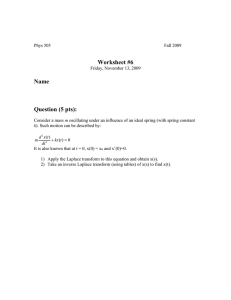

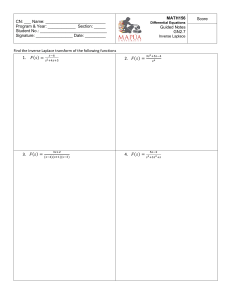

وزارة التعليم العالي والبحث العلمي Ministry of Higher Education and Scientific Research Al-Furat Al-Awsat Technical University Al-Mussaib Technical College Mechanical Power Engineering Department جامعة الفرات االوسط التقنية المسيب/ الكلية التقنية قسم هندسة تقنيات ميكانيك القدرة Measurement and Control Processes Fourth Stage Students By: Dr. Fadhil Alrubaiy E-mail: fadhil.alrubaiy@atu.edu.iq 2023-2024 1 Chapter One Introduction to Control Systems Process control refers to the methods that are used to control process variables when manufacturing a product. For example, factors such as the proportion of one to another, the temperature of the materials, how well the ingredients are mixed, and the pressure under which the materials are held can greatly affect the quality of an end product. Control System Objectives Economic Incentive Safety Equipment Protection Reduce variability Increase efficiency Ensure the stability of a process Elimination of routine 1.1 Definitions and Terminologies System: it is a combination of components that act together and perform a certain objective. Process: is defined as the changing or refining of raw materials that pass through or remain in a liquid, gaseous, or slurry state to create end products. Control: in process industries refers to the regulation of all aspects of the process. Precise control of level, pH, temperature, pressure and flow is important in many process applications. Sensor: a measuring instrument, the most common measurements are of flow (F), temperature (T), pressure (P), level (L), pH and composition (A, for analyzer).The sensor will detect the value of the measured variable as a function of time. 2 Set point: The value at which the controlled parameter is to be maintained. Controller: A device which receives a measurement of the process variable, compares with a set point representing the desired control point, and adjusts its output to minimize the error between the measurement and the set point. Error Signal: The signal resulting from the difference between the set point reference signal and the process variable feedback signal in a controller. Feedback Control: A type of control whereby the controller receives a feedback signal representing the condition of the controlled process variable, compares it to the set point, and adjusts the controller output accordingly. Steady-State: The condition when all process properties are constant with time, transient responses having died out. Transmitter: A device that converts a process measurement (pressure, flow, level, temperature, etc.) into an electrical or pneumatic signal suitable for use by an indicating or control system. Controlled variable: process output which is to be maintained at a desired value by adjustment of a process input. Manipulated variable: process input which is adjusted to maintain the controlled output at set point. Disturbance: a process input (other than the manipulated parameter) which affects the controlled parameter. Process Time Constant (τ): Amount of time counted from the moment the variable starts to respond that it takes the process variable to reach 63.2% of its total change. 3 Block diagram: it is relationship between the input and the output of the system. It is easier to visualize the control system in terms of a block diagram. Transfer Function: it is the ratio of the Laplace transform of output (response function) to the Laplace transform of the input (driving force) under assumption that all initial conditions are zero unless that given another value. e.g. the transfer function of the above block diagram is G (s) = Y(s)/X(s) 1.2 The Control Loop Control loops in the process control industry work in the same way. It requires three tasks to occur: Measurement Comparison Adjustment 1.2.1 Manual and Automatic Control 4 1.3 Closed and Open Control loops Closed-loop control system there is a feedback control system which the output signals has a direct effect upon the control action. Advantage: more accurate than the open-loop control system. Disadvantages: (1) Complex and expensive, (2) The stability is the major problem in closed-loop control system. 5 Open-loop control system: it is a control system in which the output has no effect upon the control action. (The output is neither measured nor fed back for comparison with the input). Advantages: (1) Simple construction and ease of maintenance. (2) Less expensive than closed-loop control system. (3) There is no stability problem. Disadvantages: (1) Disturbance and change in calibration cause errors; and output may be different from what is desired. (2) To maintain the required quality in the output, recalibration is necessary from time to time. 6 1.4 Laplace Transforms In this part, we introduce a mathematical tool, the Laplace transform, which can significantly reduce the effort required to solve and analyze linear differential equation models. 1.4.1 The definition of the Laplace Transforms The Laplace transform of a function f(t) is defined as : ………………. (1.1) Where: F(s) is the symbol for the Laplace transform, (s) is a complex independent variable, f(t) is some function of time to be transformed, and ℒ is an operator of Laplace transform, defined by the integral. Example 1.1: 7 1.4.2 Laplace Transform of Some Common Functions Note that in the same way as in Ex.1.1, we can determine the Laplace transform of some elementary functions: Example 1.2: 8 1.5 The First Shifting Theorem: 9 1.6 The Second Shifting Theorem: 10 1.7 Laplace of Integral: Example 1.7 1.8 Laplace Transform of the Derivatives ……………….1.10 ……………….1.11 ……………….1.12 …….1.13 11 Example 1.8: Find the Laplace Transform of the functionfollowing differential equation and initial condition: 12 Problems: Q1: Find the Laplace Transform of 𝑓(𝑡) = 𝑡𝑒 −2𝑡 Q2: Find the Laplace Transform of 𝑓(𝑡) = sin(3𝑡)𝑒 5𝑡 Q3: Find the Laplace Transform of following equation: 1.9 Inverse of Laplace Transform ……………………. (1.14) 1.9.1 Laplace Inverse of Some Common Functions Below table shows inverse Laplace transform of some common functions: 13 Example 1.9: Find the Laplace inverse of the following functions: Solution: 1.9.2 Laplace Inverse by partial fraction: Sometimes the function whose inverse is required is not recognisable as a standard type, such as those listed in Table 1.1. In such cases it may be possible, by using partial fractions, to resolve the function into simpler fractions which may be inverted on sight. For example: 14 For problems in control system analysis, the Laplace transforms, in general, have the form: f ( s) B( s) A( s) Where A(s) and B(s) are polynomials in s. In expansion F(s) = B(s)/A(s) In the form of a partial fraction, it is important that the highest force of s in A(s) is greater than the highest power of s in B(x). Let a function in the s domain be given by: f ( s) B( s ) B( s ) A( s) ( s a)(s b)(s c) Poles: The values a, b, c,…that makes the denominator zero, and hence f (s) infinite, are called the system poles of f (s). If there are no repeated factors, the poles are simple poles. If there are repeated factors, the poles are multiple poles. Zeros: Values of s that make the numerator B(s) zero, and hence f (s) zero, are called the system zeros of f (s). For example: s4 has simple poles at s=−1, and s=+2, and a zero ( s 1)( s 2) at s=4. There are three cases for the partial fraction depending on types of the poles, as shown below: Case (1): F(s) has simple poles: 15 Example 1.10: Find the Laplace inverse of the following function: F ( s) s3 ( s 1)( s 2) Solution: 16 Case (2): F(s) has multiple repeated poles: In this case the transfer function can be written in below form: f ( s) f ( s) B( s ) B( s ) A( s) ( s si )(s si ) 2 ..............(s si ) r A1 A2 B( s ) Ar ........ 2 A( s) ( s si ) ( s si ) . ( s si ) r Where (r) number of repeated poles. The coefficient of multiple repeated poles ( A1, A2,……Ar) are described as follows: Ar [(s si ) r F (s)] s si Ar 1 d r [( s s ) i F (s)] s s ds i Ar 2 1 d2 r 2 [(s si ) F (s)] 21 ds s si A1 1 d r 1 r 2 [(s si ) F (s)] (r 1)1 r 1 s si ds Partial fracture expansion when F(s) involves multiple poles. Instead of discussing the general case, we will use an example to show how to obtain 17 the expansion of a fraction Partial of F(s). (See also Problem A-2-16.) Consider the following statements: Also, differentiation of both sides of Equation (1) with respect to s yields: If we let s = -1 in equation (2) , then By differentiation both sides of Equation (2) with respect to s, the result is: 18 From the preceding analysis it can be seen that the values of coefficients are found systematically as follows: 19 Case (3): F(s) has complex-conjugated poles: If the function F(s) involves a pair of complex-conjugate poles, it is convenient not to expand F(s) into the usual partial fractions but expand to the sum of the damped sine and damped cosine functions, with referring to below Laplace inverse relationships: Example 1.11: Find the Laplace inverse of the following function: F ( s) 2s 12 s 2s 5 2 Solution: Notice that the denominator polynomial can be factored as shown: s 2 2s 5 s 2 2s 1 4 (s 1 2 j )(s 1 2 j ) F ( s) 2s 12 10 2s 2 10 2( s 1) 2 s 2s 5 s 2s 1 4 ( s 1) 2 4 F ( s) 5 2 2 s 1 2 2 2 ( s 1) 2 ( s 1) 2 4 Then: 20 1.10 Initial Value Theorem (IVT) The initial value of a function means the value of that function at time equal to zero, f (0). The initial value theorem can provide the initial value from its Laplace transforms without going through the inverse Laplace transform procedure. Example 1.12: Find the Find the initial value of the function using initial value theorem: f (t ) 2(1 e 2t ) Answer: 1.11 Final Value Theorem (FVT) The final value of a function means the value at time (∞) ,This value equal steady-state value of a time-domain. Final value theorem is applicable if F(s) satisfy the following conditions: a. No poles on imaginary axis (except simple pole at origin). b. No poles having positive real part (i.e., the value of s should not be a positive) 21 1.12 Solved problems Answer: 22 23 24 25 Chapter Two Transfer Function and Response of first order systems 2.1 Transfer Function The transfer function is an algebraic relation in the s-domain that represents the dynamic of the system. It is the ratio of the output variable to the input variable and denoted by T.F or G(s). Figure 2.1 shows a block diagram that represents the transfer function G(s) that relates the output variable y(s) and the input variable x(s). The mathematical formula for the transfer function is: 2.1.1 Conditions of the Transfer Function T.F Any system has a transfer function if; a. It can be represented by a linear differential equation in the time- domain. b. The initial values of the dependent variable and its derivatives are all zero. 26 Example 2.1: 27 28 2.2 Definitions and Terminologies 2.2.1 Open System Open system (or Open-loop): Any system which is not controlled i.e., the system has no controllers, so the output variables are subjected to changes against any change in the inlet variables. In other words, in an open-loop control system, the output is neither measured nor “fed back” for comparison with the input. Let’s take the continuous stirred tank heating system (CSTH) as an example as shown in Fig.2.4. In the continuous stirred tank heater (CSTH), a liquid of heat capacity (c p, kJ/kg oC) enters the vessel with flowrate (m, kg/s) and inlet temperature (𝑇𝑖, o C ). Amount of heat (Q, kW) inlet to the system by a steam coil. The outlet temperature of the liquid is (𝑇𝑜 , oC). The quantity of liquid inside the tank (holdup) is (M, kg). In the steady-state operation, all the inlet and outlet variables values (i.e., Ti, m, Q, To) are constant with time. Note that any change in the value of 𝑇𝑖 or m or Q will affect the value of To. That is 𝑇𝑜= f( 𝑇𝑖 ,𝑄,𝑚). For example, if the inlet temperature is increased suddenly by 5 oC and keeping all other variables (m and 𝑇𝑖) constants, this will cause the outlet temperature (𝑇𝑜) to increase to a new steady-state value. The outlet temperature will also change if any change occurs in the inlet flowrate (m) or inlet rate of heat (Q). So, we can say that the outlet temperature (𝑇𝑜) is a function of the inlet variables (𝑇𝑖, m, Q). Since the outlet temperature 28 (𝑇𝑜) will vary against any variation in the inlet variables (𝑇𝑖, m, Q), therefore; this system is called an uncontrolled or open-loop system. 2.2.2 Closed System In the continuous stirred tank heater (CSTH), if the system was built to control the value of 𝑇𝑜 at a certain value by a control process which permits us to maintain the outlet temperature 𝑇𝑜 constant at a certain value against any change that occurs in any of the input variables (𝑇𝑖 .𝑄.𝑚). In this case the system is called closed system. See Fig 2.5 which shows how the outlet temperature is controlled. 29 Note that in the closed system, we want to control the outlet temperature To, so this variable is called the controlled variable. The control valve is put on the inlet steam line in order to control the quantity of heat input to the system, so the variable (Q) is called manipulating variable. The other inlet variables (Ti and m) are called load variables since they may cause a disturbance to the system. 2.3 Terminologies 2.3.1 Disturbance Disturbance means the change that occurs in the input variables (open system) or in the load variables (closed system). This disturbance has different forms, some are regular and others are irregular. Below are some common forms of the disturbances which will be mentioned in detail in the subsequent section. 1. Step change 2. Ramp change 3. Pulse change 4. Impulse change 5. Sine change 6. Cosine change 7. Other irregular changes 2.3.2 Response Response means the variation with time of the output variable (open-loop) or the controlled variable (closed-loop). This variation occurs as a result of any disturbance or change that occurs in the input or load variables. 2.4 Special Functions of Disturbance 30 31 32 33 2.6 Development of T.F for first order system: 2.6.1 Mercury Thermometer It is a measuring device used to measure the temperature of a stream. Consider a mercury in glass thermometer to be located in a flowing stream of fluid for which the temperature x varies with time. The object is to calculate the time variation of the thermometer reading y for a particular change of x. The following assumptions will be used in this analysis:1. All the resistance to heat transfer resides in the film surrounding the bulb (i.e. the resistance offered by the glass and mercury is neglected). 2. All the thermal capacity is in the mercury. Furthermore, at any instant the mercury assumes a uniform temperature throughout. 3. The glass wall containing the mercury does not expand or contract during the transient response. It is assumed that the thermometer is initially at steady state. This means that, before time zero, there is no change in temperature with time. At time zero the thermometer will be subjected to some change in the surrounding temperature x(t). (i.e at t<0 x(t)= y(t) =constant there is no change in temperature with time). At t=0 there is a change in the surrounding temperature x(t). Unsteady state energy balance: This equation can be briefly written as: In = Out+ Accumulation 34 35 Example (2.3): A thermometer having a time constant of 0.1 min is at a steady state temperature of 90 o F. At time t = 0, the thermometer is placed in a temperature bath maintained at 100°F. Determine the time needed for the thermometer to read 98 o F. 36 2.6.2 Liquid-Level Tank Consider a system of the liquid-level tank with a uniform cross-sectional area A (m2) shown in Figure below. The liquid enters the tank at a rate 𝑞𝑖 (L/min) and exits at a rate 𝑞𝑜 (L/min). The level of the liquid inside the tank is h (m). The flow through the valve in the exit stream is assumed to be linear so, the outlet flow rate (𝑞𝑜) is related to the liquid level (h) inside the tank and the resistance of the valve (R) through a linear equation: 𝑞 ∝ ℎ 𝑞= ℎ 𝑅 ……..(1) for linear valve Now we will make a mass balance to obtain the differential equation that relates the liquid level inside the tank (h) to the inlet variables and time. The control volume in the balance equation is the tank. Mass Balance: Let’s define the parameters related to the mass balance process. 37 ρ: Density of liquid (kg/L) 𝑑ℎ 𝑞𝑖 𝜌 = 𝑞𝑂 𝜌 + 𝐴𝜌 … … … … … … … … … . (1) dividing by (ρ), use equation 𝑑𝑡 (1), and, then re-arrange to get: ℎ 𝑑ℎ 𝑞𝑖 − = 𝐴 … … … … … … … … … . (2) 𝑅 𝑑𝑡 At steady state ℎ𝑠 𝑑ℎ𝑠 𝑞𝑖𝑠 − = 𝐴 … … … … … … … … … . (3) 𝑅 𝑑𝑡 ℎ−ℎ𝑠 𝑑(ℎ−ℎ𝑠 ) Subtracting Eq(3) from Eq. (2): (𝑞𝑖 − 𝑞𝑖𝑠 ) − =𝐴 𝑅 Let: 𝑄 = 𝑞𝑖 − 𝑞𝑖𝑠 , 𝐻 = ℎ − ℎ𝑠 𝐴 𝑑𝐻 𝑑𝑡 + 𝐻 𝑅 = 𝑄 ⇒ 𝐴𝑅 𝑑𝐻 𝑑𝑡 𝑑𝑡 + 𝐻 = 𝑅𝑄 , taken Laplace for both sides: (𝜏𝑠 + 1)𝐻(𝑠) = 𝑅𝑄(𝑠) Where: 𝜏 = 𝐴𝑅 is the time constant of tank, 𝑅 is the steady-state gain of the tank. 𝐺(𝑠) = 𝐻(𝑠) 𝑄(𝑠) = 𝑅 𝜏𝑠+1 … … … … . (4) , Equation (4) represents transfer function for first order system. 𝐻(𝑠) = 𝑅 𝑄 … … … … . (5) 𝜏𝑠 + 1 (𝑠) 38 39 Example 2.4: A tank having a time constant of 1 min and a resistance of 1/9 ft/cfm is operating at steady state with an inlet flow of 10 ft3 /min (or cfm). At time t =0, the flow is suddenly increased to 100 ft 3/min for 0.1 min by adding an additional 9 ft3 of water to the tank uniformly over a period of 0.1 min. (See Figure below for this input disturbance) . Plot the response in tank level and compare with the impulse response. Solution: 40 41 2.6.3 Mixing Tank Consider the mixing process shown in side Figure. In which a stream of solution containing dissolved salt flows at a constant volumetric flow rate q into a tank of constant holdup volume V. The concentration of the salt in the entering stream x (mass of salt/volume) varies with time. It is desired to determine the transfer function relating the outlet concentration y to the inlet concentration x. If we assume the density of the solution to be constant, the flow rate in must equal the flowrate out, since the holdup volume is fixed. F: Volumetric flowrate x, y : Input and output salt concentrations (mass/vol). Unsteady state material balance Steady state 42 Example 2.5: Find the T.F for the system shown in figure 43 2.6.4. Stirred Tank Heating System 44 2.7 Response of 1st order systems in series: Many physical systems can be represented by several first-order processes connected in series as shown in figure:- 1-Non Interacting System 45 46 Example 2.6: Two non-interacting tanks are connected in series as shown in Fig. 7-1 a. The time constants are τ2 =1, τ1 =0.5; R2 =1, and R1 =1. Find the response of the level in tank 2 if a unit-step change is made in the inlet flow rate to tank 1. Solution: The transfer function for this system is found from Equation in the previous section. 47 2- Interacting System 48 49 50 51 52 Dead time Element (Time-delay element) Dead time element is the element whose transfer function is represented by 𝐺(𝑠)=𝑒−𝜏𝐷𝑠 𝑤ℎ𝑒𝑟𝑒 𝜏𝐷 𝑖𝑠 𝑡ℎ𝑒 𝑡𝑖𝑚𝑒 𝑜𝑓 𝑑𝑒𝑙𝑎𝑦. In the time-delay element, the output signal is the same as the input signal in the form and magnitude but delayed by a time equal to 𝜏𝐷. In dynamic processes, time-delay elements are mostly represented in some parts of 52 process plant such as pipes and transport belts. So, we will take these two elements into consideration. Any delay in measuring, in controller action, in actuator operation, in computer computation, and the like, is called transportation delay or dead time, and it always reduces the stability of a system and limits the achievable time of the system. The Transportation Lag The transportation lag is the delay between the time an input signal is applied to a system and the time the system reacts to that input signal. Transportation lags are common in industrial applications. They are often called “dead time”. 53 54 Transport Pipes Pipes that transport liquid or gas represent a time-delay element. In Figure below fluid enters the pipe with mass flow rate m(kg/s) and velocity u(m/s) and exits at the same values. The transfer Example Pipe transporting liquid with a mass flowrate 𝑚𝑖=3𝑘𝑔/𝑠 and velocity 𝑢=2m/s. The length of the pipe is 10 m. If a step change of value 4 occurs in the inlet flowrate, find the response of outlet flow rate 𝑚𝑜. Solution 55 56