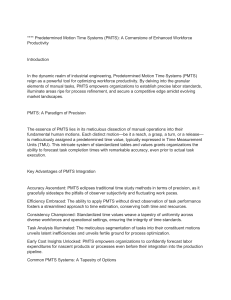

Republic of Yemen Taiz University Alsaeed Faculty for Engineering & Information Technology PREDETERMINED MOTION TIME SYSTEMS (PMTS) Prepared by: Aseel Khalid Mohammad Mahmood Salah Shams Aldeen Waleed Abdulrahman 1 1 المحتويات 3 ........................ ................................ ................................ Introduction 2 4 ................................ ................................ Definitions of (PMTS) 3 The Predetermined Motion Time Systems 4 Concept 3.1 4 ...................... Advantages of predetermined times 4 Popular Predetermined Motion Time 5 Systems 5 5 Methods Time Measurements (MTM) 5.1 5 ....................................... MTM-1 – the basic MTM module 5.1.1 5 .. MTM studies provided the following kinds of information : 5.1.2 5 ....................... MTM-1 (1948) – definition & characteristics 5.1.3 6 Basic Elements 5.1.4 9 ........................ ................................ Other MTM Systems 5.1.5 MOST – Maynard Operation Sequence 9 Technique 9 5.2 What is MOST ? 5.2.1 9 ..................................... Three activity sequences in MOST 9 Why MOST? 5.2.3 Sequence 10 2 Models 5.2.2 5.2.4 2 INTRODUCTION In the dynamic realm of industrial engineering, Predetermined Motion Time Systems (PMTS) reign as a powerful tool for optimizing workforce productivity. By delving into the granular elements of manual tasks, PMTS empowers organizations to establish precise labor standards, illuminate areas ripe for process refinement, and secure a competitive edge amidst evolving market landscapes. PMTS : is one of the work measurement techniques see Figure 1 Work measurement techniques Stopwatch time study Direct time Performance evaluation study General approaches MTM MOST FIGURE 1 3 Predetermined times Work sampling Standard data Funcional approaches (for specific activities) MTM-M, MTM-C, MTM-V 3 DEFINITIONS OF (PMTS) Predetermined motion time system (PMTS) is a work measurement technique whereby times established for basic human motions are used to build up the time for a job at a defined level of performance. PMTS also called predetermined time system (PTS), is a database of basic motion elements and their associated normal time values, together with a set of procedures for applying the data to analyze manual tasks and establish standard times for the tasks. The PMTS database is most readily conceptualized as a set of tables listing time values that correspond to the basic motion elements, the lowest level in our hierarchy of manual work activity They include motions such as reach, grasp, move, and release. 3.1 THE PREDETERMINED MOTION TIME SYSTEMS CONCEPT The concept is similar to constructing a building. A building is composed of elements-Doors, walls, beams, bricks, plumbing. The structure is the sum of the elements. Likewise, a job is also considered to consist of elements, the total of which is the sum of the elements. In formal words, the assumption is that each job element is independent and additive; that is, each element does not affect what happens before or after it independence and additivity. 4 ADVANTAGES OF PREDETERMINED TIMES A collection of basic motion times. Technique for obtaining a standard time by: o analyzing and subdividing a task into elemental motions o assigning pre-set standard times for motions and summing these to obtain a standard time for the whole task. PMT systems offer a number of advantages over stop-watch time study. With PMT systems one time is indicated for a given motion, irrespective of where such a motion is performed. 4 A PMT system, which avoids both rating and direct observation, can lead to more reliability in setting standard times. PMT systems are not too difficult to apply and can be less time consuming than other methods. PMT systems are particularly useful for very short repetitive time cycles such as assembly work in the electronics industry. 5 POPULAR SYSTEMS PREDETERMINED MOTION TIME Methods -Time Measurement Work-Factor Predetermined Time Standards Systems – Meyers MOST 5.1 METHODS TIME MEASUREMENTS (MTM) The data for the development of MTM was obtained from motion pictures (using mechanical cameras) of skilled workers performing a wide range of motions Influence factors were identified and isolated in the motion analysis The influence factors became the motion characteristics which are used for determining the standard times Each motion was separately defined and tabulated for setting the standard times MTM was accepted as a standard method in many countries all over the world 5.1.1 MTM-1 – THE BASIC MTM MODULE Basic time unit: TMU = time Measurement Unit 1 TMU = 0.00001 hour = 0.0006 min = 0.036 sec This time unit was a result of the picture technology This time unit enable investigating much shorter motions (around 3-4 hundredth of a second) than using a stopwatch 5.1.2 MTM STUDIES PROVIDED THE FOLLOWING KINDS OF INFORMATION : Developing effective work methods prior to production Improving existing methods to increase production and decrease labor cost per unit Establishing time standards as basis for wages and incentive plans Developing time formulas or standard data for future use Guiding product design for most efficient manufacture Developing effective tool designs for most efficient manufacture Selecting effective equipment for most efficient manufacture 5.1.3 MTM-1 (1948) – DEFINITION & CHARACTERISTICS 5 A procedure which analyses manual work into a basic motions required to perform it The procedure assigns to each motion a pre-determined time standard which is influenced by the environmental conditions Based on 23 basic motions and consists of approximately 5,000 time values (4,988) 5.1.4 BASIC ELEMENTS Reach (R): move the hand or finger to a destination – affected by the length of the motion and the type of reach Move (M): transport an object to a destination – affected by length of a motion, the weight of the object and the type of move Grasp (G): secure sufficient control on one or more objects with the fingers or hand in order to permit the performance of the next required motion – affected by the size shape and location of the object Position (P): align, orient, and engage object with another object (when only minor motions required) – affected by the ease of handling, symmetry and the amount of pressure required for insertion Release (RL): relinquish control of an object by the fingers or hand Disengage (D): break contact between one object to another – affected by the amount of effort required Turn (T): the motion employed to turn the hand, either empty or loaded, by a movement that rotates the hand, wrist, and forearm about the long axis of the forearm – affected by the degree of rotation and by the weight of the object Apply pressure (AP) Eye Travel (ET): considered only when the eyes must direct the hand or the body movements (includes eye focus and eye travel time) – affected by the distance between the travel points and the distance between the eye to the line of travel Body leg and foot motion (BMF): other motions which are associated with the body and legs (walking, standing, bending etc.) 6 Table 14.3 defines the MTM-1 motion elements, and Table 14.4 presents a tabulation of their time values. 7 8 5.1.5 OTHER MTM SYSTEMS Other members of the MTM family satisfy various user needs. MTM-2 – Second-level PMTS in which basic motion elements are combined into motion aggregates GET – combines Reach and Grasp PUT – combines Move and Position MTM-3 – Third-level PMTS which has four motion categories Handle Transport Step and foot motions Bend and arise 5.2 MOST – MAYNARD OPERATION SEQUENCE TECHNIQUE In MTM: o the elements are stand alone and do not relate to the sequence of the operation In MOST: o The compete sequence of the operation, which consists of smaller elements, is addressed 5.2.1 WHAT IS MOST ? Maynard Operation Sequence Technique (MOST) is a high-level predetermined motion time system (PMTS) that is based on MTM. MOST is a work measurement technique that concentrates on the movement of objects. It is used to analyze work and to determine the normal time that it would take to perform a particular process /operation. Developed by Zandin (1980) Utilizes larger blocks of fundamental motions than MTM-1 General Move o ABGABPA Controlled Move o ABGMXIA Tool Use o ABGABP_ABPA 5.2.2 THREE ACTIVITY SEQUENCES IN MOST The General Move Sequence (for a free movement through air) The Controlled Move Sequence (for a movement in which the object remains in contact with a surface or is attached to another object during the movement) The Tool Use Sequence (for the use of common hand tools) 5.2.3 WHY MOST? It is much faster than traditional time study technique (e.g. Basic MOST is 40 times faster than MTM-1) Accuracy of up to 95% can be obtained It requires less documentation 9 5.2.4 SEQUENCE MODELS FIGURE 2 General Move. The General Move sequence is applicable when an object is moved through the air from one location to another. There are four parameters (actions) in the General Move, symbolized by letters of the alphabet: A — Action distance, usually horizontal. This parameter is used to describe movements of the fingers, hands, or feet (e.g., walking). The movement can be per formed either loaded or unloaded. B — Body motion, usually vertical. This parameter defines vertical body motions and actions (e.g., sitting, standing up). G — Gain control. This parameter is used for any manual actions involving the fingers, hands, or feet to gain physical control of one or more objects. ft is closely related to the grasp motion element in MTM (e.g., grasp the object). P — Placement. The placement parameter is used to describe the action involved to lay aside, position, orient, or align an object after it has been moved to the new location (e.g., position the object). 10 Example: General Move Develop the activity sequence model and determine the normal time for the following work activity: A worker walks 5 steps, picks up a small part from the floor, returns to his original position, and places the part on his worktable. Solution: Referring to Table 14.6, the indexed activity sequence model for this work activity would be the following: A10 B6 G1 A10 B0 P1 A0 where A10 = walk 5 steps, B6 = bend and arise, G1 = control of small part, A10 = walk back to original position, B0 = no body motion, P1 = lay aside part on table, and A0 = no motion. The sum of the index values is 28. Multiplying by 10, we have 280 TMUs (about 10 sec). 11