See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/266281096

Energy Analysis, Diagnostics, and Conservation in Semiconductor

Manufacturing

Article

CITATIONS

READS

6

1,456

5 authors, including:

Yogesh Mardikar

8 PUBLICATIONS 48 CITATIONS

Bhaskaran Gopalakrishnan

West Virginia University

129 PUBLICATIONS 861 CITATIONS

SEE PROFILE

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Evaluating the Influence of Energy Consumption on Process Plan Attributes: Process Plans Indexing Based on Electrical Demand and Energy Consumption View project

All content following this page was uploaded by Bhaskaran Gopalakrishnan on 25 December 2015.

The user has requested enhancement of the downloaded file.

Energy Analysis, Diagnostics, and Conservation in

Semiconductor Manufacturing

Yogesh Mukesh Mardikar

Thesis submitted to the

College of Engineering and Mineral Resources

at West Virginia University

in partial fulfillment of the requirements

for the degree of

Master of Science

In

Industrial Engineering

B. Gopalakrishnan, Ph.D, PE, Chairman

Robert Creese, Ph.D.

Dimitris Korakakis, Ph.D.

Department of Industrial and Management Systems

Engineering

Morgantown, West Virginia

2004

Keywords: Semiconductor Manufacturing, Process Energy, Support

Energy, Oxidation, Doping

ABSTRACT

Energy Analysis, Diagnostics, and Conservation in Semiconductor

Manufacturing

Yogesh Mukesh Mardikar

Semiconductor industry accounts for 1.3% - 2% of the total US electricity

consumption in the manufacturing sector. Energy in the form of electricity is required to

operate the manufacturing process equipment, maintain the clean room conditions, and

operate equipment such as Heating Ventilation and Air conditioning (HVAC) units, and

Chillers. The process equipment accounts for 40% of the operating costs in a

semiconductor fabrication unit [8]. Since a significant amount of energy is used by the

manufacturing process, it becomes necessary to determine process parameters which

govern energy. A computer based interactive model referred to as Semiconductor Energy

Calculation Program (SECALPRO), was built in this study to estimate the energy

requirement of any particular process in semiconductor manufacturing based on the input

variables. Energy intensive processes such as layering and diffusion are studied. Process

parameters most sensitive to energy are determined. It is intended to enable the estimation

of process energy beforehand by analysis of process parameters governing energy. The

computer model also estimates the support energy requirement in semiconductor

manufacturing. It is found that process temperature is the key variable governing the

energy requirement of the processes under study. This research reports a sensitivity

analysis of process variables with respect to energy. A research in this area will help the

production managers in the semiconductor fabrication facilities to effectively select the

production parameters based on the results obtained by this research.

ACKNOWLEDGEMENT

I would like to wholeheartedly thank my advisor Dr. B. Gopalakrishnan for his

continued support, guidance and encouragement during the course of this research work. I

also wish to thank Dr. Robert Creese and Dr. Dimitris Korakakis for their advice and

support.

Above all, I wish to thank god, my parents, and all my friends for their constant

support and blessings and enabling my success and happiness in all my pursuits and

endeavors in life.

iii

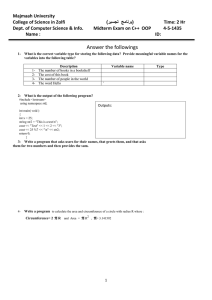

Table of Contents

ABSTRACT........................................................................................................................... ii

ACKNOWLEDGEMENT .................................................................................................... iii

1

Introduction.................................................................................................................... 1

1.1

Electronics Sector and Energy ............................................................................... 1

1.2

Semiconductor Manufacturing Process ................................................................. 2

1.2.1

Wafer Fabrication .......................................................................................... 2

1.2.2

Semiconductor Fabrication ............................................................................ 4

1.2.3

Assemblies, Encapsulation and Packaging .................................................... 6

1.3

The Semiconductor Industry Analysis................................................................... 7

1.4

Economic Profile and Trends................................................................................. 8

1.5

Energy Use in Semiconductor Industry ............................................................... 11

1.6

Energy Intensity ................................................................................................... 13

1.7

Cogeneration ........................................................................................................ 15

1.8

Need for Research................................................................................................ 15

1.9

Research Objectives............................................................................................. 16

1.10 Conclusion ........................................................................................................... 17

2

Literature Review......................................................................................................... 19

2.1

General Energy Management Activities.............................................................. 19

2.2

Productivity Improvement Activities in Electronics Sector ................................ 23

2.3

Energy Efficiency Initiatives and Best Practices in Electronics Manufacturing . 23

2.4

Conclusion ........................................................................................................... 25

3

Research Approach ...................................................................................................... 26

3.1

Methodology ........................................................................................................ 26

3.2

Oxidation/Layering .............................................................................................. 26

3.3

Thermal oxidation process................................................................................... 28

3.4

Oxidation process parameters sensitive to energy ............................................... 29

3.5

Deal Grove Model................................................................................................ 32

3.6

Doping.................................................................................................................. 35

3.7

Predeposition........................................................................................................ 36

3.8

Drive-in oxidation................................................................................................ 36

3.9

Dopant sources..................................................................................................... 37

3.10 Diffusion process parameters sensitive to energy................................................ 37

3.11 Diffusion model ................................................................................................... 39

3.12 Conclusion ........................................................................................................... 41

4

Model Development..................................................................................................... 43

4.1

Purpose of Modeling............................................................................................ 43

4.2

C ++, SECALPRO Model Programming Language............................................ 43

4.3

SECALPRO Model Assumptions........................................................................ 43

4.4

SECALPRO Model Development ....................................................................... 44

4.4.1

Layering/Oxidation Process flowchart ........................................................ 44

4.4.2

Diffusion/Doping Process flowchart............................................................ 45

4.5

Areas of significant energy consumption ............................................................ 46

4.6

Systematic approach to estimate energy consumption ........................................ 46

4.7

Flowchart Description.......................................................................................... 50

iv

4.7.1

Process selection .......................................................................................... 50

4.7.2

Input variables/ Process related ................................................................... 51

4.7.3

Horizontal Tube Furnace ............................................................................. 54

4.7.4

Input variables/ Energy related .................................................................... 57

4.7.5

Furnace/Oxidizer specifications................................................................... 60

4.7.6

Energy consuming elements in an Oxidizer/Diffuser/Furnace.................... 60

4.7.7

Support equipment energy estimation ......................................................... 63

4.7.8

Clean Room design ...................................................................................... 64

4.7.9

Total kW and kWh consumption ................................................................. 68

4.8

Conclusion ........................................................................................................... 68

5

Results and Sensitivity Analysis.................................................................................. 69

5.1

Oxidation.............................................................................................................. 69

5.1.1

Temperature effect ....................................................................................... 69

5.1.2

Throughput effect......................................................................................... 78

5.1.3

Ramp rate Effect .......................................................................................... 81

5.2

Doping.................................................................................................................. 83

5.2.1

Dopant Effect ............................................................................................... 83

5.2.2

Process time effect ....................................................................................... 84

5.2.3

Process temperature effect ........................................................................... 85

5.3

Summary of major findings ................................................................................. 89

5.4

Conclusion ........................................................................................................... 90

6

Model Validation ......................................................................................................... 91

6.1

Validation of Model............................................................................................. 91

6.1.1

Furnace energy consumption ....................................................................... 93

6.1.2

Clean room design ....................................................................................... 94

6.1.3

Total oxide growth time............................................................................... 95

6.2

Important facts revealed after personal communication...................................... 96

6.3

Conclusion ........................................................................................................... 96

7

Conclusion and Future Work ....................................................................................... 98

7.1

Conclusion ........................................................................................................... 98

7.2

Future work........................................................................................................ 102

7.2.1

Linear programming approach................................................................... 102

Reference ........................................................................................................................... 106

Nomenclature..................................................................................................................... 109

Appendix I ......................................................................................................................... 110

SECALPRO Model Screenshots........................................................................................ 110

Appendix II ........................................................................................................................ 112

List of variables.................................................................................................................. 112

Appendix III....................................................................................................................... 115

Source code........................................................................................................................ 115

v

List of Figures

Figure 1.1: Semiconductor manufacturing process flow chart .............................................. 3

Figure 1.2: Integrated circuit development............................................................................ 8

Figure 1.3: Worldwide end use of semiconductors .............................................................. 9

Figure 1.4: Integrated circuit unit and revenue growth ......................................................... 9

Figure 1.5: Worldwide semiconductor shipments ............................................................... 10

Figure 1.6: Percent market share ......................................................................................... 10

Figure 1.7: Operating costs of a clean room plant .............................................................. 12

Figure 1.8: Annual energy consumption for semiconductor fabrication units in California12

Figure 1.9: Semiconductor manufacturing energy balance ................................................. 14

Figure 1.10: Breakeven analysis for $/kWh rates possible by cogeneration ....................... 15

Figure 1.11: System schematic ............................................................................................ 17

Figure 3.1: Oxide layer formation ....................................................................................... 27

Figure 3.2: Formation of doping barrier .............................................................................. 27

Figure 3.3: Surface dielectric formation .............................................................................. 28

Figure 3.4: Oxide layer formation ....................................................................................... 29

Figure 3.5: Crystal orientation of silicon wafer ................................................................... 31

Figure 3.6: Oxide growth dynamics..................................................................................... 32

Figure 3.7: Predeposition process ........................................................................................ 36

Figure 3.8: Drive-in process ................................................................................................ 37

Figure 3.9: Dopant concentration vs. junction depth – Error function curve ...................... 40

Figure 3.10: Dopant concentration vs. junction depth – Gaussian curve ............................ 41

Figure 4.1: Oxidation/Layering process flowchart .............................................................. 45

Figure 4.2: Diffusion/Doping process flowchart ................................................................. 46

Figure 4.3: Flowchart to determine energy consumption .................................................... 47

Figure 4.4: Schematic of furnace tube and heating coils ..................................................... 55

Figure 4.5: Horizontal tube furnace along with cleaning station......................................... 57

Figure 4.6: Elements of four tube horizontal furnace .......................................................... 61

Figure 4.7: Temperature Levels for Oxidation process. ...................................................... 62

Figure 4.8: kW consumption vs. time per process cycle. .................................................... 63

Figure 4.9: Support equipment used in semiconductor manufacturing ............................... 63

Figure 4.10: Air changes per hour for a particular clean room Class .................................. 65

Figure 4.11: Continued clean room layout .......................................................................... 66

Figure 5.1: Time vs. temperature – 0.1 micron, 900 – 950 °C ............................................ 70

Figure 5.2: Percentage energy distribution – 0.1 micron, 900 – 950 °C.............................. 72

Figure 5.3: Energy (kWh) consumption per wafer vs. temperature – 0.1 micron oxide ..... 73

Figure 5.4: Time vs. temperature –1 micron, 1000 – 1150 °C ............................................ 74

Figure 5.5: Percentage energy distribution – 1 micron, 1000 – 1150 °C............................. 76

Figure 5.6: Energy (kWh) consumption per wafer vs. temperature – 1 micron oxide ........ 76

Figure 5.7: Time vs. temperature – 0.25 micron, and 950 – 1050 °C ................................. 77

Figure 5.8: Time vs. temperature – 0.5 micron, 1000 – 1150 °C ........................................ 78

Figure 5.9: Throughput vs. temperature – 0.1 micron oxide growth................................... 80

Figure 5.10 Throughput vs. temperature –1 micron oxide growth ...................................... 80

Figure 5.11: Time vs. temperature – 1 micron, 8 ºC/min, 10 ºC/min, 12 ºC/min RUR....... 82

Figure 6.1: Power (kW) consumption vs. time – facility furnace........................................ 93

vi

Figure 6.2: Power measurement using power logger........................................................... 94

Figure 6.3: Furnace loading/unloading station in Class 10 and reactor section in Class .... 94

Figure 6.4: Clean room classification used in the SECALPRO model ............................... 95

Figure 7.1: Energy usage distribution – 1 micron oxide, 1150 °C ...................................... 99

Figure 7.2: Energy usage distribution – N type dopant phosphorus, 1150 °C .................. 101

Figure 7.3: Temperature vs. time – Furnace cycle............................................................. 104

Figure I.1: Screenshot of the SECALPRO model - Introduction ...................................... 110

Figure I. 2: Screenshot of the SECALPRO model - Execution......................................... 110

Figure I.3: Screenshot of the SECALPRO model - Execution.......................................... 111

Figure I.4: Screenshot of the SECALPRO model – Results (1 micron, 1150 °C, wet,

<100>)........................................................................................................................ 111

vii

List of Tables

Table 1.1: Variations in percentage energy use in semiconductor fabrication units ............. 2

Table 1.2: Level of integration............................................................................................... 8

Table 1.3: Semiconductor industry statistics for year 1997................................................... 9

Table 1.4: Texas State Fabrication units enlisting product type and throughput per month 11

Table 1.5: Electronics sector electricity and natural gas consumption for California State 13

Table 4.1: Growth rates and activation energy .................................................................... 52

Table 4.2: Furnace/Oxidizer specifications ......................................................................... 60

Table 4.3: kVA and kW consumption of furnace elements ................................................ 62

Table 4.4: Support equipment power ratings ...................................................................... 63

Table 5.1: Results – 0.1 micron, 900 – 950 °C .................................................................... 71

Table 5.2: Results –1 micron, 1000 – 1150 °C .................................................................... 75

Table 5.3: Energy savings and productivity improvement for 0.25 micron oxide growth,

950 – 1050 °C .............................................................................................................. 77

Table 5.4: Energy savings and productivity improvement for 0.5 micron oxide growth.... 78

Table 5.5: Ramp up and ramp down rates used in the SECALPRO model......................... 81

Table 5.6: Effect of ramp up rate on energy savings and productivity improvement – 1

micron oxide growth .................................................................................................... 82

Table 5.7: Diffusion coefficient and activation energy values for P – type, and N – type

doping .......................................................................................................................... 84

Table 5.8: Effect of dopant type on junction depth ............................................................. 84

Table 5.9: Effect of drive-in time on junction depth for P type and N type doping ............ 85

Table 5.10: Temperature and drive - in time effect on junction depth ................................ 85

Table 5.11: Temperature effect on drive - in time and energy usage .................................. 86

Table 5.12: Results –P type dopant, drive-in time 2.6, 5, 10 hours, and temperature 1100 1150 °C ........................................................................................................................ 87

Table 5.13: Results – N type dopant, drive-in time 1.91, 5, 10 hours, and temperature 1100

- 1150 °C...................................................................................................................... 88

Table 6.1: Tube furnace specification.................................................................................. 92

Table 6.2: Wafer cleaner specification ................................................................................ 92

Table 6.3: Sample oxidation process ................................................................................... 92

Table 6.4: Sample doping process ....................................................................................... 92

Table 6.5: Clean room specification .................................................................................... 94

Table N.1: Nomenclature for equations............................................................................. 109

Table AII.1: Variable data type and description................................................................ 114

viii

Chapter 1

1 Introduction

1.1

Electronics Sector and Energy

Electronics sector as a whole involves manufacture of semiconductor devices,

electron tubes, computers, printed circuit boards, capacitors, resistors, transistors and

miscellaneous electronic devices. Manufacturing technology had changed since the

development of electron tubes in early 1900’s to the present day ultra large scale

integration era. Although the above ancillary industries in electronics sector produce

altogether different end products, but they definitely share something in common. That

common characteristic is the energy intensity in these units. Restricting the study to

semiconductor manufacturing has revealed that the semiconductor industry is the largest

end user of energy. Major energy consumption is in the area of process operation and

supporting utilities. Improvement in technology demands changes in the current facilities.

Almost every three to five years, the semiconductor technology demands for larger wafer

dimensions. Present day fabrication units are thus modified to accommodate changes in

technology. Here major attention is given on the new technology production facility.

Energy aspect, though important is thus sidelined. A study done by Environmental

Protection Agency (EPA) has revealed that energy use in semiconductor fabrication units

(Fabs) is not consistent. As seen in Table 1.1, Fab5, Fab6, and Fab7 process almost equal

number of wafers per month, but their energy use varies from 60% to 90%. Many other

studies done on present day Fabs show same pattern of results. Thus it becomes necessary

to analyze the elements causing this large variation in energy use. Some of the biggest

manufacturers demand more than 100 million kWh of energy per year [1]. Here lies an

opportunity to find reasons causing this high energy demand. Successful analysis will result

in tremendous energy savings. Pollution control is also a major concern for any

manufacturing sector. Also, reductions in emissions will be the added advantage.

Development in electronics sector was so fast that it was almost neglected as a

candidate for implementing energy efficiency measures. Study by USDOE has shown the

fact that traditional heavy industry like Steel and Iron, Chemical, and Pulp and Paper have

almost declining or steady energy intensities. Whereas it is estimated that electronics sector

will be one of the highest energy intensive industries in the coming future. Hence, an effort

1

is made to study the energy use in semiconductor industry – a largest end user of energy.

Basics of semiconductor manufacturing are discussed further.

Fabrication Units

Fab1

Fab3

Fab4

Fab5

Fab6

Fab7

Fab9

Fab10

Wafers/month

HVAC, Chillers

(% of total energy)

Mfg. Process

Equipment

(% of total energy)

15,000

20,000

19,500

21,700

21,700

21,700

30,000

30,300

35%

46%

31%

39%

32%

35%

54%

37%

38%

40%

42%

51%

32%

36%

18%

33%

Table 1.1: Variations in percentage energy use in semiconductor fabrication units [1]

1.2

Semiconductor Manufacturing Process

The semiconductor manufacturing process starts with the extraction of raw

materials from the earth followed by its purification. The most commonly used

semiconductor material is silicon. The silicon used needs to be refined and is called as

semiconductor grade silicon (SGS). This also involves reducing the impurities to the

specified level. The refining or purification process is the transformation of ore to silicon tri

chloride a silicon bearing gas. These gases are further reacted with hydrogen to produce

SGS, which has a crystalline structure [2]. The Semiconductor manufacturing process is in

three major steps viz. wafer fabrication, semiconductor fabrication, and assembly –

packaging. The semiconductor manufacturing process is outlined in Figure 1.1.

1.2.1

Wafer Fabrication

The first step in wafer fabrication is to have a perfect crystal structure. By perfect, it

means the crystallized structure silicon has to have a specific orientation. Different planes

of a crystal have different electrical, chemical properties depending on the binding pattern

of the atoms in that specific plane. A method known as Miller Indices is used to define the

planes, which identify the xyz location of each plane in a crystal [3].

The crystal obtained has a polycrystalline structure and is not doped. “The process

of converting the polycrystalline structure to a large crystal of single crystal structure, of

the correct orientation, and containing the proper amount of dopant is called “crystal

growing”. Czochralski method [3] is most commonly used for growing crystals. The

furnace used has a crucible, which is heated by coils. The polycrystalline chunk with

proper quantity of dopant is heated in the crucible to produce an N or P type crystal.

2

Crystal Growth

Polycrystalline Silicon

Crucible Furnace

Ingot

Crystal

Inspection

Rejected Ingot

Ingot Facing, Grinding, Slicing, Polishing

Oxidation

Patterning

Photos resist Coating

Etching

Photo Resist Removal

Doping

Heat Treatments

Die Separation and Pickup

Die Attach

Wire Bonding

Encapsulation or Sealing

Chips

Figure 1.1: Semiconductor manufacturing process flow chart

A seed crystal of the desired orientation is positioned in such a way that it barely

touches the molten polycrystalline chunk. It is then slowly raised above the melt. This is

the point when the crystal growth starts. The phenomenon of surface tension causes the

melt to adhere to the seed. The crucible and the seed are rotated in opposite directions to

3

achieve uniformity in doping and perfection in crystal. An ingot is then ready to be used for

further processes [3].

Semiconductor applications demand a very high perfection level of the crystals

from which they are made. General defects observed in crystals are the point defects,

dislocations, and the growth defects. The crystal is inspected based for the defects if any

[3]. The ingot produced in the crucible has tapered ends, which are removed by a saw. The

diameter of the ingot is not constant throughout its length. These variations in diameter

should be removed so as to facilitate easy handling of ingot for further processing. A

center-less grinder is used to perform this operation [3]. Further the crystal is checked for

its electronic properties such as resistivity and conductivity. Also it is checked for its

orientation in which the ends of the crystal are etched first. The crystal is then placed in

refraction equipment and a collimated light is reflected from the crystal surface onto a

screen. The pattern obtained on the screen represents the actual pattern of the crystal

orientation [3].

After crystal checking, the ingot is ground along its axis similar to a flat. The flat

position represents the orientation of the wafer. The ingot is then sliced into wafers by

using a circular diamond saw with inside diameter as the cutting edge. Wafer slicing

damages the wafer surface to an extent which can be overcome by polishing. Rough

polishing is an abrasive action to remove these irregularities caused by the slicing process.

In final polishing the wafer is etched while it is rotated. This causes a thin etchant film to

develop on the wafer surface, which is further removed by a buffing process. A high degree

of flatness is thus obtained after the final polishing. Further the edge of the wafer is ground,

which smoothen the edge and reduces the possibility of edge chipping and wafer damage.

The finished wafers are oxidized i.e. a very thin coat of oxide is formed on the surface

before they are used for wafer fabrication. This protects the wafer from damage while they

are transported to the fabrication section.

1.2.2

Semiconductor Fabrication

The wafer fabrication process comprises of four major operations [3]:

1. Layering/Oxidation

2. Patterning

3. Doping

4

4. Heat Treatment

Layering is the process of either growing or depositing layers of materials on the

wafer surface. These layers can be grown by oxidation process in which the silicon wafer is

exposed to high quality oxygen. Chemical vapor deposition is a deposition technique,

which deposits a film on the wafer surface by a chemical reaction of a gaseous mixture.

Patterning also referred as photolithography follows layering. “In photolithography

the required circuit pattern is first formed in photo masks and transferred onto the surface

layer(s) of the wafer through the photo masking steps [3]. The detailed circuit pattern is

obtained by applying several times the photo mask layers. It is a sequential process, which

undergoes:

a. Photo resist coating

b. Etching

c. Photo resist removal

In this process a layer of coat, resistive to etchant is applied on the oxidized layer of

wafer. The mask with circuit details is then aligned perfectly to the wafer layer and is

exposed to ultraviolet light. The mask protects the photo resist portion of the layer, which

need not be developed. The exposure of photo resist to ultraviolet light changes the

properties of resist from a soluble to an insoluble one. The soluble portion is the portion

covered with mask. Developers (chemical solvents) are then used to remove the soluble

portion of the photo resist. The portion of the wafer with photo resist coating developed

dissolves in the etchant. This results in the required circuit pattern on the wafer surface.

The photo resist coating is then removed so that a new layer can be applied again to

obtain the desired circuit pattern on the wafer surface. This process of photo resist

application, etching, and removal is repeated until the final circuit is obtained. The wafer

needs to be doped by impregnating dopants in the wafer surface. This is done to create Ntype or P-type regions in the wafer surface which further act as regions for operation of

circuit components like resistors, capacitors. Doping can be done by thermal diffusion or

by ion implantation. Thermal diffusion is the process of heating the wafer around 1000 º C

and then exposing to dopant vapors. In ion implantation, the ionized dopant atoms are

accelerated and shot on the wafer surface. The crystal structure is disrupted by the ion

implantation in the doping process. Heat treatment is heating and cooling the wafer to

5

relieve any stresses and deformations caused during previous operations. This process is

carried out at 1000 ºC and known as annealing.

1.2.3

Assemblies, Encapsulation and Packaging

The dies or individual chips are tested for their electrical properties by using special

probes connected to a programmable computer. The good and bad dies are sorted by some

identification marks. The wafer is now ready for the packaging process [3].

1. Backside preparation

2. Die separation and pickup

3. Die attach

4. Wire bonding

5. Encapsulation or sealing

6. Lead plating and trimming

7. Package marking and final testing

The wafer undergoes different processes in the wafer fabrication. Some of the

processes cause damage to the rear side of the wafer. These imperfections are removed by

removing a thin layer of rear surface either by back grinding, chemical - mechanical

process like polishing, or etching. Thicker dies need bigger packages. Also, in the die

separation process, the saw needs to cut the material to even lower depths. All of these

imperfections can thus be eliminated by backside preparation [3].

The die sort process separates good and bad dies on the wafer surface. The good

dies are then cut through the wafer and placed on a carrier plate. Die separation can be

achieved by either using a diamond scriber or by using a diamond saw. The scribing and

sawing actions are partially done and are followed by die stressing. The stressing is

accomplished by rolling a cylindrical roller on the wafer surface. Further the good dies are

attached to the package and this process of attaching a die to the package is termed as Die

attachment. This process acts like a permanent physical bond between the chip and the

package; it serves as a conducting or insulating medium in the electrical circuit, and as a

heat dissipation medium from the chip to the package. Once the dies are attached, the next

process is wire bonding. Wire bonding is the process of making electrical connections

between the chip-bonding pad and the inner leads of the lead frame to connect the chip to

the leads. Different methods like thermo-compression, thermo-sonic, and tape automated

6

bonding are used depending on the wire material. Commonly used wire materials are gold

and aluminum for their good electrical conductivity and ductility [3].

The chip is now ready for encapsulation. It encloses the chip in a protective

enclosure. The enclosure can either be made of metal, ceramic, or epoxy. In metal

enclosures like metal cans, the sealing is achieved by welding the package base to the cover

metal lid. In ceramic and epoxy enclosures, the base package along with the top cover are

passed through a conveyor furnace or placed in an oven at a temperature ranging from 300400 °C. Encapsulation is followed by lead plating and trimming. It is the process of plating

the leads of the package by tin, solder or gold. This increases the solder ability of leads to

the application like printed circuit boards. The plated leads are then trimmed properly. At

last, the finished chip is marked with specific information like product type, specifications,

lot size. The final chip is then tested for electrical, functional, and physical properties. Once

it is cleared through the inspection, the chips are packed and ready for shipping [3].

1.3

The Semiconductor Industry Analysis

The semiconductor industry is one of the major developing industries in the

manufacturing sector. Since 1950, it has become a key for advancement. The nation’s

technological growth is believed to be related with its development in the electronic sector.

With the small scale integration era which had 50 components per chip at the maximum has

changed to more than 1 million components per chip. Over a period of 50 years, the

technology has improved a thousand times. The US semiconductor industry is a $150

billion dollar plus enterprise with an expected growth rate of 10 % for the period 2001 to

2005. The computers and telecommunications sector itself demand 65% of the

semiconductor market share for the year 2001 [7]. As can be seen in Table 1.2 and Figure

1.2, the number of components per chip for the small scale integration (SSI) era was

limited to a maximum of 50. On the other hand, ultra large scale integration required use of

over 1,000,000 components per chip.

7

Level

SSI

MSI

LSI

VLSI

ULSI

Components per chip

2 - 50

50 - 5000

5,000 - 100000

100,000 – 1,000,000

>1,000,000

Table 1.2: Level of integration [3]

Components per chip

1,000,000 1,500,000

10,000,000

100,000

1,000,000

100,000

5,000

10,000

1,000

50

100

10

1

SSI

MSI

LSI

VLSI

ULSI

Components per chip

Figure 1.2: Integrated circuit development

1.4

Economic Profile and Trends

The US semiconductor industry employs 198,000 workers around the country, with

a 100,000 production task force. There were approximately 980 companies in the US alone

in 1997, manufacturing semiconductors of different varieties and specifications as against

823 companies in 1992; a 19% growth. The shipments reached a value of $78 billion as

against $33 billion, a 135 % growth. Figure 1.3 shows the worldwide end use of

semiconductors. The major consumers are the computers and the communications industry

[4]. The hourly wages of production workers were $16.36 in the year 1997. The statistics

are shown in Table 1.3 [5].

8

Figure 1.3: Worldwide end use of semiconductors [7]

Companies

Employment

Production workers

Value of shipments

Production worker hourly wage

980

198,119

105,781

78 billion dollars

$16.36

Table 1.3: Semiconductor industry statistics for year 1997 [5]

From Figure 1.4, it is evident that integrated circuit (IC) manufacturing industry is growing

Figure 1.4: Integrated circuit unit and revenue growth [4]

9

each year at a rapid pace. Also, apart from the global competition, the industry has

managed to maintain the average revenue level.

The worldwide semiconductor shipments reached an all time high value of $200 billion in

the year 2000 with US market share of 70% as can be seen in Figure 1.5 and Figure 1.6

respectively.

Worldwide Semiconductor shipments

Billions of Dollars

250

200

150

100

50

0

90

91

92

93

94

95

96 97

Year

98

99

00

01

02

Figure 1.5: Worldwide semiconductor shipments

American Market Share

Percent Market share

80

70

60

America

50

40

Japan

30

Other

20

10

0

91

92

93

94

95

96

97

98

99

Year

Figure 1.6: Percent market share

10

00

01

Table 1.4 enlists some of the major semiconductor fabrication units in Texas State. It can

be seen that National semiconductors manufacture 44,000 wafers/month [6].

Table 1.4: Texas State Fabrication units enlisting product type and throughput per month [6]

1.5

Energy Use in Semiconductor Industry

Semiconductor industry accounts for 1.3% - 2% of the total US electricity

consumption in the manufacturing sector. Energy in the form of electricity is required to

operate the process equipment, maintain the clean room conditions, Heating ventilation and

air conditioning units, and chillers. The energy information administration a part of

Department of Energy released a statistical report on energy consumption by US

manufacturing sector for the year 1998. It revealed that about 46 Trillion Btu’s of energy is

consumed by the Semiconductor Industry [7].

A typical semiconductor factory uses electricity which would at least serve 7,000 to

8,000 homes [8]. Also, it is a major consumer of natural gas. For the year 1998, the US

11

semiconductor industry consumed around 19 billion cubic feet (0.25 % of total 7,231

billion cubic feet) of natural gas [7].

Opertaing Costs

Support

3%

DI w ater

5%

Process Tools

39%

Proces s w ater pumps

4%

Proc ess Tools

Nitrogen Plant

5%

Chillers and Pumps

Rec irc. and Make-up Fans

Fans

Fans

6%

Nitrogen Plant

Process water pumps

DI water

Recirc. and Make-up

Fans

17%

Chillers and Pumps

21%

Support

Figure 1.7: Operating costs of a clean room plant [8]

The process equipment contributes to around 40% of the operating costs as shown

in Figure 1.7. The Heating ventilation and air conditioning units take the heat released by

the process equipment and occupants to maintain the clean room conditions. They account

for 40% - 45% of the total costs.

Figure 1.8: Annual energy consumption for semiconductor fabrication units in California State [10]

12

Most of the semiconductor fabrication units are located in California. As per the California

energy commission, the state had the highest energy consumption of 800 GWh in the year

1997 for San Francisco alone as shown in Figure 1.8 [10]. As seen in the Table 1.5, the

semiconductor industry is the highest consumer of electricity and natural gas in California

State. It accounts for 1,527 million kWh for the year 1997 which is 1,527 GWh [10].

CA Electronics Industry Energy

Consumption 1997

Electricity (million

KWh)

Natural Gas (million

Therms)

Electron Tubes

94.285

0.968

Printed Circuit Boards

410.182

3.324

1,527.413

23.596

Electronic Capacitors

26.801

1.546

Electronics Resistors

2.498

0.009

Electronic Connectors

65.875

0.371

Misc. Electronics Components

504.204

10.774

Electronic Computers

373.123

8.773

Computer Storage devices

468.036

1.479

8.826

0.485

Misc. Computer Peripheral equip.

146.999

0.753

Telephone and Telegraph equip.

222.118

0.957

Radio and TV Broadcasting Equip.

449.243

1.987

4,299.603

55.022

Industry

Semiconductors & Related devices

Computer Terminals

Total

Table 1.5: Electronics sector electricity and natural gas consumption for California State [10]

1.6

Energy Intensity

The energy intensity in semiconductor manufacturing varies based on the process.

Some processes use high energy consuming equipment and some use medium to low

energy consuming equipment but with high precision. As seen in the flowchart in Figure

1.9, the processes under bold dotted boxes represent high energy consuming processes.

Elements in the faint dotted boxes and continuous line boxes represent medium and low

energy consuming processes respectively. Processes like crystal growth and ingot

formation, oxidation, and doping use significant amount of energy. These involve high

energy end use equipment such as furnaces. Figure 1.9 also describes the energy balance in

semiconductor manufacturing. For example, in the third step i.e. oxidation/layering, electric

13

energy is used by the furnace as input and hot exhaust gases exit the furnace from the stack.

It also involves use of gases such as O2, H2, N2, and Steam.

Polycrystalline Silicon

Dopants

1

Electricity

Crucible Furnace

Stack

Ingot

Electricity

Scrap

Ingot Facing, Grinding, Slicing,

Polishing

2

Scrap

Wafers

Electricity

Stack

Oxidation

Diffusion Furnace

300 – 1200 ° C

3

O2, H2, N2, Steam

Electricity

4

Chemicals

Patterning

Scrap

Photos resist Coating

Etching

Heat

Photo Resist Removal

Doping

Diffusion Furnace

5 900 – 1200 ° C

Electricity

Dopants

Wafers

Scrap

6

Heat Treatments

Energy Intensity

High

7 Die Separation and Pickup

Electricity

Medium

8 Die Attach

Low

9 Wire Bonding

10

Encapsulation or Sealing

Chips

Figure 1.9: Semiconductor manufacturing energy balance

14

1.7

Cogeneration

Cogeneration is done by most of the semiconductor device manufacturers.

Semiconductor industry is strongly dependent on high power quality and reliability. Recent

blackouts in California and northeastern states have raised the need for onsite power

generation. Some of the advantages of cogeneration would be control over the own power

plant to increase reliability, constant cost for power over a long term, and control over

power quality. Advanced micro devices, a semiconductor fabrication unit has cogeneration

plant at their manufacturing site. Onsite power generation helped reduce the annual CO2

emissions by 20,000 metric tons. Texas Instruments also realized reduction in power costs

by 30% [11]. “A study by the United States Federal Government for their facilities showed

that cogeneration became feasible for all types of machines at about $0.15/kWh as seen in

Figure 1.10” [11].

Figure 1.10: Breakeven analysis for $/kWh rates possible by cogeneration [11]

1.8

Need for Research

As stated earlier that the process equipment account for 40% of the operating costs

for a semiconductor fabrication unit. The minimum energy use for processing an 8 inch

wafer by implementing the energy efficiency measures would not be less than 450 kWh

15

[8]. This amount accounts for energy used by the equipment, the HVAC system for

cleanroom, and de-ionized process water. Since a significant amount of energy is used by

the process equipment, it becomes necessary to determine process parameters which define

energy. Once the parameters are defined, sensitivity analysis could be done to study the

effect of change in parameters with respect to energy. Sufficient amount of research is

being done on the HVAC and plant clean room requirements. Efforts are made to estimate

the energy consumed by the process equipment/manufacturing process, but no effort is

done to specifically determine the production parameters and analyze its effects on energy.

Present day energy estimation methods use power meters to monitor the power

consumed by equipment for a specific period of time. The methods used are risky and not

safe enough to be carried out by any operator and also consume a lot of time. An electrician

will be required to connect all the current and voltage probes to the control panel of the

equipment. These methods can only estimate the energy but cannot provide information on

production parameters responsible for it. Semiconductor fabrication units cannot afford to

have shutdowns even for a short duration of time. As compared to the other manufacturing

industries, here the process uses a significant amount of support energy in the form of

HVAC and clean rooms. The technology used in electronics sector is changing rapidly,

almost every six months. In order to be up to this mark so as to accommodate changes in

technology, the fabrication units undergo severe changes in infrastructure almost every

year or a two. Fierce competition amongst the fabrication industries nationally as well as

internationally demand for even lower costs. Hence, continuous operating cost reduction is

necessary to make the payback on these high investments attractive. Here lies an

opportunity to study and analyze the manufacturing process which is a key component of

operating cost in a semiconductor fabrication unit. Hence, an investigation in this area will

help the production managers in the wafer fabrication facilities to effectively use the

process equipment based on the results obtained from this work.

1.9

Research Objectives

The aim of this research is to determine the process equipment and support energy

in the semiconductor manufacturing process. The goal is to apply the research objectives to

all the energy intensive processes in semiconductor manufacturing.

16

A layering technique, “Oxidation process”, and a diffusion process – “Doping” in

semiconductor manufacturing are studied. A computer based interactive model in C ++

referred to as Semiconductor Energy Calculation Program (SECALPRO) is build to

estimate the energy consumed by these processes. The SECALPRO also determines the

support energy required for a specific operation. A system schematic is shown in Figure

1.11. The specific objectives of this research can be listed as follows:

1. Energy utilization and analysis in semiconductor manufacturing.

2. Sensitivity of production parameters with respect to energy consumption.

3. Verification and Validation of the designed SECALPRO model.

Input

Process

parameters

Output

Process Energy

+ Support energy

User

Model

No

Satisfied

Yes

Exit the System

Figure 1.11: System schematic

1.10 Conclusion

Increasing energy costs and dependability on foreign energy sources no further

allows neglecting energy conservation. The operating cost of a semiconductor fabrication

unit is a function of its energy requirement. Constant hike in energy costs and limited

availability of finance puts a never ending need of curtailment of the operating costs in the

production facilities. Process energy requirement must be analyzed in order to be

minimized. Energy awareness atmosphere alone doesn’t really help achieving energy use

optimization, but also needs energy quantification background along with it. It is wise to

say here, that energy or anything that matters can be saved only when it can be quantified,

and the factors affecting it can be defined. Also, replacement of physical energy

17

quantification with an equivalent reliable method is important. Hence, an interactive model

SECALPRO was built to determine the energy requirement of energy intensive processes

in semiconductor manufacturing. Based on the process parameters, the energy requirement

in semiconductor manufacturing could then be estimated, analyzed and studied for energy

conservation opportunities.

18

Chapter 2

2 Literature Review

2.1

General Energy Management Activities

Several energy management activities have been carried out in the U.S.

manufacturing sector. These involve initiatives taken to monitor process energy using

various control systems. Energy auditing also plays a major role in providing energy

management services. Several government funded research oriented organizations such as

Industrial Assessment Centre (IAC) perform these kinds of activities on a daily basis. Also,

private organizations are getting involved in most of the energy management and

conservation services.

Energy management through energy auditing activities is performed throughout the

Nation. A study by Packer [12] discusses about the energy audit performed at the Hewlett –

Packard Company (HP) Facility in Loveland, Colorado. The facility is a state of the art

involving research, wet process manufacturing, assembly and test, and surface mount

technology. Out of the total six buildings in the plant covering 1.1 million square feet area,

five buildings were audited. Important areas concerning energy such as utility management,

demand side management, developing an energy strategy, renegotiating gas costs were

implemented. Based on the recommendations from the energy audit from the regional IAC,

HP developed a utility monitoring and analysis system. It involved utility quality

monitoring, power management, integratability of monitoring systems, modeling of utility

flow, and data storage. It also collects and stores data such as kWh, amperage, power

factor, kW, and kVA. This information is further shared by several users and software

applications.

Energy conservation and management has applied Expert systems to develop

interactive software systems. Gopalakrishnan, Plummer, and Nagarajan [13] developed

computer

software

ENERGEX

capable

of

recommending

energy

conservation

opportunities (ECOs). It deals with opportunities in the area of lighting, boilers, motor

drives, and compressed air system. The software aids the user in arriving at appropriate

ECOs by presenting an interactive questionnaire. Based on the information input to the

19

system, corresponding ECOs are generated. It also provides an expert advice and

information on the generated ECOs and in general.

Dunning, Segee, and Allen [14] developed software for the self assessment of any

manufacturing facility. The software is capable of providing the common recommendations

provided by the U. S. Department of Energy’s, Industrial Assessment Program. Its

simplicity even enables a computer novice. It leads the user through an assessment of their

total facility. Once, the user inputs the necessary data, appropriate recommendations are

generated by the software. It is also an Expert system application successfully used as an

energy management tool.

Throughout the U.S., it is found that corporate practices regarding energy

management are uneven. Some facilities have strong energy management and conservation

policies while some are even unaware of it. Norland and Lind [15] made a study on

companies exhibiting best energy management practices. These companies do have a

strong commitment to reduce energy use and costs based on continuous energy monitoring.

One such company is the Owens Corning, manufacturers of fiberglass insulation products.

They have a three step approach on energy conservation and management: first, creative

procurement of energy resources, second, critical assessment and improvement in energy

quality, and last enhancement of energy efficiency. This approach is implemented by the

organization throughout. It resulted in annual savings of twelve million dollars for the year

1999.

Another example of corporate involvement in energy management activites would

be 3M [15]. This facility has been tracking its energy use since 1973. They have a target of

3 % reduction in energy usage per unit of output per year. Each 3M facility voluntarily

implements energy efficiency projects. They have a separate energy management

department which handles the energy usage data reported by these individual facilities.

Based on the quarterly reports, the management and application of energy conservation

policies becomes easy to implement. These activities are estimated to save approximately

2.7 million tons of carbon dioxide each year.

“As the field of energy management matures, so do the tools and best practices

available to ensure that the energy required by an organization is used in the most efficient

way possible. In the past, energy management practices consisted primarily of replacing

20

inefficient equipment and then using any number of methods to estimate the savings

gained. Studies performed by the Department of Energy (DOE) and the Texas State Energy

Conservation Office (SECO) have shown, however, that energy savings can be

dramatically increased and maintained over time by adopting and implementing consistent

energy management practices and recognized measurement and verification procedures. As

energy management standards and best practices begin to see widespread adoption, the

information systems required to support them will play a crucial role in their

implementation and success. These enterprise energy management (EEM) systems can

provide the detailed data and analysis capabilities required to ensure energy management

strategies and conservation measures are on track throughout an organization.

Organizations can apply EEM systems to gain a comprehensive understanding of current

energy performance, plan and select cost-effective energy conservation measures, track

performance of measures that have been implemented and verify the savings realized” [16].

Energy quantification on an individual equipment basis and also on a facility wide

energy monitoring system has been developed. Guidelines on energy quantification for

semiconductor manufacturing and equipment utilities are discussed. The semiconductor

equipment association of Japan (SEAJ) presented certain guidelines to calculate the energy

consumed by the semiconductor manufacturing equipment and in the clean room. The goal

of this study is to estimate the energy consumption of the plant utilities for the equipment

and items related to the equipment. These guidelines mostly deal with the use of power,

exhaust air, vacuum, dry air, cooling water, and ultra pure water by the equipment as well

as clean room energy [17].

The electric power measurement is carried out in three states viz. startup state,

processing state and idling state. An electric power meter and a voltmeter are used to

measure the equipment electric power in kW. The total process time is recorded for a

specific process. Processing energy per wafer can then be obtained by using the following

formula:

Processing Energy per wafer [kWh]

=

[kW] x [h]

N

Where;

[kW] : - Average Electric Power in kW’s

21

2.1

[h]

: - Wafer processing time in hours

N

: - Number of wafers processed during the time period

Energy Efficiency Survey for semiconductor manufacturing tools and equipment is

discussed. An Energy Analysis Survey (EAS) of a semiconductor plant in Santa Clara, CA

was done by XENERGY. The field study was conducted for the period between March 18,

1998 and May 12, 1998 by monitoring the load on the equipment [18]. Of the various

tools/equipment used in the facility, the XENERGY survey team monitored some of the

major equipments. A diffusion furnace was one of them. Diffusion furnaces are used for

chemical vapor deposition, which is one of the layering techniques. The facility had three

diffusion furnaces. The electrical service panel that distributes power to the diffusion

furnaces was monitored for the time period April 7th-April 16th. The data was monitored on

24 hour basis. The panel has three wires, three phase delta electrical configuration. The

current of each phase is measured and results show that the load is fairly balanced. The data

obtained from the study shows that the load is relatively constant the majority of the time.

Short duration spikes are most likely the result of inrush currents caused by the start up of a

furnace. The average load over the monitoring period was found to be close to the rated

current. The facility practices some energy efficiency activities to date. The important ones

are briefly listed further. The semiconductor plant in Santa Clara, CA has installed an

Energy Management System manufactured by Johnson Controls to monitor and control the

building systems. This system is set up to monitor critical data regarding the performance

and energy consumption of the building’s mechanical systems. Graphic representations of

building systems aid the facility staff in operating and controlling all of the support systems

in the building. Alarm points are set up to alert the building staff of equipment or outputs

needing immediate attention. This system enables trending of data to follow items of

interest over time and provide data needed for fine tuning various outputs. For example,

this feature is utilized on an ongoing basis to monitor temperature and humidity in the clean

room spaces and it was used to obtain useful data for this report on other system sensor

points.

Utility Consumption Characterization Protocol for Semiconductor Tools is an

article describing the methodology to determine power and energy requirements of

semiconductor tools. It addresses specific requirements for measurements and provides

22

electrical fundamentals for data interpretation and analysis. The system describes process

for monitoring the energy use by connecting the current and voltage probes to the control

panel of the equipment [19].

2.2

Productivity Improvement Activities in Electronics Sector

Product life cycles in electronics manufacturing are short. This in return demands

shorter design cycles [20]. Software tools can thus accelerate this design process to suit

short term product life cycles. The purpose of this study was to see how software tools help

in increasing the productivity of design process. The study also focuses on the risk

associated with the dependability on design software tools. A minute error on part of the

user might cause a complete rework.

Chatterjee’s [21] work on microelectronics industry stated that, the semiconductor

industry success will be governing the future of semiconductor industry. He mentions about

a productivity engine which cycles. The cycle starts from exponential trends in technology,

which will enable expansion of markets and revenues, which will further enable large

research and development. Continuous development in semiconductor devices helps keep

the cycle running.

Hong, Kim, Hang and Chae [22] in their article on “Throughput Analysis and

Productivity Enhancement for Chemical Vapor Deposition (CVD) Equipment”, stated that

the equipment efficiency and the productivity can be analyzed based on the history log. It

was found that there can be either a transfer bottleneck or a process bottleneck. Transfer

bottleneck could be nullified using productivity enhancement techniques, whereas process

bottleneck could be verified using process techniques.

2.3

Energy Efficiency Initiatives and Best Practices in Electronics Manufacturing

The Pacific Northwest Pollution Prevention Resource Center published a report

under the heading “Energy and Water Efficiency for Semiconductor Manufacturing” [9].

This report puts emphasis on improving the energy efficiency of the semiconductor

fabrication unit. Specific energy efficiency opportunities are presented to reduce energy

consumption and the associated energy costs. The opportunities are mainly categorized into

HVAC, Clean room, Process tools, and support utilities. The process tool opportunities

discuses about using high efficiency tool components such as motors, fans, pumps,

23

compressors. Efficient lighting systems result in high energy savings as well as reduction in

cooling load. Vacuum systems should be located as close to the application to reduce loss

of energy. Clean room energy conservation opportunities include, lower clean room make

up air flow rates, use of variable flow drives for recirculation and exhaust fan motors.

Major emphasis is put on reducing the clean room volume. Implementing these will reduce

the quantity of fresh and makeup air circulations, which in turn would, need lower clean

room energy requirements [9].

United States Environmental Protection Agency believes that moving of air to,

through and out of the clean room is the major concern for high energy consumption in

fabrication units. Reducing the amount of air flow or increasing the efficiency of the

equipments used for circulation will achieve significant savings. To verify the above

methodology, EPA modeled a hypothetical fabrication unit with a total square feet area of

16,000. The fabrication unit could manufacture wafers of size 125 mm. With reduction in

air velocity from 100 fpm to 90 fpm, a 10 % reduction resulted in a 27 % reduction in

power requirements [1].

Motorola has nine semiconductor fabrication units around the world implementing

significant energy conservation projects. Some of the major steps to achieve energy

conservation are discussed here [8].

•

Manufacturing tooling power consumption during idle times: Most of the

facilities do not operate for 100% utilization. Process tools like vacuum pumps in

turn consume more energy at the idling state. Significant energy savings can be

realized by turning off these equipments in idle conditions.

•

Clean room air velocity reduction: High efficiency particulate attenuation (HEPA)

filters are used in the plant clean rooms to maintain the specified class room

levels. It is observed from studies that reducing the air velocity from 90 fpm to 70

fpm does not have any effect on the clean room conditions, room pressurization,

and temperature and humidity set points. A substantial amount of energy is saved

alone by this implementation. Throughout its nine fabrication units, Motorola

achieved an average saving for $378,000 per year for a total clean room area of

380,000 square feet.

24

•

Other practices include optimizing chiller operating conditions, and exhaust

reductions: Water conservation energy savings are also one of the important areas

amongst those described earlier. A facility at Austin TX can save as much as 5.11

kWh of energy in order to pump 1,000 gallons of water. Most wafer fabrication

units use as much as 3 million gallons of ultra pure water per day. On an average

1,500 gallons of city water makes 1,000 gallons of ultra pure water [9].

At Toshiba a cogeneration system uses gas turbine with an output of 4,520 kW. The

cogeneration system operates from 8 in the morning till 10 in the night to reduce the

daytime load on the commercial power requirement. It also satisfies the steam requirements

of the plant. “Because the load reduction in the daytime raised the ratio of night-time power

use, the plant could make an adjustment contract based on the daily demand period. By

increasing the contract, demands in off-peak rate periods (22:00 - 8:00 on weekdays and all

day on Sundays and national holidays), and the plant now enjoys a very low-priced offtime rate by operating highly efficient turbo refrigerators in off-time.” The plant also

replaced motors with energy efficient ones and is now enjoying the benefits of lower

energy consumption [37].

2.4

Conclusion

The above literature describes energy management, quantification and conservation

in semiconductor industry and the measures taken towards reducing the energy cost in

semiconductor industry. It can be seen that significant research has been carried out in the

area of energy conservation in HVAC and clean room energy use. As stated earlier, process

tools consume a significant amount of process energy. There is an urgent need to identify

the production parameters which drive energy used for process tools. Literature is thin on

the determination of production parameters for a specific manufacturing process. Also, the

effect of these parameters on energy is yet to be analyzed. Developing a model such as in

any of the programming languages will give a better understanding of the use of process

energy as a whole without any interruptions in the production cycle. Also, models such as

these will help in sensitivity analysis of the parameters with respect to energy. Thus

research in this area will be of immense help to the semiconductor industry for analyzing

and improving on their energy efficiency.

25

Chapter 3

3 Research Approach

3.1

Methodology

The goal here is to estimate the energy used in semiconductor manufacturing. Not

all processes in semiconductor manufacturing are energy intensive. Referring to Figure 1.9

in Chapter 1 Introduction, it is found that layering and diffusion are the two energy

intensive processes in semiconductor manufacturing. Hence, it becomes necessary to

determine the manufacturing parameters for these two processes which are most sensitive

to energy.

Oxidation, a layering technique and doping, a diffusion technique are therefore

studied. Hence, an effort is made to apply the research approach to these processes. Before

going into detailed analysis in Chapter 4, Model Development, and Chapter 5, Results and

Sensitivity Analysis, relevant information regarding oxidation and doping processes is

described.

3.2

Oxidation/Layering

When a bare silicon surface is exposed to oxygen, the surface layer turns to silicon

dioxide. Silicon dioxide is a molecule having two atoms of oxygen and one atom of silicon.

Silicon is a semiconducting material and the silicon dioxide layer formed acts as a

dielectric (insulator). This combination of a semiconducting material with a dielectric

makes it one of the most commonly used layers for the semiconductor devices [23].

The important uses of silicon dioxide layer on a silicon surface are as follows [23]:

1 Surface passivation

2 Doping Barrier

3 Surface Dielectric

4 Device Dielectric

Surface passivation

Semiconductor devices are prone to contamination. Enough measures are taken to

limit the quantity of impurities in a clean room, but still there are minute particles left

which can cause the device to malfunction. Silicon dioxide layer serves this purpose of

26

protecting the silicon layer from contamination. It protects the surface in two ways viz.

physical protection and chemical protection.

The wafer surface is sensitive to dirt and other contaminants. Silicon dioxide also

known as glass is one of the hardest and non porous materials. As can be seen in Figure

3.1, silicon dioxide acts as a physical protection layer on the silicon surface. It also protects

the surface from scratches and wear, during fabrication processes. Some mobile ions or

electrically active elements end up on the silicon wafer surfaces. If left on the silicon

surface may interfere with the device functionality. Silicon dioxide layer grown on the

wafer surface uses silicon from the wafer itself. Oxide growing thus raises the mobile ions

to the silicon dioxide surface and restrains them from reaching the wafer surface. The

mobile ions are less harmful when brought to the silicon dioxide layer.

Silicon Dioxide

Layer

Silicon wafer

Figure 3.1: Oxide layer formation

Doping Barrier

Doping is the process that puts specific amounts of dopants through openings in the

silicon surface. Most of the dopants have a very low rate of movement in a silicon dioxide

layer as compared to the silicon. Hence only the exposed silicon wafer surface is doped as

shown in Figure 3.2.

Figure 3.2: Formation of doping barrier

Surface Dielectric

Dielectrics are also termed as insulators when used on an electrical circuit. The final

microchip or the end product has various layers of silicon dioxide with different circuitry at

each level. It is like a multi storied building. The silicon dioxide layer acts as an insulator in

between them. The oxide layer that covers most of the wafer surface is called a field oxide.

Figure 3.3 depicts the application of silicon dioxide layer as a surface dielectric.

27

Metal Layer

Silicon Dioxide Layer

Silicon wafer

Figure 3.3: Surface dielectric formation

Device Dielectric

The thin layers of silicon dioxide grown in the gate region are called gate oxides.

The gate is that part, which controls the operation of the device. It is used in Metal Oxide

Semiconductors (MOS) transistors. It is used to separate the metal from the semiconductor

and acts as the dielectric in the capacitor formed between metal and semiconductor.

3.3

Thermal oxidation process

The silicon dioxide layers are grown on the silicon surface by a method known as

thermal oxidation. The thermal oxidation process is carried out in the temperature range of

900º C to 1200º C. The atmosphere in the furnace where oxidation takes place can contain

either pure oxygen or water vapor. Oxygen arriving at the silicon surface then combines

with the silicon to form silicon dioxide.

Initially the reaction between oxygen and silicon at the surface is a surface reaction

only. After a specific thickness is build on the silicon surface, the oxygen molecules must

diffuse through the already grown silicon dioxide layer to reach and interact with the

silicon surface. The growth of silicon dioxide takes place in two stages viz. linear stage and

parabolic stage. The initial stage is called linear because the oxide growth is uniform for

each interval of time. After a thickness of about 500 angstroms or 0.05 microns is achieved,

a certain limit is imposed on the growth rate. This is due to the resistance or barrier

developed by the grown oxide. Either the silicon atoms or the oxygen atoms must move

across the silicon dioxide layer to further react. The oxygen diffuses through the oxide

layer to the silicon surface to form silicon dioxide. The source for the silicon is the wafer