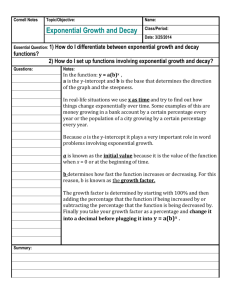

Proceedings of the 8th International Pipeline Conference IPC2010 September 27-October 1, 2010, Calgary, Alberta, Canada FINAL IPC2010- IPC2010-31346 INNOVATIVE METHOD TO DOUBLE BLOCK AND BLEED Frank Dum T.D. Williamson Inc Tulsa, Oklahoma, United States Colin Drysdale T.D. Williamson Inc Tulsa, Oklahoma, United States ABSTRACT Double Block and Bleed (DBB) is the preferred approach used to maximize safety while performing piping maintenance. The aim of the paper is to outline an innovative method of achieving DBB on pressurized piping or pipelines. shutting off a branch of the pipeline supplying natural gas to a large shopping mall. Part of the pipeline company’s safety requirements included a double block and bleed method of pipeline isolation. There were existing valves and a bleed port to provide DBB downstream of the installation but there was no method of DBB upstream. To add to the complexity of the job, the pipeline was next to a very busy street. Because of rush hour traffic, the pipeline could only be repaired between the hours of 9am to 4pm. In addition, other requirements of the customer included minimized intrusion into piping, less number of fittings, less welding time and the material and labor costs associated with purchasing and installing half the fittings. In response to the requirements and for a double block and bleed capability, the STOPPLE Train plugging system was deployed to meet these customer needs. DBB is traditionally achieved by several methods, for example, through using Two Valves, a Valve & a STOPPLE® plugging head, a STOPPLE plugging head & an Isolation Plug or Tandem STOPPLE plugging heads. There are also several DBB methods which utilize inflatable bags or bladders. The STOPPLE Train is a patent pending tool that uses 2 STOPPLE® plugging heads. Only one hot tap is required in the piping for which the STOPPLE Train is inserted. The first STOPPLE plugging head is the trailing plugging head and forms a primary seal. The second STOPPLE plugging head is the leading plugging head and forms a secondary seal. Once sealed, the bleed is accomplished through a relief port allowing downstream maintenance to commence. INTRODUCTION On 20 November 2008, an isolation valve needed to be added to a natural gas distribution pipeline. The pipeline needed to be cut and the isolation valve installed without 1 Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 03/28/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use Copyright © 2010 by ASME Supply to Shopping Mall Isolation valve to be installed STOPPLE Train & Bleed Port Figure 2 A traditional method of DBB Existing downstream block valves and bleed port. HOW THE STOPPLE® TRAIN WORKS The patent pending STOPPLE Train plugging system is unique in that it links two plugging heads into a “train” capable of providing a double block and bleed function. Figure 1 Job Site Schematic The STOPPLE Train could achieve DBB through a single STOPPLE fitting resulting in less excavation, and only half of the tapping and STOPPLE equipment. This resulted in less congestion and a significant decrease in the time needed for welding, tapping, and setting/pulling STOPPLE plugging heads. Bleed TRADITIONAL METHODS OF DOUBLE BLOCK AND BLEED Historically, pipeline operators have used a number of different methods to achieve double block and bleed. For example, two separate valves with a bleed port between them can achieve this. Or, the combination of a valve and a plugging head with a port between them can work, as can the tandem of a plugging head and an isolation plug with a port between them. Many operators have simply used two plugging heads and a bleed port. What all of these methods have in common is the dual barrier concept. Whether the barriers are valves, plugging head seals or combinations thereof, the basic premise is that a second barrier serves as a failsafe for the first. Primary Block Secondary Block Figure 3 STOPPLE® Train in Cutaway Fitting This new innovative system requires only one hot tap and a single standard STOPPLE® fitting to achieve DBB compared to traditional methods. Its linked plugging heads can be inserted into a line through just one opening. A single hot tap and fitting thus yields the double block benefit of two inline plugs. A pressure bleed port positioned between the two plugging heads allows the void between the heads to be bled down, creating a zone of zero energy. This port also allows for seal verification and monitoring. If the operator so chooses, this system can also be used without the bleed port to simply get the safety advantage of redundant seals. EQUIPMENT TESTING The STOPPLE® Train system is also robust enough to handle both low pressure and high pressure environments. 2 Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 03/28/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use Copyright © 2010 by ASME SUBSTANTIAL SAVINGS As part of the customer request to reduce costs, the STOPPLE Train plugging system was selected and provided substantial cost savings over other double block and bleed methods. This was achieved by reducing the material cost of fittings placed on the line. Further savings resulted from less excavation, fewer pieces of tapping and STOPPLE equipment required on site, less welding and a shorter overall job time, resulting in lower labor costs and less exposure time to potential hazards for personnel and the general public at a busy intersection. Tests have shown that at low pressures, compression between the sealing elements and the pipe ID creates an excellent barrier. In fact, the sealing element does not even need to be energized to seal. At 0.5 psi to 5 psi, the compression fit alone is sufficient. Once energized, the seal will remain intact until broken by an external force, such as retraction of the plugging head. The most cost-effective aspect of this new plugging system stems from the fact that it is based on nearly six decades of proven STOPPLE technology. The STOPPLE system was first designed and patented in 1952 with minimal changes to the initial design. Pressure ratings for the STOPPLE Train system follow traditional STOPPLE parameters, and all standard STOPPLE tools apply to the maintenance of the STOPPLE Train heads. Overall, use of the STOPPLE Train plugging system requires nearly identical training, operation and maintenance as for all STOPPLE systems, meaning many experienced users will see very little change (other than a little extra plugging head travel length) from their typical plugging operations. Figure 4 Low Pressure sealing element tests Since there are a variety of methods of achieving double block and bleed, the STOPPLE Train provides substantial cost savings especially compared to using two conventional STOPPLE heads. As illustrated in the following figure, the cost savings vary over various pipe sizes and the number of fittings that are required in order to successfully perform the job. But the point to note is that a conventional double and double tandem could potentially cost a significant amount more to achieve the same level of safety that the STOPPLE Train can provide. On the other end of the pressure spectrum, both plugging heads in a STOPPLE Train system are rated to 1,000 psi at 180°F, or to 600 psi at 350°F. They have been tested successfully at 1.5 times this rating, and the pressurized plugging heads have been successfully tested together and independently. Because the STOPPLE Train plugging system requires only one hot tap and a standard fitting, fewer potential leak paths are left on the piping once work is complete. Compared to other methods for achieving double block and bleed, which typically require twice as many line penetrations, this represents a major improvement. Fewer fittings also results in less expense. Savings when using a STOPPLE Train compared to various other methods of DBB $35,000 $30,000 $25,000 $20,000 MAXIMUM SAFETY There was no initial means of isolation for this section of pipeline. Since the project was driven by safety concerns, the added safety of the STOPPLE Train system comes from its two seals, thus providing double block and bleed. With a tap between the two seals, that area can be monitored for leakage before and during work on the pipeline downstream. In the unlikely event that the first seal leaks, the second seal is fully capable of holding the line pressure by itself. $15,000 $10,000 $5,000 $0 4” 6” 8” 10” 12” Range of Pipeline Inches up to 12' CONVENTIONAL DOUBLE & DOUBLE TANDEM VS. STOPPLE TRAIN DOUBLE & DOUBLE TANDEM CONVENTIONAL STOPPLE VS. STOPPLE TRAIN Figure 5 Projected savings comparison when using a STOPPLE Train vs. other traditional forms of DBB. 3 Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 03/28/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use Copyright © 2010 by ASME Figure 6 Project was on a pipeline located next to a very busy street ACTUAL FIELD JOB On the actual day of the job, standard pressure tests on the STOPPLE Fittings were carried out, the hot taps were made and the STOPPLE Train Housing was installed along with blow down and equalization hoses. The STOPPLE Train was inserted and sweeping conducted. The pipe was bled and the DBB seal was established. With the STOPPLE Train set in place, cold cutting welding of both sections of the pipe were executed completed. Completion plug was set in place and STOPPLE Train was retracted. The housing was unbolted completion plug inserted and set. and and the and CONCLUSION The STOPPLE Train performed according to expectations. The sealing elements sealed properly and the bleed port allowed the gas to be evacuated to a safe location. The project was successfully completed with all the objectives and requirements satisfied. 4 Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 03/28/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use Copyright © 2010 by ASME