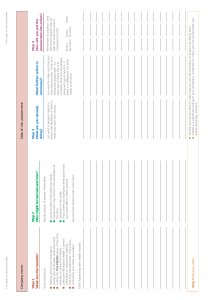

1. Student and trainer details Student details Full name: Student ID: Contact number: Email address: Trainer details Full name: 2. Qualification and unit of competency Qualification/Course/Program Details Code: Name: Unit of competency Code: CPCCWHS2001 Name: Apply WHS requirements, policies and procedures in the construction industry Releases: 1.0 Release date: 17/Jan/2019 3. Assessment Submission Method ☐ By hand to trainer/assessor ☐ ☐ Online submission via Learning Management System (LMS) ☐ Any other method _________________________________________________ By email to trainer/assessor (Please describe here) 4. Student declaration • • • • I have read and understood the information in the Unit Requirements prior to commencing this Student Pack I certify that the work submitted for this assessment pack is my own. I have clearly referenced any sources used in my submission. I understand that a false declaration is a form of malpractice; I have kept a copy of this Student Pack and all relevant notes, attachments, and reference material that I used in the production of this Student Pack; For the purposes of assessment, I give the trainer/assessor permission to: o o Reproduce this assessment and provide a copy to another member of staff; and Take steps to authenticate the assessment, including communicating a copy of this assessment to a plagiarism checking service (which may retain a copy of the assessment on its database for future plagiarism checking). Student signature: ________________________________ Date: ____/_____/______________ 5. Assessment Plan The student must be assessed as satisfactory in each of the following assessment methods in order to demonstrate competence in a variety of ways. Evidence number/ Assessment method/ Type of evidence/ Sufficient evidence Task number Task name recorded/Outcome Assessment task 1 Knowledge Test (KT) S / NS (First Attempt) S / NS (Second Attempt) Assessment task 2 Skills Test (ST) S / NS (First Attempt) S / NS (Second Attempt) Assessment task 3 Skill Test (ST) S / NS (First Attempt) S / NS (Second Attempt) Outcome C ☐ NYC ☐ Date assessed: 6. Completion of the Assessment Plan Trainer signature: Your trainer is required to fill out the Assessment Plan Outcome records above, when: • • • • You have completed and submitted all the requirements for the assessment tasks for this cluster or unit of competency. Your work has been reviewed and assessed by your trainer/assessor. You have been assessed as either satisfactory or unsatisfactory for each assessment task within the unit of competency. You have been provided with relevant and detailed feedback. Every assessment has a “Feedback to Student” section used to record the following information. Your trainer/assessor must also ensure that all sections are filled in appropriately, such as: • • • • Result of Assessment (satisfactory or unsatisfactory) Student name, signature and date Assessor name, signature and date Relevant and detailed feedback 7. Unit Requirements You, the student, must read and understand all of the information in the Unit Requirements before completing the Student Pack. If you have any questions regarding the information, see your trainer/assessor for further information and clarification. Pre-Assessment Checklist: Task 1 - Knowledge Test The purpose of this checklist The pre-assessment checklist helps students determine if they are ready for assessment. The trainer/assessor must review the checklist with the student before the student attempts the assessment task. If any items of the checklist are incomplete or not clear to the student, the trainer/assessor must provide relevant information to the student to ensure they understand the requirements of the assessment task. The student must ensure they are ready for the assessment task before undertaking it. Section 1: Information for Students ☐ Make sure you have completed the necessary prior learning before attempting this assessment. ☐ Make sure your trainer/assessor clearly explained the assessment process and tasks to be completed. ☐ Make sure you understand what evidence is required to be collected and how. ☐ Make sure you know your rights and the Complaints and Appeal process. ☐ Make sure you discuss any special needs or reasonable adjustments to be considered during the assessment (refer to the Reasonable Adjustments Strategy Matrix - Appendix A and negotiate these with your trainer/assessor). ☐ Make sure that you have access to a computer and the internet (if you prefer to type the answers). ☐ Make sure that you have all the required resources needed to complete this assessment task. ☐ The due date of this assessment task is in accordance with your timetable. ☐ In exceptional (compelling and compassionate) circumstances, an extension to submit an assessment can be granted by the trainer/assessor. Evidence of the compelling and compassionate circumstances must be provided together with your request for an extension to submit your assessment work. ☐ The request for an extension to submit your assessment work must be made before the due date. Section 2: Reasonable adjustments I confirm that I have reviewed the Reasonable Adjustments guidelines and criteria as provided in Appendix A and attached relevant evidence as required and select the correct checkbox. ☐ I do require reasonable adjustment ☐ I do not require reasonable adjustment Declaration (Student to complete) ☐ I confirm that the purpose and procedure of this assessment task has been clearly explained to me. ☐ I confirm that I have been consulted about any special needs I might have in relation to the assessment process. ☐ I confirm that the criteria used for this assessment has been discussed with me, as have the consequences and possible outcomes of this assessment. ☐ I confirm I have accessed and understand the assessment information as provided in the Training Organisation’s Student Handbook. ☐ I confirm I have been given fair notice of the date, time, venue and/or other arrangements for this assessment. ☐ I confirm that I am ready for assessment. Student Name: ______________________________________ Student Signature: ___________________________________ Assessment method-based instructions and guidelines: Knowledge Test Assessment type ● Written Questions Instructions provided to the student: Assessment task description: ● This is the first (1) assessment task you must successfully complete to be deemed competent in this unit of competency. ● The Knowledge Test is comprised of nine (9) written questions ● You must respond to all questions and submit them to your Trainer/Assessor. ● You must answer all questions to the required level, e.g. provide an answer within the required word limit, to be deemed satisfactory in this task Applicable conditions: ● All knowledge tests are untimed and are conducted as open book assessment (this means you can refer to your textbook during the test). ● You must read and respond to all questions. ● You may handwrite/use a computer to answer the questions. ● You must complete the task independently. ● No marks or grades are allocated for this assessment task. The outcome of the task will be Satisfactory or Not Satisfactory. ● As you complete this assessment task, you are predominately demonstrating your written skills and knowledge to your trainer/assessor. Resubmissions and reattempts: ● Where a student’s answers are deemed not satisfactory after the first attempt, a resubmission attempt will be allowed. ● The student may speak to their trainer/assessor if they have any difficulty in completing this task and require reasonable adjustments. ● For more information, please refer to the Training Organisation’s Student Handbook. Location: ● This assessment task may be completed in: a classroom learning management system (i.e. Moodle), ☐ workplace, ☐ or an independent learning environment. ☐ ☐ ● Your trainer/assessor will provide you with further information regarding the location for completing this assessment task. Instructions for answering the written questions: ● Complete a written assessment consisting of a series of questions. ● You will be required to answer all the questions correctly. ● Do not start answering questions without understanding what is required. Read the questions carefully and critically analyse them for a few seconds; this will help you to identify what information is needed in the answer. ● Your answers must demonstrate an understanding and application of the relevant concepts and critical thinking. ● Be concise, to the point and write answers within the word-limit given to each question. Do not provide irrelevant information. Remember, quantity is not quality. ● You must write your responses in your own words. ● Use non-discriminatory language. The language used should not devalue, demean, or exclude individuals or groups based on attributes such as gender, disability, culture, race, religion, sexual preference or age. Gender-inclusive language should be used. ● When you quote, paraphrase, summarise or copy information from other sources to write your answers or research your work, always acknowledge the source. Purpose of the assessment This assessment task is designed to evaluate student’s knowledge essential to apply WHS requirements, policies and procedures in the construction industry a range of contexts and industry settings and knowledge regarding the following: ● Knowledge of the jurisdictional work health and safety (WHS) and environmental legislation and regulations ● Knowledge of the workplace requirements for undertaking all aspects of applying WHS requirements, policies and procedures in the construction industry including interpreting work orders and reporting problems ● Knowledge of the procedures and policies for identifying and reporting hazards, safety risks and hazardous materials, including asbestos, in the workplace ● Knowledge of the procedures for following safe practices when dealing with hazards and hazardous materials, and controlling risks associated with them ● Knowledge of the use of appropriate protective equipment and clothing, choice of tools, use of barricades and signage, and the necessity of following relevant safety procedures as indicated ● Knowledge of the methods of safely performing tasks in accordance with legislative requirements and workplace policies and procedures ● Knowledge of the procedures for reporting hazards, incidents and injuries ● Knowledge of the necessity for keeping work site clear of risks to prevent accidents and to meet environmental requirements ● Knowledge of the policies and procedures to be followed in an accident, fire or other type of emergency. Task instructions ● This is an individual assessment. ● To ensure your responses are satisfactory, consult a range of learning resources and other information such as handouts, textbooks, learner resources etc. ● To be assessed as Satisfactory in this assessment task, all questions must be answered correctly. Assessment Task 1: Knowledge Test Provide your response to each question in the box below. Q1: Answer the following questions: Satisfactory response 1.1. Explain the purpose of Work Health and Safety Laws (WHS laws). 1.2. Mention the jurisdictional work health and safety (WHS) legislation and regulations for state territory. State or territory Act Victoria The 1970 Environment Protection Act New South Wales Act of 1997 Operations Queensland The 1994 Environmental Protection Act South Australia the 1993 Environment Protection Act Western Australia the 1986 Environmental Protection Act Tasmania Act of 1994 on Environmental Management and Pollution Control Northern Territory Act on Waste Management and Pollution Prevention ACT the 1997 Environmental Protection Act Concerning Environmental 1.3. Mention the environmental legislation applicable in your states or territory given in column 1 of the table. State or territory Act ACT the 2019 Environmental Protection Act New South Wales Act of 1997 Operations Northern Territory Act on Waste Management and Pollution Prevention Queensland the 1994 Environmental Protection Act South Australia the 1993 Environment Protection Act Tasmania Act of 1994 on Environmental Management and Pollution Control Victoria 2017 Environmental Protection Act Western Australia the 1986 Environmental Protection Act Concerning Environmental Yes ☐ No ☐ 1.1The goal of work health and safety (WHS) regulations is to establish a framework for guaranteeing the welfare, health, and safety of employees and other people who may be impacted by work activities. The primary goals of WHS laws are: WHS legislation are intended to detect and manage workplace risks, put in place suitable control measures, and encourage safe work practices in order to prevent accidents and reduce the risk of injuries and illnesses. WHS rules set legal requirements for employers, employees, and other duty holders to prioritize health and safety in the workplace in order to promote a culture of safety. To develop a safe and healthy work environment, they promote active participation, dialogue, and cooperation among all stakeholders. WHS rules aim to defend employees' rights by defining their entitlement to a safe and healthy workplace. This serves to further the rights and interests of workers. These rules give employees the freedom to speak up about workplace health and safety issues, get pertinent information and training, and do so without fear of retaliation. Ensuring legal compliance and enforcement: WHS rules provide down the obligations that apply to employers, independent contractors, employees, and other duty holders. They give regulatory agencies a framework for conducting inspections, audits, and imposing sanctions for non-compliance while also monitoring and enforcing compliance with health and safety regulations. 1.2. In Australia, different states and territories have different work health and safety (WHS) laws and regulations. Here are a few instances: Work Health and Safety Act of 2011 and Work Health and Safety Regulation of 2017 for New South Wales. Victoria: Occupational Health and Safety Act 2004; 2017 Regulations for Occupational Health and Safety. Work Health and Safety Act and Regulation for Queensland as of 2011. Work Health and Safety Act and Regulations for South Australia were passed in 2012. Occupational Safety and Health Act of 1984; Occupational Safety and Health Regulations of 1996; Western Australia. Tasmania: The Work Health and Safety Act and Regulations were passed in 2012. The Work Health and Safety (National Uniform Legislation) Act and Regulations are in effect in the Northern Territory. Work Health and Safety Act and Regulation 2011 for the Australian Capital Territory (ACT). These are a few instances of WHS laws and rules that each state and territory must follow. For complete details and any revisions, please refer to the applicable jurisdiction's unique laws and regulations. State Act Victoria The 1970 Environment Protection Act Act of 1997 Concerning Environmental Operations New South Wales the 1994 Environmental Protection Act Queensland South Australia the 1993 Environment Protection Act the 1986 Environmental Protection Act Western Australia Act of 1994 on Environmental Management and Pollution Control Tasmania Act on Waste Management and Pollution Prevention Northern Territory ACT the 1997 Environmental Protection Act . State or territory Act the 1997 Environmental Protection Act ACT Act of 1997 Concerning Environmental Operations New South Wales Act on Waste Management and Pollution Prevention Northern Territory the 1994 Environmental Protection Act Queensland the 1993 Environment Protection Act South Australia Act of 1994 on Environmental Management and Pollution Control Tasmania The 1970 Environment Protection Act Victoria the 1986 Environmental Protection Act Western Australia Q2: Answer the following questions regarding workplace requirements for undertaking all aspects of applying WHS requirements, policies and procedures in the construction industry, including interpreting work orders and reporting problems: 2.1. Explain the purpose of WHS requirements, policies and procedures. 2.2. How should you report accidents and injuries in the workplace? Explain the procedures. 2.3. What are the key requirements for carrying out construction work under the model WHS Act? 2.4. Why are the key requirements for the interpretation of work orders? Satisfactory response Yes ☐ No ☐ 2.1 To guarantee the health, safety, and welfare of everyone participating in the workplace, WHS (Work Health and Safety) requirements, rules, and procedures are in place. By detecting and managing workplace dangers, encouraging safe work practices, and giving guidance for compliance with pertinent laws and regulations, these measures are put in place to prevent accidents, injuries, and diseases. The overarching objective is to establish a secure and healthy working environment for all personnel who may be present, including workers, visitors, contractors, and anybody else. 2.2. Reporting workplace accidents and injuries is essential for effective incident management and ensuring that the required steps are taken to prevent recurrences. Depending on the particular workplace and jurisdiction, the processes for reporting accidents and injuries may vary, but generally speaking, the following steps are involved: a. Inform a manager or supervisor right away: As soon as you can, tell a manager or supervisor about the mishap. Accurate information about what happened, who was involved, and whether any immediate medical assistance was necessary should be given to them. b. Seek medical care: If required, make sure the injured person receives the necessary medical care. This can entail contacting emergency services or making travel arrangements to a hospital. c. Record the occurrence: Write an incident report that includes the incident's details as well as the date, time, place, and people involved. Include any pertinent pictures, witness accounts, or other proof. d. Turn in the incident report: Turn in the incident report to the designated individual or division in charge of handling workplace mishaps. Depending on the jurisdiction, this could be the employer, the health and safety representative, or the relevant regulatory authority. 2.3. The model WHS Act's (Work Health and Safety Act) main guidelines for doing construction work are as follows: a. Construction workers and employers are accountable for detecting potential risks connected to their work activities and taking the necessary steps to eliminate or control them. This entails carrying out risk analyses, putting control mechanisms in place, and routinely assessing and upgrading safety protocols. b. Ensuring workers receive the right instruction and supervision: Employers are responsible for making sure that workers receive the guidance and supervision they need to complete their work safely. This covers specialized instruction on how to utilize equipment, handle dangerous substances, and adhere to safe work standards. c. Employers are required to create and enforce safe work methods that address the particular risks and hazards associated with construction activity. This entails creating protocols for high-risk tasks such as working at heights, in restricted spaces, electrical safety, and other similar situations. d. Consultation and communication: Maintaining a safe workplace requires effective communication and consultation between employers, employees, and any other pertinent stakeholders. To ensure that everyone is informed of potential hazards and control methods, workers should be involved in decision-making processes involving health and safety issues. 2.4. It's crucial to understand the key criteria for interpreting work orders to guarantee that construction work is completed correctly and in line with the specifications. These prerequisites consist of: a.Understanding the scope of work is important since work orders specify the precise duties, goals, and specifications of a construction project. Understanding the scope of work, including project dates, deliverables, and any particular instructions or standards that must be followed, is necessary for interpreting work orders. b. Identifying risks and hazards: Work orders may list specific risks or hazards related to the building work. Workers can identify possible hazards and ensure that the right control measures are put in place to limit risks by accurately understanding the work instructions. c. Adherence to applicable laws, rules, and industry standards: Work orders may make mention of relevant laws, rules, and standards that must be adhered to during construction activities. To guarantee that the work is carried out safely and in line with applicable regulations, personnel must comprehend and abide by work orders. d. Coordinating and exchanging information: Q3: Answer the following questions related to procedures and policies for identifying and reporting hazards, safety risks and hazardous materials, including asbestos, in the workplace: 3.1. What are the different risks associated with asbestos? 3.2. Describe the procedures for identifying and reporting asbestos. 3.3. How can you identify hazardous materials? What are the key WHS requirements for Safety Data Sheets (SDSs)? Satisfactory response Yes ☐ No ☐ 3.1. Because of its fibrous form and capacity to release microscopic fibers when disturbed, asbestos poses a variety of dangers to health and safety. The several dangers connected to asbestos include: a.Asbestos inhalation can cause significant respiratory conditions such asbestosis, lung cancer, and mesothelioma. b. Environmental contamination: When asbestos-containing materials (ACMs) are handled or disposed of improperly, asbestos fibers may be released into the environment and could harm neighboring people and ecosystems. c. Asbestos is heat-resistant, which increases the risk of fire and makes it more difficult to put out a fire when it is present in buildings or other structures. 3.2.The following steps are commonly included in asbestos identification and reporting procedures: A workplace assessment or inspection should be conducted to find any materials that might contain asbestos. Make and keep an asbestos register that details the whereabouts, state, and kind of materials that contain asbestos. b. Asbestos Testing: If there is any doubt regarding the existence of asbestos, samples may need to be gathered and examined by a trained expert. This entails adhering to established sample practices, which include donning the right personal protective equipment (PPE) and applying authorized sampling methods. c. Reporting: If asbestos is discovered or suspected, notify the designated individual or division in charge of handling workplace asbestos-related issues. The employer, a health and safety official, or a professional asbestos management team could be in this position. d. Control Procedures: Adopt procedures to reduce the risks related to asbestos. This can entail labeling products that contain asbestos, limiting access to places where asbestos is found, and creating safe handling and removal methods for ACMs. 3.3. The actions listed below can be implemented to recognize hazardous compounds in the workplace: a.Safety data sheets (SDSs) or material safety data sheets (MSDSs) SDSs are documents that offer comprehensive details regarding dangerous chemicals and substances. They often come from the supplier or manufacturer and include details on the characteristics of the substance, safe handling techniques, storage needs, and emergency response methods. Workers should receive training in SDS interpretation and reading. b. Labeling and signage: To warn workers and others of the presence of possible hazards, hazardous products should be properly labeled or marked with appropriate signs. This aids in identifying and distinguishing between hazardous and non-hazardous compounds. c. Education and training: Employees need to know what kinds of hazardous materials are often present in their particular workplace and undergo training on hazard identification. Understanding the visual cues, symbols, and labels connected to various hazardous compounds is part of this. d. WHS SDS Requirements: Safety Data Sheets must adhere to particular WHS criteria, such as: Availability: Workers must have easy access to SDSs and be able to receive them upon request. Accuracy and currentness: SDSs should be accurate, current, and take into account any changes to the material's composition or dangers. SDSs should be presented in a language that the workers can understand and in a manner that is clear, legible, and simple to understand. SDSs are required to provide information on hazards, their makeup, first aid methods, safe handling and storage practices, exposure controls, and emergency response techniques. By adhering to these WHS guidelines, employers may be sure that employees are knowledgeable about how to handle hazardous items properly and how to take the essential steps to avoid exposures or accidents. Q4: Answer the following questions regarding procedures for following safe practices when dealing with hazards and hazardous materials and controlling risks: 4.1. Explain the procedures for following safe practices when dealing with the following hazards and hazardous materials. a) Treated timber b) Glass fibres c) Glass fibres 4.2. Describe the procedures for controlling risks, including the hierarchy of risk control. Satisfactory response Yes ☐ No ☐ 4.1. When working with dangers and hazardous materials like treated wood and glass fibers, safe handling techniques usually entail a. Treated Wood ● ● ● ● When handling treated wood, use the proper personal protective equipment (PPE), such as gloves, safety glasses, and (if necessary) breathing protection. Following safe handling procedures can help you avoid splinters and limit contact with the treated surface. Keep treated wood away from sources of ignition in a space that is wellventilated. Dust control: To reduce dust produced while cutting or sanding treated wood, use wet techniques or vacuum systems. Hygiene Standards: To reduce the possibility of ingesting or absorbing the chemicals used in the treatment process, properly wash your hands after handling treated lumber. Glass Fibers ● ● ● ● When dealing with glass fibers, use the proper personal protective equipment (PPE), such as gloves, safety glasses or goggles, and breathing protection (if required). Reduce Dust and Fiber Release: To reduce dust and glass fiber release, use wet techniques or vacuum systems. Avoid Skin Contact: Wear appropriate protective clothes to avoid coming into contact with glass fibers directly. Proper Cleaning: To prevent spreading any spilled or loose glass fibers further, wipe up any messes as soon as possible using the right techniques (for example, wet cleaning). 4.2. The hierarchy of risk control and the risk control processes are as follows: a.Systematic method of managing risks and controlling hazards is known as the hierarchy of risk control. It is divided into the following levels, listed in order of greatest to greatest effectiveness: ● ● ● ● ● Elimination: Completely remove the risk or eliminate the hazard. For instance, developing a procedure that eliminates the need for hazardous tasks or replacing a hazardous item with a safer one. Substitution: Use a less dangerous substitute to replace the danger. This might entail employing a less hazardous chemical or engineering controls rather than personal protection gear. Engineering controls: Put in place structural alterations or design adjustments to reduce or eliminate exposure to dangers. To limit human involvement, some examples include constructing ventilation systems, deploying barriers or guards, or automating procedures. Administrative controls: Put in place protocols, guidelines, and working methods to reduce exposure to risks. This may entail instruction, oversight, task rotation, and appropriate signage or warnings. Equipment for personal protection (PPE): When all else fails, use PPE. b. Risk-controlling procedures: ● ● ● ● Identify dangers: To identify dangers in the workplace, conduct a complete risk assessment. Determine the level of risk by assessing the likelihood and potential repercussions of the specified risks. Implement Controls: Using the hierarchy of risk control, implement the best possible controls. Engineering controls, administrative controls, and the usage of PPE may all be included in this. Watch and Examine: To maintain continuing safety and effectiveness, review risk assessments and periodically check the effectiveness of the control mechanisms that have been put in place. ● ● Q5: Communication and Education: Train employees on the risks that have been identified, the controls that are in place, and the right procedures to follow to reduce risks. Investigation and Reporting of Incidents: Create processes for reporting incidents, near misses. Answer the following questions regarding the use of appropriate protective equipment and clothing, choice of tools, use of Satisfactory response barricades and signage, and the necessity of following relevant safety procedures as indicated: 5.1. How can you choose appropriate protective equipment and clothing for the work task? 5.2. What are the key considerations for choosing appropriate protective equipment and clothing for the work task? 5.3. Identify the meaning of the different signs as indicated in images given in column 1 of the table below. Barricades and signs Explanation (1-2 sentences each) These warning indicators point to an immediate danger that could be fatal. On a red background, they often have white writing or symbols. Health Safety signs and indication of medicine or hospital These notices inform people of any potential risks or dangers in the vicinity. On a yellow background, they frequently have black writing or symbols. In order to inform people about current construction activity or to provide warnings, these signs are frequently used on construction sites. They assist in ensuring both employee and public safety. 5.4. Discuss the necessity of safety procedures as indicated in the traffic management plan. Yes ☐ No ☐ 5.1. Take into account the specific hazards present and the amount of protection necessary when selecting the proper protective gear and attire for a job task. The following actions will aid in the choosing process: a. Identify Hazards: Examine the workplace and note any potential risks, such as those posed by chemicals, physical dangers, or biological agents. b. Establish Protection Requirements: Based on the identified hazards, establish the necessary level of protection. This could entail referring to safety requirements, guidelines, or advice particular to the work or industry. c. Research Your Options: Look into the different types of clothes and safety gear that are available to guard against the threats that have been highlighted. Think about things like comfort, durability, and material compatibility. d. Fit and Comfort: Make sure the worker can comfortably wear the chosen protective gear and attire while doing the task. A poor fit can make the protective equipment less effective. e. Consider Standards and Certifications: Seek out protective gear and attire that complies with pertinent safety standards and certifications. This guarantees that the equipment complies with established safety standards and has been tested for its intended use. 5.2. The following factors should be taken into account when selecting the right clothing and protective gear for an activity at work: a. Compatibility with dangers: Make that the protective equipment is appropriate for the particular dangers present in the task. It need to offer sufficient defense against the hazards found. b. Level of Protection: Take into account the degree of protection required in light of the seriousness of the hazards. For example, simple protective clothes for everyday handling or more specialist equipment for high-risk activities may be needed depending on the task. c. Comfort and Fit: Opt for safety gear and attire that fits the worker well and is at ease to wear. A good fit guarantees that the equipment will stay in place and offer the desired protection throughout the task. d. Quality and Durability: Choose protective gear of the highest caliber that can endure the conditions and demands of the job. This guarantees that the equipment will function properly and be dependable during its intended use. e. Standards Compliance: Look for protective gear and attire that complies with the necessary safety standards and certifications. This proves that the equipment has undergone testing and complies with all safety regulations. 5.3. I am unable to precisely determine the meaning of the various indications without the assistance of the photos in column 1 of the table. However, the following are some typical warning signs regarding safety and barricades: ● ● ● These signs warn people about any potential risks or dangers in the region. On a yellow background, they frequently have black writing or symbols. These warning indicators point to an immediate danger that could endanger life. On a red background, they often have white writing or symbols. Keep Out Signs: These signs denote areas with limited access. They are employed to stop unauthorized access or to safeguard people from potential threats. ● Q6: building Signs: In order to convey information or cautions about ongoing building projects, these signs are frequently used in construction sites. xplain the methods of safely performing high-risk construction tasks in accordance with legislative requirements and workplace policies and procedures. E Satisfactory response Yes ☐ No ☐ Several techniques can be used to safely carry out high-risk construction projects in compliance with statutory requirements and workplace policies and procedures. Here are some crucial things to remember: Risk Assessment: Before beginning any high-risk construction activity, perform a complete risk analysis. Determine the likelihood and severity of any hazards, then decide on the best control strategies to reduce the risks. Safety Training and Competency: Ensure that employees performing high-risk tasks have received the appropriate training and have the skills required to do so safely. Training should encompass the precise risks connected to the job, safe work practices, and effective tool and equipment use. Use of Personal Protective Equipment (PPE): For high-risk construction operations, provide and enforce the use of suitable PPE. Depending on the task at hand, this could also comprise safety helmets, goggles, gloves, respiratory protection, fall protection equipment, and other specialist gear. Safety Concerns Regarding Equipment and Tools: Ensure that all tools and equipment used for high-risk operations are properly cared for, inspected, and approved for use. Follow the manufacturer's instructions on how to use the equipment, conduct routine inspections, and take immediate action to fix any problems or flaws that are found. Develop and implement safe work practices that are especially suited to high-risk construction projects. These protocols should include hazard controls, equipment use, communication protocols, and emergency response procedures. They should also include step-by-step directions for carrying out the operation properly. Promoting effective communication and teamwork among team members engaged in highrisk assignments is important. Make sure that everyone is aware of their roles and duties, shares any safety observations or concerns, and adheres to the established procedures for collaboration and coordination. Emergency Preparedness: Create and share strategies for high-risk task-specific emergency responses. Establish evacuation routes, educate employees on emergency procedures, and make sure first aid supplies and emergency gear are accessible and available. Compliance with Legislative Requirements: Keep abreast of pertinent legal requirements, industry standards, and codes of conduct regarding high-risk construction projects. Review and update workplace policies and procedures frequently to ensure compliance. To ensure the safe performance of high-risk construction projects, it is imperative to consult and abide by the specific legislative requirements and workplace rules and procedures applicable in your jurisdiction. Q7: Explain the procedures for reporting hazards. Satisfactory response Yes ☐ No ☐ The following stages are frequently included in reporting processes for dangers at work: Identification of Hazards: Employees should receive training on how to spot hazards at work. Physical, chemical, biological, ergonomic, and psychosocial risks might all fall under this category. Hazards can be found through regular workplace inspections and risk assessments. Action Right Away: If a worker discovers an urgent hazard that puts them or others in immediate danger, they should act right away to reduce the risk. This can entail pausing work, alerting neighbors, and putting into action any applicable emergency protocols or control measures. Notify Immediate Supervisor or Designated Responsible Person: The employee should notify their immediate supervisor or the designated responsible person in the workplace of the hazard. This could be a designated safety contact, health and safety representative, or safety officer. A thorough explanation of the risk, its location, and any potential risks connected to it should all be included in the report. Employers often have specified reporting channels in place, such as an incident reporting form, an electronic reporting system, or a designated reporting hotline. Use the appropriate reporting channel. To report the hazard, the employee should make use of the appropriate reporting system that their company has set up. include Supporting Information: It is helpful to include more details when reporting hazards so that others can better grasp the type and gravity of the threat. This could involve pictures, witness accounts, or any other pertinent records. There should be a clear protocol in place for follow-up and communication once the hazard has been reported. This can entail having a conversation with management, looking into the risk, and communicating any corrective actions or control measures that need to be put in place. Documentation and record-keeping are important. Employers should keep track of reported dangers and the steps they took to remedy them. This documentation aids in the process's tracking and may be useful for future reference and ongoing development. It is critical that employees comprehend that reporting dangers is a critical duty that helps to maintain a safe working environment. Employees should feel empowered and supported to report dangers without fear of retaliation, and employers should foster a culture of open communication. Q8: Answer the following questions regarding the necessity for keeping the work site clear of risks to prevent accidents and to meet environmental requirements. 8.1. Explain the necessity for keeping the work site clear of risks to prevent accidents according to state and territory regulations. 8.2. Explain the environmental requirements for keeping the work site clear of risks to prevent accidents. 8.3. Describe the waste management strategies for construction sites. Satisfactory response Yes ☐ No ☐ 8.1. State and territorial occupational health and safety rules emphasize the importance of maintaining the work site free of hazards to prevent accidents. These laws seek to safeguard the welfare, health, and safety of both employees and anybody else who might be impacted by their job. Main justifications for keeping a tidy workplace include: a. Worker safety: Removing hazards from the workplace reduces the possibility of worker accidents and injuries. The risk of events can be considerably decreased by eliminating dangers including unsecured equipment, dangerous substances, and tripping or slipping hazards. b. Legal Compliance: State and territorial laws require employers to give their workers a safe workplace. The only way to avoid legal trouble is to abide by these rules. c. Productivity and Efficiency: A tidy workspace promotes efficient operations and a smoother workflow. Workers can concentrate on their duties without unneeded interruptions or delays when risks and impediments are removed, which increases productivity. d. A positive workplace culture is fostered by keeping a tidy and organized workspace. It exhibits a dedication to safety, fosters professionalism, and encourages workers to feel proud of and accountable for their work. 8.2 Environmental criteria for maintaining a risk-free work environment center around reducing negative effects and conserving the environment. Important factors include: a. Preventing Pollution: Removing hazards from the work site aids in preventing air, soil, and water pollution. Hazardous materials and garbage are kept out of the environment and properly handled, stored, and disposed of to reduce the chance of contamination. b.A clean work site lessens the disruption of natural habitats and ecosystems, protecting ecosystems and biodiversity. By preventing habitat degradation or fragmentation and maintaining biodiversity, it contributes to the protection of native plants and animals. c. Resource conservation: Effective risk and waste management at the job site can help to save resources. Utilizing energy and water resources effectively, processing and recycling items properly, and reducing waste all contribute to lessen the effects on the environment. d. Adherence to Environmental Regulations: Maintaining a risk-free work environment complies with environmental laws and permits. By minimizing damage to ecosystems and natural resources, compliance with these regulations helps to guarantee that construction operations are carried out in an environmentally responsible manner. 8.3 To reduce their negative effects on the environment, waste management solutions for building sites must be successful. These tactics consist of: a.Reduce the quantity of waste produced during building activities to make waste minimization a priority. This can be done by carefully planning, choosing the right materials, and putting effective work procedures into practice. b. Implement proper waste segregation and sorting on the construction site. b. Segregation and Sorting. To make proper disposal and recycling operations easier, separate recyclable goods, dangerous chemicals, and general waste. c. Recycling and Reuse: Make the most of the potential for recycling and reusing building trash. Determine which materials may be recycled, such as concrete, metal, wood, and plastic, and make sure they are delivered to the proper recycling facilities. Reduced waste production can also be achieved by reusing items on-site, such as by salvaging and reusing components. d. Appropriate Disposal: Make that hazardous and non-recyclable garbage is disposed of in accordance with local laws. To protect the environment and public health, dispose of waste products, including hazardous compounds, correctly using authorized facilities or services. a. Education and Training: Inform and instruct personnel on waste disposal procedures unique to the building site. To promote appropriate waste management practices, spread awareness about the value of trash reduction, segregation, and suitable disposal techniques. In addition to assisting in meeting environmental regulations, putting into practice efficient waste management techniques also encourages sustainability and lessens the environmental impact of construction activities. Q9: Explain the policies and procedures to be followed to respond to an accident, fire or other types of emergencies on the worksite. Satisfactory response Yes ☐ No ☐ For the safety and wellbeing of employees, policies and procedures for handling accidents, fires, and other crises on the jobsite are essential. The following are the main components of these policies and procedures: Emergency Response Plan: Create a thorough emergency response strategy tailored to the workplace. The methods, roles, and responsibilities for dealing with various crises, including accidents and fires, should be outlined in this plan. All employees should be informed about it, and it should be routinely reviewed and modified as necessary. Maintain a list of emergency contacts that is easily available to all employees. This should contain the phone numbers for site supervisors, safety officers, and other important individuals who must be notified in the event of an emergency, as well as emergency services (fire department, ambulance, and police). Establish concise evacuation protocols for various types of emergencies, such as fires and gas leaks. To facilitate everyone's safe evacuation from the workplace, these protocols should include evacuation routes, assembly locations, and instructions for accounting for every employee. Installation and maintenance of suitable emergency alarm systems, like fire alarms, are necessary to rapidly inform employees of emergencies. To enable quick and unambiguous communication during emergencies, provide efficient communication systems, such as twoway radios or specific communication channels. Make sure there are dedicated first aid stations or kits available on the jobsite for first aid and medical assistance. Provide instruction on when and how to provide emergency medical treatment to wounded workers until professional medical help arrives. Train selected personnel in first aid and CPR techniques. Fire Control and Prevention: Implement fire prevention measures, such as routinely checking and maintaining electrical equipment, storage places, and fire extinguishers. Fire exits, extinguisher locations, and other firefighting supplies should all be well marked. train employees Conduct regular emergency exercises to make sure staff members are familiar with the protocols for responding to emergencies. These exercises assist find any holes in the response strategy and offer a chance for training and development. Conduct a comprehensive investigation to determine the source of the disaster and gauge the efficiency of the emergency response once it has passed. Make any necessary adjustments to the emergency response plan and procedures in light of the findings. Training and Education: Ensure that employees receive thorough instruction on emergency response procedures, such as how to identify and report incidents, evacuate safely, and use emergency gear. Refresh and reinforce this training frequently to keep staff members educated and ready. All employees must be made aware of the emergency response policies and procedures and must be clear on their duties and responsibilities in case of an emergency. Maintaining a safe and effective response to accidents, fires, or other emergencies on the jobsite requires regular communication, training, and drills. Assessment Results Sheet Outcome First attempt: Outcome (make sure to tick the correct checkbox): Satisfactory (S) ☐ or Not Satisfactory (NS) ☐ Date: _______(day)/ _______(month)/ _______(year) Feedback: Second attempt: Outcome (please make sure to tick the correct checkbox): Satisfactory (S) ☐ or Not Satisfactory (NS) ☐ Date: _______(day)/ _______(month)/ _______(year) Feedback: Student Declaration ● I declare that the answers I have provided are my own work. Where I have accessed information from other sources, I have provided references and/or links to my sources. ● I have kept a copy of all relevant notes and reference material that I used as part of my submission. ● I have provided references for all sources where the information is not my own. I understand the consequences of falsifying documentation and plagiarism. I understand how the assessment is structured. I accept that the work I submit may be subject to verification to establish that it is my own. ● I understand that if I disagree with the assessment outcome, I can appeal the assessment process, and either re-submit additional evidence undertake gap training and or have my submission reassessed. ● All appeal options have been explained to me. Student Signature Date Trainer/Assessor Name Trainer/Assessor Declaration I hold: ☐ Vocational competencies at least to the level being delivered ☐ Current relevant industry skills ☐ Current knowledge and skills in VET, and undertake ☐ Ongoing professional development in VET I declare that I have conducted an assessment of this student’s submission. The assessment tasks were deemed current, sufficient, valid and reliable. I declare that I have conducted a fair, valid, reliable, and flexible assessment. I have provided feedback to the student. Trainer/Assessor Signature Date Office Use Only The outcome of this assessment has been entered into the Student Management System on _________________ (insert date) by (insert Name) __________________________________