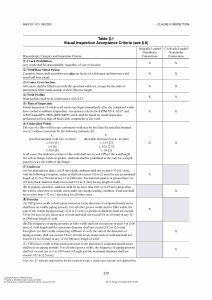

DPT Acceptance Criteria Presented by Md. Arman Hossain NDT Engineer Bangladesh Industrial X-ray (BIX) 1. ASME BPVC for Pressure vessel (Reference: ASME BPVC-2019, Sec. –VIII, Division -01, Mandatory appendix-08 ) 2. API 650 for oil storage tanks (Reference: API 650- 2007 ten editions, section-08, paragraphs- 8.4) 3. API 620 for low pressure storage tanks (Reference: API 620 Twelfth edition, OCTOBER 2013, section-07, paragraph- 7.15.4.4) 4. ASME B 31.3 for process piping (Reference: ASME B 31.3-2020, Chapter-VI, 344.4) Evaluations of indication: An indication of an imperfection may be larger than the imperfection that causes it; however, the size of the indication is the basis for acceptance evaluation. Only indications with major dimensions greater than 1 ⁄ 16 in. (1.5 mm) shall be considered relevant. (a) A linear indication is one having a length greater than three times the width. (b) A rounded indication is one of circular or elliptical shape with the length equal to or less than three times the width. (c) Any questionable or doubtful indications shall be reexamined to determine whether or not they are relevant Acceptance criteria: All surfaces to be examined shall be free of: (a) Relevant linear indications. (b) Relevant rounded indications greater than 3⁄16 in. (5 mm); (c) Four or more relevant rounded indications in a line separated by 1⁄16 in. (1.5 mm) or less, edge to edge. 5. ASME B 31.1 for Power piping (Reference: ASME B 31.1-2018, Chapter-VI, clause- 136.4.4 ) Evaluation of Indications: (I) Mechanical discontinuities at the surface will be indicated by bleeding out of the penetrant; however, localized surface imperfections, such as may occur from machining marks or surface conditions, may produce similar indications which are non-relevant to the detection of unacceptable discontinuities. (2) Any indication that is believed to be non-relevant shall be regarded as a defect and shall be reexamined to verify whether or not actual defects are present. Surface conditioning may precede the reexamination. Non-relevant indications and broad areas of pigmentation which would mask indications of defects are unacceptable. (3) a) Relevant indications are those which result from mechanical discontinuities. b) Linear indications are those indications in which the length is more than three times the width. c) Rounded indications are indications which are circular or elliptical with the length less than three times the width. (4) An indication of a discontinuity may be larger than the discontinuity that causes it; however, the size of the indication and not the size of the discontinuity is the basis of acceptance or rejection. Acceptance Criteria: Indications whose major dimensions are greater than >16 in. (2.0 mm) shall be considered relevant. The following relevant indications are unacceptable: (1) Any cracks or linear indications. (2) Rounded indications with dimensions greater than 3/16 in. (5.0 mm). (3) Four or more rounded indications in a line separated by 1/16 in. (2.0 mm) or less edge to edge. (4) Ten or more rounded indications in any 6 sq in. (3870 mm’) of Surface with the major dimension of this area not to exceed 6 in.(150 mm) with the area taken in the most unfavorable location relative to the indications being evaluated. 6. AWS D 1.1 for steel structural welding inspection. (Reference: AWS D 1.1 23rd edition-2015, chapter-6, part –c, para- 6.10.) Acceptance / Rejection criteria are dependent on service condition. Refer to the relevant project engineer or the Inspection Department. (Table 6.1 for visual inspection acceptance criteria can be applied) Discontinuity Category and Inspection Criteria (1) Crack Prohibition Any crack shall be unacceptable, regardless of size or location. (2) Weld/Base-Metal Lack of Fusion Thorough fusion shall exist between adjacent layers of weld metal and between weld metal and base metal. (3) Crater Cross Section All craters shall be filled to provide the specified weld size, except for the ends of Intermittent fillet welds outside of their effective length. (4) Weld Profiles Weld profiles shall be in conformance with 5.23. (5) Time of Inspection Visual inspection of welds in all steels may begin immediately after the completed welds have cooled to ambient temperature. Acceptance criteria for ASTM A 514, A 517, and A 709 Grade 100 and 100 W steels shall be based on visual inspection performed not less than 48 hours after completion of the weld. On web-to-flange welds on girders, under run shall be prohibited at the ends for a length equal to twice Statically Loaded Non-tubular Connections Cyclically Tubular Loaded Connection Non-tubular (All Loads) Connections X X X X X X X X X X X X X X X the width of the flange. (6) Undersized Welds The size of a fillet weld in any continuous weld may be less than the specified nominal size (L) without correction by the following amounts (U): L U specified nominal allowable decrease weld size, in. [mm] from L, in. [mm] ≤3/16 [5] 1/16 (2) 1/4 [6] ≤3/32 [2.5] ≥5/16 [8] ≤1/8 [3]. 0In all cases, the undersize portion of the weld shall not exceed 10% of the weld length. On web-toflange welds on girders, underrun shall be prohibited at the ends for a length equal to twice the width of the flange. (7) Undercut (A) For material less than 1 in. [25 mm] thick, undercut shall not exceed 1/32 in. [1 mm],with the following exception: undercut shall not exceed 1/16 in. [2 mm] for any accumulated length up to 2 in. [50 mm] in any 12 in. [300 mm]. For material equal to or greater than 1 in. thick, undercut shall not exceed 1/16 in. [2 mm] for any length of weld. (B) In primary members, undercut shall be no more than 0.01 in. [0.25 mm] deep when the weld is transverse to tensile stress under any design loading condition. Undercut shall be no more than 1/32 in. [1 mm] deep for all other cases (8) Porosity (A) CJP groove welds in butt joints transverse to the direction of computed tensile stress shall have X X X X X X no visible piping porosity. For all other groove welds and for fillet welds, the sum of the visible piping porosity 1/32 in. [1 mm] or greater in diameter shall not exceed 3/8 in. [10 mm] in any linear inch of weld and shall not exceed 3/4 in. [20 mm] in any 12 in. [300 mm] length of weld. (B) The frequency of piping porosity in fillet welds shall not exceed one in each 4 in. [100 mm] of weld length and the maximum diameter shall not exceed 3/32 in. [2.5 mm]. Exception: for fillet welds connecting stiffeners to web, the sum of the diameters of piping porosity shall not exceed 3/8 in. [10 mm] in any linear inch of weld and shall not exceed 3/4 in. [20 mm] in any 12 in. [300 mm] length of weld. (C) CJP groove welds in butt joints transverse to the direction of computed tensile stress shall have no piping porosity. For all other groove welds, the frequency of piping porosity shall not exceed one in 4 in. [100 mm] of length and the maximum diameter shall not exceed 3/32 in. [2.5 mm]. X X x X X 5.23 Weld Profiles All welds shall meet the visual acceptance criteria of Tables 6.1 and 9.16, and shall be free from cracks, overlaps, and the unacceptable profile discontinuities exhibited in Figure 5.4, Table 5.8, and Table 5.9, except as otherwise allowed in 5.23.1, 5.23.2, and 5.23.3. 5.23.1 Fillet Welds. The faces of fillet welds may be slightly convex, flat, or slightly concave as shown in Figure 5.4 and as allowed by Tables 5.8, 5.9, 6.1, and 9.16. 5.23.2 Exception for Intermittent Fillet Welds. Except for undercut, as allowed by the code, the profile requirements of Figure 5.4 shall not apply to the ends of intermittent fillet welds outside their effective length. 5.23.3 Groove Welds. Groove weld reinforcement shall comply with Tables 5.8, and 5.9 and with the provisions below. Welds shall have a gradual transition to the plane of the base metal surfaces. 7. API 1104 for Welding of Pipelines and Related Facilities. (Reference: API 1104 twenty-first edition-2013, content-9, para-9.5) Classification of Indications: Indications produced by liquid penetrant testing are not necessarily imperfections. Machining marks, scratches, and surface conditions may produce indications that are similar to those produced by imperfections but that are not relevant to acceptability. The following criteria shall apply when indications are evaluated. a) Any indication with a maximum dimension of 1/16 in. (2 mm) or less shall be classified as nonrelevant. Any larger indication believed to be non-relevant shall be regarded as relevant until reexamined by liquid penetrant or another NDT method to determine whether or not an actual imperfection exists. The surface may be ground or otherwise conditioned before reexamination. After an indication is determined to be non-relevant, other non-relevant indications of the same type need not be reexamined. b) Relevant indications are those caused by imperfections. Linear indications are those in which the length is more than three times the width. Rounded indications are those in which the length is three times the width or less. Acceptance Standards Relevant indications shall be considered defects should any of the following conditions exist: a) linear indications are evaluated as crater cracks or star cracks and exceed 5/32 in. (4 mm) in length, b) linear indications are evaluated as cracks other than crater cracks or star cracks, c) linear indications are evaluated as IF and exceed 1 in. (25 mm) in total length in a continuous 12 in. (300 mm) length of weld or 8 % of the weld length. Rounded indications shall be evaluated according to the criteria of 9.3.9.2 and 9.3.9.3, as applicable. For evaluation purposes, the maximum dimension of a rounded indication shall be considered its size. NOTE: When doubt exists about the type of imperfection being disclosed by an indication, verification may be obtained by using other NDT methods 8. American bureau of shipping (ABS) for Hull I inspection . Reference: ABS-2020, section-6, paragraph-11) Evaluation from Surface Inspection: Evaluation from surface inspection is to be made in accordance with the following acceptance criteria. 1.5.3(a) Weld Appearance, Size and Shape (1 September 2020) Welds are to meet the following requirements: I) Welds are to be regular and uniform with a minimum amount of reinforcement. ii) Welds are to be free from excessive overlap, excessive convexity, and undersize weld or underfill. iii) Thorough fusion is to exist between adjacent layers of weld metal and between weld metal and base metal. iv) All craters are to be filled to their specified weld size. v) For welds exhibiting undercut, refer to 10/1.5.3(e) below. At the discretion of the Surveyor, undercut considered non-conforming is subject to be inspected further by other nondestructive test methods such as magnetic particle method, penetrant method, radiographic method, or ultrasonic method. vi) Arc strikes outside the weld groove are to be dressed and removed 1.5.3(b) Cracks Welds are to be free of any type of crack. 1.5.3(c) Incomplete Fusion Welds are to be free of any lack of fusion between weld metal and base metal 1.5.3(d) Porosity i) Complete joint penetration (CJP) groove welds in butt joints transverse to the members subject to tensile stress are not to have piping porosity. For all other complete joint penetration (CJP) groove welds and full penetration fillet welds, the frequency of piping porosity is not to exceed one in each 100 mm (4 in.) of length and the maximum diameter is not to exceed 2.5 mm (3 / 32 in.). ii) For fillet welds connecting stiffeners to web and partial penetration fillet welds, the sum of the piping porosity 1 mm (1 / 24 in.) or greater in diameter is not to exceed 10 mm (3 / 8 in.) Section 10 Acceptance Criteria for Hull Welds 10 ABS GUIDE FOR NONDESTRUCTIVE INSPECTION • 2020 101 in any linear 25 mm (1 in.) of weld and is not to exceed 19 mm (3 / 4 in.) in any 300 mm (12 in.) length of weld. The maximum diameter of the piping porosity is not to exceed 2.5 mm (3 / 32 in.). 1.5.3(e) Undercut (1 September 2020) Undercut refers to a groove melted in the base metal adjacent to a weld toe at the face or root of the weld. In addition to visual inspection requirement on undercut in 10/1.5.3(a) above, undercut revealed from VT, MT or PT have the following acceptance criteria for butt welds and fillet welds: i) In primary members, undercut is to be no more than 0.25 mm (0.01 in.) deep when the weld is transverse to tensile stress under any design loading condition. ii) For all other cases: ● Undercut depth up to 0.5 mm (1 / 64 in.) is acceptable, whatever the length ● Undercut depth up to 0.8 mm (1 / 32 in.) with a maximum continuous length of 90 mm (31 / 2 in.) is acceptable. Adjacent undercuts separated by a distance shorter than the shortest undercut are to be regarded as a single continuous undercut. iii) Assessment of depth is to be done by visual and mechanical means, and assessment of depth using magnetic particle or penetrant method is not acceptable. 9. ISO 23277 metallic materials weld inspection (Reference: ISO 23277:2015, chapter-05) 10. ISO 17635 a) For Non-destructive testing of welds - General rules for metallic materials (Reference: ISO 17635:2016, annex-A, table-A.3). b) For hull weld inspection Reference: American bureau of shipping (ABS), section-06,paragraph-11) General description: o The width of the test surface shall include the weld metal and the adjacent parent metal up to a distance of 10 mm on each side. o Indications produced by penetrant testing do not usually display the same size and shape characteristics as the imperfection causing that indication. For the purposes of this International Standard, it is the size of the indication which should be assessed against the values shown in Table 1. o Indications that are approximately in line, which are separated by less than the length of the smaller indication, shall be considered as a single, continuous indication. o Acceptance levels prescribed for linear indications are those corresponding to the evaluation level. Indications lower than this shall not be taken into account. Normally, acceptable indications shall not be recorded. o Local grinding can be used to improve the classification of all or part of a test surface when it is required to work to a higher detection limit than that recommended by the existing weld surface condition in TableA.1. NOTE: Local grinding is a very often used practice. Acceptance levels for welds in metallic materials are given in Table 1. Table 1 — Acceptance levels for indications Type of indication 1 Acceptable levela 2 3 Linear indication l≤2 l≤4 l≤8 l = length of indication Nonlinear indication d≤4 d≤6 d≤8 d = major axis dimension a Acceptance levels 2 and 3 can be specified with a suffix, “X”, which denotes that all linear indications detected shall be evaluated to level 1. However, the probability of detection of indications smaller than those denoted by the original acceptance level can be low. Acceptance level Surface condition Type of penetrant system Fluorescent penetrant system, normal sensitivity or a 1 Fine surface higher to ISO 3452-2. Colour contrast penetrant, high sensitivity to ISO 3452-2 b 2 Smooth surface Any c 3 General suface any a. The weld cap and parent material offer smooth clean surfaces with negligible undercut, rippling, and spatter. The surface finish is typical of welds made by automatic TIG-welding, submerged arc welding (fully mechanized), and manual metal arc welding process using iron powder electrodes. b. The weld cap and parent material offer reasonably smooth surfaces with minimal undercut, rippling, and spatter. The surface finish is typical of welds made by manual metal arc welding vertical downwards and MAG welding using argon rich gas for the capping runs. c. The weld cap and parent material are in the as-welded condition. The surface finish is typical of welds produced by the manual metal arc and MAG welding processes in any position. 11. IACS for shipbuilding inspection. (Reference: IACS Req. 2019/Rev.1 2020, contents-33,para-7.6,table-5) Note: ISO 23277:2015 described above. ISO 5817:2014 for assessment of imperfection for quality level Assessment of imperfections Limits for imperfections are given in Table 1. If, for the detection of imperfections, macro-examination is used, only those imperfections shall be considered which can be detected with a maximum of tenfold magnification. Excluded from this are micro lack of fusion (see Table 1, 1.5) and microcracks (see Table 1, 2.2). Systematic imperfections are only permitted in quality level D, provided other requirements of Table 1 are fulfilled. A welded joint should usually be assessed separately for each individual type of imperfection (see Table 1, 1.1 to 3.2). Different types of imperfection occurring at any cross-section of the joint need special consideration (see multiple imperfections in Table 1, 4.1). The limits for multiple imperfections (see Table 1) are only applicable for cases where the requirements for a single imperfection are not exceeded. Any two adjacent imperfections separated by a distance smaller than the major dimension of the smaller imperfection shall be considered as a single imperfection. 12. AWS D1.5 for bridge welding inspection (Reference: AWS D1.5-7th edition-2015, chapter-06, para- 6.26.) Acceptance criteria Weld that is subject to PT, in addition to visual inspection, shall be evaluated on basis of the requirement for visual inspection. 6.26.1.1 Any crack shall be unacceptable, regardless of size or location. 6.26.1.2 Thorough fusion shall exist between adjacent layers of weld metal and between weld metal and base metal. 6.26.1.3 All craters shall be filled to provide the specified weld size, except for the ends of Intermittent fillet welds outside of their effective length. 6.26.1.4 Weld profiles shall be in conformance with 3.6 6.26.1.5 Undercut allowance: except when weld reinforcement Is required to be removed undercut limits hall be as follows, 1. Undercut in main members, undercut shall be no more than 0.01 in. [0.25 mm] deep when the weld is transverse to tensile stress under any design loading condition. 2. Undercut shall be no more than 1/32 in. [1 mm] deep for all other cases. 6.26.1.6 The frequency of piping porosity in fillet welds shall not exceed one in each 4 in. [100 mm] or six in 1200 mm(4 ft.) of weld length and the maximum diameter shall not exceed 2.5 mm (3/32 in). 1) A subsurface inspection for porosity shall be performed whenever piping porosity 2.4 mm(3/32) or larger in diameter extends to the surface at interval of 300 mm (12 in) or ;sees over a distance of 1200 mm (4 ft) or when the condition of electrodes ,flux, base metal or the presence of weld cracking indicates that there may be problem with piping of gross porosity 2) This subsurface inspection shall be a visual inspection of 300 mm(12 in) exposed length s of the4 fillet weld throat after it has been ground or removed any air carbon arc gouging to a depth of ½ the design throat , diameters of all porosity shall not exceed 10 mm(3/8 in) in any 25 mm (1 in) length of weld or 20 mm(3/4 in) in any 300 mm (12 in) length . 6.26.1.7 A fillet weld in any single continuous weld may under run the nominal fillet weld size specified by 2 mm (1/6 in) without correction, provided that the undersize portion of the weld does not exceed 10% of the length of the weld .on the web-to-flange welds on girders, under run shall be prohibited at the ends for a length equal to twice the width of the flange. 6.26.1.8 CJP groove welds in butt joints transverse to the direction of computed tensile stress shall have no piping porosity. For all other groove welds, the frequency of piping porosity shall not exceed one in 100 mm (4 in.) of length and the maximum diameter shall not exceed 2.5 mm (3/32 in.). 6.26.1.9 Visual inspection of welds in all steels may begin immediately after the completed welds have cooled to ambient temperature. Acceptance criteria for M 270M/M270 (A709/A709M) grade HPS 690W (HPS 100 W) steels shall be based on visual inspection performed not less than 48 hours after completion of the weld. 3.6 Weld profiles 3.6.1 Fillet welds. The faces of fillet welds may be slightly convex, flat, or slightly concave as shown in figure 3.4 (A) and (B) with none unacceptable profiles shown in figure 3.4(C) . the convexity C of a weld or individual surface beaded shall not exceed 0.07 times the actual face width of the weld or individual bead, respectively, plus 1.5 mm (0.06) (see figure 3.4(B). these profile requirements shall not applying to the ends of intermittent fillet welds outside the specified effective length or for outside corner joints: these exceptions do not modify the weld quality provisions, including the undercut limits of 6.26 3.6.2 groove welds: in the case of butt and corner joints, the face reinforcement shall not exceed 3 mm (1/8 in) height and shall have gradual transition oto the plane of the base metal surface (see figure 3.4 D) welds shall be free of unacceptable groove weld profiles shown in figure 3.4(E) 3.6.2.1 Removal of weld reinforcement 3.6.2.1.1 When surface of butt joints are specified in contract documents to be finished flush, the following shall apply (1) The nominal thickness of the thinner base metal or weld metal shall not be reduced by more than 2 the weld or thinner base metal cross – sectional area along the weld length shall not be reduced to less than 98% of the cross section 3. Remaining reinforcement shall not exceed 1 mm (1/32 in) and shall blend smoothly into the base metal surfaces except no reinforcement is allowed on faying surface. 4. Ground areas shall be free from undercut. Undercut removal shall be such that the base metal and weld metal blend smoothly without exceeding the limits of (1) and (2) above. 5. Chipping shall not be used for reinforcement removal 3.6.2.1.2 All reinforcement shall be removed where the weld forms a part of the faying surface. 3.6.2.2 Where surface finishing is required, the surface roughness values shall not exceed 6 µm(250 µin) .surface finished to values over 3 µm (150 µin) or less may be finished in any direction, subject to the following additional requirements: but joint’s between parts subject to tensile stress, whether joining parts of equal or unequal width or thickness , shall be finished flush or to a smooth transition to a roughness not exceeding over 3 µm (150 µin). 3.6.3 Welds shall be free from overlap 13. BS EN ISO 10228-2 for steel casting inspection Reference: BS EN ISO 10228-2:2016, chapter -9, table-2. 14. EN 10228-2 for steel casting inspection Reference: BS EN ISO 10228-2:2016, chapter -9, table-2. Parameter 1 ≥7 Quality class 2 3 ≥3 ≥3 4a ≥1 Recording level (mm)b Allowable length L of isolated linear indications and allowable length Lg of ≤ 20 ≤8 ≤4 ≤2 b interacting indications (mm) Allowable cumulative length of linear indications in the reference surface ≤ 75 ≤ 36 ≤ 24 ≤5 b (mm) Allowable size of isolated rounded ≤ 30 ≤ 12 ≤8 ≤3 indications (mm)b Maximum allowable number of recordable indications on reference 15 10 7 5 c surface a Quality class 4 is not applicable to the test of areas with machining allowance ≥ 0,5 mm per face. b The tabulated values apply to the indication size, not to the surface extent of the flaw. c Reference surface = 148 mm × 105 mm (i.e. A6 format) For objects smaller than the reference surface, or if only an area is examined smaller than the reference surface, then the maximum allowable number of indications should be determined and agreed accordingly (the acceptance criteria for the dimensions remain unchanged).. 15. ISO 4987 for steel casting inspection Reference: ISO 4987:2020-3rd Edition, chapter-06) Acceptance criteria 6.1 Definition of liquid penetrant indications 6.1.1 General Indications revealed by the liquid penetrant testing can have different shapes and sizes. The distinction between the indications is made depending on the ratio of the length L of the indication to its width W, in the manner described in 6.1.2 and 6.1.3. 6.1.2 Non-linear indications (SP) Indications are considered to be non-linear when the length L is smaller than three times the width W. Indications are considered to be aligned when the distance between non-linear indications is less than 2 mm and at least three indications are aligned. An alignment of indications is considered to be a unique non-linear indication and its length is equal to the overall length L of the alignment specified in Table 1. Non-linear indications that are not aligned are considered to be isolated. NOTE: The symbol for non-linear indications is SP (S for surface and P for liquid penetrant) Characteristic Testing means Magnification for observation of penetrant indication Length L1 of the smallest indication to be considered, in millimeters Maximum number of non-linear indications allowed Maximum individual length L2 allowed, in millimeters a SP 001 SP 01 Magnifying glass or eye Severity levels SP 1 SP 2 SP 3 SP 4 SP 5 Eye ≤3 1 0,3 0,5 1,5 2 3 5 5 5 6 8 8 12 20 32 1 2 3a 6a 9a 14a 21a A maximum number of two indications of the designated dimension are permitted 6.1.3 Linear indication (LP) The indications are considered to be linear when the length L is greater than or equal to three times the width W. The lengths of the linear indications greater than the minimum length shall be added together and the result shall be compared to the total (T) length specified in Table 2. Characteristic Testing means LP 001 LP 01 Magnifying glass or eye Severity levels LP 1 LP 2 LP 3 LP 4 LP 5 Eye Magnification for observation of ≤3 1 penetrant indication length L1 of smallest indication to 0,3 1,5 2 3 5 5 be considered, in millimeters Acceptable indications Individual I or T I T I T I T I T I T (I) or Total (T) length section 0 1 2 4 4 6 6 10 10 18 18 25 Maximum length thickness type a L2 of linear (LP) t ≤ 16 mm indications section allowed thickness type b 0 1 3 6 6 12 9 18 18 27 27 40 depending on 16 mm < t ≤ 50 the section mm thickness t, in section millimetersa thickness type c 0 2 5 10 10 20 15 30 30 45 45 70 t > 50 mm a No functional relationship exists between each type of section thickness and maximum crack length, relative to a fracture-mechanics study. However, this table is a useful guide where no relevant fracture-mechanics parameters currently exist. Indications are considered to be aligned when the distance between two indications is smaller than the length L of the longest indication. An alignment of indications is considered to be a unique indication and its length is equal to the overall length L of the alignment. NOTE: The symbol for linear indications is LP (L for linear and P for liquid penetrant) 6.2 Severity levels 6.2.1 General The severity levels are a reference scale, each level depends on the types of indications. 6.2.2 Non-linear indications For the non-linear indications, the severity levels (see Table 1) are defined by: a) The length (largest dimension) L1 of the smallest indication to be considered, and b) The maximum length L2 of the indications. 6.2.3 Linear indications 6.2.3.1 General The severity levels for linear indications (see Table 2) are defined by: a) The length (largest dimension) L1 of the smallest indication to be considered, b) The maximum length L2 of the linear individual (I) indications, and c) The total (T) of the lengths of the linear indications exceeding the length L1 in a frame measuring 105 mm × 148 mm. 6.2.3.2 Section thickness type Three section thickness types are specified (see Table 2): a) t ≤ 16 mm; b) 16 mm < t ≤ 50 mm; c) t > 50 mm; where t is the section thickness. 6.2.4 Selection of the severity level The severity levels shall be selected from Tables 1 and/or 2 as seen in, if necessary, the reference figures given in Annexes B and C. The reference figures are drawn to a scale of 1:1 and are given as examples. The largest non-relevant indication is shown in a 26 mm × 37 mm frame corresponding to the ISO format A10. Table 1 and Annex B correspond to non-linear (SP) indications (isolated). Table 2 and Annex C correspond to linear (LP) indications. NOTE: Note that several equivalent severity levels defined in Table 2 are represented by the same reference figure. In certain cases, the equivalence of the figure is only approximate because of slight differences in the parameters in Table 2. The severity levels cannot be considered in the same progression from Table 1 to Table 2. They should not be considered equivalent as regards severity. The severity criteria and the severity levels can differ from one part of a casting to another. 6.2.5 Designation of severity levels The requirements in the order or in the specifications shall conform to the terminology used in this document. Examples of correct terminology are given below: — SP 2 for non-linear indications with a maximum of 8 non-linear indications, L1 of 2 mm and L2 of 6 mm (see 6.1.2, 6.2, and Table 1); — LP 5c for linear indications and t > 50 mm with L1 of 5 mm and L2 of 45 mm for Individual indications or 70 mm for Total indications (see 6.1.3, 6.2, and Table 2) 16. GE Standard for GE turbine and GE accessories inspection Reference: as per GE procedure Acceptance criteria at Visible dye penetrant testing 1. Acceptance criteria for GE turbine components A). For compressor blades & all stationary components – Relevant indication size equal greater than 0.062 inches (1.5 mm) shall be reported to GE. B). Rotating partsThis Visual PT procedure is not applicable for rotating parts except compressor blades or vanes (FPI only allowed for rotating parts). Note: GE field team to contact engineering for disposition. 2. Acceptance criteria for accessories parts and balance of plant parts (BOP) All surfaces to be examined shall be free of: 1.Relevant linear indications 2.Relevant rounded indications greater than 5 mm (3/16 in.) 3.Four or more relevant rounded indications in a line separated by 1.5 mm (1/16 in.) or less edge-to-edge. Acceptance criteria at fluorescent dye penetrant testing 1. Acceptance criteria for GE turbine components A. For rotating parts-relevant indications size 0.03 inches (1 mm) & greater shall be reported to GE. B. For stationary parts: relevant indications size 0.062 inches (1.5 mm) and greater shall be reported to GE. Note: GE field team to contact engineering for disposition. 2. Acceptance criteria for accessories parts and balance of plant parts (BOP) All surfaces to be examined shall be free of: 1. Relevant linear indications 2. Relevant rounded indications greater than 5 mm (3/16 in.) 3. Four or more relevant rounded indications in a line separated by 1.5 mm (1/16 in.) or less edge-to-edge.