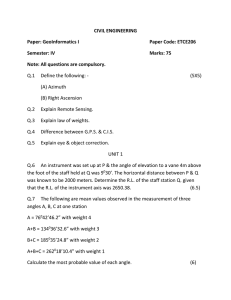

Total Station Manual: Setup, Measurement, and Safety Guide

advertisement