: (14441514) Italian Renaissance architect; notable buildings include St. Peter’s Basilica and the Tempietto, both in Rome. Brise-soleil: Shading screen attached to the exterior of a building. Brunelleschi, Filippo: (1377-1446) Italian Renaissance architect and engineer; notable buildings include the Dome of the Cathedral of Florence, and the Basilica of Santo Spirito in Florence. Glossar y 243 25 Building code: Legal restrictions meant to enforce safety and health in the built environment. Cavity wall: Masonry wall with a continuous airspace between wythes. Built-up roof: Roof membrane composed of asphaltsaturated felt layers laminated together and bonded with bitumen or pitch. Cement: Dry powder that combines chemically with water and bonds aggregate particles together to form concrete. Also known as portland cement. Buttress: Masonry or concrete reinforcement applied to a wall to resist diagonal forces from an arch or vault. Change order: Written document between the owner and contractor of a project authorizing a change in the project. Chase wall: Cavity wall containing electrical runs or plumbing pipes in its cavity. Cold rolling: Rolling of metal at room temperature and stretching its crystals to harden the metal. Colonnade: Linear series of columns carrying an entablature or arches. Column: Upright structural member. Concrete: Mix of cement, aggregates, and water that forms a structural material. Concrete masonry unit (CMU): Solid or hollow block of cured concrete. Chord: Structural member of a truss. C CAD: Computer-aided drafting. Caisson: Long cylindrical foundation element formed by drilling deep into irm clay and pouring concrete into the hole. Clear floor space: Minimum unobstructed loor or ground space required to accommodate a single, stationary wheelchair and occupant. Clerestory: Windows placed high in a wall, usually above lower roof levels. Also called clearstory. Canopy: Projection over doors or windows. Coping: Protective cap or cover on top of a wall to throw off water. Corbel: Series of spanning stones or bricks in which each successive course projects over the course below it; also, a projecting masonry or concrete bracket. Cantilever: Beam or slab extending beyond its last point of support. Capital: Uppermost element of a column. 244 Coefficient of expansion: Fractional change in length, area, or volume or an object per unit change in temperature at a given constant pressure. THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Cornice: Projecting molding at the top of a building; also, the uppermost element of an entablature. 25 Course: Horizontal layer of one-unit-high masonry units. Cricket: Component used to divert water away from roof curbs, platforms, chimneys, walls, or other roof forms. Dome: Bowl-shaped volume created by rotating an arch about its vertical axis. Dormer: Protrusion in a sloping roof, usually containing a window. Cripple stud: Short wood framing member in walls interrupted by a header or sill. D Deck: Horizontal surface spanning across joists or beams. Deflection: Under an applied load, the amount of bending movement of any part of a structural member perpendicular to that member’s axis. Deliverables: Set of items such as construction documents provided by the architect to the client, and as agreed on in the ownerarchitect agreement. Detail: Drawing that provides very speciic information about the materials and construction of a component of a project and that is keyed into largerscale drawings. Dimensional stability: Ability of a section of wood to resist changes in volume at luctuating moisture levels. Engaged column: Non-freestanding column attached to a wall. Entablature: Uppermost part of a classical order, comprised of architrave, frieze, and cornice and supported on a colonnade. Cupola: Domed roof structure rising from a building. Curtain wall: Non-loadbearing exterior wall system supported on the building’s frame. Energy efficiency: Reducing energy requirements without reducing the end result. Duct: Hollow conduit for circulating and directing air. DWG: Computer drawing ile. E Eave: Edge of a roof plane, usually projecting over the exterior wall. Egress: Means of exiting safely. Eisenman, Peter: (1932- ) American architect; notable buildings include House VI, Wexner Center for the Arts, and the University of Phoenix Stadium. Elevation: Architectural drawing of a view of the vertical planes of the building, showing their relationship to each other. Encroachment: Portion of a building that extends illegally beyond the property owned and onto another property. Expansion joint: Surface divider joint allowing for surface expansion. F Façade: Face or elevation of a building. Fascia: Exposed vertical face of an eave. Fenestration: Windows and window arrangements on a façade. Finial: Ornament at the top of a spire or roof. Fire-resistance rating: Determination of the amount of time (in fractions of an hour) that an assembly or material will resist ire. Glossar y 245 25 Flashing: Continuous sheet of thin metal, plastic, or other waterproof material used to divert water and prevent it from passing through a joint into a wall or roof. Float glass: Common plate glass made by loating the material on a bed of molten metal, producing a smooth, lat surface. Footing: Widened base of a foundation that spreads a building’s loads across the soil. Foundation: Lowest portion of a building that transfers the building’s structural loads into the earth. G Galvanic action: Corrosion resulting from an electrical current between two unlike metals. Girder: Large horizontal beam that supports other beams. Girt: Horizontal beam that supports wall cladding between columns. Golden section: Unique proportional ratio of two divisions of a line such that the smaller of the two is to the larger as the larger is to the sum of the two. 246 Grab bar: Bar attached parallel to a wall to provide a handgrip for steadying oneself. Grade: Classiication of size or quality; the surface of the ground; the act of moving earth to make the ground level. Gropius, Walter: (18831969) German architect and founder of the Bauhaus. Notable buildings include the Bauhaus School and the Pan Am Building in New York. Hard metric: Conversion of component sizes to fall within a rational metric module, not a strict translation of other units into their exact metric equivalents. Hardwood: Wood from deciduous trees. Head joint: Vertical layer of mortar between units in a masonry wall. Guardrail: Protective railing to prevent falling into stairwells or other openings. Gusset plate: Flat steel plate to which truss chords are connected at a truss joint. Gypsum wallboard (GWB): Interior facing board with a gypsum core between paper facing. Also called drywall and plasterboard. H Hadid, Zaha: (1950- ) IraqiBritish architect; notable buildings include Vitra Fire Station in Weil-am-Rhein, Germany, the London Aquatics Centre for the 2012 Olympics, and the Broad Art Museum in Lansing, Michigan. Header: Lintel; in steel, a beam that spans between girders; also, masonry unit laid across two wythes, exposing its end in the face of the wall. Heavy timber: Structural lumber having a minimum width and thickness of 5” (127). Hot-rolled steel: Steel formed and shaped by being heated and passed through rollers. HSLA: High-strength lowalloy grade of steel. HUD: Housing and Urban Development. Half-timbered: Timber wall with the spaces between illed with masonry. HVAC: Heating, Ventilating, and Air-Conditioning. Handrail: Railing running parallel to the rise of a stairway or ramp, providing a continuous gripping surface. IBC: International Building Code. THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK I 25 I-beam: Obsolete term for American Standard steel section that is I- or H-shaped. Keystone: Central wedgeshaped stone at the top of an arch. Koolhaas, Rem: (1944- ) Dutch architect; notable buildings include the Kunsthal in Rotterdam, the Seattle Central Library, and the CCTV Headquarters in Beijing. Insulation: Any material that slows or retards the low or transfer of heat. J Jamb: Vertical frame of a window or door. Johnson, Philip: (19062005) American architect; notable work includes the Glass House in New Canaan, Connecticut, the AT&T Building in New York, and the Four Seasons Restaurant in New York. Joists: Light, closely spaced beams supporting loors or lat roofs. K Kahn, Albert: (1869-1942) German-American architect; notable buildings include Hill Auditorium at the University of Michigan, the Packard Automotive Plant in Detroit, and the Detroit Athletic Club. Kahn, Louis: (1901-1974) American architect; notable buildings include the Philips Exeter Academy Library in New Hampshire, the Salk Institute in La Jolla, California, and the Kimbell Art Museum in Fort Worth, Texas. L Laminate: Material produced through bonding together layers of other materials. Le Corbusier: (1887-1965) Swiss architect notable for the Villa Savoye (19xx), the Unite d’Habitation, and the chapel at Ronchamp. Ledoux, Claude Nicolas: (1736-1806) French neoclassical architect; notable designs include the Royal Saltworks at Arc-et-Senan, and the Theatre of Besancon. Lintel: Beam over a door or window that carries the load of the wall above. Lite: Pane of glass; also “light,” though often spelled differently to avoid confusion with visible light. Loads: Forces acting on a structure. Dead loads are ixed and static elements such as the building’s own skin, structure, and equipment; live loads are the changing weight on a building and include people, snow, vehicles, and furniture. Loos, Adolf: (1870-1933) Austro-Hungarian architect; notable buidlings include the Kärntner Bar in Vienna, the Villa Müller in Prague, and Maison Tzara in Paris. Louver: Opening with horizontal slats that permit passage of air, but not rain, sunlight, or view. M Masonry: Brickwork, blockwork, and stonework; also, the trade of a mason. Metrication: Act of changing from the use of customary units to metric units. Mezzanine: Intermediate level between a loor and ceiling that occupies a partial area of the loor space. Mild steel: Steel with a low carbon content. Millwork: Interior wood inish components of a building, including cabinetry, windows, doors, moldings, and stairs. Model: Physical representation (usually at a reduced scale) of a building or building component; in computer drafting and modeling, it is the digital two- or threedimensional representation of a design. Molding: Strip of wood, plaster, or other material with an ornamental proile. Longitudinal: Lengthwise. Glossar y 247 25 Mortar: Material composed of portland cement, hydrated lime, ine aggregate (sand), and water, used to adhere together and cushion masonry units. Mullion: Horizontal or vertical bar or divider in the frames of windows, doors, or other openings, and that holds and supports panels, glass, sashes, or sections of a curtain wall. Muntin: Secondary system of horizontal or vertical divider bars between small lites of glass or panels in a sash. Mylar: Polyester ilm that, when coated, can be used as drafting sheets. N Niche: Recess in a wall, usually for holding a sculpture. Overhang: Projection beyond the face of a wall below. P Palladio, Andrea: (15081580 Italian architect; notable work includes numerous villas in the Veneto region of Italy, the Teatro Olimpico in Vicenza, and his treatise The Four Books of Architecture. Parametric: Having one or more variables (parameters) that can be altered to achieve different results. In parametric modeling, a database tracks changes to all elements of a design simultaneously. Parapet: Low wall projecting from the edge of a platform, usually on a roof. Parti: Central idea governing and organizing a work of architecture. Partition: Interior nonload-bearing wall. Nominal: Approximate rounded dimensions given to materials for ease of reference. O Occupancy: Category of the use of a building for determining speciic code requirements. Passive solar: Technology of heating and cooling a building naturally, through the use of energy-eficient materials and proper site placement. Pediment: Triangular space that forms the gable end of a low-pitched roof, often illed with relief sculpture. Ogee: Proile section with a reverse-curve face (that is, concave above and convex below). 248 Pedestal: In classical architecture, a base supporting a column or statue. THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Pendentive: Curved, triangular support that results from transforming a square bay into a dome. Penthouse: Enclosed space above the level of the main roof used for mechanical equipment; an above-roof apartment. Peristyle: Colonnaded courtyard. Pier: Caisson foundation; also, a structural element that supports an arch. Pilaster: Pier engaged in a wall. Pillar: Columnar support that is not a classical column. Pilotis: Columns or pillars that lift a building from the ground. 25 Pitch: Slope of a roof or other inclined surface, usually expressed as inches of rise per foot of run (X:12, when X is a number between 1 and 12). built off-site (often in a factory), then shipped to the site for assembly. Rise: Vertical difference in elevation, as in the rise of a stair. Purlin: Beams spanning across the slope of a roof that support the roof decking. Riser: Vertical face between two treads of a stair; also, vertical run of plumbing, ductwork, or wiring. Q Quoin: Corner stones in a wall made distinct from the surrounding wall by being larger, of a different texture, or having deeper joints to make the stones protrude. Plan: Architectural drawing of a view of the horizontal planes of the building, showing their relationship to each other, and acting as a horizontal section. Plenum: Space between a suspended ceiling and the structure above, used for mechanical ductwork, piping, and wiring. Pointing: Process of applying mortar to the outside surface of a mortar joint after laying the masonry, as a means of inishing the joint or making repairs to an existing joint. Portico: Entrance porch. Precast concrete: Concrete that is cast and cured in a location other than its inal position. Prefabricated building: Buildings consisting of components such as walls, loors, and roofs that are R Rabbet: Notch in wood for joining pieces or recessed parts in a typical door frame. Rafter: Roof framing member that runs in the direction of slope. Reflected ceiling plan: Upside-down plan drawing that documents the ceiling plane. Room cavity ratio: Ratio of room dimensions used to determine how light will interact with the room’s surfaces. Rotunda: Space that is circular in plan and covered by a dome. Run: Horizontal dimension of a stair, ramp, or other slope. Rustication: Masonry pattern consisting of large blocks with deep joints. Retaining wall: Site wall built for resisting lateral displacement of soil, water, or other material. RFP (Request for Proposal): Oficial invitation for architects to submit qualiications and proposals to perform a project. R-value: Measure of the capacity of a material to resist the transfer of heat. Rib: Fold or bend in a sheet of deck. Saarinen, Eero: (1910-1961) Finnish-American architect and son of Eliel Saarinen. Notable buildings include the Miller House in Columbus, Indiana, the Gateway Arch in St. Louis, and the TWA Terminal at JFK Airport. Ridge: Horizontal line created at the connection of two sloping roof surfaces. S Glossar y 249 25 Saarinen, Eliel: (18731950) Finnish architect and father of Eero Saarinen. Notable buildings include the Kleinhans Music Hall in Buffalo, New York, and the Cranbrook Educational Community in Bloomield Hills, Michigan. Schedule: Chart or table in a set of architectural drawings, including data about materials, inishes, equipment, windows, doors, and signage; also, plan for performing work. Schinkel, Karl Friedrich: (1781-1841) Prussian architect, city planner and painter; notable buildings include the Altes Museum, the Neues Schauspielhaus, and the Neue Wache, all in Berlin. Scope of work: Written range of view or action for a speciic project. Section: Architectural drawing of a view of a vertical cut through the building’s components, acting as a vertical plan. Shaft: Trunk of a column between base and capital; also, enclosed vertical clear opening in a building for the passage of elevators, stairs, ductwork, plumbing, or wiring. Sheetrock: Brand name for gypsum wallboard, often incorrectly used to describe any gypsum board or drywall. Sitecast: Concrete that is poured and cured in its inal position; also called cast-inplace or poured-in-place. Slab on grade: Concrete slab that rests directly on the ground Soane, Sir John: (17531837) English architect; notable buildings include the Bank of England and Sir John Soane’s Museum. Soffit: Finished underside of a lintel, arch, or overhang. Soft metric: Precise conversion between customary and metric units. Stile: Framing member in a door. Stud: Vertical structural member used in light-frame wall construction and made of dimension wood or metal. Stringer: In a stair, the sloping wood or steel member that supports the treads. Softwood: Lumber from coniferous (evergreen) trees. Spall: Splitting off from a surface, in concrete or masonry, as a result of weathering. Span: Distance between supports. Spandrel: Exterior panels of a wall between vision areas of windows that conceal structural loors; the triangular space between the curve of an arch and the rectangular outline enclosing it. Specifications: Written instructions about the materials and means of construction for a building, and included as part of the construction document set. SI: Système International d’Unités (metric system). 250 STC: Sound Transmission Class, a number rating of airborne sound transmission loss as measured in an acoustical laboratory under carefully controlled test conditions. THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK Strut channel: Standardized metal framing system used for light structural support of electrical wiring, mechanical ductwork, and plumbing. Commonly referred to by many of its manufacture trade names, including Unistrut, Flex-Strut and G-Strut Sustainable design: Environmentally aware design using systems that meet present needs without compromising the needs of future generations. T Thermal performance: Ability of a glass unit to perform as a barrier to the transfer of heat. 25 Transom: Opening above a door or window that may be illed with a glazed or solid operable panel. U Undressed lumber: Lumber that is not planed. V Valley: Trough formed at the intersection of two sloping roofs. Transverse: Crosswise. Tread: Horizontal surface between two risers of a stair. Value engineering: Analyzing the materials and processes in a project in an effort to achieve the desired function at the lowest overall cost. van der Rohe, Ludwig Mies: (1886-1969) German architect; notable buildings include the New National Gallery in Berlin, the Seagram Building in New York (with Philip Johnson), and Crown Hall and other buildings at the Illinois Institute of Technology. W Waler: Horizontal support beam used in concrete formwork. Winder: L-shaped staircase that used wedge-shaped treads to turn a 90-degree corner. Wright, Frank Lloyd: (18671959) American architect; notable buildings include Fallingwater, the Johnson Wax Building, and the Solomon R. Guggenheim Museum. Wythe: One-unit-thick vertical layer of masonry. Z Ziggurat: Stepped-back pyramid temple. Vault: Arched form. Trompe-l’oeil: Twodimensional painting or decoration made to look three-dimensional; literally, “trick the eye.” Truss: Structural element made up of a triangular arrangement of members that transforms the nonaxial forces acting on it into a set of axial forces on the truss members. Veneer: Thin layer, sheet, or facing. Vernacular: Structures built with indigenous materials, methods, and traditions. Vitruvius: (c. 80 BCE - 15 BCE) Roman architect, engineer and writer; most notable for his treatise De Architectura (On Architecture). Glossar y 251 26 Chapter 26: Resources The contents of this book offer a quick-reference relection of numerous sources of information on architectural design and construction—the tip of a formidable iceberg. Any reader wishing to ind out more on a speciic topic is advised to consult the listing of sources that follow, which is itself an abridged acknowledgment of a wealth of available information. Many of these sources can be found in a well-stocked architecture irm’s in-ofice library, in the libraries of most schools of architecture, and even in some local libraries. Websites have quickly established themselves as excellent resources for (usually) free information on many subjects, and are especially invaluable for exploring the offerings of product manufacturers or trade-related information. It should be noted, however, that Web-based content and addresses are always subject to change. Architecture and Design Professions JOURNALS & PERIODICALS Architecture (monthly, USA); www.architectmagazine.com Architectural Record (monthly, USA); www.archrecord.construction.com Architectural Review (monthly, UK); www.architectural-review.com Arquitectura Viva (bimonthly, Spain); www.arquitecturaviva.com a+u (Architecture and Urbanism) (monthly, Japan); www.japan-architect.co.jp Casabella (monthly, Italy) Detail (bimonthly, Germany); www.detail.de El Croquis (ive times yearly, Spain); www.elcroquis.es JA (Japan Architect) (quarterly, Japan); www. japanarchitect.co.jp Lotus International (quarterly, Italy); www.editorialelotus.it Metropolis Magazine (monthly, USA); www.metropolismag.com WEBSITES www.archinect.com www.dezeen.com www.archinform.net www.designboom.com www.architectureweek.com 252 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 26 Primary Sources Architectural Graphic Standards, 11th ed. Charles George Ramsey, Harold Sleeper, and John Hoke; John Wiley & Sons, 2007 CD-ROM also available. previous editions: 1 (1932); 4 (1951); 5 (1956); 6 (1970); 9 (1994); 10 (2000) Neufert Architects’ Data, 4th ed. Blackwell Publishers, 2012 Fundamentals of Building Construction: Materials and Methods, 5th ed. Edward Allen and Joseph Iano; John Wiley & Sons, 2008 Pocket Ref, 4th ed. Thomas J. Glover, Sequoia Publishing, 2010 Understanding Buildings: A Multidisciplinary Approach Esmond Reid; MIT Press, 1994 Building Construction Illustrated, 4th ed. Francis D. K. Ching and Cassandra Adams; John Wiley & Sons, 2008 The Architect’s Studio Companion, 4th ed. Edward Allen and Joseph Iano; John Wiley & Sons, 2006 Skins for Buildings: The Architect’s Materials Sample Book David Keuning et al.; Gingko Press, 2004 Annual Book of ASTM Standards American Society for Testing Materials, 2013 Seventy-plus volumes contain more than 12,000 standards available in print, CD-ROM, and online formats. www.ansi.org (American National Standards Institute) www.nist.gov (National Institute of Standards and Technology) Resources 253 26 01_MATERIALS 01 Wood Laminated Timber Construction Christian Müller; Birkhäuser, 2000 Wood Handbook: Wood as an Engineering Material Forest Products Laboratory, U.S. Department of Agriculture Timber Construction Manual Thomas Herzog et al.; Birkhäuser, 2004 Detail Praxis: Timber Construction—Details, Products, Case Studies Theodor Hughs et al.; Birkhäuser, 2004 AITC Timber Construction Manual, 5th ed. American Institute of Timber Construction, 2004 AWI Quality Standards, 7th ed., 1999 www.awinet.org (Architectural Wood Institute) www.lumberlocator.com 02 Masonry and Concrete Masonry Construction Manual Günter Pfeifer et al.; Birkhäuser, 2001 Masonry Design and Detailing for Architects and Contractors, 5th ed. Christine Beall; McGraw-Hill, 2004 Complete Construction: Masonry and Concrete Christine Beall; McGraw-Hill Design of Reinforced Masonry Structures Narendra Taly; McGraw-Hill Professional, 2000 Reinforced Masonry Design Robert R. Schneider; Prentice-Hall, 1980 Indiana Limestone Handbook, 21st ed. Indiana Limestone Institute, 2002 www.bia.org (Brick Industry Association) 254 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 26 Concrete Construction Manual Friedbert Kind-Barkauskas et al.; Birkhäuser, 2002 Construction Manual: Concrete and Formwork T. W. Love; Craftsman Book Company, 1973 Precast Concrete in Architecture A. E. J. Morris; Whitney Library of Design, 1978 Concrete Architecture: Design and Construction Burkhard Fröhlich; Birkhäuser, 2002 www.fhwa.dot.gov (Federal Highway Administration) www.aci-int.org (American Concrete Institute) 03 Metals SMACNA Architectural Sheet Metal Manual, 7th ed. 2012 Metal Architecture Burkhard Fröhlich and Sonja Schulenburg, eds.; Birkhäuser, 2003 Steel and Beyond: New Strategies for Metals in Architecture Annette LeCuyer; Birkhäuser, 2003 www.corrosion-doctors.org 04 Finishes The Graphic Standards Guide to Architectural Finishes: Using MASTERSPEC to Evaluate, Select, and Specify Materials Elena S. Garrison; John Wiley & Sons, 2002 Interior Graphic Standards Maryrose McGowan and Kelsey Kruse; John Wiley & Sons, 2003 Detail Magazine—Architectural Details 2003 Detail Review of Architecture, 2004 Extreme Textiles: Designing for High Performance Matilda McQuaid; Princeton Architectural Press, 2005 Sweets Catalog McGraw-Hill Construction, ongoing; www.sweets.com Resources 255 26 02_STRUCTURES AND SYSTEMS 05 Structural Systems LRFD (Load and Resistance Factor Design) Manual of Steel Construction, 3rd ed. American Institute of Steel Construction, 2001; www.aisc.org Steel Construction Manual, 14th ed. American Institute of Steel Construction, 2010 Steel Construction Manual Helmut Schulitz, Werner Sobek, and Karl J. Habermann; Birkhäuser, 2000 Structural Steel Designer’s Handbook Roger L Brockenbrough and Frederick S. Merritt; McGraw-Hill Professional, 1999 Steel Designers’ Manual Buick Davison and Graham W. Owens, eds.; Steel Construction Institute (UK). Graphic Guide to Frame Construction: Details for Builders and Designers Rob Thallon; Taunton Press, 2000 www.awc.org (American Wood Council) 06 Mechanical Systems Mechanical and Electrical Systems in Construction and Architecture, 4th ed. Frank Dagostino and Joseph B. Wujek; Prentice Hall, 2004 Mechanical and Electrical Equipment for Buildings, 9th ed. Ben Stein and John S. Reynolds; John Wiley & Sons, 1999 Mechanical Systems for Architects Aly S. Dadras; McGraw-Hill, 1995 www.buildingwell.org www.homerepair.about.com www.efftec.com www.salex.com Sustainable Architecture White Papers (Earth Pledge Foundation Series on Sustainable Development) David E. Brown, Mindy Fox, Mary Rickel Pelletier, eds.; Earth Pledge Foundation, 2001 Cradle to Cradle: Remaking the Way We Make Things William McDonough and Michael Braungart; North Point Press, 2002 256 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 26 www.greenbuildingpages.com www.buildinggreen.com (Environmental Building News) www.usgbc.org (U.S. Green Building Council) www.ashrae.org (American Soc. of Heating, Refrigeration, and Air-Cond. Eng.) 07 Electrical Systems Lighting Handbook Reference, 9th ed. Mark S. Rea, ed.; IESNA, 2000 Lighting the Landscape Roger Narboni; Birkhäuser, 2004 1000 Lights, vol. 2: 1960 to Present Charlotte and Peter Fiell; Taschen, 2005 www.archlighting.com www.iesna.org (Illuminating Engineering Society of North America) www.iald.org (International Association of Lighting Designers) 08 Plumbing and Fire Protection Systems Fire Protection Systems A. Maurice Jones, Delmar Cengage Learning, 2008 Plumbing Engineering Design Handbook American Society of Plumbing Engineers, 2004 09 Building Enclosure Systems Glass Construction Manual Christian Schittich et al.; Birkhäuser, 1999 Detail Praxis: Translucent Materials—Glass, Plastic, Metals Frank Kaltenbach, ed.; Birkhäuser, 2004 www.GlassOnWeb.com (glass design guide) www.glass.org (National Glass Association) www.nrca.net (National Rooing Contractors Association) Resources 257 26 03_STANDARDS 10 MEASURE AND DRAWING Measurement and Geometry Measure for Measure Thomas J. Glover and Richard A. Young; Sequoia Publishing, 2001 Metric Handbook Planning & Design, 2nd ed. David Adler, ed.; Architectural Press, 1999 www.onlineconversion.com www.metrication.com 11 Architectural Drawing Types Design Drawing Francis D. K. Ching and Steven P. Juroszek; John Wiley & Sons, 1997 Graphics for Architecture Kevin Forseth with David Vaughan; Van Nostrand Reinhold, 1980 Basic Perspective Drawing: A Visual Approach, 4th ed. John Montague; John Wiley & Sons, 2004 12 Architectural Documents The Architect’s Handbook of Professional Practice, 13th ed. Joseph A. Demkin, ed.; American Institute of Architects, 2005 www.uia-architectes.org www.aia.org www.iso.org www.constructionplace.com www.dcd.com (Design Cost Data) 258 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 26 MasterSpec Master Specification System for Design Professionals and the Building/Construction Industry ARCOM, ongoing; www.arcomnet.com Construction Specifications Portable Handbook Fred A. Stitt; McGraw-Hill Professional, 1999 The Project Resource Manual–CSI Manual of Practice Construction Speciications Institute and McGraw-Hill Construction, 2004 www.csinet.org (Construction Speciications Institute) Masterformat 2012 CSI Construction Speciications Institute, 2012 13 Hand Drawing Architectural Drawing: A Visual Compendium of Types and Methods, 2nd ed. Rendow Yee; John Wiley & Sons, 2002 Architectural Graphics, 4th ed. Francis D. K. Ching; John Wiley & Sons, 2002 14 Computer Standards U.S. National CAD Standard, version 3.1 2004; www.nationalcadstandard.org AutoCAD User’s Guide Autodesk, 2001 AutoCad 2006 Instructor James A. Leach; McGraw-Hill, 2005 www.nibs.org (National Institute of Building Sciences) www.pcmag.com Resources 259 26 03_STANDARDS 15 PROPORTION AND FORM The Human Scale The Measure of Man and Woman: Human Factors in Design, rev. ed. Alvin R. Tilley; John Wiley & Sons, 2002 Human Scale, vol. 7: Standing and Sitting at Work, vol. 8: Space Planning for the Individual and the Public, and vol. 9: Access for Maintenance, Stairs, Light, and Color Niels Diffrient, Alvin R. Tilley, and Joan Bardagjy; MIT Press, 1982 Both above-cited books draw on information produced by Henry Dreyfuss Associates, a leading irm in the development of anthropometric data and its relationship to design. 16 Residential Spaces In Detail : Single Family Housing Christian Schittich; Birkhäuser, 2000 Dwell Magazine (bimonthly, USA); www.dwellmag.com www.residentialarchitect.com www.nkba.org (National Kitchen & Bath Association) Time-Saver Standards for Interior Design and Space Planning, 2nd ed. Joseph De Chiara, Julius Panero, and Martin Zelnik; McGraw-Hill Professional, 2001 The Architects’ Handbook Quentin Pickard, ed.; Blackwell Publishing, 2002 In Detail: Interior Spaces: Space, Light, Material Christian Schittich, ed.; Basel, 2002 260 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 26 17 Form and Organization Architecture: Form, Space and Order, 2nd ed. Francis D. K. Ching; John Wiley & Sons, 1995 Harmonic Proportion and Form in Nature, Art and Architecture Samuel Colman; Dover Publications, 2003 18 Architectural Elements A Visual Dictionary of Architecture Francis D. K. Ching; John Wiley & Sons, 1996 De architectura (Ten Books on Architecture) Marcus Vitruvius Pollio, ca. 40 B.C. The Four Books of Architecture Andrea Palladio, 1570 On the Art of Building Leon Battista Alberti, 1443-1452 Seven Books of Architecture Sebastiano Serlio, 1537 Resources 261 26 03_STANDARDS 19 CODES AND GUIDELINES Building Codes 2012 International Building Codes International Code Council, 2012 The complete collection is available in book or CD-ROM format at www.iccsafe.org. Building Codes Illustrated: A Guide to Understanding the International Building Code, 4th ed. Francis D. K. Ching and Steven R. Winkel; John Wiley & Sons, 2012 Code Check series Redwood Kardon, Michael Casey, and Douglas Hansen; The Taunton Press, ongoing This series is available at www.codecheck.com. Illustrated 2009: Building Code Handbook Terry L. Patterson; McGraw-Hill Professional, 2009 20 ADA and Accessibility ADA Standards for Accessible Design U.S. Department of Justice - www.ada.gov 1991 and 2010 Standards ADA and Accessibility: Let’s Get Practical, 2nd ed. Michele S. Ohmes; American Public Works Association, 2003 Guide to ADA & Accessibility Regulations: Complying with Federal Rules and Model Building Code Requirements Ron Burton, Robert J. Brown, and Lawrence G. Perry; BOMA International, 2003 Pocket Guide to the ADA: Americans with Disabilities Act Accessibility Guidelines for Buildings and Facilities, 2nd ed. Evan Terry Associates; John Wiley & Sons, 1997 262 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 26 21 Parking Parking Structures: Planning, Design, Construction, Maintenance & Repair, 3rd ed. Anthony P. Chrest et al.; Springer, 2001 The Dimensions of Parking Urban Land Institute and National Parking Association, 2000 The Aesthetics of Parking: An Illustrated Guide Thomas P. Smith; American Planning Institute, 1988 Parking Spaces Mark Childs; McGraw-Hill, 1999 www.apai.net (Asphalt Paving Association of Iowa – Design Guide) www.bts.gov (Bureau of Transportation Services) 22 Stairs Stairs: Design and Construction Karl J. Habermann; Birkhäuser, 2003 Staircases Eva Jiricna; Watson-Guptill Publications, 2001 Stairs: Scale Silvio San Pietro and Paola Gallo; IPS, 2002 23 Doors Construction of Buildings: Windows, Doors, Fires, Stairs, Finishes R. Barry; Blackwell Science, 1992 Resources 263 26 04_COMPENDIUM 24 Timeline History of Architecture on the Comparative Method: For Students, Craftsmen & Amateurs, 16th ed. Sir Banister Fletcher; Charles Scribner’s, 1958 Modern Architecture: A Critical History, 3rd ed. Kenneth Frampton; Thames & Hudson, 1992 A World History of Architecture Marian Moffett et al.; McGraw-Hill Professional, 2003 Source Book of American Architecture: 500 Notable Buildings from the 10th Century to the Present G. E. Kidder Smith; Princeton Architectural Press, 1996 Architecture: From Prehistory to Postmodernism, 2nd ed. Marvin Trachtenberg and Isabelle Hyman; Prentice-Hall, 2003 Encyclopedia of 20th-Century Architecture V. M. Lampugnani, ed.; Thames and Hudson, 1986 Modern Architecture Since 1900 J. R. Curtis, Phaidon Press, 1996 264 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK 26 25 Glossary The Penguin Dictionary of Architecture and Landscape Architecture, 5th ed. John Fleming, Hugh Honour, and Nikolaus Pevsner; Penguin, 2000 Dictionary of Architecture, rev. ed. Henry H. Saylor; John Wiley & Sons, 1994 Dictionary of Architecture and Construction, 3rd ed. Cyril M. Harris; McGraw-Hill Professional, 2000 Means Illustrated Construction Dictionary R. S. Means Company, 2000 Architectural and Building Trades Dictionary R. E. Putnam and G. E. Carlson; American Technical Society, 1974 Resources 265 Index A accelerating admixtures, 34 access aisle, 206 accessibility, 197, 206–217 elevators, 216 means of egress, 209 parking spaces, 210 ramps, 216 signage, 208–209 stairs, 217 terminology, 206–208 wheelchair space allowances, 211–215 accessible, 206 accessible design dimensions, 166–167 accessible element, 206 accessible route, 206 accessible space, 206 acid-etched glass, 105 acoustic ceiling tiles (ACT), 53 adaptability, 206 adaptive reuse, 77 addendum, 132 addition, 206 adjustable triangle, 150 administrative authority, 206 admixtures, concrete, 34 air and water systems, 72 air duct, 72 air handling unit (AHU), 73 air-entraining admixtures, 34 Alberti, Leon Battista, 194 all-air systems, 72 alloys, 36, 38 all-water systems, 72 alteration, 206 alternate, 132 aluminum, 38, 39 aluminum alloys, 38 ambient lighting, 78 American National Metric Council (ANMC), 108 Americans with Disabilities Act (ADA), 206–217 ampere (amp), 78 ancient architecture, 234–235 annealing, 36 anodic index, 40 anodizing, 36 ANSI (American National Standards Institute), 132 antirelective glass, 105 appliances, 173 arches, 58, 191–192 architectural documents, 132–147 abbreviations, 140–141 common paper sizes, 136 construction documents, 143 drawing set order, 138–139 drawing sheet layout and set assembly, 137 sheet folding, 136 and speciications, 144–147 terminology, 132–135 architectural drawing types, 120–131 architectural elements, 186–195 arches, 191–192 classical elements, 186 classical orders, 188–189 Gothic elements, 190–192 modernism, 193 architectural publications, 194–195 architecture, history of, 234–241 area formulas, 116–119 area measures, 108, 110 area of rescue assistance, 206 area units, 108, 109 art deco, 240 art nouveau, 239, 240 arts & crafts, 240 as-built drawings, 132 ash, 18 ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers), 72 aspect ratio, 155 assembly area, 207 266 assembly use group, 200 attached ceilings, 53 Authority Having Jurisdiction (AHJ), 199 AutoCAD, 154–161 external references, 157 ile-naming conventions, 160–161 model space, 158 paper space, 158 terminology, 155 text scale chart, 159 windows, 156 automatic doors, 207 automatic sprinklers, 86–87 awning windows, 97 axial force, 58 B bafle, 78 ballast, 78 balloon framing, 62 Baroque architecture, 238 bars, 178 base lashing, 89 baseboards, 51 bathrooms, 174–175, 214–215 bathtubs, 215 beam, 58 bearing walls, 93 bed molding, 51 beds, 176 Belgian truss, 71 bid, 132 birch, 18 black water, 77 blast furnace slag, 34 block, 155 board foot, 10, 16 body-tinted glass, 104 boiler, 73 bond paper, 149 book-matched, 10 Boolean operations, 183 booths, 178 bowstring truss, 71 braced frame, 65 brass, 39 brazing, 37 bricks, 24–29 bond types, 27 colors, 29 grades, 24 manufacturing, 25 orientations, 27 standard coursing, 28 standard sizes, 26 types, 24 units, 26 bronze, 39 brownields, 77 brutalism, 241 building, 207 building codes, 198–205 building elevations, 124–125 Building Oficials and Code Administrators International (BOCA), 198 building permits, 132 built-up roof (BUR), 91 bulbs, 78, 82–83 burl, 10 business use group, 200 butternut, 18 buttress, 58 Byzantine architecture, 235 C cabinets, 173 CAD (computer-aided design), 155 cadmium, 38, 39 caissons, 61 candela, 78 candlepower (CP), 78 cantilever, 59 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK carpet, 52 caryatid, 187 casement windows, 97 casework, 54 cast iron, 38 cast or channel glass, 103 casting, 37 cathedral grain, 10 caulk, 96 cavity walls, 72, 93 cedar, 18 ceiling moldings, 51 ceilings, 53 attached, 53 suspended, 53 cella, 186 cement, portland, 32 ceramic tile, 52 certiicate of occupancy, 133 Certiied Construction Speciied (CCS), 144 chair rail, 51 chair widths, 180 change order, 133 charrette, 133 chase wall, 72 check, 10 chemically strengthened glass, 105 chestnut, 19 chiller, 73 chip board, 149 chloroluorocarbons (CFCs), 77 chromium, 38, 39 circles, 118, 182 circular zone, 118 circulation path, 207 circumference, 118 classical elements, 186 classical orders, 188–189 clear, 207 clear loor space, 207 clearway allowances, for wheelchairs, 211–215 closed loop, 72 closets, 177 coated metals, 36 codes building codes, 198–205 and occupancy type and use groups, 200–201 coeficient of utilization (CU), 78 cold rolling, 36 cold-worked metals, 36 color rendering index (CRI), 78 color temperature, 78 coloring agents, 34 columns, 59, 63 combustible materials, 202 command line, 155 common use, 207 compact luorescent, 78, 83 compass, 150 competitions, design, 142 Complete Works (Le Corbusier), 195 composite orders, 189 composite walls, 93, 95 compression, 58 computer programs, 154. see also AutoCAD computer standards and guidelines, 154–161 concrete, 32–35 admixtures, 34 casting, 33 colors, 35 composition, 32 inishes, 35 loor and roof systems, 64–67 placing and curing, 34 sitecast, 33 slabs, 66 concrete blocks, 30–31 concrete masonry units (CMUs), 30–31 decorative, 31 grades, 31 production, 31 standard sizes, 30 types, 31 weights, 31 condensation, 96 condenser unit, 75 cones, 117, 182 connections in heavy-timber construction, 63 steel-frame, 70 conoid, 183 conservative disassembly, 77 construction administration, 143 construction cost, 133 construction documents, 143 construction management, 133 construction management contract, 133 Construction Speciications Institute (CSI), 144 construction types, 202 consultant, 133 contract administration, 133 contract over- (or under-) run, 133 contractor, 133 control joints, 33 convection, 96 cooling tower, 73 coordinates, 155 copper, 38, 39 Corinthian orders, 189 corrosion inhibitors, 34 counters, 178 countertops, 54 cove molding, 51 cross slope, 207 crosshairs, 155 crown molding, 51 CSI MasterFormat system, 144–147 cubes, 182 curb ramp, 207 cursor, 155 curtain wall, 99 curved stairs, 223 customary units, 108–109 cylinders, 117, 182 D date of substantial completion, 133 daylight compensation, 78 dead loads, 58 decay, 63 decking, in heavy-timber construction, 63 Declaration of Interdependence, 76 deconstructivism, 241 decorative glass, 105 deep foundation, 60, 61 desiccant, 96 design development, 142 design-build construction, 133 desk lamp, 81 detail drawings, 127 detectable warning, 207 dew point, 96 diffuser, 78 dimensional stability, 10 dimetric drawings, 128, 129 direct glare, 78 directional signs, 208 dome, 59 doors, 226–231 dimensions, 226 egress, 204 ire, 227 hollow metal, 230–231 types, 227 wood, 228–229 Doric orders, 188 double-curved solids, 119 double-hung windows, 97, 98 dovetail joints, 23 downlight, 78 drafting by hand, 148–153 supplies, 150–151 drafting brush, 150 drafting powder, 150 drawing ile, 155 drawing interchange format (DXF), 155 drawing metal, 36, 37 drawing web format (DWF), 155 drawings, 107. see also architectural documents abbreviations, 140–141 architectural, 120–131 drawing set order, 138–139 drawing sheet layout and set assembly, 137 hand drawings, 148–153 symbols, 122 three-dimensional, 128–129 working, 143 drilled pier, 61 dry bulb, 72 drywall. see gypsum wallboard (GWB) dual-sealed units, 96 DWG, 155 E early growth/late growth, 10 eating areas, 178–179 edge joints, 22 educational use group, 200 egress, means of, 203–205, 207, 209 egress doors, 204 egress stairs, 204 egress widths, 204, 205 Egyptian architecture, 234–235 electrical outlets, in bathrooms, 175 electrical systems, 78–83 electrically heated glass, 105 electroluminescent, 78 electroplating, 36 elements, 207 elevation drawing, 121, 124–125, 127 elevator control panels, 208 elevators, 209, 216 ellipses, 119 ellipsoid, 119 embodied energy, 77 emissivity, 96 enameled glass, 105 enclosure systems, 88–105 exterior walls, 94–95 lashing, 89 glass and glazing, 102–105 masonry bearing walls, 93 roofs, 88, 90–91 stone, 92 windows, 96–101 end joints, 22 energy, 78 energy distribution systems, 72–75 English units, 108 entasis, 187 entity, 155 entrance, 207 equilateral triangles, 116 erasing shield, 150 estimating, 133 Etruscan architecture, 235 exit passageways, 204 exits, 203–204 explode, 155 exterior walls, 94–95 external reference, 155 external reference (X-Ref) drawings, 157 extraction, 183 extrusion, 37 F fabrication techniques, for metal, 37 factor and industrial use group, 200 fan coil units (FCUs), 74 farmed wood, 14 fast-track construction, 133 feet and meters scale, 112 ferrous metals, 36, 38 FF&E, 133 Fibonacci sequence, 185 ibrous admixtures, 34 ield order, 134 igure, 10 inish carpentry, 54–55 inishes, 44–55 ceilings, 53 inish carpentry, 54–55 looring, 52 plaster, 50–51 wall systems, 46–49 ink truss, 71 ire doors, 227 ire protection systems, 86–87 ire-resistance ratings, 202 irst and second (FAS) grade, 16 ixed windows, 97 lashing, 89 lat beam and slab, 64 lat howe truss, 71 lat pratt truss, 71 loat glass, 102 loor lamp, 80 loor plans, 123 looring, 52, 63, 175 luorescent, 78, 82 lush hollow core doors, 228 lush solid core doors, 228 ly ash, 34 foam board, 149 foam board models, 9 foot-candle (FC), 79 footings, 61 forced air duct system, 75 forging, 37 form and organization, 182–185 formulas area, 116–119 circumference, 118 perimeter, 116–119 volume, 117, 119 foundation systems, 60–61 The Four Books of Architecture (Palladio), 195 4-pipe system, 74 fraction to decimal equivalents, 109 framed connections, 70 framing balloon, 62 doors, 229 hollow slab, 67 platform, 62 precast concrete, 66–67 steel, 68–71 stemmed deck, double tree (DT), 67 wood light-framing, 62 French curve, 150 French doors, 97 furnace, 72 G galvanic action, 40 galvanic series, 40 galvanizing, 36 garages, 177 gas-illed units, 96 gauging plaster, 50 general contractor, 134 geodesic domes, 183 geodesic spheres, 183 geometry plane igure formulas, 116–119 slopes and percentage grade, 114–115 Georgian architecture, 239 girder, 59 glass and glazing, 102–105 in bathrooms, 175 glass forms, 103 glass production, 102 thickness, 102 types, 104–105 glass block, 103 Index 267 glaze, 96 golden mean, 184 golden rectangle, 184 golden section, 184 Gothic architecture, 237 Gothic elements, 190–192 grain, 10 granite, 92 gray water, 77 Greek architecture, 235 grille, 96 grinding, 37 ground line (GL), 130 gum pocket, 11 gypsum, 46, 50 gypsum plaster, 50 gypsum wallboard (GWB), 46–49 board thickness, 47 common partition assemblies, 49 edge types, 47 ireprooing, 49 panel types, 46 partition wall installation, 48 H habitable rooms, 176–177 hand drawing, 148–153 drafting supplies, 150–151 papers and boards, 149 pencils for, 152 technical ink pens, 153 work surface, 148 handrails, 217 hard conversions, 111 hardness, 11 hardwood, 16 heartwood, 11 heat pump, 72 heat-treated metals, 36 heavy timbers, 63 high output (HO), 79 high-density overlay plywood, 55 high-density plywood, 55 high-hazard use group, 201 high-intensity discharge (HID), 79 high-strength basecoat, 50 hollow core slab, 66 hollow metal doors, 230–231 hollow slab framing system, 67 hopper windows, 97 horizon line (HL), 130 horizontal console, 74 horizontal FCU, 74 human scale, 164–171 HVAC (heating, ventilating, and airconditioning), 72, 73 hydro chloroluorocarbons (HCFC), 77 hydronic heating, 77 hydronic systems, 75 hyperbolic paraboloid, 183 hyperboloid of revolution, 183 I IALD (International Association of Lighting Designers), 79 IAQ (indoor air quality), 72 icosahedron, 183 IESNA (Illuminating Engineering Society of North America), 79 igneous rock, 92 illuminance, 79 illustration board, 149 incandescent, 79, 83 indirect cost, 134 information signs, 208 inspection list, 134 institutional use group, 201 insulating glass, 104 interior elevations, 127 International Building Code (IBC), 198–199 International Code Council (OCC), 198 268 International Conference of Building Oficials (ICBO), 198 Interprofessional Council on Environmental Design (ICED), 76 intersection, 183 interviews, with potential clients, 142 Ionic orders, 188 iron, 38 isometric drawings, 128, 129 J Janka hardness test, 11 joints control, 33 mortar, 29 wood, 22–23 K Keenes cement, 50 kitchens, 172–173 L laminate counters, 54 laminated glass, 105 laminated veneer lumber (LVL), 15 lamp, 79 lap joints, 23 late modernism, 241 lavatories, wheelchair space allowances, 215 layer, 155 lay-in troffer, 79 Le Corbusier, 193, 195 lead, 39 LEED (Leadership in Energy and Environmental Design), 76 LEED Green Building Rating System, 76 length units, 108, 109 lens, 79 life cycle analysis (LCA), 77 light (lite), 96 light ixtures, 80–81 light-emitting diode (LED), 79 light-gauge framing, 42 lighting, 78–83, 175 limestone, 92 linear measures, 108, 110 lines, regulating, 185 lintel, 59 live loads, 58 loads, 58 louver, 72 low-E glass, 104 L-shaped stair with landing, 222 L-shaped stair with offset winders, 223 L-shaped stair with winders, 223 lumber, 12–13 lumber grades hardwood, 16 softwood, 13 lumen, 79 luminaire, 79 luminance, 79 lux (LX), 79 M machining, 37 magnesium, 38, 39 mahogany, 19 malleable iron, 38 manganese, 38 maple, 19 marble, 92 marked crossing, 207 marketing, 142, 143 masonry, 24 bearing walls, 93 bricks, 24–29 concrete, 32–35 concrete masonry units (CMUs), 30–31 mortar, 29 preferred SI dimensions for, 27 stone, 92 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK masonry opening (Mas Opg), 98 mat foundation, 61 materials inishes, 44–55 masonry and concrete, 24–35 metals, 36–43 selection of, 9 structural, 59 wood, 10–23 mattress sizes, 176 means of egress, 203–205, 207, 209 measurement, 108–113 measuring line (ML), 130 mechanical systems, 72–77 energy distribution systems, 72–75 HVAC systems, 73 and sustainable design, 76–77 medium-density iber core hardwood plywood, 55 medium-density overlay plywood, 55 melamine, 55 mercantile use group, 201 metal doors, 230–231 metal panel roofs, 91 metal roofs, 90 metal stud wall, 94 metal studs, 15, 42 metals, 36–43 alloys, 36, 38 anodic index, 40 coated, 36 cold-worked, 36 ferrous, 36, 38 forms and sheets, 43 gauges and mils, 40–41 heat-treated, 36 joining, 37 modifying properties of, 36 nonferrous, 36, 39 rooing seams, 43 sheet thickness, 43 types, 38–39 metamorphic rock, 92 metric conversions, 109, 111–113 metric system, 108–113 metrication, 108 Microllam, 15 middle ages, architecture of, 236 mild steel, 38 millwork, 54–55 mils, 40–41 miscellaneous use group, 201 miter joints, 22 mixed-use occupancy, 200 model iles, 160–161 model space, 155, 156, 158 modeling programs, 154. see also AutoCAD models, 9, 155 modern architecture, 240–241 modernism, 193, 240 modiied bowstring truss, 71 moisture content, 11 molding plaster, 50 moldings, 51 molybdenum, 38 moment frame, 65 mortar, 29 mortar joints, 29 mortise and tenon joints, 23 movement in performance, 11 mullion, 96 multi-faceted relector (MR), 83 muntin bar, 96 Mylar, 149 N nadir, 79 National Institute of Standards and Technology (NIST), 110 neoclassic architecture, 239 NIBS (National Institute of Building Sciences), 134 NIBS Standard sheet layout, 137 nickel, 38 noncombustible materials, 202 nonferrous metals, 36, 39 O oak, 19–20 oblique drawings, 128, 129 occupancy loads, 205 occupancy types, 200–201 occupancy use groups, 200–201 ofice workspaces, 181 On the Art of Building (Alberti), 194 one-point common method perspective, 131 one-way beam and slab, 64 one-way ribbed slab, 64 opaque, 79 open loop, 72 operable part, 207 opisthodomos, 186 optics, 79 owner-architect agreement, 134 P Palladio, Andrea, 195 panel doors, 228 panel molding, 51 paper sizes, 136 paper space, 155, 156, 158 paper space scales (XP), 159 parabolic aluminized relector (PAR), 83 paraline drawings, 128 parallelograms, 116 parking, 218–221 parking garages, 221 parking spaces, 210, 220 Parthenon, 186 parti, 134 particle board core plywood, 55 partition walls, 49 passive solar, 77 passive solar gain, 96 pecan, 20 pencils, 152 pendant, 81 pens, 153 percentage grade, 114–115 perimeter formulas, 116–119 peripteros, 186 perspectives, 121 one-point common method perspective, 131 two-point common method perspective, 130 photovoltaic glass, 105 photovoltaics, 77 picture frame, 131 picture plane (PP), 130 picture rail, 51 piles, 61 pine, 20 pipes, 85 pitched howe truss, 71 pitched pratt truss, 71 plainsawn, 11 plan drawing, 120 plane igure formulas, 116–119 plaster lath assemblies, 50–51 over masonry, 51 types, 50 wall assemblies, 51 plasterboard. see gypsum wallboard (GWB) plastic laminate counters, 54 platform framing, 62 platonic solids, 182 plenum, 53, 72 plumbing, 84–85 plywood, 11, 17, 55, 62 Pollio, Marcus Vitruvius, 194 polygons, 117 polyhedra, 183 polyline, 155 polymer-modiied bitumen sheet membranes, 91 portland cement, 32 postmodernism, 241 power-assisted door, 207 pozzolans, 34 precast concrete framing, 66–67 pre-design phase, 142 prehung doors, 229 premodern architecture, 238 pressure-treated lumber, 11 prestressing, 59 primary elements, 182 primary shapes, 182 prisms, 117 program, 134 progress schedule, 134 project cost, 134 project directory, 134 project manager, 134 project manual, 134 Project Resource Manual, 144 project timeline, 142–143 pronaos, 186 proportion, and human scale, 164–171 public seating, 180 public use, 208 punched opening, 99 pyramids, 117, 182 Q quadrilaterals, 116 quarry tile, 52 quarter-round molding, 51 quartersawn, 11 R radiant heat, 72 radiation, 96 raft foundation, 61 ramps, 114, 208, 216, 221 rebar, 33, 34–35 recessed lighting, 80–81 rectangles, 116 reduction coeficient (NRC), 53 relectance, 79 relected ceiling plans (RCPs), 126 relective glass, 104 relector, 79 refractor, 79 regular polygons, 117 regulating lines, 185 reinforcing masonry, 93 reinforcing steel bars, 33, 34–35 Renaissance architecture, 237–238 renewable, 77 requests for information (RFIs), 134 requests for proposal (RFPs), 134, 142 requests for qualiications (RFQs), 142 residential spaces, 172–181 bathrooms, 174–175 habitable rooms, 176–177 kitchens, 172–173 residential use group, 201 resilient looring, 52 resources, 252–265 retaining wall, 59 retarding admixtures, 34 Rheims Cathedral, 190 riftsawn, 12 right-angle joints, 22–23 risers, 225 Rococo architecture, 239 rolling, 37 Roman architecture, 235 Romanesque architecture, 235, 236 roof forms, 88 roof windows, 97 rooing seams, metal, 43 roofs lashing, 89 low & lat slopes, 91 steep slopes, 90 types, 90–91 room cavity ratio (RCR), 79 room signs, 209 rosewood, 21 rough lumber, 12 rough opening (Rgh Opg), 98 row spacing, 180 rules surfaces, 183 running slope, 208 R-value, 96 S Safety Code for Elevators and Escalators, 209 safety glass, 105 sand-blasted glass, 105 sandstone, 92 sapwood, 12 sash, 96 sash opening (Sash Opg), 98 scales, 151, 158–159 schedule, 134 schematic design, 142 scheme, 134 scissors truss, 71 scope of work, 134 screen-printed glass, 105 seated dimensions, 168–169 seating, 176 clearances, 179 public, 180 types, 178 section drawing, 120 sector of circle, 118 sector of sphere, 119 sedimentary rock, 92 segment of circle, 118 segment of sphere, 119 select, No. 1 common grade, 16 select, No. 2 common grade, 16 select, No. 3 common grade, 16 self-cleaning glass, 105 Serlio, Sebastiano, 195 Seven Books of Architecture (Serlio), 195 shading coeficient, 96 shaft, 72 shallow foundation, 60, 61 shear, 59 sheet ile, 155 sheet iles, 157, 160–161 sheet folding, 136 sheet metal, 37, 40, 43 Sheetrock. see gypsum wallboard (GWB) shingles, 90 shop and factory lumber, 12 shop drawings, 134 shoring, 59 showers, wheelchair space allowances, 215 signage, 208–209 silica fume, 34 silicon, 38 sill lashing, 89 single-hung windows, 97 SIP (structured insulated panel) wall, 94 site, 135 sitecast concrete framing, 33 skylights, 97 slab on grade, 61 slate, 92 sliding doors, 97 sliding windows, 97 slopes, 114–115 slump test, 59 soft conversions, 111 soft costs, 135 softwood, 12 softwood lumber, 12–13 soldering, 37 solid lat slab, 66 solid surface countertops, 54 Southern Building Code Congress International (SBCCI), 198 space, 208 specialty glass, 105 speciications, 144–147 spheres, 182 Index 269 spiral stairs, 223 split, 12 spray polyurethane foam board (SPF), 91 sprinkler head distribution types, 87 squares, 182 stain, 12 stainless steel, 38 stairs, 222–225 accessibility, 217 components, 224 egress, 204 plan and elevation of, 224 treads and risers, 225 types, 222–223 stamping, 37 standard units, 108 standards of professional practice, 135 station point (SP), 130, 131 steel, 36, 38 fabrication techniques, 37 ireprooing at steel structural members, 49 galvanic action, 40 light-gauge framing, 42 steel alloys, 38 steel framing, 68–71 connections, 70 structural shape designations, 68–69 truss design, 70–71 Steel Stud Manufacturers Association (SSMA), 42 stemmed deck, double tree (DT), 66, 67 stemmed deck, single tree (ST), 66 stone, 92 stone countertops, 54 storage use group, 201 straight grain, 12 straight run stairs, 222 strain, 59 stress, 59 structural systems, 58–71, 135 concrete loor and roof systems, 64–67 foundation systems, 60–61 heavy timbers, 63 and loads, 58 materials, 59 steel framing, 68–71 terminology, 58–59 wood light-framing, 62 stucco, 50 stucco walls, 95 studs, 12 subcontractors, 135 substitution, 135 substructure, 60 super-plasticizers, 34 superstructure, 60 surfaced (dressed) lumber, 12 suspended ceilings, 53 sustainable design, 76–77, 197 symbols, drawing, 122 Système International d’Unités (SI). see metric system T T12 lamp, 79, 82 table lamps, 80 tables, 178 tactile, 208 teak, 21 technical ink pens, 153 tempered glass, 96, 105 tempering, 36 template, 150 Ten Books on Architecture (Pollio), 194 tenant improvements (TIs), 135 tension, 58 terrace doors, 97 terrazzo, 52 text telephone, 208 texture, 12 thermal performance, 96 three-coat plaster, 50 270 three-dimensional drawings, 128–129 three-dimensional representations, 121 tiles acoustic ceiling tiles (ACT), 53 loor, 52 roof, 90 time and materials (T&M), 135 timeline of architecture, 234–241 tin, 39 titanium, 38, 39 toilets, wheelchair space allowances, 214 total solar energy, 96 tracing paper, 149 translucent, 79 transparent, 79 trapezium, 116 trapezoids, 116 treads, 225 triangles, 116, 182 triangular architect’s scale, 151 trim shapes, 51 trimetric drawings, 128, 129 troffer, 79 truss design, 70–71 tube, 65 tungsten, 38 Tuscan orders, 188 two-coat plaster, 50 2-pipe system, 74 two-point common method perspective, 130 2x6 studs, 14–15 two-way lat plate, 64 two-way lat slab, 64 two-way wafle slab, 64 U UCS icons, 155 UHPC concrete walls, 95 ultraviolet (UV), 79, 96 Underwriters’ Laboratories (UL), 79 union, 183 Union Internationale des Architectes (UIA), 76 unit conversions, 109, 111–113 United States Metric Association (USMA), 108 units of measure, 108–113 universal design, 166–167 upstream/downstream, 77 U.S. customary units, 108–109 U.S. Green Building Council (USGBC), 76 user coordinate system (UCS), 155 U-shaped stair with landing, 222 utility use group, 201 U-value, 96 V value engineering, 135 vanishing point, 130, 131 variable air volume (VAV), 72 vault, 59 vellum, 149 veneer core hardwood plywood, 55 veneer grades, 17 veneer plaster, 51 vertical stack, 74 viewport, 155 vinyl looring, 52 visible light, 96 volatile organic compound (VOC), 77 volume, 117, 119 W walk, 208 wall sconce, 81 walls bearing, 93 cavity, 72, 93 chase, 72 common conigurations, 93 composite, 93, 95 exterior, 94–95 lashing, 89 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK gypsum board, 46–49 plaster, 50–51 retaining, 59 trim shapes, 51 walnut, 21 warp, 12 Warren truss, 71 water-reducing admixtures, 34 welded moment connections, 70 welding, 37 wet bulb, 72 wheelchair space allowances, 211–215 wheelchairs, 166–167 wind loads, 58 window wall, 99 windows, 96–101 considerations for, 100–101 sizing, 98 terminology, 96 types, 97 windows (AutoCAD), 155, 156 wired glass, 105 wood, 10–23 board feet, 16 dimensional variations of 2x6 stud, 14–15 doors, 228–229 exposure durability, 17 looring, 52 grades, 229 hardwood, 16 joinery, 22–23 light-framing, 62 plywood, 17 softwood lumber, 12–13 stud wall, 94 terminology, 10–12 types and characteristics, 18–21 veneer grades, 17 wood-based board types, 55 worked lumber, 12 working drawings, 143 workspaces, 181 written speciications, 107, 144–147 wrought iron, 38 X X-Acto knife, 150 XP scales, 159 X-ray protection glass, 105 Y yard (structural) lumber, 12 Z zebrawood, 21 zinc, 38, 39 zoning, 135 zoning permit, 135 PHOTOGRAPHY CREDITS Pyramid of Giza: Erich Lessing, Art Resource, New York; 236 Stonehenge: Anatoly Pronin, Art Resource, New York; 236 Parthenon: Foto Marburg, Art Resource, New York; 237 Colosseum: Alinari, Art Resource, New York; 237 El Castillo: Vanni, Art Resource, New York; 237 San Vitale: Scala, Art Resource, New York; 238 Notre-Dame: Scala, Art Resource, New York; 238 Duomo, S. Maria del Fiore: Scala, Art Resource, New York; 239 S. Maria Novella: Erich Lessing, Art Resource, New York; 239 Villa La Rotonda: Vanni, Art Resource, New York; 239 S. Carlo alle Quattro Fontane: Scala, Art Resource, New York; 240 Salt Works of Chaux: Vanni, Art Resource, New York; 241 Crystal Palace: Victoria & Albert Museum, Art Resource, New York; 241 Marshall Field Wholesale Store: Chicago Historical Society / Barnes-Crosby; 241 Barcelona Pavilion: Museum of Modern Art / licensed by Scala, Art Resource, New York. © 2006 Artists Rights Society (ARS), New York / VG Bild-Kunst, Bonn; 242 Einstein Tower: Erich Lessing, Art Resource, New York; 242 Bauhaus: Vanni, Art Resource, New York. © 2006 Artists Rights Society (ARS), New York / VG Bild-Kunst, Bonn; 242 Fallingwater: Chicago Historical Society / Bill Hedrich, Hedrich-Blessing; 242 Vanna Venturi House: Rollin R. La France, Venturi, Scott Brown and Associates; 243 Seattle Public Library: LMN Architects / Pragnesh Parikh; 243 ACKNOWLEDGMENTS Special thanks to Anna Buzolits, Adam Balaban, Dan Dwyer, John McMorrough, Rick Smith, and Ron Witte. Every attempt has been made to cite all sources; if a reference has been omitted, please contact the publisher for correction in subsequent editions. 271 About the Author Julia McMorrough has designed a wide range of project types, including hospitals, libraries, university buildings, and schools for architecture irms in Boston, Kansas City, New York, and Columbus, Ohio. Currently, she practices as a partner of studioAPT, a design and research collaborative, and is associate professor of practice at Taubman College of Architecture at the University of Michigan. She received a Bachelor of Architecture from the University of Kansas and a Master of Science in architecture from Columbia University. DEDICATION For Walter, Matthew, and John 272 THE ARCHITECTURE REFERENCE + SPECIFICATION BOOK © 2013 by Rockport Publishers, Inc. All rights reserved. No part of this book may be reproduced in any form without written permission of the copyright owners. All images in this book have been reproduced with the knowledge and prior consent of the artists concerned, and no responsibility is accepted by producer, publisher, or printer for any infringement of copyright or otherwise, arising from the contents of this publication. Every effort has been made to ensure that credits accurately comply with information supplied. First published in the United States of America by Rockport Publishers, a member of Quayside Publishing Group 100 Cummings Center Suite 406-L Beverly, Massachusetts 01915-6101 Telephone: (978) 282-9590 Fax: (978) 283-2742 www.rockpub.com Originally found under the following Library of Congress Cataloging-in-Publication Data McMorrough, Julia. Materials, structures, and standards : all the details architects need to know but can never ind / Julia McMorrough. p. cm. ISBN 1-59253-193-8 (vinyl) 1. Architecture—Handbooks, manuals, etc. 2. Building—Handbooks, manuals, etc. I. Title. NA2540.M43 2006 720—dc22 2005019669 CIP ISBN-13: 978-1-59253-848-5 Digital edition published 2013 eISBN: 978-1-61058-781-5 10 9 8 7 6 5 4 3 2 1 DISCLAIMER The content of this book is for general information purposes only and has been obtained from many sources, professional organizations, manufacturers’ literature, and codes. All illustrations in this book (except photographs) are those of the author. The author and publisher have made every reasonable effort to ensure that this work is accurate and current, but do not warrant, and assume no liability for, the accuracy or completeness of the text or illustrations, or their itness for any particular purpose. It is the responsibility of the users of this book to apply their professional knowledge to the content, to consult sources referenced, as appropriate, and to consult a professional architect for expert advice if necessary. Editor and Art Director: Alicia Kennedy Design and Illustrations: Julia McMorrough Production Design: Leslie Haimes Cover Design: Burge Agency, www.burgeagency.com Printed in China