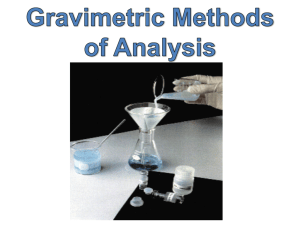

Laboratory work 6 Qualitative analysis. Gravimetric analysis The aim of work: to obtain laboratory skills (work with analytical scales, muffle furnace, desiccator, quantitative precipitation and filtration) and process results of gravimetric analysis. Gravimetric determination of iron (III) Iron is precipitated in the form of hydroxide, moving protolytic reaction to the right by addition of ammonia: [Fe(H2O)6]3+ + H2O = [Fe(OH)(H2O)5]2+ + H3O+ [Fe(OH)(H2O)5]2+ + H2O = [Fe(OH)2(H2O)4]+ + H3O+ [Fe(OH)2(H2O)4]+ + H2O = [Fe(OH)3(H2O)3] +H3O+ Iron hydroxide is fired at temperature of 800 °C to oxide Fe2O3. Fire of the precipitate at a temperature about 1200°C can lead to errors in the determination due to the reaction 6Fe2O3 = 4Fe3O4 + O2 If the analyzed solution contains iron (II), it is pre-oxidized with nitric acid. Form of precipitation Fe(OH)3xH2О, gravimetric form - Fe2O3. Reagents, glasses and equipment Nitric acid, HNO3, 2М solution. Ammonia, NH3, solution 1:1. Silver nitrate, AgNO3, 1% solution. Ammonium nitrate, NH4NO3, 1% solution. Graduated cylinder (10 mL), glass (300-400 mL), glass stick, funnel, porcelain crucible. Technical scales, analytical scales, hot plate, muffle furnace, drying oven, crucible tongs, desiccator, no ash filter "red ribbon". Working process Add 1-2 mL of 2M HNO3 to analyzed solution located in a 300-400 mL glass. Solution is diluted by hot water until 100 mL then heated to almost boiling (75-90 С) and add ammonia solution with stirring to the appearance of an obvious odor. Provide precipitate to gather at the bottom of the glass and filtered through the filter "red ribbon". Precipitate is washed by decantation with hot 1% NH4NO3 solution prior to removal of Cl- ions. Completeness of washing check by solution of silver nitrate, acidified with nitric acid (only weak opalescence is permissible). Precipitate is moved to filter and washed 2 times by hot 1% NH4NO3 solution. Remaining precipitate particles on the walls of the glass removed by small pieces of filter paper with a glass stick. Pieces of paper with precipitate particles is added to precipitate. The funnel with the filter is placed in the drying oven, the precipitate is dried and the filter with precipitate are placed in a crucible and bring to a constant mass. Caution charred filter and fired precipitate during 30-40 min at 800 °С. Repeating of fired precipitate (by 10-15 min) until constant mass. The obtained results of measurements are wrote in the table. Empty crucible Crucible with Fe2O3 precipitate Mass, g … … Fe2O3 precipitate The iron mass in the sample is calculated by the formula: m(Fe) = m(Fe2O3)F … Questions for self-preparation 1. What are the main types of gravimetric method? On what are based stripping and deposition of methods? 2. List the main stages in gravimetric analysis in the order in which they are performed. 3. In what case precipitation is considered to be almost complete? 4. Give the formula for calculating the amount of sample. 5. List the basic requirements for the deposited form. 6. Requirements for gravimetric form. 7. Why an excess of precipitant is used? 8. Formulate the conditions for the analytical separation of crystalline and amorphous precipitates. 9. List the main causes of sediment pollution. 10. What is the purpose of washing the precipitates? What methods of washing of precipitates are used? 11. What are the advantages of washing of precipitates by decantation compared to washing on the filter? 12. What are the principles for choosing a washing liquid for washing amorphous and crystalline precipitates? 13. Which precipitator solution NaOH or NH3 is used for precipitating Fe(OH)3?