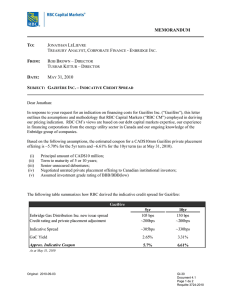

Title Course Code Student name Student ID Due Date Name of the Company Enbridge Inc. Chapter 2 Conceptual Framework Of Supply Chain Management Literature review of the Supply Chain Management Strategy According to Bozarth et al. (2009) and Pathak et al. (2007), the entire supply chain is a complicated adaptive structure. This structure is composed of connecting design and architecture, in addition to external factors and systems relevant internal components as given by (Melnyk et al., 2013). The supply chain strategy element can be thought of as a research project into how a supply chain needed to work smoothly to effectively participate. This happens by evaluating the expenses, advantages, and compromises in the various operational elements that comprise the distribution network. In addition, supply chain management is the method that transforms supplies into a result. This provides an ongoing emphasis where verification ought to continue across a long period of time (Mentzer et al., 2001; Saad et al., 2002). Based on the results of Mckone et al. (2009), there's proof that businesses often fail to connect the supply chain approach to their competitive strategy. These results raise concerns about the development of method as an effective supply chain approach demands an ongoing dedication to long terms relationships with partners: sharing the same goals, integrated procedures, behavior as well as cooperation, and a reciprocal exchange of: information, hazards and advantages (Mentzer et al., 2001). On the contrary, the interorganizational and cooperative collaboration among those involved in the supply chain necessitates a connection that brings together assets, grows capacity, and cooperates. This blend of views from every individual affects the efficacy of each other (Mentzer et al., 2001), and the competitive edge of the group depends upon the strategic 'alignment' of tasks (Sakka et al., 2011). 2.1.Supply Chain Management strategy of Enbridge Enbridge keeps relationships with many different vendors including manufacturers, developers and independent contractors, retailers, and advisors, who supply it a variety of goods and services. They are needed for creating pipelines as well as the infrastructure, equipment, parts, and services necessary for project development, implementation, and management. The achievement of Enbridge is contingent upon the vendors they work with. Enbridge's integrated Supply Chain Management (SCM) splitting, which is responsible for of all logistical activities involving strategy and leadership, operational and strategy buying, handling of materials, transportation, and handling contracts, defines the way it handles its supply chain. A centralized staff dedicated entirely to accelerating its sustainability, variety of suppliers, and Indigenous engagement efforts constitutes another component of its SCM function. 2.2.Legal, regulatory and contractual obligations Enbridge's Legal Obligations In addition to 250 legal professionals across the United States and Canada make up of Enbridge's extensive Legal Services group, and they work diligently in 15 different subject groups. A significant percentage of these lawyers have come from several various histories, including private legal companies, public groups, and not-for-profit organizations, amongst others. The company believes one will be capable of getting all the support one needs to be effective in legal education as well as throughout the rest of one's career by drawing from the wide range of company's legal training skills. Enbridge's dedication to finding creative legal solutions The United States Department of Justice and EPA accepted claims from the 2010 Marshall, Michigan, and Romeoville, Illinois, oil catastrophes with Enbridge Energy limited liability company and many affiliated Enbridge businesses right now. Enbridge is going to spend at least $110 million to avoid leaks and enhance operation on approximately 2,000 miles of the company's Great Lakes pipeline system. Enbridge will pay $62 million in civil penalties for Clean Water Act incidents, $61 million for throwing at least 20,082 gallons of oil in Marshall and $1 million for dumping at least 6,427 barrels in Romeoville. The proposed agreement additionally addresses Enbridge's accountability under the Oil Pollution Act by demanding Enbridge to compensate over $5.4 million in unreimbursed costs incurred by the government for Marshall spill cleanup and all the future evacuation expenses. Today's agreement contains multiple particulars designed to prevent accidents and enhance the detection of leaks in Enbridge's Lakehead pipeline system, which consists of 14 pipelines spanning over 2,000 miles over seven different states. Enbridge must also considerably boost accident preparation and emergency response. After obtaining all authorizations, Enbridge has to substitute almost 300 miles of a pipeline within the terms of the agreement. Enbridge's Lakehead System supplies 1.7 million metric tonnes of oil every day to the United States of America. “This agreement will make the transportation of our country's fossil fuels safer and more ecologically responsible,” said the Justice Department's Natural Resources and Environment Division Associate Assistant Attorney General John C. Cruden. Enbridge will improve the upkeep and surveillance of its Lakehead pipeline system to prevent damage to waterways, agricultural land, and villages all throughout the upper Midwest and paid a massive fine. Enbridge agrees to to the these steps under the agreement, which it thinks will amount to at least $110 million: Improved pipeline monitoring and spill prevention programmes should be developed; Improve the detection of leaks and manage room operations through the adoption of new procedures; A subsection of Enbridge's Line 5 in Michigan that traverses the Straits of Mackinac has to conform to extra detection of leaks and spill control standards; For its Lakehead Pipeline System, develop and oversee an integrated data; Four emergency spill action drills to evaluate and refine Enbridge's reaction to a major inshore oil leak as a component of its emergency spill reaction preparedness initiatives; By requiring incident management system training for employees, providing training to those who are taking part in area response planning, and organizing reaction drills, you can enhance foster education and coordination with state and local disaster services; Engage a third party who is neutral who will assist with the evaluation of the petition of the settlement agreement's terms. Regulatory and contractual obligations related to health and safety at Enbridge All of Enbridge's approaches to leadership are strictly regulated by contracts. As we observe from a brief overview of Enbridge's health plan, security remains the main concern when creating any sort of strategies. The six safety principles emphasise the fundamental principles that the company upholds as they seek towards an atmosphere with no accidents and zero injuries. These six guidelines also specify that each of these options must adhere to standards of safety and health. • It can be accomplished to prevent all accidents, happenings, and illnesses associated with work. • Every functioning exposure is regulated. • Safety outcomes is the duty of management. • Safety is a duty of all staff members, especially service providers. • Assessment and growth are important. • Company constantly encourage their employees for taking care of their safety and good health. Sustainability is integral to our ability to safely and reliably deliver the energy people need and want. How well we perform as a steward of our environment, a safe operator of essential energy infrastructure, a good neighbor and a diverse employer is inextricably linked to our business success and our ability to create long-term value for all stakeholders. Our environmental, social and governance (ESG) goals represent the next stage of our evolution as an ESG leader to ensure we’re positioned to grow sustainably for decades to come. Environmental protection at Enbridge Enbridge’s ESG goals include: Net zero greenhouse gas (GHG) emissions by 2050; with an interim target to reduce GHG emissions intensity 35% by 2030 Increased representation* of diverse groups within our workforce by 2025 including a goal of 28% from underrepresented ethnic and racial groups, along with new initiatives to enhance supplier diversity Strengthening diversity on our Board with a goal of 40% representation of women and 20% from underrepresented ethnic and racial groups by 2025 Annual safety and reliability targets that drive continuous improvement towards our goal of zero incidents, injuries and occupational injuries, and implementation of robust cyber defense programs Accountability at Enbridge Enbridge maintains a set of fundamental beliefs that help explain what the company represents as it deliver energy that fuels the lives of others. Enbridge employees assist our towns and cities, the natural world, and each other by engaging with security, honesty, kindness, and inclusion.Accountability at Enbridge, n.d. 2.3.PESTLE analysis of the company Political factors Non-governmental businesses, opposition and pressure groups, and activist movements impact the policies of the United States. To better meet public and business purposes, Enbridge ought to collaborate together with such organisations. Political stability in up to date markets—Enbridge operates in multiple nations and has to adapt its strategies to each country's Natural Gas Facilities companies. The present rise in populism all through the world could give rise to greater volatile markets in the United States of America. The US government faces increasing globally pressure for compliance with WTO greenhouse gas utilities regulations. Enbridge benefits from reduced west quarter taxation for a period of two decades. Profits and expenditures on research and development have risen. Wealth in the US could impact the tax code. Second, municipalities are looking into Natural Gas Utilities pricing methods for lowering the industry's greenhouse gas emissions. Enbridge have to manage differing rules in its marketplaces. Lately, the US and other developing nations have amended market doorway and local market operational standards for Natural Gas Infrastructure firms. Economic factors Inflation rate - The inexpensive liquidity in the markets following the devastating recession of 2018 will lead to prices to accelerate in the US gdp. Increasing trade liberalisation by the US could motivate Enbridge to increase its ventures in previously neglected markets. - Exchange rates - Enbridge's investment strategies could be affected by the unpredictable exchange rate for the US currency throughout an extended period as well as the short-term volatility of the currency. Social factors - Behaviour towards safety and well-being - As deregulation advances, views on safety have become less restrictive. The cost of failing in the United States is too excellent for Enbridge to follow these points of view. - Gender positions - In the United States, gender norms are shifting. Enbridge could look at an array of concepts in order to promote a shift in gender roles in American culture. - Social hierarchy and norms contrary among American culture and Enbridge's native marketplace. To provide better service to customers in the United States, it ought to attempt to create an indigenous staff that is mindful of cultural rules and views. - Easy access to all the required amenities - In general, throughout the past ten years and a half, much of the population in the United States has been granted possession of the services that are required. Increased spending on public services is partially responsible for such. Technological factors Enbridge licencing and transfer of technology worries - There is not an established tradition of innovation transfer in the energy business, and companies often reluctant to share or licence developments for worry about converting their partners into competitors. The chain of supply has been quickly impacted by advances in technology as it gives bigger participants in the utility company the ability to obtain data along with to supply chain partnerships. - The most recent technological advancements developed by Enbridge's competitors; this could provide us an accurate grasp of what competitors might be thinking as well as where the prospects of the Natural Gas Services company model rests. - Technology has reduced an item's life span and made it accessible to suppliers to generate fresh goods more quickly. The result has strengthened supply chain partners. This has positioned pressure on Enbridge's marketing department to advertise a variety of items in order that will satisfy the vendors. It enhanced the Enbridge's expenses for operation. Legal factors American requirements for safety and health, the measures that Enbridge has to take in order to meet them in their final days and the costs related to doing so. Business Regulations: The US's legal framework for the business system are those regulations in line with global organisations like the World Trade Organisation, the European Union, etc. Laws and regulations relating to the surroundings, as well as what Enbridge must do in accordance with themselves, are addressed. Environmental factors In the economy of the United States, recycling has quickly grown into a norm rather than a beneficial activity. Enbridge has created strategies that adhere to rules and standards in the energy market. - Renewable energy technology is possibly a further intriguing field for Enbridge. It could profit from its tendencies. The United States provides rewards to promote the development of the renewable energy sector. Bad weather additionally raises the price of operation for Enbridge as it must invest in improving the adaptability of the supply of the network. The management of waste, especially in installations right next to big center's, is growing becoming increasingly important for enterprises like Enbridge. For trash the leadership team urban areas, the US governance has implemented rigors rules. 3.1.Inventory Management Strategy By tracking operations in the entire supply chain, Enbridge Inc. can cut lower on delays, resulting in a positive effect on inventory management. An organization might be able to discover and capitalize on novel opportunities and decrease external dangers with improved information flow. The ongoing examination of the value chain may lead towards the prompt resolution of important gaps that may influence the efficiency of a business. Enbridge Inc.'s effective value chain analysis deployment could boost material and product flow owing to better customer demand and revenue predictions Baldwin & Evenett, 2014.The procedure of governing the inventory of a business in an efficient and organized manner, including the acquisition of items, the preservation and sale, and the replenishing, is commonly referred to as inventory management. For a business to be profitable, inventory management must include the management of materials that are raw, which are necessary to produce items and finished goods that could be marketed. Chang et al., 2016 In the framework of the value chain, "procurement" pertains to the procedures that take place in acquiring the inputs into the process, which could encompass any from machines and other machinery to supply chains, raw materials, and other supplies that must be obtained for the manufacturing process of a final product. Enbridge Inc. should carefully analyze its procurement operations to maximize efficiency throughout the incoming, functional, and outgoing value chains due to its recognition that it is connected to many different operations in the overall value chain. Enbridge uses a variety of methods for inventory management.By recording and assessing images as they occur in the natural world, the NPS inventory is intended to document viewers' opinions. The leadership team evaluate called Net Promoter Score (NPS) may be utilized to evaluate how well-maintained a company's relationships with customers are. NPS is gaining popularity as an essential metric often associated with the revenue prospective for the products or services offered by a business. The statistic is established by consumer responds to the following questionnaire: "How inclined are you, on a scale of 0 to 10, for recommending this piece of equipment to a friend?" People who give a score of 9 to 10 are considered to be Promoters and frequently associated with activities that add value, such as strongly urging others to utilize the good or service at question. Passive responses are those who provide an answer with a score of 7 or 8, and they have been considered to be less likely to demonstrate the producing value traits associated with. Promoters having a fundamentally neutral influence over other customers. Detractors typically individuals who rate the product between 0 and 6, are often unsatisfied customers and occasionally openly recommend avoiding adopting it. As Enbridge NPS is given 3.2.Application of Six Sigma Six Sigma is an approach to management which was developed by Motorola in 1986. It involves establishing high targets, collecting information, and analysing outcomes with the goal to reduce the overall number of problems that are found in products and services. It is being used in an extensive range of applications in industry. A systematic method for enhancing the quality of process outcomes along with variability reduction in business and manufacturing procedures is a different name for this idea ( Jirasukprasert P, 2014). . The implementation of DMAIC Six Sigma in computer systems has increased the flexibility in supplier chain-related challenges. Pepper, M. P., and Spedding, T. A (2010). With an abundance of accurate data and relevant details, it has been demonstrated that the incorporation of DMAIC Six Sigma to the supply chain management system has improved the effectiveness of delivering completed goods. Manuj, I., and Sahin, F.(2011). Through the sharing of knowledge derived from accurate and required data, DMAIC Six Sigma has also benefited from supply chain targets in terms of delivery of goods, response time, and prevention measures as stated by Liu, R., & Kumar, A. (2011).Just before the start of DMAIC Six Sigma, logistics expenses had an important impact on many businesses' yearly financial information, especially for transportation Goldsby, T. J., & Martichenko, R. (2005). despite this DMAIC Six Sigma for petroleum spill authentication, especially for the analysis of problems, has been impressive, it serves more purposes than that, as can be seen in the advancement of the procedures when dealing with a complex mixture of petroleum products with a high level of unpredictability. It is apparent that constant improvement continues to be searched by many investigators for accurate analysis procedures and methods of statistical analysis. Enbridge utilises just-in-time manufacturing to simplify operations while reducing expenses and lead times. The value of customers is given highest priority in the implementation of lean manufacturing all through all divisions, including manufacturing, advertising, and transportation. Just in time strategy According to its definition, JIT is "a managerial management structure, used for the scheduling and oversight of activities that must be carried out with the goal of the purpose of manufacturing and delivering the requested goods and services at the right time that are required at the correct location, and at the exact required quantities." R. A. Hokoma Eliminating wastage of all kinds is the characteristic of a JIT system, which can be done by scheduling all of the actions across the chain of production. In addition, JIT systems constantly try to enhance the Enbridge's complete supply chain underlying processes. A significant distinction between JIT and a system that uses JIT is that JIT is focused on the whole removal of waste. This is something that doesn't enhance the services and products in any manner Kanban system and Lean production Kanban is an approach of work/process timing with the goal at boosting manufacture by reducing down on wastage and time wasted. The expression "Kanban" denotes a means of buying and the actual payment card that is utilised to permit an upstream procedure or working location (or vendor or supplier) to re-supply a particular amount of components or elements, frequently exactly what was required in the next step or work their centre. Although numerous individuals who utilise Kanban purchasing processes make this oversight, Kanban isn't related to the container or what is contained within. Lean Production is a process which seeks to substantially decrease or eliminate unnecessary operations or wastage with the goal to lower unit costs and increase both quality and production efficiency. Kanban systems are an essential aspect of lean production environments. For the purpose for Lean Manufacturing environments to be productive and effective, Kanban organization procurement processes are essential. A crucial component of Just-in-Time and Organized Manufacturing settings are Kanban management systems for purchasing. Lean Manufacturing means minimizing waste during manufacturing. The production of equipment's uses standard and shared procedures for capitalizing on the commonalities between items. Since production layouts are the most efficient when employing JIT for initial supplies and component purchase, just-in-time and lean manufacturing are closely connected ideas. Work in progress (WIP) levels of inventory may be significantly decreased with JIT by employing new manufacturing framework. If these modifications are successfully implemented, companies will be able to "Build-to-Order" and create the items that customers want, when they're looking for them, in the quantities that are needed. This will inevitably end up in a significant decrease in the amount of inventory, together with savings and improved cash flow. 3.3.Information system at Enbridge It is now possible to store thousands of gigabyte of records from every aspect of the energy industry because to advances in technology, especially in information technology. R. K. Perrons, J. W. Jensen, and others (2015). The integration of these upstream company information, if recently obtained or obtained from files, once implied a laborious, everyday life, and ineffective task; similar to the control of Excel spreadsheets, even if there was bodily data, data disappeared due to human error when putting them into the application. Tools for managing data innovations in the petroleum and energy industry have been proposed by Hassani and Sirimal (2018): Enbridge constantly searches for methods to enhance the company's pipeline and complex security programmes via the application of technologies. Company made an investment in Syscor's technology in 2011, conducted a two-year trial programme in northern Alberta to assist in the research and development of FR-Tracker 2.0, successfully and currently have the device installed on five tank in the Fort McMurray region—with an additional installation planned shortly. The tank terminals team guarantees the dependability and safety of our network via periodic examinations and sound judgement. Based on Dr. Chris O'Neill, a technical manager with Enbridge's Research, Growth and Development, and Creative thinking (RDI) category, "boosting the programme with a 'always-on' tracking system helps ourselves identify tiny shifts and trends that occur in a roof's movement—developments that may offer a warning sign of an upkeep need and lead to greater reliability in operation. "Syscor's software can spot these initial indications and notify management there's something amiss worthwhile investigating—typically sooner than we would have other known—and that allows us act when the problem gets expensive to address," says O'Neill. Giving oneself the information you need to make prompt decisions is truly what it's intended for. The contemporary wireless surveillance system by Syscor takes advantage of a cutting-edge Internet of Things (IoT) infrastructure to combine data analysis, enhance reliability and performance, and significantly decrease consumption and total cost. It's also makes use of Wireless HART, a measurement technology that is more secure and reliable and is currently gaining industrial use. According to Tzonev, "Enbridge's RDI group truly rendered version 2.0 possible." "This is a real facility surveillance system, with applications beyond hovering roofs," he continues. Enbridge believe that this new approach is going to lead to a fundamental change in safety while still being exceptionally affordable. 4.1.Findings The data that we collected through this shows that the supply chain as a whole is a complex operation as a whole its own. For us to ensure that the supply chain operates successfully, we will need to create several different strategies. In this text, we will analyse the logistics network of Enbridge as well as the Supply Chain Management approach that Enbridge employs, which demonstrates that the firm retains strong connections with its wholesalers, retailers, and suppliers. The company is additionally spending an enormous sum of money in the process of preventing oil leaks so that it can safeguard itself from any possible legal issues.We additionally carried out a PESTLE analysis, and our results showed that the company main goal is to promote political stability to the nations by paying all applicable taxes. In addition, the company is aiming to improve its economic structure in order to produce goods that are simple to purchase despite the nation's high inflation rate. The company is striving to address its legal challenges while also focusing on environmental considerations to generate garbage that is biodegradable. A corporation checks the views of its customers using a system called Net Promoter Scores as part of its inventory management policy. Using Six Sigma or DMAIC is another way in which a corporation may improve its ability to concentrate on the procurement process and examine the manner in which products are distributed to various individuals all over the world. In addition, the JIT, Kanban, and Lean technologies assist the organisation in working on strategies to lower value-added pricing and locating issues that are related to supply chain. Additionally, the business makes use of a variety of tools and software, such as Syncor's wireless system. This system makes use of Internet of thing technology, which increases reliability and lowers costs, ultimately leading to an improvement to the distribution network as a whole. 4.2.Suggestions I proposed that the corporation should concentrate on problems such as upstream green house emission and handle the dispute about the oil leaks that have occurred in the past. Enbridge has to make further investments in technology so that it can preserve and improve its safety, trustworthiness, and effectiveness while additionally safeguarding itself from physical risks associated with the effects of climate change. Both the construction of new pipelines and maintaining of existing oil pipelines need to be the primary focuses of the company. In order to make sure that spills across Line 5 and Line 6B are unlikely to happen in the future, the business has to adhere with the United States Environmental Protection Agency's (EPA) requirements. A business undoubtedly has to use IoT technology in the near future in order to save costs, enhance operational efficiency, raise productivity, and boost profitability. 4.3. Conclusion Enbridge's efficient SCM is due to its strong connections to manufacturers and retailers. Enbridge employs a wide range of strategies to maintain its market position. For this business, investments are being made in the resolution of legal and environmental issues. Additionally, the business employs the JIT, Kanban, and Six Sigma systems for procurement. Although Lean Six Sigma is methodically implemented to a problem, irrespective of its nature-operational, supervisory, monetary logistical, or other it can be demonstrated that it has several rewards. If every requirement have been fulfilled initially before moving further with the process, then favorable results are guaranteed. The oil and gas industry has been using many of the Lean manufacturing Sigma methods and ideas. The legal dispute stories also demonstrate that the Lean framework, if applied systematically with an objective and commitment for change, may provide favorable results through choosing the data that is accessible and the proper statistical instruments. Employing Lean Six Sigma ensures ongoing enhancement and problem suppression, which are essential for any firm to be successful, especially one that is as competitive as the oil and gas industry. Applying forecasting software assists the business as well. The DMAIC Six Sigma process is a trustworthy, affordable way to improve research and development and broadening improvement in quality, which allows a successful and efficient grouping of oil spills. Future business expansion may result from more innovation and the application of cutting-edge technology by the company at large. References Bozarth, C. C., Warsing, D. P., Flynn, B. B., & Flynn, E. J. (2009). The impact of supply chain complexity on manufacturing plant performance. Journal of operations management, 27(1), 7893. Pathak, S. D., Day, J. M., Nair, A., Sawaya, W. J., & Kristal, M. M. (2007). Complexity and adaptivity in supply networks: Building supply network theory using a complex adaptive systems perspective. Decision sciences, 38(4), 547-580. Melnyk, S. A., Narasimhan, R., & DeCampos, H. A. (2014). Supply chain design: issues, challenges, frameworks and solutions. International Journal of Production Research, 52(7), 18871896. Enbridge’s sustainability goals. (n.d.). Www.enbridge.com. https://www.enbridge.com/aboutus/our-values/sustainability-goals#:~:text=Enbridge Accountability at Enbridge. (n.d.). Www.enbridge.com. Retrieved August 20, 2023, from https://www.enbridge.com/aboutus/safety/accountability#:~:text=We%20adhere%20to%20a%20set Mentzer, J. T., DeWitt, W., Keebler, J. S., Min, S., Nix, N. W., Smith, C. D., & Zacharia, Z. G. (2001). Defining supply chain management. Journal of Business logistics, 22(2), 1-25. Saad, M., Jones, M., & James, P. (2002). A review of the progress towards the adoption of supply chain management (SCM) relationships in construction. European Journal of Purchasing & Supply Management, 8(3), 173-183. Supply chain management. (n.d.). Retrieved August 7, 2023, from https://www.enbridge.com//media/Enb/Documents/Reports/Sustainability-Report-2019/7Delivering-sharedvalue/02_CSR_2019_Delivering-shared-value_Supply-chainmanagement.pdf?rev=b8beb46dd8c140cfb8b1085e97f8da08 United States, Enbridge Reach $177 Million Settlement After 2010 Oil Spills in Michigan and Illinois. (2016, July 20). Www.justice.gov. https://www.justice.gov/opa/pr/united-states-enbridgereach-177-million-settlement-after-2010-oil-spills-michigan-and Wrigley, L. (1970). Divisional autonomy and diversification (Doctoral dissertation, Graduate School of Business Administration, George F. Baker Foundation, Harvard University). White, R. E. (1986). Generic business strategies, organizational context and performance: An empirical investigation. Strategic Management Journal, 7(3), 217-231. Baldwin, R. E., & Evenett, S. J. (2014). VALUE CREATION AND TRADE IN 21ST CENTURY MANUFACTURING. Journal of Regional Science, 55(1), 31–50. https://doi.org/10.1111/jors.12175 Chang, W., Ellinger, A. E., Kim, K. (Kate), & Franke, G. R. (2016). Supply chain integration and firm financial performance: A meta-analysis of positional advantage mediation and moderating factors. European Management Journal, 34(3), 282–295. https://doi.org/10.1016/j.emj.2015.11.008 Strategy Scenarios. (n.d.). Www.enbridge.com. Retrieved March 27, 2022, from https://www.enbridge.com/sustainability-reports/resilient-energy-infrastructure/strategyscenarios Jirasukprasert, P., Arturo Garza-Reyes, J., Kumar, V., & K. Lim, M. (2014). A Six Sigma and DMAIC application for the reduction of defects in a rubber gloves manufacturing process. International journal of lean six sigma, 5(1), 2-21. Pepper, M. P., & Spedding, T. A. (2010). The evolution of lean Six Sigma. International Journal of Quality & Reliability Management, 27(2), 138-155. Manuj, I., & Sahin, F. (2011). A model of supply chain and supply chain decision‐making complexity. International Journal of Physical Distribution & Logistics Management, 41(5), 511549. Liu, R., & Kumar, A. (2011). Leveraging information sharing to configure supply chains. Information Systems Frontiers, 13, 139-151. Goldsby, T. J., & Martichenko, R. (2005). Lean six sigma logistics: Strategic development to operational success. J. Ross Publishing. Hokoma, R. A. A WAY FORWARD FOR IMPLEMENTING JUST-IN-TIME TECHNIQUES WITHIN THE LIBYAN OIL AND GAS INDUSTRIES. Integrators, L. A. E. (2015, September 17). Kanban Procurement Systems. Strategic Systems Group (SSG) - Transformation to the Intelligent Enterprise. https://ssgnet.com/kanbanprocurement-systems/ Perrons, R. K., & Jensen, J. W. (2015). Data as an asset: What the oil and gas sector can learn from other industries about “Big Data”. Energy Policy, 81, 117-121. Hassani, H., & Silva, E. S. (2018). Big Data: a big opportunity for the petroleum and petrochemical industry. OPEC Energy Review, 42(1), 74-89.