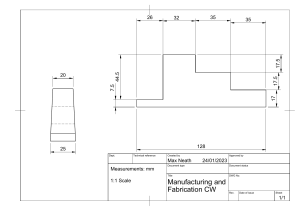

COURSE DESCRIPTION: TECHNICAL RESEARCH CHAPTER 3 METHODOLOGY Note: The following content in your methodology is just a guide to writing methodology. Research is always flexible to additional sections or topics for discussion. COURSE MODULE Methodology describes the plan and strategies for attaining the stated objectives. of the research. (i.e. How are you going to accomplish the specific objectives described in your study); represents the way the researcher conducts his observation collects information or performs the design/development/implementation, and evaluates including specifics such as the location of the study, sampling design, specification of variables, data collection, and data analysis. Should describe how the following are undertaken: • Design, [all designs of components and sub-components should be clear. presented, and techniques described in this section including all relevant technical. drawings, sketches, schematics, circuits, diagrams, flow charts, truth tables, and the like. Figures and tables should be properly marked accordingly.] • Development, [the sequential processes of assembly and prototyping should be explicitly described including a description of theoretical aspects utilized.] • Implementation & [this section may describe how the project/prototype will be technically tested and tried.] • Evaluation [This section should thoroughly explain the evaluation parameters and another relevant testing instrument. Statistical test methods and/or technical performance measurement should also be emphasized. 1. You can start the first section with “Design Considerations”: Design Considerations can include the following: a. Purpose and Function: Clearly define the purpose and intended function of the equipment. What problem does it solve, and what tasks does it need to perform? b. User Needs:Understand the needs and expectations of the end-users. Design the equipment with user-friendliness in mind to enhance usability. c. Safety: Safety is paramount. Ensure that the equipment is safe to use, addressing potential hazards and minimizing risks through safety features and fail-safes. d. Reliability and Durability: Design the equipment to be reliable and durable, capable of withstanding normal wear and tear. Use high-quality materials and components. e. Cost Constraints: Consider budget limitations and cost constraints in the design. Strive for a balance between functionality and cost-effectiveness. f. Size and Weight: Determine the optimal size and weight of the equipment, considering portability and ease of transportation. g. Energy Efficiency: Design equipment to be energy-efficient, reducing energy consumption and environmental impact. h. Environmental Impact: Consider the environmental impact of the equipment's COURSE MODULE manufacturing, use, and disposal. Aim for sustainable design and materials. i. Regulatory Compliance: Ensure that the equipment complies with relevant industry standards and regulations, which may include safety, quality, and environmental requirements. j. Ergonomics: Design the equipment with ergonomic principles in mind to ensure user comfort and minimize the risk of injury or strain during operation. k. Maintenance and Serviceability: Make the equipment easy to maintain and service by incorporating features like accessible components, user-friendly interfaces, and diagnostic tools. l. Adaptability and Scalability: Consider the adaptability of the equipment to different contexts or the potential for scalability if the demand for the equipment increases. m. Materials Selection: Choose appropriate materials that match the equipment's purpose and environment. Consider factors like corrosion resistance, strength, and compatibility. n. Aesthetics: The appearance of the equipment can influence user perception. Consider aesthetics in the design to enhance marketability and user acceptance. o. Integration with Existing Systems: Ensure that the equipment can integrate seamlessly with existing systems or technologies if necessary. p. Noise and Vibration: Address issues related to noise and vibration, especially if the equipment is expected to operate quietly or without excessive vibration. q. Performance: Specify the desired performance parameters and ensure that the equipment meets or exceeds these requirements. r. Testability: Design the equipment to be easily testable during quality control and maintenance processes. s. Human-Machine Interface (HMI): If applicable, design the user interface to be intuitive and user-friendly, with clear instructions and feedback. t. Future-proofing: Anticipate future needs and technological advancements to ensure the equipment remains relevant and adaptable. 2. Then your next section can be the Prototype Fabrication, which may include the following: a. Materials Selection: Selection of materials that best suit the prototype's intended purpose, including considerations like strength, durability, weight, and cost. b. Prototyping Methods: Determining the fabrication method, whether it's 3D printing, CNC machining, manual assembly, or other manufacturing processes. c. Prototyping Equipment and Tools: Listing the equipment, machinery, and tools required for the fabrication process. d. Fabrication Steps: A step-by-step breakdown of the fabrication process, including cutting, shaping, assembly, and finishing. e. Quality Control and Tolerances: Specification of quality control measures to COURSE MODULE ensure the prototype meets design tolerances and performance criteria. 3. Testing and Evaluation: You can separate this to two sections if necessary. This sections may include a. Data Collection Methods: Describe the methods used to collect data, whether they involve surveys, experiments, observations, interviews, archival data, or a combination of these. b. Sampling Design: Explain how the sample was selected, including details about the population, sampling methods, and sample size. c. Variables and Measures: Define the variables under investigation and explain how they are measured or operationalized. Include information about measurement instruments, scales, or metrics used. d. Data Collection Procedure: Detail the step-by-step process for collecting data, including any specific protocols, tools, or equipment used. e. Data Analysis Methods: Describe the statistical or analytical techniques employed to analyze the collected data. This may include descriptive statistics, inferential statistics, content analysis, coding, or qualitative analysis methods.