AD 723 397

T E C H N I C A L R E P O R T NO. 6

STATIC AN D DYNAM IC A N A L Y S IS OF

ROCK BOLT SUPPORT

RESEARCH ON

ROCK BOLT REINFORCEMENT

by

RICHARD E. G O O D M A N AND J A C Q U E S D U B O I S

■

J A N U A R Y 1971

mm

OMAHA

gw»?

DISTRICT, C O R P S O F E N G I N E E R S

O M A H A , N E B R A S K A 68102

THI S R E S E A R C H WA S F U N D E D

CHI E F OF E N G I N E E R S ,

BY O F F I C E ,

D E P A R T M E N T OF

THE A R M Y

P R E P A R E D UNDER CONTRACT DACA45-67-C-0015 MOD. P 0 0 2

BY THE UNIVERSITY OF CA LIFO R N IA , B E R K E L E Y , CALIFORNIA

.W 3 ¿ í

m^6

<9 71

I

A p p ro v e d for

public release; distribution u nlim ited

BUREAU OF RECLAMATION LIBRARY

DENVER, CO

Destroy this report when no longer needed.

Do not return it to the originator.

The findings in this report are not to be construed as

an official Department of the Army position unless

so designated by other authorized documents.

IRARY

BUREAU OF RECLAMi

92073860

9207Í

TECHNICAL REPORT NO. 6

STATIC AND DYNAMIC ANALYSIS OF ROCK BOLT SUPPORT^

RESEARCH ON ROCK BOLT REINFORCEMENT

^ by

RICHARD E. GOODMAN AND JACQUES DUBOIS f

y JANUARY

1971

V

OMAHA DISTRICT, CORPS OF ENGINEERS

OMAHA, NEBRASKA 68102

THIS RESEARCH WAS FUNDED BY OFFICE,

CHIEF OF ENGINEERS, DEPARTMENT OF THE ARMY

PREPARED UNDER CONTRACT DACAU5-67-C-0015 MOD. P002

BY THE UNIVERSITY OF’d ALIFORNIA^ BERKELEY^ CALIFORNIA

Approved for public release, distribution unlimited.

60

STATIC AND DYNAMIC ANALYSIS

OF ROCK BOLT SUPPORT

ABSTRACT

This report describes progress in a continuing effort to develop and

evaluate methods which can be used to design underground openings to sur­

vive blast loadings.

It includes discussion of the action of rock bolts

Under static loads and considers aspects of the interaction between rock

and rock bolt under dynamic loads.

Only computational methods were used

in this study.

|

First, closed form solutions for point loads are summed and superim­

posed to examine stresses induced by patterns of rock bolts around tunnels

in linearly elastic material.

The stress fields are compared to rock

strengths according to simplified failure criteria, to appreciate the

relative strengthening effect of different combinations of bolt and rock

parameters.

It was found that very substantial bolt pressures are required,

e.g. 10% of the maximum applied pressure, to restrict rock breakage in

ideally elastic material.

Then elastic-plastic material behavior is considered.

Stresses in­

duced by unequilibrated line loadings on the inner circumference of the

tunnel are used to simulate rock bolt patterns.

It is found that the rock

bolt strengthening effect can more easily be substantiated in weaker

materials.

For example, when rock inside the "plastic" zone was taken as

cohesionless, less than 1% of the blast pressure is a sufficiently high

rock bolt pressure to provide significant strengthening effect.

Dynamic considerations are discussed in terms of an energy balance

for the case of a plane rock wall bolted in a regular pattern which receives

a stress wave impulse from inside.

The problem is examined in two ways:

First a calculation is made of the kinetic energy of the system in the

i

most serious increment of time during the response, assuming the bolt to

behave elastically.

Then, the total work during all of the blast response

period is considered, presuming the bolt damage to be cumulative.

The

objective of these computations is to provide a basis for scaling sur­

vivability conclusions from one experiment to another.

to Hardhat and Piledriver experiments.

ii

Reference is made

PREFACE

This investigation was authorized by the Chief of Engineers

(ENGMC-EM) and was performed in FY 1969 and 1970 under Contract

No. DACAU5-67-C-OOI5, Mod. P002, between the Omaha District, Corps

of Engineers and Dr. Richard E. Goodman, Berkeley, California.

This

work is a part of a continuing effort to develop methods which can

be used to design underground openings in jointed rock to survive

the effects of nuclear weapons.

This report was prepared under the supervision of Dr. R. E.

Goodman, Principal Investigator.

Personnel who contributed to the

report were Dr. Hans EWoldsen, Mr. Jacques Dubois, Mr. Iraj

Farhoomand, and Mrs. Anne Bornstein.

During the work period covered by this report, Colonel William H.

McKenzie III and Colonel B. P. Pendergrass were District Engineers;

Charles L. Hipp was Chief, Engineering Division; C. J. Distefano was

Technical Monitor for the Omaha District under the general supervision

of Kendall C. Fox, Chief, Protective Structures Branch.

D. G.

Heitmann and Dr. J. D. Smart participated in the monitoring work.

iii

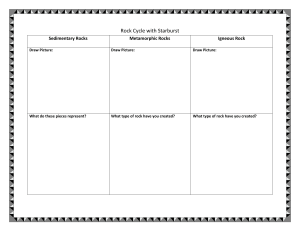

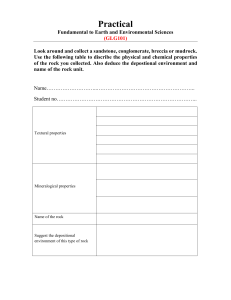

TABLE OF CONTENTS

ABSTRACT-----------------------------------------------------------

i

PREFACE------------------------------------------------------------

iii

NOTATION------------

viii

CONVERSION FACTORS, BRITISH TO METRIC UNITS OF MEASUREMENT-------

xi

CHAPTER 1

INTRODUCTION--------------------------------------- —

1

CHAPTER 2

AN ELASTIC APPROACH FOR DESIGN OF PATTERNED ROCK BOLT

SUPPORTS UNDER STATIC ORQUASI-STATIC LOADING---------

2.1 Approach--------------------------------------------------- *

2.2 Global Stress Field Around the Tunnel - Elastic Behavior—

2.3 The Extent of the Slip Zone---- --2.1+ Calculation of Rock Loads--------------------------------2.5 The Principle of the Design Method---------------2.6 Illustrative Example----------------------2.7 Conclusion---------CHAPTER 3

DESIGN APPROACH FOR ELASTIC-PLASTIC ROCK UNDER

HYDROSTATIC LOADING----- -----------------------------

3.1 Mathematical Conditions-----------------------------------3.2 Solution for Stresses and Extent ofPlastic Zone----------3.3 Examples------------------------------------------- ■-------3.3.1 Example No. 1-----------------------------------------3.3.2 Example No. 2-----------------------------------------3.1+ Conclusions-----------------------------------------------CHAPTER 1+

3

3

5

8

9

10

11

13

55

55

57

6l

63

63

6k

DYNAMIC ANALYSIS OF THE TUNNEL SUPPORT PROBLEM-------

86

Introduction---------------------------------------- ---- -—

k.2 Rigid Two Body Analysis-----------------------------------1+.3 Elastic - Two Body Analysis------------------------------1+.1+ Energy Approach to Rock Bolt Problem---------------------l+.l+.l Case 1: Only KineticEnergyConsidered----------------1+.J+.2 Case 2: Total Work Considered-----------------------1*.5 Discussion---------------------------------

86

l+.l

CHAPTER 5

EMPIRICAL APPROACH TO SUPPORT DESIGN AGAINST

BLASTS----------

5.1 Definitions---- •------------------------------------------5.1.1 Wave Travel Time-----------------5.1.2 Energy Absorption by the Support System--------------5.1-3 Energy Dissipation Time of the Support System---------

iv

87

89

90

92

99

102

110

110

110

111

112

5.2 Results of the Pile Driver Tests--------------------------5.2.1 General EmpiricalEnergy Equation-----------------------5.2.2 Application toPile Driver Test-----------------------5-3 Hardhat Drift---------- ----------------------------------—

5 .1+ Conclusion--------------------------------------------- ----

112

113

115

117

11 8

REFERENCES--------------------------------------------------

119

APPENDIX I-------------------------

120

APPENDIX II—

127

-----------------------------------------------------

v

TABLES

2 .1

Economic Comparison of Rock Bolt Design------------------Comparison of Rock Bolt Design I--------------------------Comparison of Rock Bolt Design II---------------------Radius of 3he Plastic Zone for Various Rock Properties_—

Variation of the Plastic Zone with C--------------Example No. 1 Results------------------

2.2

2.3

3.1

3.2

3.3

16

17

18

66

66

66

FIGURES

2 .1

2.2

2.3a

2.3b

2.3c

2.3d

2.k&

2.4b

2.4c

2.4d

2.5a

2.5b

2.5c

2.5d

2.6a

2.6b

2.6c

2.6d

2.7a

2 .7b

2.7c

2.7d

2.8a

2.8b

2.8c

2.8d

Stresses Due to a Single Rock Bolt--- — ______

Comparison of Stresses with Failure Criterion________ ._____

Joint Influence Diagrams for Case (SlAl) - Horizontal

Joint------------------------------------------------------Joint Influence Diagrams for Case (SlAl) - 30° Joint_______

Joint Influence Diagrams for Case (SlAl) - 60° Joint_______

Joint Influence Diagrams for Case (SlAl) - Vertical

Joint-------Joint Influence Diagrams for Case (S1 A 2 ) - Horizontal

Joint------------------------------------------------------Joint Influence Diagrams for Case (S1A2) - 30° Joint------Joint Influence Diagrams for Case (S1A2) - 60° Joint____ 27

Joint Influence Diagrams for Case (S1 A 2 ) - Vertical

Joint— ---------------------Joint Influence Diagrams for Case (S1A3) - Horizontal

Joint------------------------------------------------------Joint Influence Diagrams for Case (S1A3) - 30° Joint______

Joint Influence Diagrams for Case (S1A3) - 60° Joint______

Joint Influence Diagrams for Case (S1A3) - Vertical

Joint---------------------------------Joint Influence Diagrams for Case (S3A2) - Horizontal

Joint------------------------------------------------------Joint Influence Diagrams for Case (S3A2) - 30° Joint-----Joint Influence Diagrams for Case (S3A2) - 60° Joint_____

Joint Influence Diagrams for Case (S3A 2 ) - Vertical

Joint-----------Joint Influence Diagrams for Case (S3A3) - Horizontal

Joint Influence Diagrams for Case (S3A3) - 30° Joint----Joint Influence Diagrams for Case (S3A3) - 60° Joint----Joint Influence Diagrams for Case (S3A 3 ) - Vertical

Joint------- ------------------------------------ ----------Joint Influence Diagrams for Case (L2A1) - Horizontal

Joint----------- — ------------------------------------ ----Joint Influence Diagrams for Case (L2A1) - 30° Joint_____

Joint Influence Diagrams for Case (L2A1) - 60° Joint_____

Joint Influence Diagrams for Case (L2A1) - Vertical

Joint__________

vi

19

20

21

22

23

¿k

25

26

28

29

30

31

32

33

34

35

36

38

39

1^2

42

43

k4

2.9a Joint Influence Diagrams for Case (L2A2) - Horizontal

Joint---------------------------------------------1+5

2.9b Joint Influence Diagrams for Case (L2A2) - 30° Joint-----1*6

2.9c Joint Influence Diagrams for Case (L2A2) - 60° Joint-----1*7

2.9J Joint Influence Diagrams for Case (L2A2) - Vertical

Joint— •---------------------------------------------------1*8

2.10a Joint Influence Diagrams for Case (L2A3) - Horizontal

Joint— ---1+9

2.10b Joint Influence Diagrams for Case (L2A3) - 30° Joint--- 50

2.10c Joint Influence Diagrams for Case (L2A3) - 60° Joint---51

2.10d Joint Influence Diagrams for Case (L2A3) - Vertical

Joint--------52

2.11 The Rock Load--------------------- •------ ---------- :-------53

2.12 Required Ultimate Strength for Rock Bolt Support Scheme-5I*

3.1 Plastic and Elastic Zones------------------------------ ■

---67

3.2 Plastic Stress Criterion----------------------------------68

3.3 Peak and Residual Strength---------------69

3.4 Equilibrium Diagram of anInfinitesimal Element-----------70

3.5 Mohr Circle andFailure Characteristics 4>r»Cr , and <J>p, Cp 71

3.6 Mohr Circle and Failure Characteristics <|>r> Cr , and <}>p, Cp 72

3.7 Mohr Circle and Failure Characteristics <|>r ,C r , and (j>p, Cp 73

3.8 Mohr Circle and Failure Characteristics <f>r »Cr , and <J>p, Cp 7I*

3.9 Radius of Destressed Zone---------------------------------75

3.10 Radius of Destressed Zone---------------------------------76

3.11 Radius of Destressed Zone---------------------------------77

3.12 Radius of Destressed Zone----------78

3.13 Radius of Destressed Zone---------------------------------79

3.11* Radius of Destressed Zone-----------------------80

3.15 Effect of Rock Bolts on Stresses---------81

3.16 Effect of Rock Bolts on Stresses--------------------------82

3.17 Effect of Rock Bolts on Stresses--------------------------83

3.18 Effect of

RockBoltson Stresses-------------------------8U

3.19 Effect of Rock Bolts on Stresses--------------------------85

l+.l Typical Wave Forms for Direct Transmitted Ground Shock

from Explosions---------------------------------------------- 10U

h.2 Model for Rigid Body Analysis------------------------------- 105

1+.3 Rock Bolt Tension and Plate Pressure Variation with Time— 106

l+.U Momentum per Unit Area----------107

U .5 Additional Energy in a Rock Bolt under an Initial Tension

T as a Result of Elastic Stretching------------------------108

1+.6 Plastic Yield Energy Absorption by the Rock Bolt----------- 109

vii

NOTATION

Angle between wave front normal and wall normal

%+V

% +*r/2

Function of t^ and tg (eq h-22)

-

Kinetic energy

erotal-

energy associated with area A of wave front

er * -

Proportion of energy associated with motion perp. to tunnel

eg« -

Proportion of total energy associated with motion parallel to

tunnel

er

Proportion of er * that is not absorbed by the rock, or reflected,

thus which goes to the rock bolts

-

erg -

Maximum energy that can be absorbed by rock bolts

es

Proportion of er ' that is not reflected or absorbed by rock and

therefore is

directed to the supports (same as er if supports

are rock bolts)

-

e0 ’ -

Maximum value of er ' that can be withstood by a tunnel without

support

eQ

e •' per unit area; = eo '/s^ for rock bolts spaced s feet

-

<j>p -

Peak friction angle

<j>r

- Residual friction angle

p

- Mass density

o

- Stress of elastic wave

ar

- Radial stress

<jg

- Tangential stress

Og

-

a_s

-

Bolt stress increment due to blast

Initial bolt stress

viix

Stress tensor

Tij

c

Increment of strain to reach yield in a rock holt under initial

strain

Polar coordinates

Transformation tensor-direction cosines between xyz, and x'y’z'

axes

Area

Cross-section area of rock bolt

Constant = 8q / i;

Constant defined by equation (5-*0

Residual cohesion

Peak cohesion

Phase velocity

Phase velocity of rock bolts

e

Strain

E

Elastic modulus of bolts

F

Force of rock bolts necessary to prevent any displacement

k

Constant - see p. 78

K

Constant that is determined by boundary conditions

K

Constant - see p. 80

1

Length of rigid bodies in chapter 3 } length of rock bolt in

chapters H and 5

M

Mass

-y

M

Momentum vector per unit area

%

Component of momentum vector parallel to tunnel wall

Component of momentum vector perpendicular to tunnel wall

n

R/(tdC)

ix

p

-

Hydrostatic pressure (external) due to rock stress or external

loading

Pg

-

Average internal pressure on wall of tunnel due to bolting

R

R

o

-

Value of r at elastic -

-

Radius of tunnel

R

S

T

- Range —

-

plastic boundary

the distance to the blast point

Spacing between rock bolts on a regular pattern

Initial bolt tension

AT

- Bolt tension increment due to blast

t„

B

- Transit time of stress wave in rock bolt

t

td

-

CB

Rise time of velocity pulse

Duration of positive phase of velocity pulse

U

-

Particle displacement

V

-

Particle velocity

V'

- Particle velocity after impact (in rigid body analysis)

Xrb

- Area under rock bolt stress-strain curve up to maximum allowable

stress

x

CONVERSION FACTORS, BRITISH TO METRIC UNITS OF MEASUREMENT

British units of measurement used in this report can be converted to

metric units as follows:

Multiply

Bj1

To Obtain

inches

2 . 5 1*

centimeters

feet

0.3 0 U 8

meters

cubic inches

16.3871

cubic centimeters

pounds

0.^5359237

kilograms

pounds per square inch

0.070307

kilograms per square

centimeter

pounds per cubic foot

16.0185

kilograms per cubic

meter

inch-pounds

0 .0 1 1 5 2 1

meter-kilogr ams

inches per second

2 5

centimeters per second

.^

xi

CHAPTER 1

INTRODUCTION

In previous work, blast loading was approximated by a static

pressure, i.e., dynamic effects have been ignored.

bolts, and with tunnel liners has

Support with rock

been considered in particular

analyses; in addition, some basic analyses of rock bolt action were

pursued to gain an understanding of their action as structural

elements.

All work has been in the framework of the Piledriver test,

that is, the underlying motive has been to obtain means for analyzing

rock performance in this test.

In this report, background gained in previous studies has been

brought to focus on the question of how to assign design parameters to

structural supports in tunnels subjected to static or dynamic loads.

First, the action of systematic bolting patterns is analyzed in

variably jointed rock masses assuming that elastic theory can be

applied.

Then the case of systematic rock bolting of tunnels with a

"destressed" or "plastic" zone contained within an enveloping elastic

rock mass was considered.

These first two approaches consider only

static or quasi-static loadings.

The next approach attempts to

consider the dynamics of the support problem under impulsive loading.

Some of the ideas presented herein have not been tested in actual

experiments and this must be left to future studies to validate this

approach.

The dynamic analysis presented is based on energy considera­

tions and could be applied to tunnel liner design with some modifications.

Finally, the energy formulations are used to develop an empirical

equation for dynamic design of tunnel supports and evaluates the

constants of the equation from the results of the Piledriver test.

CHAPTER 2

AN ELASTIC APPROACH FOR DESIGN OF PATTERNED ROCK BOLT SUPPORTS

UNDER STATIC OR QUASI STATIC LOADING

2.1

APPROACH

The first uses of rock bolts were as dowels —

passive

reinforcement in which the yield force of the bolts is available

as a reaction to rock load after approximately a tenth inch of

rock movement.

Then pretensioning was added to bring the bolts

into their working range without additional rock movement.

Many

convincing demonstrations and models entice the designer to specify

pretensioning but as yet there is no true understanding of rock

bolt behavior.

Present design approach is generally based on

previous experience without a rational scheme for selecting the

principal parameters —

rock bolts.

length, spacing, prestress, and size of

Three theories have been advanced to try to explain

rock bolt action and to guide its design as rock reinforcement.

First, in laminated rock, the bolt stress is thought to increase

interlayer shear strength, thereby stiffening the roof into a load

carrying beam.

Second, the radial confinement that is offered by

the average pressure supplied by the bolts raises the strength of

the rock around the gallery.

Third, that rock bolts are depicted

as passive members preventing large deformations from destroying

the keying action of joint blocks.

Rock bolts are installed in the inner surface of an excavation

carved in an initially stressed body.

3

At the time of installation

the stresses around the excavation approach the final values for

an unlined tunnel.

Depending on the initial stress field, joints

in the rock, and the manner of excavation, the prebolting stress

state may approach the applicable elastic solution, eg. the Kirsch

solution for a circular tunnel, or may contain a destressed zone

of permanently deformed rock.

Some rock blocks fall out during excavation of the gallery or

remain suspended in a delicate equilibrium.

Other blocks become

partially detached from the rock mass but remain entirely stable.

After installation of the rock bolts, the stress state may be

radically altered, as the bolts are tensioned to become active

structural partners with the rock.

Finally, the rock in service

comes under additional live loads imposed by operation of the

gallery and the stiffness of the remaining steel exercises a passive

resistance against further rock movements.

The proportion of the available steel area that should be

assigned to the contrasting active and passive roles depends on the

combination of geological conditions, prebolt installation stress

state, and post installation live loads.

Each gallery is unique

and one cannot hope for a universal design.

By combining solutions

to the relevant components of the total stress field and introducing

an appropriate criterion of failure, it is possible to compare the

relative merits of trial rock bolt designs.

The individual compo­

nents of the final stress state are the stresses imposed by the

anchor and plate of each rock bolt, the prebolting stress field

1

I

I

around the tunnel, and the stresses imposed by live loads.

I

slippage of rock blocks along jointing planes.

I

I

I

I

Ia

a

a

8

I

I

I

I

I

The

criterion of failure most appropriate to use is that describing the

Since the behavior of

jointed rock is nonlinear, and the installation is sequential, no

linear, elastic, one-step analysis cam reproduce rock bolt action.

Initial efforts to represent rock bolts in finite element analysis

were disappointing.

Success is now being achieved using incremented

loading techniques using finite element programs which model joints

and bedding planes and which represent the excavation and construction

sequence.

Still something may be learned from elastic solutions as

demonstrated below.

2.2

GLOBAL STRESS FIELD AROUND THE TUNNEL - ELASTIC BEHAVIOR

Many publications give stress fields about galleries subjected

to various load conditions.

Exact solutions are available for

idealized tunnel shapes in isotropic and orthotropic plastic materials,

as well as for isotropic elastic-plastic materials.

Heterogeneous

materials and complex tunnel shapes have been studied by photoelastic

techniques, as well as by use of the finite-element analysis.

For

the purposes of this discussion, the starting point has been the well

known Kirsch solution (Ref. l) giving the stress field about a cir­

cular gallery excavated in an initially stressed, linearly elastic,

homogeneous and isotropic medium.

Simulation of the loads imposed by the rock bolt is achieved by

superposition of the stress fields of two co-linear point loads, one

5

a surface loading representing the bolt bearing plate, the other an

interior point loading representing the rock bolt anchor.

The first

point load solution is the familiar Boussinesq problem (Boussinesq,

1885 ); the second solution vas developed by Mindlin (1963 ).

If

desired, a more exact simulation could be achieved through the

superposition of a surface plate loading solution and an interior

point load solution.

Investigations have shown that for points of

interest removed from the immediate vicinity of the ends of the

bolt, use of the point load solution is sufficient.

Ewoldsen

(Ref. 2) evaluated the error involved in using point loads on a half

space to represent rock bolts on the wall of a circular tunnel.

In

effect the circular wall is being replaced by a series of planes

normal to each bolt.

For an 8 bolt ring, of 10,000 pound preloaded

bolts in a tunnel 16 feet in diameter, the maximum error is of the

order of 0.5 psi.

The form of the stress component expressions resulting from

superposition of the two point load solutions is:

= P * f (Xi, L)

(2-1)

Where:

P = bolt loading

Xi

= coordinates of the point of interest referenced to the

bolt axis

^

L * length of bolt

ta

Thus for an assumed bolt length, the stress field components

for a given bolt load may be obtained by multiplying previously

6

I

I

i

I

computed unit bolt load stresses by the given loading.

Examples

of single rock bolt stress components are given in Figure 2.1.

In order to ascertain the global stress field existing around

I

the rock bolted tunnel, it is necessary to reference all stress

I

components from individual bolts must be summed, and added to the

I

y-v.

I

1

1

1

M

I

I

I

1

fields, tunnel and rock bolt, to a global coordinate system.

Further,

existing tunnel stress, at every point of interest in the global

coordinate system.

In the present example bolt stresses are initially referenced

to a cylindrical coordinate system whose axis is coincident with

the bolt axis.

These bolt stresses are transformed through the use

of a second rank tensor transformation into components referenced to

the cylindrical tunnel coordinate system.

Tkl x AkiAlJTij

Where:

Amn « direction cosines between the two coordinate systems

k,l refer to tunnel coordinates

ij refer to bolt coordinates

Knowing the location and orientation of each bolt with respect to

the tunnel coordinate system, the stresses due to single bolts may

be summed since we are dealing with a linearly elastic, isotropic

medium-.

This summation is accomplished by first finding the location

of the point of interest with respect to the individual bolt coordi­

nate systems.

This location will vary as the position and orientation

I

7

I

I

of each bolt with respect to the particular point is, in general,

not uniform.

of

As the bolt stresses decrease radially as a function

1/r2 or greater, it is in general only necessary to consider

f

I

bolts lying within a 30° cone around a radial line from the tunnel

centerline through the point of interest.

The transformed stress

components at the point contributed by the several bolts are then

summed.

N

n

“ stress at a point due to n**1 bolt

1

H = total number bolts considered

The resultant multiple bolt stress field is then added to the

existing tunnel stress field.

Tkl

* Vi

+Tkl

(2-4)

total

KXtunnel

xrock bolts

The final transition to the desired global coordinate system is

accomplished through another second rank transformation.

Trs * ^Ltk.As l \ l

(2-5)

From this point, examination of the effects of the rock bolts under

various failure criteria is easily accomplished.

2.3

I

I

I

Where:

Tkl

1

THE EXTENT OF THE SLIP ZONE

The criterion of failure adopted should reflect the way in

which the tunnel would behave if there should be no reinforcement.

In hard rock, the usual failure mode involves the relative movement

8

I

I

I

i

I

I

1

i

I

1

1

I

I

I

t

I

I

I

I

I

I

1

I

I

I

i

1

of blocks bounded by structural surfaces such as joints or bedding

planes; therefore, in the illustrations presented here a criterion

of failure has been selected in which the shearing strength of

geological weakness planes is the sole consideration.

portrays the failure criterion —

Figure 2.2

a linear mohr envelope characterized

by a cohesion and an angle of friction but with no tensile strength.

Any stress field can be examined with such a failure criterion if

the orientations of weakness surfaces are specified.

Examining each point around the tunnel in turn, it is possible

to identify the loci of points having a factor of safety of 1; any

weakness surface of the given orientation passing through the locus

will be critically stressed.

Thus the whole region around the tunnel

is subdivided into subregions within which weakness surfaces of the

given set are either over-stressed or under-stressed according to

the failure criterion.

Actually no rock can be "over stressed" as

the elastic stress distribution must give way to one which is

everywhere acceptable.

The scheme pursued here is simply a calcula­

tion method making use of elastic stress distributions to estimate

the maximum extent of rock requiring support.

Figure 2.3-2.10

gives examples of such charts, which can be considered as joint

influence diagrams to allow examination of the relative influence

of weakness planes at different positions near a tunnel.

2.1+

CALCULATION OF ROCK LOADS

Gravity urges the rock within the over-stressed subregions to

drop into the tunnel.

An upper bound to the rock loads is therefore

9

I

I

calculated by establishing the mass of rock within the joint influence

areas.

Above the tunnel, side restraint does not appreciably reduce

this load, whereas in the tunnel walls, the residual shear strength

along the joint orientation considered partially offsets the rock

load.

Figure 2.11 illustrates the principle of calculation.

The

I

1

I

rock bolts should be anchored behind the farthest extent of the

influence region.

To provide an upper bound to the rock load per

bolt, it is calculated here as simply the wall area per bolt times

the maximum extent of the slip zone for any joint.

2.5

THE PRINCIPLE OF THE DESIGN METHOD

The object of the design is to achieve an optimum reduction of

the influence volume through prestressing the rock bolts, always

allowing sufficient reserve steel area to support the rock load with

the required factor of safety.

The following information must be known:

1.

The diameter of the tunnel

2.

The preferred orientation of each set of planar weaknesses

3.

The cohesion and friction angle for each set of discontinu­

I

I

8

8

8

I

8

ities

h.

The initial principal, stresses near the tunnel

In seeking an optimum design, trial rock bolt parameters are

selected.

The object is to specify the following parameters of the

rock bolts:

10

ft

1

I

I

8

I

I

I

I

.^

I

I

V

I

I

I

I

I

t

I

I

1

1.

Lengths

2.

Spacings

3.

Yield force

U.

Pretension force

Each joint set can "be analyzed separately.

tension loads are low or absent, a relatively large slip volume will

exist and steel dowels sufficient to hold hack this mass of rock

will have to he provided.

By tensioning the rock holts, the mans of

rock to he restrained is reduced.

It is usually desirable in design

against static loads to avoid yielding the rock holts:

the rock mass

may suffer deterioration if allowed the several inches of inward

movement a rock holt of common dimensions will sustain in yield.

By associating costs with the emplacement of rock holts, the

cheapest acceptable design can he found.

A computer program was

employed to cumulate the global stresses, apply the failure criterion

at selected points, and plot the influence regions from which the

costs of each trial design can he calculated.

The solutions are

three dimensional and arbitrary joint orientations can be considered

as well as imbalanced rock holt patterns.

An example will illustrate

the method.

2.6

ILLUSTRATIVE EXAMPLE

A tunnel 16 feet in diameter is to be excavated at a point where the

initial principal stresses are 1000 psi horizontally and 333 psi

I

I

If rock holt pre­

11

vertically.

The rock is divided by cohesionless Joints having a

friction angle of 50°.

Establish the rock bolt design parameters.

Several trial designs are selected as listed in the four left

columns of Table 2.1, Part 1.

The Joint influence diagrams for each

of the eight cases are presented in Figures 2.3-2.10.

In these

figures, "2” denotes the position of a rock bolt, while "1" denotes

a position inside the slip zone.

(In cases S1A1 and L2A1, to save

computation time, bolts were included only in the region affecting

stresses in the upper half of the tunnel.)

The working loads for

the bolts are the sum of the installed tension and resistance for the

rock load, whose maximum value per bolt is calculated from the height

of the biggest slip zone.

For the example cited, Table 2.1, Part 1, the use of low tensions

and wide spacings is cheapest (S1A3); however the large extent of the

slip zone is dangerous for the eight-foot bolts.

would be more reasonable.

Twelve-foot bolts

Table 2.1, Part 2, is for the initial

principal stresses vertically; in this instance, the eight-foot bolts

are too short unless a very close pattern is used.

Table 2.1, Part 3,

is a similar computation where the tunnel is to be subjected to a 5 g

blast acceleration in the horizontal direction.

The basic idea is restated in Figure 2.12.

As the bolt tension

is increased, or spacing reduced, the bolting pressure is increased

and this has the effect of reducing the rock load (curve A).

Since

the rock load reduces the precompression supplied by the bolts to

12

the elastic zone, the volume of broken rock will enlarge unless

the bolting capacity is increased by an amount equal to the rock

load.

The required supporting strength curve (B), the sum of

rock load and bolting pressure, displays a minimum.

(The economic

minimum, however, may be situated differently.)

Prejudices concerning the style of rock bolt installations can

emerge from extensive calculations of the above sort.

This, however,

is not the intention here, but rather the presentation of a particular

train of logic.

the results.

Obviously, the details c m be changed and with them,

The tunnel may be loaded by high or low pressures,

before or after rock bolt installations.

The shape need not be

circular, the bolts need not be radial, and the design need not be

symmetric.

Instead of mathematical solutions, the stress fields can

\

be summed from finite element results.

The criteria of failure

can represent a continuous material about the tunnel rather than

ubiquitous Joints.

Only the sequence of logical steps is at issue.

The bolting scheme is pre-stressed to keep the zones of potential

rock fall from growing too large.

But it must also have additional

untapped strength equal to the load of rock zones that tend to move

into the opening.

Finally, the bolts must be long enough that their

anchors be well behind the slip zones.

2.7

CONCLUSION

The designer of a rock bolt reinforcement scheme has several

options.

He can install ungrouted, untensioned rock anchors;

13

continuously grouted, untensioned reinforcing rods ("Perfo 'bolts");

or highly pretensioned bolts with or without protective grouting.

Prestressing tends to minimize the rock load by altering the stress

field around the gallery and by preventing rock deformations.

In

the illustration presented which was based on an "elastic analysis",

significant reduction of the rock load by increasing the prestress

could not be demonstrated until the average wall pressure exerted

by the bolt pattern reached a significant percentage (about 10?) of

the initial rock stresses (Table 2 . 5 ).

in certain classes of problems.

This can be attained only

A significantly lower threshold

pressure for rock load reduction by bolting is being obtained using

"nonelastic" solution methods where a degree of deformation is

tolerated.

These studies are reported in the next section.

It is

interesting to note that only the average rock bolt pressure and not

the length, and spacing of bolts seems to affect the extent of

reinforcement achieved (Table 2 .1+).

Ihe design approach offered here, which is an elastic analysis,

can be summarized as follows.

estimated.

for reaction

The maximum extent of rock fall-in is

Applying the design acceleration, a total force required

c m

be computed.

If this is quickly applied by a rock

bolt installation, the full extent of the slip zone may not have time

to materialize, and the reinforcement system may be overdesigned.

If

the function relating the slip zone volume to the bolting pattern is

determined, it is possible to balance the reinforcement scheme.

Ik

A large percentage of the cost of a rock holt surrounds the

drilling of the hole, the setting of the anchor, and tensioning

and grouting •

The cost of a large bolt is therefore not much

greater than the cost of a small bolt, and it would seem the

cheapest solution to supply the full required reaction force with

a small number of large capacity bolts.

However, the results of

this elastic analysis suggest that the mechanism of failure may

involve local movements that could occur between the bolts of a

coarse pattern.

Thus the best design is a matter requiring geologic

and engineering analysis.

The enormous differences in reinforcement

costs according to the scheme adopted demand that rational effort

be made to design the rock bolting installation.

15

Table 2 . 1 Economic Comparison of Rock Bolt Design; Free-field Rock Stresses: pi = 1000 psi, P2 — 333 psi. 16 foot diameter, circular tunnel, rock

weighs 170 pounds/cubic foot; friction angle of joints = 50°.

Trial

design

N o.

Bolt

length

(feet)

Bolt

tension

(pounds)

Bolt

:spacing

(feet)

W all area M ax. height of joint slip zone (feet)

from horiz. (°)

per bolt joint inclination**

(feet2)

0

30

60

90

Maximum W orking

Rock load load per

per bolt bolt required

(pounds) (pounds)

Bolt feet Bolt ring Bolting

Selected

ring

cost

1Rock bolt Installed

foot

cost per

(lineal oper

diameter bolt

f tunnel $/foot

$/foot

feet)

(inches)

1. Pi horizontal/ 1 g vertical

384 0.950 912

2.50

18,100

DJa

100

0.0

0.0

0.0

1.1

0.5

18,000 1.05

SI A l

8

256

192 0.475

2.80

21,000

3U

3,000

1.0

4.0

0.0

4.4

2.0

S1A2

8

18,000 2.10

74

0.238

96

3.25

30,100

Vs

12,100

0.0

1.0

4.0

17.7

2.0

4.20

18,000

S1A3

8

420

0.475

192

65,400 1-* la 4.60

400

0.0

0.0

0.5

0.5

4.4

S3A2

8

65,000 2.10

105

96 0.238

74,000 U / s 4.60

9,000

0.0

3.0

2.0

17.7

2.0

S3A3

65,000 4.20

8

2,371

0.950

768

3.25

36,100

Vs

100

0.0

0.0

0.5

1.1

0.5

1.05

L2A1

36,000

16

593

384 0.475

39,000

Vs 3.25

3,000

0.0

4.0

1.0

4.4

2.0

L2A2

16

36,000 2.10

174

0.238

192

3.80

1

48,000

12,000

1.0

4.0

2.0

2.0

17.7

L2A3

16

36,000 4.20

2. p1 vertical, 1 g vertical

384 0.950 912

18,100

Vs 2.50

100

0.0

0.4

0.0

0.5

1.1

S1A1

8

18,000

1.05

192 0.475 257

24,000

V* 2.80

6,000

0.0

4.0

2.5

8.0

4.4

S1A2

8

18,000 2.10

87

96 0.238

3.80

1

40,200

1.0 24,200

4.0

2.5

8.0

17.7

S1A3

8

18,000 4.20

420

0.475

192

4.60

65,400

l-Vs

400

0.0

0.0

0.0

0.5

4.4

S3A2

8

65,000

2.10

151

96 0.238

89,200 l-*/a 6.60

1.0 24,200

4.0

3.0

8.0

S3A3

17.7

8

65,000 4.20

2,371

0.950

768

3.25

36,100

Vs

100

0.5

0.5

0.5

0.5

L2A1

16

1.1

36,000

1.05

3.80 384 0.475 694

1

42,000

6,000

0.0

4.0

3.0

8.0

4.4

L2A2

16

36,000 2.10

210

192 0.238

4.60

60,200 1-V»

1.0 24,200

4.0

2.0

8.0

17.7

L2A3

16

36,000 4.20

3. p1 horizontal, 5 g horizontal

384 0.950 912

18,500

Vs 2.50

500

0.0

0.4

0.0

0.5

S1A1

8

1.1

18.000

1.05

346

192 0.475

3.80

1

48,000

30,000

0.0

4.0

2.5

S1A2

8.0

8

4.4

18,000 2.10

192

0.238

96

1.0 121,000 139,000 1-V* 8.40

4.0

2.5

8.0

8

17.7

S1A3

18,000 4.20

420

0.475

192

4.60

67,000 l-J/8

2,000

0.0

0.0

0.0

0.5

S3A2

8

4.4

65,000 2.10

96 0.238 234

2 10.20

1.0 121,000 186,000

4.0

3.0

8.0

8

S3A3

65,000 4.20

17.7

0.950 2,371

768

36,500

Vs 3.25

500

0.5

0.5

0.5

0.5

16

36,000

1.05

1.1

L2A1

820

0.475

384

4.60

66,000

l-J/8

0.0 30,000

4.0

3.0

8.0

4.4

16

36,000 2.10

L2A2

384

0.238

192

8.40

157,000

1-»/«

121,000

1.0

4.0

2.0

8.0

17.7

16

36,000 4.20

L2A3

* These calculations are based on the joint influence diagrams in Figure 4 which were computed for pi horizontal. But by a simple rotation, they

can be used for the case pi vertical, or in any other orientation.

.

** Angle listed is the trace of the joint across the tunnel section. If the real joint planes do not strike parallel to the tunnel axis, their in uence

areas will be smaller than the ones shown.

Table 2.2

COMPARISON OF ROCK BOLT DESIGNS

I.

Design No.

Effect of changing spacing at constant

rock bolt wall pressure

Average Rock Bolt

Wall Pressure

(psi)

Spacing

(feet)

Maximum Rock Load

in Feet of Rock

Case 1

Case II

Case

S1A2

28

2.1

4

8

8

S3A3

26

4.2

4

8

8

S1A1

114

1.05

0.5

0.5

.5

S3A2

103

2.10

0.5

0.5

.5

*

Calculated on basis of wall area.

Tunnel diameter is 16 feet.

Table 2.3

COMPARISON OF ROCK BOLT DESIGNS

II.

Design No.

Effect of changing rock bolt wall pressure

Average Rock Bolt Wall

*

Pressure

(psi)

*

(%PX)

Maximum Rock Load

in Feet of Rock

Case I

Case II

Case

S1A3

7

0.7

4

8

8

L2A3

14

1.4

4

8

8

S3A3

26

2.6

4

8

8

S1A2

28

2.8

4

8

8

L 2A 2

57

5.7

4

8

8

S3A2

103

10.3

0.5

0.5

0.5

S1A1

H4

11.4

0.5

0.5

0.5

L2A1

227

22.7

0.5

0.5

0.5

Calculated on basis of wall area.

Tunnel diameter is 16 feet.

I

LO AD

1 0.0 00 PO U N D S;

LEN G TH

10 FEET; TENSION PO S ITIV E .

T

o -H

r

i

TENSION

SHEAR FAILURE

BOTH

UNSHADED REGION REPRESENTS NEITHER

TENSION NOR SHEAR FAILURE

FIG.2.2 COMPARISON OF STRESSES WITH

FAILURE CRITERION.

After Duncan and Goodman (1968)

*0*0

i

1

min

1

J

}i

iu in

U n i

1111

n

n 11¿1211

U'12

inn

.

.2

2

2

•¿i

¿121211 n

n n li nn

? i¿i

n i n i

12*

i u u

?.

m u

.2

•*

2«

.

.2

..

inn

n.

ii ii

ii ii

m

mi n mi un i

i 11n n u ii m i

n in n u i nn n i i i

i i i u mi m u n i v i

u n i i n i i n n n n m un ni i ii i nni

i

i i

ii

i

inn

40

7 r a Cl

Ju IfjT s

,

ANuLF OF NORMAL WITH Y

axis

= 9 0 . 0 S EC T I ON s ~ 0 ,

>1 A l

Figure 2.3a

Joint Influence Diagram for Case (SlAl) - Horizontal Joint

21

.

I

I

I

I

I

I

I

I

c

I

I

I

K

I

«

i

i

(

i

.•¿.?U^l?i21]

?i*u

121

<

i

l?

ii

?A

•?

i

1

1

2. 1

4

4

?•

2

•••4

(

11 J?

.1 1 i

m

?!

¿1

n

4

*•

.2

a

a

li i

1111

n iiu n

mi

u li

ii n i

a

a

.o

T^Ce.

J'vI'J!

; i<M' ial

v l I fi

i

h«: i i

-

gy, u

ACTION

--o#

SI l

Figure 2.3b

Joint Influence Diagram for Case (SlAl) - 30° Joint

22

I

I

21^1

.2#2

121

•2 -

2.

••

i i

i nn

?1

m i

12

i i i

n

11

21

1

21

i

21

2

1

..••2

1

1

<L

1 12

] 1 1

¿1

1 111

min 1 21

m i l 1111

i i 1 111

n nu

••

.2

• •1

1•«

40.

4u.o

TRACc.

of

Jol'll

=

>)}■

Y AA1S

= yO • u S E C T I O N

"-O*

S 1a 1

! Figure 2.3c

Joint Influence Diagram for Case (SlAl) - 60° Joint

23

\

*

<H).U

. 2.2

*•2m2• ¿•2.2..

2.¿-

.2.

?.

12

U

2.

11

12

21

12

1

12

?

1

21

1

21

2

1

»?. ...

2

2

12

21

1

1

21

U

21

.2

•••

....

••••

. . . .

......

i

0*0

u

T f í ACt

SI Al

r'F

JOI NT

= ^ . ‘y A,( )|J'

<)K (J')Rm a L

-»l íH

Y AXI S

=

S E C T I ON =-Q •

1

Figure 2.3d

Joint Influence Diagram for Case (SlAl) - Vertical Joint

2k

1

i

1 11

i i

1

il

! I•

I I i ) ii¿il; li 1 .i «•l1'•• i

il i i • .2

•

l

i l i

i 1. 2 • 1 1 1 1 1

1.2*t..lI l 111I 1l1 i11 1

?.

i n

i

U

11 1

i

•

I

«

.2

i 11

•2

*

l.l

1..

1 i i

! I

•

i.¿* n

M i l l

1 1 1 Al 1 1 . 2 . 1

\

1

i 111 1 1 * ’l - ^ . l <r 1 . 2 . 1 . 1 X 1 11 1

1• 1• 1

• 1 • !1 i

li

i

i i li

1] 1 l ‘

il

1

t

•

4(

-*+ ••n

HK Jv> i i J' S 1 i* 2

A i Mj !..

IA) K¡., L

;Î

TH

Y

A U : i

=

4^.0

S EC TIO N

=“ 0

•

Figure 2.Ua Jo in t Influence Diagram fo r Case (S1A2) - H orizontal Jo in t

25

x •

\

\

1 1 1)

••¿»•if •11.2*1 1

A.I

2. 1

1.1 1

.2

••

1

•?

.

2

••

1

11

1

1

1. 11

.Il

?•

2

11 £ '

11 I*

1 11

11121

1 1.1

!

.

..'

.2

2*

.2

1. 1

.... 2*1

1.1*^*1 *■ ..2«.

1.1 i.i.i

111

.0

T‘-?a L

4D

l

Of-

JOi'l!

Figure

4!>inLh

2 . kb

Of

NJK-' AL

<ITH

Y AXij,

»

SECTION

=" 0 .

Joint Influence Diagram for Case (S1A2) - 30 Joint

26

'O . U

*2••

1*¿* 1

M n

i

?. 1 i i i

.2

i. i n

i. i

• *

ii

2« 1 1 1

»2

Al

U

Ì

?.

1

1

i

i •

11 i.

1 i

11

i ?A

1

1 11

1 i

.2

1 .1

). \ .2

1

i 1.1

11 . 2.1

.

.2••«

•

o

-'+Ü

TNACL

40

of

jo

X fJT = f

A-JOLH OF N O H ^ a l

v ITH

Y A X l * Ä g O . ü S E C T I O N = **0.

Si..2.

1 Figure 2.he

joint Influence Diagram for Case (S1A2) - 60° Joint

27

.(

n

i i

i

2*

2

.1

l

.

1

}¿

)

► ...

2

I • ¿ # #

40-0

ím

Figure 2.Uà

>

j

3KCTI on

Joint Influence Diagram for Case (S1A2) - Vertical Joint

28

h r..

o

ï

1

1

11 1

?

I l l

1 1

1 1 1 • l . l i . *■. V V . l . l 1

1

1

1 1 .¿.1

)

1 Il

1..1

1

#•

•

Il

1

1

• •

•

• •

*

•3

•

• •

•

•

•

•

•

•

•

1

1

U

1 l

1

1

1

1

1 Ì

Í

A. . 1

11

• •

• •

• •

?..

• •

•

•

•

•

•

,

•

•

•

• •

•

• •

•

•

•

.?

m •

?..

1

• •

•

• •

*

11

1

1

1 1 1 . 1

1

Il

11 . ¿ . 1

1 1

l

1

111

1 1.1 • 1.1

?

1 . 1 , 1 .1

1

1

1

11

1 .1.1

11

11

1

1

•

1

1

1

11

1

1

1 1

1

1

1

11

1

1

1

1

• •

1

1

11

1

1 1

w •

l

11

U

1

X

111

1

l

1

1

1

1

1

11

1

J ,o

T <ACL

40

n.f-

J >!■ T r

.1 i ^ L f

Figure 2.5a

n

ÜOWIAL

wIM

y Axis = VO'V StCTlON * - o 9

Joint Influence Diagram for Case (S1A3) - Horizontal Joint

29

'»■ \ l . I)

• • ••2• •

1

1. .

i 1 11 1. .

11

1 1

i 21

1 1 .1

1 1 .1

1 1.1

.¿.1

•

•

•

•

•

•

•

•

•

•

1

• 1 1 11

U f.1 1 .1 .1 1

1 .4 .

.

A. 1 1

•

1. 1 1

•

1.11

•

1.1

1

•

2. 1 1 1

•'

1. 11

•

. 1 1

•

. 1

•

.

•

•

•

«

•

•

•

»

•.

•

.

•

.2

•

••

•

.•

«

.

1 ^

i.i.i

1 A A

■9j#0

TWACt.

S]AJ

of

JOINT = 3i:.‘ AN^L.I- <)F N O H M a L WITH Y AXIS s 9^.0 SE CT I O N *-f).

Figure 2.5b Jo in t Influence Diagram fo r Case (S1A3) - 30 Jo in t

30

h

l.<* 1

M H li 1

1.111 1

ì« 1 11

t. 1 11

2. 1 1 1

11 U

1

il I.

Ili

11 i 21

l 11 1 •!

1 1 1 1 .1

1

-4

i

1

11*1

11 . ¿ . 1

;•. o

1-i-.L'.

4(

J J l '1

•f.u -, I f H

r ^Àis

= V' J . U

SFC r Tou - - c .

Figure 2.5c Joint Influence Diagram for Case (S1A3) - 60 Joint

31

40 . Ü

-

40.0

SI AJ

] Figure 2.5<1 Joint Influence Diagram for Case (S1A3) - Vertical Joint

32

I

\

» f l ))

0

j i

>4390

a

> O O '> o ^ ® ° i ■» a » 8 a j o «

©

i

l l,UlUloll.Ul i

II

l

alol

o

l«lo

lili

val

o

l<

l Ï

U I

1

i

1

>0 0 0 9 0 3 0

» 0 0 0 3 13399 0 0 0 9 0 1

I I) O 3 9 © 'J 0 0 0 9 9 0 t f © © © © 0 0 l

* oo r

1

l l

l l U

1 I I{

l

I

1

1

1

V

11

« o

O *

oo

3

9339

9999090

oo

O

3 9 9 0 0 0 0 0 9 9 9 0 9 0 0 0 0 00 * 5 O 0 0 0 0 0 0 0 3

*©«3000990

©O© 9 0 0 0 0 * ^ 9 0 0 0 0 0 3

• 0 0 0 9 0 0 0 0 9 9 0

®

»0 0 0 0 0 0 0 0 0 9 3 0 0

«

O

«

’

O

9

9

3 9

O

O O

O

O

11

li

1

l

O

°

—4 O 9 O

lo l » l 9 l

i

l

11

9 O 3 3 3

) o 9990000

9 9 o 9 9 3 O ï 'J 9 •

'

lol<

lo lo lo l

lolol

1

* 0 3 3 9 9 3 0 9 ‘3 9 9 0 0 9 9 0 9 9

300"

rn t 7

r)F

J 'H N T

1

>00909009.»3

l

il

> 0 9 9 3 9 0 9 0 0 9 0 3 0 0 9 0 0 0 0 0 0 0 9 9 0 0 0 0

O

- 40„0

T^'Cf:

l H

i

lili

l l l

1

>loi

i

i

9

O

trai F

Of

isjfpM.M

W ITH

Y

A X IS

=

0 0 :>r» S F C . T U Ì N

--0 ,

Figure 2.6e Joint Influence Diagram for Cane (S3A2) - Horizontal Joinj

33

40

1

A^o0 ®9 :

’ ■■»>■» j o o o o o o o o o o o o o o o o o o n o o o o o o o o o o o o o o o o o o a o o o o o o o o o o o o o o o o o a i o o o o o o o o o o o o o o o ' o o o o o

I

1

I

I

I

1

1

1

1

1

1

1

1

1

0

o

o

o

» o o o o l o I® l i ® l e i

sono

®

Loie

o

u

0

1>

1,

1®

1®

1

11

io

o

1

0

0

> 0 9 0 0

:> O 5 * » » 0 5 o -3 n > 0 0 0 9 0 0 0

1

1

U

9 0 0 0 0 0 9 0 0 9 0 0 9 0

9 0 9 9 0 0 9

0 0 0 9 0 0

9 5 oo<

09

9 0 0

9 0 9 0 0 9 9 0 0 0 9 0 0

9 O

lo

0

l

11

9

9 O

1

O 9

0

lo 1

*

lo 1

O

0 9 0 ®

e

O l 9 1 o 1

oo oooo

lo l, i

•»

0

e

0

©

0

0

-'♦no0

- 4 0 „

, ,,

19 0 0 0 9 0 0 9 0

> 5 59 9 O O 1

> 0 9 9

9 9 9 9 -

> 9 0 9 9 9

9 9 0 0

>9 9 0 9 9 -

>9

5 9 0®

0

0

'*p j >nr

!■

‘:».»LC nf NfinMM WIrM Y ^XTS = <-?n,n SECTION =-0,

i Figure 2.6b

Joint Influence Diagram for Case (S3A2) - 30° Joint

3^

9 * 0 9 0 0 0

9 0 9 9 '

4'ìl

1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

r

i

i

40o0

L»—

ooooooooooftoaooooooooooooooooooooooooooooooooooooooooeoooooooooooooo

>990000

oaoo• <

oo

0o

O5

oo

1o

»ÓOOOOOOOO

ioloU1 1

lo 1 l l i

lo

il

Ulo i i 1l

Il1 1

O o 9 8 0 ' > 0 l > 0 > 0 î l ' > 0 a 0 0 î 9 0 i 0 4 « * 9 0 « 0 a 5 i > 9 9 l > ( > i » 0 |,> î 9 0 # 0 a i 0 a

O

l

.

1

1*

9

1

1.

o'

*

Il

11

,

1

il

«I

.

i

l 1 1 -9 1

o

l

1.1

9

O lo l

«

• o oaof

1 1

AOo ^

•> o > o ft n i f

9 0 9 0 0 0 9 0999000*:

-40„ o

•yo^r.fi MF JHTM‘T = '/» n ,n

cv ?

o

>00 0 9 0 9 O0 9 0 0 0 0 9 O 0 0 0 0 0 0 0 0 9 0 0 0 9 0 9 9 a

>0090000

»

9 0 0 9 0

«

fïGI T; n F T»RMM_ WITH Y AXIf' = ‘^QoO SECTION =-0«

Figure 2.6c • Jo in t Influence Diagram fo r Case S3A2) - 60° Jo in t

35

40

>00 0 9 0 9 0 > 0 0 0 0 0 0 0 0 0

o » 8 0 0 ' ) ' ) 0 9 ' ) í ( » n o * o j ‘» 0 9 J o > o « i> * ' > « # o # o o ( » 9 ' > 9 ' » o o e * » n * * o « # #

o

®

O

*

O O• O • O«

8 9 4 10 9 0

9 OO «

9 9 0

99

19

• O

«1

lo

lo

9 1

11

1

11

1

0

9 0 3 9 0 9 9 0 0 0 0 9 0 0 0 0 0 0 0 0

1

.

i

1

9

1

*>0 0 9 0 0 0 0 9 9 0 0 0 0 1 ) 9 0 0 0 0 0 0 0 9 0 9 9 9 9 9 9 0 « 0 0 0 9 « 1 ^

i

.

i

1

•

1•

o

lo

o

1

I

i

• i

1

o

11

o

11

o

1

•

9 9

O

OO

9 O

009

• 9 O

0900

9991

>O 9

00 90 99

O

9

O

9

O

9

9

O

^ Oí n

03 » 3 9 3 0 0 9 93 9 9130 0 90 '> 9.1 0 0 0 0 9 0 . 10 0 « > 0 0 0 0 » 0 0 0 9 0 0 « 0 0 ©0 ©0 0 0 0 0 9 0 0 0 9 0 0 0 0 0 0 0 0 0 0 9 0 0 0 0 0 9 1 0 0 0 0 0 0 0 0 0 9 0 0 0 0

-40*0

t r a c

rv?

F

OF

o

JOINT

=

00, 9

A N Gl . F

Figure 2.6d

np

NORMAL

W ITH

Y

AXIS

=

9 O „0

S EC T ION

=r*n.

Joint Influence Diagram for Case (S3A2) - Vertical Joint

36

*

•

•

*

•

•

»

*

»

*

•

»

.

*

»

4

1

*

4

*

«kiil i it

«*

**.••••*•*•¿4»*

i

è

_ . i

k

%

■J

•

__ k

k

k

i

%

ï

__ 3

i. i . J

S l

l

U

r yr r n

ï r v a . v u » i m i l . r .i 1- i ï S

^ ■ ¡ w

I r l i

i i f*ii

ì V n ii.i

l w L 11 \ S i

i\ i

i

l

..

k k .............................

kk

2k

»2

kk

i

m• • 4 k • • • • • • • • • kI

» • • k k k • k • k k • 2 Vk k k k k • • k k • • •

k k

k•

k

k

• k • « k k k • k k' kk • k • k k k k 2 k k • • • k k k k k k k k k k k k k ’k k

k

kk

k

• •

k

•2

2.

i1 «

ÌÌ \

Y. l

iv. i i L ï L

Ì \ 1

Yì

k

ïwfe> li il i Y 1

^ \ 11 ^ \ n \ n S . i ; \ ? i ’. v.yiï i

; ï

1\ \ 1

1

U

V .i-.l it

1

1 V W

i

i

Ì

SVa')

I

T

1

\

1

• k k k '1« rVkkl

1

1

1

1

_1

1

*VÒ.'Ò

TRÀCE n‘r Joint

.

1

1

'I

1

Ì

'*6

s

f(.

ang'l'e

or

norNa'l witn v axis

» $o»o

section

*h-ô.

J o i n t In flu e n c e Diagram f o r Case S3A3) - H o riz o n ta l J o i n t

37

V

40,0

.2..

11H

.lM.l

1

..l.*

•••

1.1

1. 1

1.1 1 _

1. 1 1

2. 1 1 1

1. U

.11

•2

11.

1

11 1 .

11

11

1 21

.2

•.

1 1.1

1 .1

1.1

.2.1

U ill

1.1.1

1 • 1i 1• 1

i*

.•2•

......

<►0.0

•<►0

40

TRACE. OF JOINT = 3a. o AN^Lfc OF NORMAL WITH Y AXIS 3 90.0 SECTION *-()•

S3A 3

Figure 2.Jb

Joint Influence Diagram for Case (S3A3) - 30° Joint

V

1/

40.0

.2..

l.¿» 1

l.U Ï 11

ï. 1 1 1 1

i-, 1 11.

1. 1 1 ï

2. 1 1 1

11 11

1

•'

1

1

• ••

••

••

.2

1

1

1

1

11 1.

11

1 1

121

1 11 1 .1

1 1 1 1 .1

•

.

1 11.1

•••

1 11 2.1

- 4 0 •o

2

»• •

ü

r■

40

■

'

I

TRACI: or JOINT s feo.M AMOLE OK NORMAL WITH Y AXIS = 90.0 SECTlpN s-0.

S 3A3

Figure 2.7c

Joint Influence Diagram for Case (S3A3) - 60

39

Joint

•• ìC- r,f JOINT = M9.9 ANGLE OF NORMAL WITH Y AXIS = 90.0 SECTION “-0.

Figure 2.7d

Joint Influence Diagram for Case (S3A3)

1»0

I

I

I

I

I

I

I

I

I

I

I

I

I

I

ì

1

1

uni i

1 11 1

l\

121 ?

11

2

#•

112121122121211

•?!

•2

.

?121

1*.

2

1 11111

.

1 11 1

11 U

2.

2*

2

2

.2

1

1 1

i mi

i l i

l in

?

2.

?•

2

*

.2

.2

2.

.

.?

121

121 1

1121

211212

.2

11111

21211?

1

mi

l l

m

1

l

i

l

40

I

I

I

I ,, r {- Dr j »i ' T =

<) . J

a N'-U.

OK hOPMAL Wt T h Y AXIS = 9 0 . 0 SECTION s -0 00

: J I !

F igure 2 .8 a

J o in t In flu en ce Diagram fo r Case (L2A1) - H o rizo n tal J o i n t

Ul

..2 .2 1 1 2 2 1 H 1 2 U

2.2

2121

•2

1*1

2

21

2

1?

U

•2

21

.2

2

?•

2

2

*

2

2

2

.

2

12

1

?1

2l

1?

2

.2

2.

121

1211

, 211212

..2

2

2 . 2,.2

11 111

0

]'" T =

*r"lt OF NORMAL

"Figure 2.8b

w t Tk

Y AXIS = 90.0 StCUON =-() •00

Joint Influence Diagram for Case (L2A1) - 30° Joint

k2

I

I

H(>.0

I

.2.?

••?•2• ¿•2.2..

2121

1¿1

.2

21

2.

1?

U

.*5

21

.2

21

1

?1

2

1

2

2

2.

12

1

.2

"5 l

21

1?

121

1211

.

»

.

*2

2

• *2.

2.2..?-

2♦2

0.0

o

I^ATF

•

OK J O I N T

= i i .i

a :*.-i.K

OK

I OPMAL

WT T>- Y A X I S

= 90.0

SECTION

40

= - 0»00

i

Figure 2.8c

Joint Influence Diagram for Case (L2A1) - 60° Joint

I'UO

•¿

1

. . .. ?.2,

• 2 • 22 2 2

,2.?

•2•

..

2

2.

1?

11

21

.2

i1

1?

1?

1

)?

2

1

.2.... .

■2i

Î

?1

2

1

.... 2.

?

21

1

12

?

12

1

r>\

2i

.2

2•

.2.

•*2.

•2 «

. 2 ..

2••2•2

2 . 2 . •?

li . o

40.0

fPArt-

Oh

ju p

I

= '<i.v

Af (, t f.

OK

KOHhAL

Y a XTS

= 40*0

StCHON

a " 0 # 00

^ A I

Figure 2.8d

Joint Influence Diagram for Case (L2A1) - Vertical Joint

1+4

/*

u.

0. 0

1

1

11

1 1

1

11

1

1

1

1

1

1

1

1

1

1

11

1 1 1.2

.2 .1

.1

.

11

.

. 2.11.

.2

•

•

•

•

•

•

•

•

•

•

•

•

2

.•

•

V0

i

I

I

. (J

.2

1

1

1

11

.

••

1

11

1

1

H

I

1 .1

1 .2 .1

1 1. 1. 2 . 1

11

1

.

-^C•0

I mU

l

F JOINT =

1

1

1

1

1

1

1

1

•

•

•

•

2

1

2

, •

1

.2.

.2

••

•

l

1

1.

.2

l

1

1

••

•.

11

1

11

2.1

1

.

••

••

2.

••

•

2.

•

1

11

1

1 1

1

11

m

•

•

2

••

.

.2

••

2 .

1. •

11

1.2. l

2

1. 2.1 .1

1 . 1 1 1

1

111

1

1

11

1

1

1

1

1

1

1

l

n

0

0.0

ANOLI

OF NORMAL WITH Y AXIS = 9 0 . 0

SECTION =-0.00

l ,a;

;

Figure 2.9a

Joint Influence Diagram for Case (L2A2) - Horizontal Join

^5

40

,

vO.U

»2 . •1 1

1 1 11

»11 • 2 • 1

1 .2.

1.1

1. 1 1

1. i 1

2.1 1 i

1

.2

2

11 1

.

•

2

11

.

.

1 1 1

11 1 21

1

1 .1

2

.2

1.1

.

2. 1

. 1 . 2. 1

11

.

.. 2 .

.

2 . . 2 ...

1 1.1

l 1

* 0.0

40*

-4 0

TK/Ct:

UF

JOI NT

= 30.0

ANGLF

OF NORMAL

WITH

Y

AXIS

= 90.0

SECTION

=-0.00

L 2 A2

Figure 2.9b

Joint Influence Diagram for Case (L2A2) - 30° Joint

/

I

I

I

0.0

1

I

I

. .1 . 1 1 1

1 2

.2

2

1

.1

1

1 1

1

1.1

11

1.1

11

2. l i i

11

•

I

I

I

I

I

I

1

1

2.

1

1

2

1

1

»2•«

1

1

2

1 l.

I l l

1

11

1 21

11

l .1

1

1 1 1 .2

.

.2

2

1 11.1

1 . 2.1

. . . 2..

». 2 . ..

-4Q.0

I

I

-40.0

IKAC l

CF

0

JO INI = 60. 0 /NOLfc OF NORMAL

WITH Y AXIS

= 90.0

L2A2

Figure 2.9c

Joint Influence Diagram for Case (L2A2) - 60° Joint

1

I

SFCTI ON = - 0 . 00

1*7

40.0

I 2k 2

Figure 2.9d

Joint Influence Diagram for Case (L2A2)

U8

I

i

I

I

I

I

i

(

V

‘1

t0.0

i l l .

i

n

11

Il

l

l

l i

li

11

.11.1.1

i l l.i.ii,

1 1 1 1 .2.1

1

1 11

l

1

1 1 1

1 1

1

..

..

11 1

I

I

k

2.

..

1

11

1

1

1 1 1

1 1 1

1

11

1

l

l

11

1

.

.

1.1

.

11 . 2. 1

111

.

!..

..

..

1 .2 . 11

l 1.1.1.1

2 1.1.1.1 1

Î

11

1.1.1

li

T

.

Ili

1

1

1 11,

1

. ........

2

1

1

lì

1.2. 1 1 1 1 1 1

1..1

1..1

1

1 1

1

1

1

11

1 1 1

11

1

1

1 1 1

1

11

1

1

1

.0

iL"s-..

■I

-4C.Ü

^..V k ACL

CF JOI NT

0

=

0.0

ANGL*

OF NORMAL WITH V AXI S

= 90.0

40.0

SLCT ION = - 0 . 00

Figure 2 .1 0 a J o in t In flu en ce Diagram fo r Case (L2A 3)-H orizontal J o in t

1

1*9

I

I

I

1 1 11

, 1. 2 , 1 1 . 1 . 1 1

1.?.

1.1

1. 1

1. 1 1

1.1

1

2. 1 1 1

1. 11

. 1 l

t 1 .

1

11 1.

11

i

1 1

121

•2

1 .1

1 .1

1.1

.2.1

..

1 1 1.1

• 11

2

. .2.

1.1.1

1 1 1

(

;0. J

—0.0

0

i I oc OF Jiilfv'l - V>.0 / H( |_ OF UmPOIAI

with

Y AXIS = 90.0 SI C7 l LN =- 0 . 00

L,

Figure 2.10b

J o i n t I n f l u e n c e Diagram f o r Case (L2A3) - 3 0 ° J o i n t

50

40

I

I

I

1

X

I

I

I

1

I

1

I

I

I

I

I

t

1.2. 1

1 .1 1 1 11

1.111 1

1.1 11

1.1

11

?. 1 l 1

11 11

l

1

... ?.

l

1

l

1

1

111.

1 11

U 1 21

.2

1.1 1 .1

1 1 1 1 .1

1 1 l.l

1

. 2.

11 . 2 . 1

'.0

f jfU r1

i

f]<.i ,

it

Figure 2.10c

m th

v vx

sr ( i I r r ~ - 1). oo

t

Jqint Influence Diagram fop Case (L2A3) - 60° Joint

51

I

I

I

1

I

1

1

I

I

I

I

'

2

.3

2

.

1.

1«

2•.....

11 1

11

• 1

1

1

.1

.2

11

l 1

1 .

1

1

..2 ........

1

I 1

11

l i.

1

21

12

.1

.2

• •

1

1 l

11

•1

1

2

2

• -

'j. Ü

o

jnira =

s

j

ur-

normal

with y axis

= 90.o

sfction

=-o, oo

F igu re 2 .1 0 d Jo in t In flu en ce Diagram fo r Case (L2A3) - V e r tic a l J o in t

52

I

1

I

I

4G

Joint influence zones for the given stress field

Vertical structural, support required is Mgg on the left roof. On the right

spring line, the supports must supply a reaction parallel to the joint of

magnitude M^g sin a -

£.

FIG. 2.11 The Rock Load

53

FIG. 2.12 REQUIRED ULTIMATE STRENGTH FOR ROCK BOLT

SUPPORT SCHEME-SHOWING A MINIMUM AT A

GIVEN BOLTING PRESSURE

5k

I

I

I

I

I

I

8

I

CHAPTER 3

DESIGN APPROACH FOR ELASTIC-PLASTIC

ROCK UNDER HYDROSTATIC LOADING

Chapter 2 considered an approach to selection of rock bolt

design parameters.

A specific illustration of the suggested

approach to examine the relative influences of bolt length,

spacing, prestress, and diameter made use of elastic stress

distributions assuming the rock bolts to be colinear point loads

in a linearly elastic medium.

Joints were considered as a

criterion of failure, but Joint failures were not allowed to modify

the global stresses.

I

For simple stress states it is possible to obtain an elastic-

8

plastic type of solution in which the failure of specific portions

K

I

I

I

This chapter will draw on the logical steps of Chapter 2 to obtain

I

I

I

I

of the rock around the tunnel changes the conditions of the problem.

a closed form solution for design of rock bolt support of a circular

tunnel in broken rock under a hydrostatic state of stress.

The

rock bolts are replaced by an average bolting pressure Pg.

1

3.1

MATHEMATICAL CONDITIONS

Excavation of the cavity and external loading are considered

to develop a stress state that is plastic near the opening and

elastic beyond as in Figure 3.1.

The stresses in the plastic

1 Ref. 3

55

zone are constrained by the Coulomb strength characteristics of

the broken material Cr and <|>r (Figure 3.2), which may be

approximated by the residual strength parameters deduced from

direct shear tests carried to large deformation.

The dimensions

of the plastic zone are fixed, on the other hand, by the criterion

of failure applicable to the rock mass at the limit of strength

and therefore by Cp and $p, the peak strength values determined

by triaxial or direct shear test.

In a continuous rock mass,

or one with initially tightly closed or incipient extension joints,

Cp and <|>p are essentially the peak strength parameters for rock

substance and greatly exceed Cr and <(>r .

In an open, jointed rock,

or one with shear joints, the values of Cp and <|>p may be close to

Cr and <j>r (Reference *0.