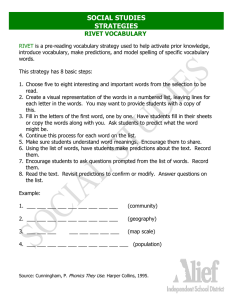

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/307180123 Analysis of Residual Stresses Induced by Riveting Process and Fatigue Life Prediction Article in Journal of Aircraft · August 2016 DOI: 10.2514/1.C033715 CITATIONS READS 9 570 4 authors, including: Bin Zheng Haidong Yu Shanghai Jiao Tong University Shanghai Jiao Tong University 11 PUBLICATIONS 101 CITATIONS 66 PUBLICATIONS 480 CITATIONS SEE PROFILE All content following this page was uploaded by Bin Zheng on 22 April 2017. The user has requested enhancement of the downloaded file. SEE PROFILE JOURNAL OF AIRCRAFT Vol. 53, No. 5, September–October 2016 Analysis of Residual Stresses Induced by Riveting Process and Fatigue Life Prediction Bin Zheng,∗ Haidong Yu,† Xinmin Lai,‡ and Zhongqin Lin§ Shanghai Jiao Tong University, 200240 Shanghai, People’s Republic of China Downloaded by SHANGHAI JIAO TONG UNIVERSITY on April 22, 2017 | http://arc.aiaa.org | DOI: 10.2514/1.C033715 DOI: 10.2514/1.C033715 Residual stress induced by riveting process is critical to the fatigue life of riveted structures. A residual stress model is proposed to predict the residual stress distribution after riveting process. In the residual stress model, the radial pressure at the hole boundary is obtained, and the strain hardening effect of the rivet material is taken into consideration. The other characteristic of the model is that the solution of radial and circumferential residual stresses is extended to include an unfree springback process by using a springback coefficient. The residual stresses on the faying surface with various parameters, such as the height of the rivet drive head, the hole diameter, and the material property, are predicted with the residual stress model. The residual stresses calculated by the model are employed in the fatigue life prediction using the multi-axial fatigue criterion. The predicted results of the fatigue life show a good agreement with the experimental data. The investigation in this paper can help the residual stress prediction of riveted joints and improve the awareness of the effect of the residual stress on the fatigue behavior of riveted structures. σa , σm Nomenclature D dz = = dθ E, υ = = f−1 , f−1p = J2;a , J2;m = H, n = h h0 = = k kt , kf = = p1 r r1 unload rload 1 , r1 = = = = r2 rp r∞ ur1 α, β λ = = = = = = diameter of the rivet drive head thickness of the equivalent thick-walled cylinder central angle of the fan-shaped element Young’s modulus and Poisson’s ratio, respectively fatigue limit in fully reversed bending and in fully reversed tension, respectively amplitude and mean value of second invariant of deviatoric stress tensor, respectively strength coefficient and strain hardening exponent height of the rivet drive head initial length of protruding portion of the rivet shank spingback coefficient stress concentration factor and fatigue notch factor, respectively radial pressure on the hole surface distance from the axis of rivet radius of the rivet hole hole radius under the squeeze force and after unloading, respectively radius of the region beneath the rivet drive head radius of plastic region radius of the equivalent thick-walled cylinder displacement of the hole surface parameters in Marin fatigue criterion parameter of the fatigue notch factor = σ ar σ eq 1a , σ eq 1m = = σ eq 2a , σ eq 2m = σ eq 3a , σ eq 3m = σr, σθ , σz = σ sheet , σ sheet r θ = σ sheet , σu s = σ sheet z τ τsheet rz ψ = = = = amplitude and mean value of the applied load, respectively equivalent stress amplitude amplitude and mean value of equivalent stress in the loading direction, respectively amplitude and mean value of equivalent stress in the transverse direction, respectively amplitude and mean value of equivalent stress in the axial direction, respectively radial stress, circumferential stress, and axial stress of the rivet drive head radial stress and circumferential stress of the sheet, respectively yield stress of the sheet and ultimate stress of material, respectively axial stress of the sheet shear stress of the rivet drive head shear stress of the sheet in r-z plane displacement function I. R Introduction ESIDUAL stresses induced by the riveting process significantly affect the fatigue behavior of riveted joints. Some analytical models for residual stresses induced by the riveting process were proposed to be employed in the residual stress analysis [1,2]. Shishkin [3] derived expressions for the stress distribution in the sheets based on the Malinin small plastic-elastic deformation model. Some discrepancies of the residual stress in the sheets occurred near the rivet hole because the strain hardening effect is not considered for calculating the radial pressure on the hole surface. The riveting process is analogous to the cold expansion process where the fastener holes are expanded to a desired level before inserting a fastener. Thus, the analytical models for the cold expression process [4–6] were also employed in the analysis of the stress distribution of the riveting process. Park and Atluri [7] presented formulas for the residual stress field with the Tresca yield criterion, where the residual stresses along the radial direction are given for various radial pressures on the surface of the rivet hole. Nevertheless, all of these models are limited in their applicability to the riveting process. First, the radial pressure on the hole surface is calculated without consideration of the strain hardening effect of the rivet. Second, the unloading after the riveting process is not a free springback procedure for the rivet hole resulted from the limitation of the rivet. Residual stresses are affected by a number of parameters involving the geometric dimensions and the material property parameters. In the geometric parameters, the height of the rivet drive head and the hole diameter directly influence the residual stress field of riveted Received 12 September 2015; revision received 6 December 2015; accepted for publication 16 December 2015; published online 17 August 2016. Copyright © 2015 by the American Institute of Aeronautics and Astronautics, Inc. All rights reserved. Copies of this paper may be made for personal and internal use, on condition that the copier pay the per-copy fee to the Copyright Clearance Center (CCC). All requests for copying and permission to reprint should be submitted to CCC at www.copyright.com; employ the ISSN 0021-8669 (print) or 1533-3868 (online) to initiate your request. *Ph.D. Student, School of Mechanical Engineering, Key Laboratory of Mechanical System and Vibration; 19890118bln@sjtu.edu.cn. † Associate Professor, School of Mechanical Engineering, Shanghai Key Laboratory of Digital Manufacture for Thin-Walled Structures; hdyu@sjtu. edu.cn (Corresponding Author). ‡ Professor, School of Mechanical Engineering, Key Laboratory of Mechanical System and Vibration; xmlai@sjtu.edu.cn. § Professor, School of Mechanical Engineering, Shanghai Key Laboratory of Digital Manufacture for Thin-Walled Structures; zqlin@sjtu.edu.cn. 1431 Downloaded by SHANGHAI JIAO TONG UNIVERSITY on April 22, 2017 | http://arc.aiaa.org | DOI: 10.2514/1.C033715 1432 ZHENG ET AL. joints [8,9]. Li et al. [8,10] conducted the riveting process with strain gauges mounted on the sheet surface to capture the strain variation of riveted specimens with different heights of the rivet drive head. Rans et al. [11] employed a three-dimensional finite element model to obtain the residual stress field with various heights of the rivet drive head. Aman et al. [12] carried out finite element analysis to study the effect of some controllable process parameters on the quality of riveted lap joints. Yoon and Kim [13] conducted a riveting simulation of laminated composites with the consideration of the washer inner fillet. The mechanical behaviors of the sheet material also affect the residual stress significantly. As the new lightweight materials, such as the Al-Li alloy, are generally applied to the aircraft structures, the residual stress distribution is different from that in the traditional aluminum alloy due to the improved material properties. Manes et al. [9] and Viganò et al. [14] investigated the residual stresses of the riveted structure with 8090 Ai-Li alloy sheets by the numerical method. In this paper, the parameters of the height of the rivet drive head, the hole diameter, and the material property of the sheet are considered to investigate the residual stresses induced by the riveting process. The fatigue behavior of riveted joints is influenced by the residual stress in the vicinity of the rivet hole. The fatigue life of a riveted joint was investigated with the experimental and analytical methods [15,16]. Skorupa et al. [17] conducted an experimental research on the influence of several production-related factors on the fatigue behavior of riveted lap joint specimens. The fatigue experiments of riveted joints are time-consuming. Therefore, the numerical simulation and the fatigue criterion are used in the fatigue life prediction of the riveted joint. Fung and Smart [18] conducted the fatigue life estimation employing both the strain-based Coffin– Manson method and a stress-based method. However, the residual stress induced by the riveting process is not involved in the fatigue life estimation. Viganò et al. [14] studied the local stress of a T-joint from the riveting process through the tensile loading stage. A multi-axial fatigue criterion was applied to predict the fatigue life of the T-joint. The tensile load was coupled with the residual stress induced by the riveting process, and the combination of the stresses was used in the fatigue life prediction. The effect of the residual stress on the fatigue life is not presented separately, which is unfavorable of the optimization of the parameters in the riveting process. In this study, a residual stress model is established. There are two main characteristics in the residual stress model. First, the radial pressure between the rivet and the hole is obtained with the consideration of the plastic behavior of the rivet material. Second, the springback coefficient is applied to describe the sheet springback degree after expansion. The effects of various parameters on residual stresses of the faying surface are predicted with the proposed model. The residual stresses calculated by the model are also employed in the fatigue prediction of the riveted lap joint. II. Residual Stress of Riveted Sheets A residual stress model is proposed to predict the residual stress induced by the riveting process. The radial pressure on the hole surface is obtained first. Then, the stress components in the riveting process and unloading process are calculated. The unfree springback of the rivet hole in the unloading process is taken into consideration. Fig. 1 Stress components of the rivet drive head. A fan-shaped element of the rivet drive head is shown in Fig. 1. The height of the rivet drive head is h, and the hole radius is r1 . The force equilibrium equation can be expressed as dθ σ r hrdθ − σ r dσ r hr drdθ 2σ θ hdr sin 2 − 2τrdθdr 0 (1) Because of the small value of the central angle, it can be obtained that sindθ∕2 ≈ dθ∕2. The compression of the rivet shank is an axisymmetric process that σ r is equal to σ θ [19]. Neglecting the second-order infinitesimal, Eq. (1) can be simplified as dσ r − 2τ dr h (2) The shear stress increases to τmax and is then kept constant. The maximum shear stress is τmax 0.5σ z [20]. Thus, the shear stress of the chosen element in Eq. (1) is τ τmax 0.5σ z . Substituting the shear stress into Eq. (2) gives dσ r − σz dr h (3) On the contact surface of the rivet drive head and the inner sheet, the radial stress σ r is equal to zero at r r1 b. With this boundary condition, the radial stress in Eq. (3) can be solved as σr σz r b − r h 1 (4) Let 2r1 2b D, where D is the diameter of the rivet drive head. Thus, the radial stress σ r becomes σr σz D − 2r 2h (5) A. Radial Pressure on the Hole Surface The cylindrical coordinate is employed to facilitate the analysis of stress components. The z direction is along the axial direction of the rivet, and the radial direction is in accordance with the direction of the radius of the rivet hole. The radial pressure on the hole surface is caused by the plastic flow of the rivet. The protruding portion of the rivet shank is squeezed in the riveting process, which results in the plastic flow of the rivet. The compression of the protruding portion of the rivet shank in the riveting process is analogous to the upsetting process. The principle stress method is widely used in the analysis of the upsetting process [19]. Here, the principle stress method is employed to solve the radial pressure induced by the riveting process. The plastic behavior of the rivet material influences the stress components induced by the riveting process directly. Here, the Ramberg–Osgood relationship is chosen to describe the stress-strain relationship with the consideration of the plastic behavior of the rivet material. The Ramberg–Osgood relationship is simple, in which the correlation between the stress and the plastic strain is established. Besides, the Ramberg–Osgood model is shown to provide a realistic treatment of the plastic behavior of the material [21]. The axial compression stress σ z on the contact surface of the rivet drive head and the inner sheet can be given according to the Ramberg–Osgood model as 1433 ZHENG ET AL. σ z Hεpz n The elastic strain in the riveting process is ignored for the small value compared to the plastic strain. The average strain in the axial direction can be written as Z εpz h ho dh h ln h h0 (7) Downloaded by SHANGHAI JIAO TONG UNIVERSITY on April 22, 2017 | http://arc.aiaa.org | DOI: 10.2514/1.C033715 Substituting Eq. (7) into Eq. (6), the axial compression stress on the contact surface of the rivet drive head and the inner sheet is given by n h (8) σ z H ln h0 The radial stress at the bottom of the hole surface, which is denoted as “A” in Fig. 1, can be calculated by substituting Eq. (8) into Eq. (5) and replacing the variation r with the initial radius of the hole r1 . Thus, the radial pressure at point A can be calculated with geometric parameters and material properties, which is given by n D − 2r1 h ln (9) p1 −σ r −H h0 2h Here, the radial pressure on the hole surface is assumed to be uniform, and the radial pressure at point A is employed to calculate the residual stress. Actually, the radial pressure is not uniform through the sheet thickness. The radial pressure at point A, p1 , is larger than those at other locations of hole surface through the thickness direction. The peak tensile stress of the circumferential residual stress predicted with the radial pressure, p1 , will also be larger than the real value. However, the larger peak tensile stress can result in a conservative fatigue life result, which is beneficial for the safety of the riveted structure in service. In addition, the prediction of the residual stress can be simplified with the uniform distribution assumption of the radial pressure. B. Stress Components of Sheets in Riveting Process The sheets are subjected to the radial pressure on the hole surface and the axial stress beneath the rivet drive head. Because of the small ratio of the hole diameter to the dimension of the sheets, the region containing a rivet hole in the sheets can be equivalent to a thickwalled cylinder. A thin layer of the sheet is chosen to analyze the stress components. The equivalent thick-walled cylinder with inner pressure and axial stress is shown in Fig. 2. The sheets deform elastically at first in the riveting process. The general formation of the displacement function for the spatial axisymmetric problem is given as [22] ψr; z A1 z4 A2 r4 A3 z3 A4 z2 r2 A5 z2 ln r A6 zr2 A7 r2 ln r A8 z ln r (10) The equivalent thick-walled cylinder in Fig. 2 is subjected to the uniform stresses on the hole surface and beneath the rivet drive head. Thus, the radial stress and the circumferential stress are independent of the z direction. The displacement function can be simplified for the equivalent thick-walled cylinder as z r2 r1 p1 dz Fig. 2 ψr; z α1 z3 α2 zr2 (6) Thick-walled cylinder of the sheet. r (11) The Love method is employed to solve the correlation between the stress components and the displacement function [23]. The stress components that satisfy the biharmonic function are given as ∂ ∂2 ψ ∂ 2 ψ − 1 ∂ψ υ∇2 ψ − 2 ; σ sheet υ∇ θ ∂z ∂z r ∂r ∂r 2 ∂ ∂ ψ ∂ ∂2 ψ sheet 2 sheet 2 σz 2−υ∇ ψ − 2 ; τrz 1−υ∇ ψ − 2 (12) ∂z ∂z ∂r ∂z σ sheet r where the Laplacian is given by ∇2 ∂2 ∕∂x2 ∂2 ∕∂y2 ∂2 ∕∂z2 . The boundary conditions derived in Sec. II.A are τsheet 0 rz r r1 : σ sheet −p1 r r r∞ : σ sheet 0 r z 0; z dz: σ sheet σ z r ≤ r2 ; z σ sheet 0r > r2 z (13) Combining Eqs. (12) and (13), the stress components in the elastic stage are solved as 2 r21 r∞ − 1 r2∞ − r21 r2 2 r2 r p1 2 1 2 ∞2 − 1 r∞ − r1 r −p1 σ sheet r σ sheet θ σ sheet σ z r ≤ r2 ; z σ sheet 0r > r2 z τsheet 0 rz (14) As far as the actual riveted joint is concerned, r2∞ ≫ r21 . Equation (14) can be simplified as −p1 σ sheet r r21 r2 r21 r2 σ z r ≤ r2 ; σ sheet p1 θ σ sheet z τsheet 0 rz σ sheet 0r > r2 z (15) The plastic deformation will appear in the vicinity of the hole bound by r1 ≤ r ≤ rp as the radial pressure is increased. For the thick-walled cylinder, the axial stress σ sheet is the middle stress z among the principle stresses [24]. Based on the Tresca yield criterion, it can be obtained that σ sheet − σ sheet σ sheet . The equilibrium r s θ equation for this axisymmetric problem is dσ sheet ∕dr r σ sheet − σ sheet ∕r 0. Thus, the radial and the circumferential r θ stresses can be written with the yield stress of sheet material, σ sheet . s The boundary condition σ sheet −p1 at r r1 is also employed in r solving the stress components. The radial and the circumferential stresses in the plastic stage can be expressed as r sheet 1ln r −p r ≤ r −p1 ; σ sheet σ 1 p s θ r1 r1 rp 2 rp 2 1 1 − σ sheet ; σ sheet σ sheet r > rp (16) σ sheet r θ 2 s 2 s r r σ sheet σ sheet ln r s where the radius of the plastic region can be solved with the stress continuity condition at r rp . 1434 ZHENG ET AL. C. Limited Unloading Process The residual stresses after the removal of the squeeze force are obtained by subtracting the elastic stresses from the plastic stresses [7]. However, the sheets are not free to spring back after the expansion due to the rivet shank remaining in the rivet hole [2]. Here, a springback coefficient is defined, which is used to describe the springback magnitude of the rivet hole. The springback of the rivet hole after the removal of the squeeze force is an elastic process. The springback magnitude of sheets can be described by the ratio of the displacement of the hole surface. Thus, the springback coefficient k is defined as Downloaded by SHANGHAI JIAO TONG UNIVERSITY on April 22, 2017 | http://arc.aiaa.org | DOI: 10.2514/1.C033715 k1− runload − r1 1 rload − r1 1 It can be seen from Eq. (17) that the spingback coefficient is zero when runload rload 1 1 , which represents the condition that there is no springback of the rivet hole. The spingback coefficient is equal to 1 when runload r1 , which represents the complete springback of the 1 rivet hole. The hole radius under the squeeze force can be calculated as rload r1 ur1 1 (18) The displacement of the hole surface, ur1 , is solved in [24] as ur1 1 − 2υ1 υ sheet r1 r2p r1 r1 σs r ln − 1 E 2 r2∞ rp 2 r2p 1 − υ2 σ sheet s E r1 (19) Substituting Eq. (19) into Eq. (18), the hole radius under the squeeze force can be presented as rload r1 1 1 − 2υ1 υ sheet r1 r2p r1 r1 σs r ln − 1 E 2 r2∞ rp 2 r2p 1 − υ2 σ sheet s E r1 (20) , is an important parameter The hole radius after unloading, runload 1 to describe the quality of the riveted joints. It is generally measured by the experimental testing [25] or by the numerical simulation [11]. Here, the hole diameter after unloading is obtained by the measurement of riveted joints. The residual stresses of sheets can be written as r r2 − p1 − k −p1 12 ; r1 r r r21 sheet 1 ln σ − k p σ re − p r ≤ rp 1 1 s θ r1 r2 1 sheet rp 2 r2 σ re − k −p1 12 ; r − σs 2 r r 2 1 sheet rp 2 r − k p1 12 r > rp σ re θ σs 2 r r Specimen with riveted lap joints. The sheet materials of specimens include 2060-T8 Al-Li alloy and 2024-T3 aluminum alloy. There are three heights of the rivet drive head for riveted joints with the sheet material of 2060-T8 Al-Li alloy, which are 1.8, 2.1, and 2.5 mm, respectively. The height of the rivet drive head is 2.1 mm for riveted joints with the sheet material of 2024T3 aluminum alloy. There are also two radii of the rivet hole for the riveted joints with the sheet material of 2060-T8 Al-Li alloy. The specific parameters of riveted joints are listed in Table 1. Different conditions of riveted joints are denoted as numbers 1–5. The geometrical dimensions are measured, such as the diameter of the rivet drive head (D), the height of the rivet drive head, and the hole radius after unloading (runload ). The diameter and the height of the 1 rivet drive head are measured directly on the riveted joints. The hole radius of the riveted joint, runload , is measured after splitting the 1 riveted joint along the axial direction of the rivet. The toolmaker microscope is employed to measure the hole radius after the rivet process, as proposed in [26]. The hole radius at the faying surface is measured, where cracks are easy to initiate [8,17]. The measurement results of the diameter of the rivet drive head and the hole radius after unloading are summarized in the Table 2. The numbers in Table 2 represent the same riveted joints with those in Table 1. The mechanical parameters of materials are also indispensable to calculate the residual stress. Two different materials of sheets are considered to study the effect of material property on the residual stress. The sheet materials of 2060-T8 Al-Li alloy and 2024-T3 aluminum alloy are chosen in the investigation. The mechanical parameters of 2117-T4 aluminum alloy and 2060-T8 Al-Li alloy are obtained by the uniaxial tension experiments. For 2024-T3 aluminum alloy, the mechanical parameters in [11] are applied. The Ramberg– Osgood model is employed to describe the stress–strain relationship of the materials. The mechanical parameters of materials are given in Table 3. IV. sheet ln σ re r σs III. Fig. 3 (17) Effects of Parameters on the Residual Stress Riveting process parameters and material properties have a significant influence on the residual stress of the riveted structure. Table 1 (21) Number 1 2 3 4 5 Parameters employed for the investigation Height of rivet drive head, mm 1.8 2.1 2.5 2.1 2.1 Hole radius, mm 2.45 2.45 2.45 2.40 2.45 Sheet material 2060-T8 2060-T8 2060-T8 2060-T8 2024-T3 Experiments for Parameters in the Residual Stress Model The geometric parameters involved in the residual stress model are measured from the riveted lap joints. The lap joints are riveted by using the multi panel assembly cell automatic riveting machine. The riveted specimen consists of two 2.0-mm-thick sheets and 4.76-mmdiam 2117-T4 aluminum rivets, which are countersunk-type NAS1097AD6-6 rivets. The configuration of the riveted specimen is presented in Fig. 3. Table 2 Measurement results of D and runload 1 Parameters Diameter of rivet drive head (D) Hole radius runload 1 1 8.20 2.460 2 7.68 2.458 Number 3 4 7.22 7.74 2.455 2.408 5 7.58 2.467 1435 ZHENG ET AL. Table 3 Mechanical parameters of sheets and the rivet 2060-T8 (sheets) 75.5 485 0.33 714 0.069 Parameter Young’s modulus E, GPa Yield stress σ s , MPa Poisson’s ratio υ Strength coefficient H, MPa Hardening exponent n Table 4 2117-T4 (rivet) 71.7 165 0.33 598 0.222 B. Effect of the Hole Diameter Relevant parameter values for joints with different heights of rivet drive head Parameter h0 h Value 5.525 mm 1.8, 2.1, 2.5 mm Parameter σ sheet (for 2060-T8) s D r1 2.45 mm runload 1 r∞ H (for 2117-T4) n (for 2117-T4) 12.50 mm 598 MPa 0.222 E (for 2060-T8) υ (for 2060-T8) — — Value 485 MPa 8.20, 7.68, 7.22 mm 2.460, 2.458, 2.455 mm 75.5 GPa 0.33 — — Here, the influences of the height of the rivet drive head, the hole diameter, and the material property on the residual stress are studied by the proposed model. Fatigue cracks tend to nucleate on the faying surface in the vicinity of the hole [27]. Therefore, it is important to investigate the residual stresses on the faying surface. Here, the residual stresses on the faying surface are predicted with various riveting parameters listed in Table 1. There are some parameters involved in the equations to calculate the residual stress on the faying surface. To be brief, only the relevant parameter values for joints with different heights of rivet drive head are summarized in Table 4. The other values of relevant parameters for joints with different hole diameters and material properties can be found in Tables 2 and 3. The hole diameter is another important parameter in the riveting process. Here, the hole radius varies from 2.40 to 2.45 mm. The radii in this research are in the tolerance range of the rivet hole, as suggested in [26]. The circumferential and radial residual stresses on the faying surface are shown in Figs. 5a and 5b, respectively. The gray regions in the figures are enlarged and presented at the right side. In Fig. 5a, the magnitude of the peak tensile stresses are approximate to 130 MPa for both conditions. The location of the peak tensile stress moves a short distance from the hole edge for the hole radius of 2.40 mm. As shown in Fig. 5b, the radial residual stresses are in a compressive state. The compressive residual stress slightly increases with the decrease of the hole diameter. C. Effect of the Material Property The 2024-T3 aluminum alloy is commonly used in the fuselage of metallic aircraft. In addition, Al-Li alloys are generally used in the aircraft for weight reduction. Here, sheets of 2024-T3 aluminum and 2060-T8 Al-Li alloy are chosen to investigate the influence of the material properties of sheets on the residual stress. The circumferential residual stresses on the faying surface are illustrated in Fig. 6a. A larger compressive residual stress on the hole edge and a farther location of the peak tensile stress away from the hole edge appear on the faying surface for the 2024-T3 aluminum sheet. As shown in Table 3, the elastic moduli of two sheet materials are close to each other. However, the yield stress of 2024-T3 aluminum is approximately 35% lower than the 2060-T8 Al-Li alloy. With the same height of the rivet drive head, the compressive residual stress with a wider range and a larger magnitude tends to be induced in the sheet with lower yield stress. The radial residual stresses of sheets are shown in Fig. 6b. Larger compressive residual stresses are also presented in the sheet of 2024-T3 aluminum. A. Effect of the Height of Rivet Drive Head The height of the rivet drive head has a remarkable effect on the residual stress around the rivet hole. The circumferential residual stresses on the outer-sheet faying surface are illustrated in Fig. 4a. The compressive residual stress on the hole edge increases with the decrease of the height of the rivet drive head. Meanwhile, the peak tensile stress moves away from the rivet hole edge and slightly decreases with the decrease of the height of the rivet drive head. The peak tensile stresses are close to the value of 120 MPa for joints with heights of the rivet drive heads of 1.8 and 2.1 mm and 130 MPa for the joint with the height of the rivet drive head of 2.5 mm. The radial residual stresses on the faying surface are shown in Fig. 4b. The radial residual stresses are in a state of compressive stress. It can be seen that larger compressive stresses appear on the faying surface for the joint with lower height of the rivet drive head. V. Fatigue Life Prediction Riveted joints are the critical elements for the fatigue behavior of the airframe [17]. The residual stress and the cyclic load lead to the failure of the riveted structure. Here, the residual stress calculated by the proposed model is employed in the fatigue life prediction. The predicted results are validated by the experimental data. A. Prediction Procedure The residual stress and the load applied on the component are considered in the fatigue life prediction of riveted structures. The notch effect exists in the vicinity of the rivet hole, which increases the value of the applied load. The stress concentration factor kt along the radial direction can be calculated as [28] 150 0 0 h=1.8 mm h=2.1 mm h=2.5 mm -150 -300 Faying surface Residual stress(Mpa) Residual stress(Mpa) Downloaded by SHANGHAI JIAO TONG UNIVERSITY on April 22, 2017 | http://arc.aiaa.org | DOI: 10.2514/1.C033715 2024-T3 (sheets) 72.4 310 0.33 530 0.100 The residual stress comparison of riveted joints with various heights demonstrates that the decrease of the height of the rivet drive head increases the compressive stress in both radial and circumferential directions, and the increase of the compressive stress will be beneficial to prolong the fatigue life of the riveted joint. -40 h=1.8mm h=2.1mm h=2.5mm -80 -120 Faying surface -160 -450 1 2 3 X/r1 Fig. 4 4 -200 1 2 3 4 X/r1 a) b) Effect of the height of the rivet drive head on the residual stress of the faying surface: a) circumferential residual stress and b) radial residual stress. 1436 ZHENG ET AL. 150 90 0 r1=2.40mm r1=2.45mm Faying surface -90 -180 1 2 3 Residual stress(Mpa) Residual stress(Mpa) 180 125 100 75 1.2 4 1.4 1.6 X/r1 1.8 X/r1 a) r1=2.40mm r1=2.45mm -80 -120 Faying surface -160 Residual stress(Mpa) Residual stress(Mpa) -60 -40 -200 -90 -120 -150 -180 1 2 3 1.2 4 1.5 X/r1 1.8 2.1 X/r1 b) Fig. 5 Effect of the hole diameter on the residual stress of the faying surface: a) circumferential residual stress and b) radial residual stress. 150 0 75 0 2024-T3 2060-T8 -75 -150 Faying surface -225 -300 1 Fig. 6 2 3 X/r1 4 2060-T8 2024-T3 -80 -120 Faying surface -160 -200 1 2 3 4 a) b) Effect of material properties on the residual stress of the faying surface: a) circumferential residual stress and b) radial residual stress. (22) The fatigue notch factor kf is defined to represent the life reduction caused by the notch effect [22]. The correlation between kt and kf is kf 1 kt − 1 q 1 rλ1 (23) where λ is a parameter related to the ultimate stress σ u . Here, λ is 0.52 for 2060-T8 Al-Li alloy and 0.63 for 2024-T3 aluminum alloy. The classical approach to predict the fatigue life of specimen with the residual stress is to linearly superimpose the applied load with the residual stress. The residual stress is equivalent to the mean stress in the fatigue life prediction [29–31]. Thus, the equivalent stresses in the uniaxial tension can be calculated as 1a -40 X/r1 1 r1 2 3 r1 4 kt 1 2 r 2 r σ eq Residual stress(Mpa) Residual stress(Mpa) Downloaded by SHANGHAI JIAO TONG UNIVERSITY on April 22, 2017 | http://arc.aiaa.org | DOI: 10.2514/1.C033715 0 kf σ a ; σ eq1m σ re θ σ eq kf σ m ; 2a 0; σ eq 2m σ eq3a 0; σ re r ; σ eq 3m 0 (24) where σ eq 1a and σ eq 1m are the amplitude and the mean value of equivalent stress in the loading direction. σ a and σ m are the amplitude and the mean value of the applied load. σ re θ is the circumferential residual stress in the loading direction, which is located on the faying surface. σ eq 2a and σ eq 2m are the amplitude and the mean value of equivalent stress in the transverse direction. The stress amplitude in the transverse direction is equal to zero, and the mean stress in the transverse direction is the radial residual stress. The stress in the thickness direction is ignored for the small value compared to the stresses in the loading and the transverse directions [14]. The Marin fatigue criterion [32] is employed in the fatigue life prediction. It is a valid multi-axial fatigue approach, which is suggested in [33]. This criterion is established based on the amplitude and the mean value of the second invariant of deviatoric stress tensor. The Marin model and its parameters can be written as q α2 J2;a β2 J2;m ≤ f−1p α p f−1p 3 ; f−1 β3 f−1p (25) σu Here, α is 2.65 for 2060-T8 Al-Li alloy and 2024-T3 aluminum alloy. β is 0.67 for 2060-T8 Al-Li alloy and 0.82 for 2024-T3 aluminum alloy. In the fatigue life prediction, the equivalent stress amplitude can be written in the form of the Marin model as σ ar q α2 J2;a β2 J2;m (26) where the equivalent stress amplitude is the maximum in the vicinity of the rivet hole. 1437 ZHENG ET AL. Table 5 Downloaded by SHANGHAI JIAO TONG UNIVERSITY on April 22, 2017 | http://arc.aiaa.org | DOI: 10.2514/1.C033715 Number 1 2 3 4 5 Replicate specimen A 220,813 123,652 98,137 181,958 215,084 Fatigue life results of riveted joints Experimental results, cycles Replicate specimen B Replicate specimen C 203,474 112,802 182,085 175,212 113,089 99,222 160,317 174,541 215,671 209,883 The fatigue testing to obtain the stress versus life (S-N) curve of the 2060-T8 Al-Li alloy is carried out according to the American Society for Testing and Materials Standard number E466. The S-N data of the 2024-T3 aluminum alloy are obtained from [34]. The data of the S-N curve of the 2060-T8 Al-Li alloy and the 2024-T3 aluminum alloy for the stress ratio R −1 and the stress concentration factor kt 1 can be written as log10 N 9.38 − 2.52 log10 σ ar − 61.32060 − T8 log10 N 10.4 − 3.06 log10 σ ar − 53.12024 − T3 (27) The equivalent stress amplitude calculated with Eq. (26) is substituted into Eq. (27) to solve the fatigue life of riveted joints. The predicted results of fatigue life in Table 5 are calculated with Eq. (27). A good description of the fatigue cycles is given by Eq. (27) from 3.46 × 104 cycles to 107 cycles for 2060-T8 Al-Li alloy and from 4.62 × 103 cycles to 107 cycles for 2024-T3 aluminum alloy. The correlation coefficient R2 is equal to 0.91 and 0.82, respectively. B. Comparison of the Fatigue Life Results Riveted lap joints are prepared to conduct the fatigue experiments with the dimensions of length L 230 mm and width W 60 mm. Tabs with dimensions of 60 × 60 × 2 mm are clamped on the ends of sheets to eliminate the second bending moment induced by the loading procedure. The geometry of the riveted lap joint used in fatigue experiments is presented in Fig. 7. Each specimen consists of three 2117-T4 aluminum alloy countersunk-type rivets and two 2.0-mm-thick sheets. The lap joint specimen is loaded in tension with an MTS Landmark fatigue machine. A sinusoidal load with a load ratio R 0.1 is used to test the specimens. A maximum remote stress of 77.11 MPa is applied. To reduce the frequency effect in the fatigue testing, a low frequency of 10 Hz is chosen. Four fatigue experiments of riveted specimens are conducted for each condition listed in Table 1, and the riveted specimens are denoted as replicate specimens A–D. The results of fatigue life of riveted lap joints are summarized in Table 5. 2 Tab 2 Replicate specimen D 200,469 165,279 129,176 241,423 258,287 Average value, cycles 184,389 161,557 109,906 189,559 224,731 Predicted result, cycles 210,311 150,075 83,321 175,512 262,984 Compared with the experimental data of the fatigue life, the agreement is appropriate for the fatigue life prediction with the residual stress model and the Marin criterion. The fatigue life results also confirm the effect of the height of the rivet drive head, the hole diameter, and the material property on the fatigue life of riveted joints. The increase of the fatigue cycles of specimens with the reduction of the height of the rivet drive head and the hole diameter can be attributed to the movement of the peak tensile stresses on the faying surface. However, the hole diameter shows a slight influence on the fatigue life due to the limited tolerance range of the rivet hole. The traditional 2024-T3 aluminum alloy has advantages to prolong the fatigue life of riveted joints, compared with the lightweight 2060-T8 Al-Li alloy, due to the reduction and the movement of the peak tensile residual stress on the faying surface. The residual stress is equivalent to the mean stress in the fatigue life prediction. The influence of residual stresses on the fatigue life can be investigated with this prediction method. It is beneficial to obtain the correlation between the riveting parameters and the fatigue life of riveted joints because the residual stress is tightly related to the riveting parameters. The prediction method can be used in the design stage of the riveted structure. VI. Conclusions The residual stress induced by the riveting process significantly influences the fatigue life of the riveted joints. A residual stress model is established to analyze the residual stress distribution around the rivet hole. This model is employed to investigate the effects of various parameters on the residual stress distribution. The fatigue life of riveted lap joints is predicted with the consideration of the residual stress and the applied load. In this paper, the following conclusions can be drawn. 1) The radial pressure between the hole and the rivet is solved where the plastic behavior of the rivet material is also considered. In the unloading process, the rivet hole is not free to spring back. Thus, a springback coefficient is defined to describe the springback degree of the rivet hole rather than employing the complete springback. 2) The residual stress model is employed to investigate the effects of parameters, such as the height of the rivet drive head, the hole diameter, and the sheet material property, on the residual stress distribution of the sheet faying surface. The decrease of the height of the rivet drive head and the hole diameter result in the peak tensile stress moving a short distance from the hole edge. The compressive residual stress in the traditional 2024-T3 aluminum sheets is larger than that in the lightweight 2060-T8 Al-Li alloy. 3) The residual stresses calculated by the residual stress model are used in the fatigue life prediction of riveted joints. The predicted results are in good agreement with the results obtained by the fatigue experiments. The prediction procedure can be used in the design stage of the riveted structure. Tab Acknowledgments a) Fig. 7 b) Fatigue testing and the specimen. The present study was supported by the National Basic Research Program of China (grant number 2014CB046600), the National Natural Science Foundation of China (grant number 51275292), and the Fund of National Engineering and Research Center for Commercial Aircraft Manufacturing, China (SAMC13-JS-15-026). 1438 ZHENG ET AL. Downloaded by SHANGHAI JIAO TONG UNIVERSITY on April 22, 2017 | http://arc.aiaa.org | DOI: 10.2514/1.C033715 References [1] Zhang, K. F., Yang, D. G., Li, Y., Cheng, H., and Zhang, J., “Deformation Analysis and Application of Automatic Riveting for Wing Panel,” Aeronautical Manufacturing Technology, Vol. 23, No. 1, 2010, pp. 67–72. doi:10.3969/j.issn.1671-833X.2010.23.012 [2] Rans, C. D., “The Role of Rivet Installation on the Fatigue Performance of Riveted Lap Joints,” Ph.D. Dissertation, Carleton Univ., Ottawa, ON, Canada, 2007. [3] Shishkin, S. S., “Computation of the Contact Load in a Rivet Bond,” Journal of Machinery Manufacture and Reliability, Vol. 39, No. 1, 2010, pp. 43–46. doi:10.3103/S1052618810010061 [4] Hsu, Y. C., and Forman, R. G., “Elastic-Plastic Analysis of an Infinite Sheet Having a Circular Hole Under Pressure,” Journal of Applied Mechanics, Vol. 42, No. 2, 1975, pp. 347–352. doi:10.1115/1.3423579 [5] Chang, J. B., “Prediction of Fatigue Crack Growth at Cold-Worked Fastener Holes,” Journal of Aircraft, Vol. 14, No. 9, 1977, pp. 903–908. doi:10.2514/3.58870 [6] Ball, D. L., “Elastic-Plastic Stress Analysis of Cold Expanded Fastener Holes,” Fatigue and Fracture of Engineering Materials and Structures, Vol. 18, No. 1, 1995, pp. 47–63. doi:10.1111/j.1460-2695.1995.tb00141.x [7] Park, J. H., and Atluri, S. N., “Fatigue Growth of Multi-Cracks near a Row of Fastener-Holes in a Fuselage Lap-Joint,” Computational Mechanics, Vol. 13, No. 3, 1993, pp. 189–203. doi:10.1007/BF00370135 [8] Li, G., Shi, G., and Bellinger, N. C., “Stress in Triple-Row Riveted Lap Joints Under the Influence of Specific Factors,” Journal of Aircraft, Vol. 48, No. 2, 2011, pp. 527–539. doi:10.2514/1.c031129 [9] Manes, A., Giglio, M., and Viganò, F., “Effect of Riveting Process Parameters on the Local Stress Field of a T-Joint,” International Journal of Mechanical Sciences, Vol. 53, No. 12, 2011, pp. 1039–1049. doi:10.1016/j.ijmecsci.2011.07.013 [10] Li, G., Shi, G., and Bellinger, N. C., “Studies of Residual Stress in Single-Row Countersunk Riveted Lap Joints,” Journal of Aircraft, Vol. 43, No. 3, 2006, pp. 592–599. doi:10.2514/1.18128 [11] Rans, C., Straznicky, P. V., and Alderliesten, R., “Riveting Process Induced Residual Stresses Around Solid Rivets in Mechanical Joints,” Journal of Aircraft, Vol. 44, No. 1, 2007, pp. 323–329. doi:10.2514/1.23684 [12] Aman, F., Cheraghi, S. H., Krishnan, K. K., and Lankarani, H., “Study of the Impact of Riveting Sequence, Rivet Pitch, and Gap Between Sheets on the Quality of Riveted Lap Joints Using Finite Element Method,” International Journal of Advanced Manufacturing Technology, Vol. 67, Nos. 1–4, 2012, pp. 545–562. doi:10.1007/s00170-012-4504-6 [13] Yoon, T. H., and Kim, S. J., “Refined Numerical Simulation of ThreeDimensional Riveting in Laminated Composites,” Journal of Aircraft, Vol. 48, No. 4, 2011, pp. 1434–1443. doi:10.2514/1.c031311 [14] Viganò, F., Manes, A., and Giglio, M., “Investigation on the Fatigue Life of an Al 8090 Helicopter Riveted T-Joint,” Journal of Aircraft, Vol. 48, No. 1, 2011, pp. 315–323. doi:10.2514/1.c031117 [15] Rans, C., Alderliesten, R., and Straznicky, P., “Assessing the Effects of Riveting Induced Residual Stresses on Fatigue Crack Behaviour in Lap Joints by Means of Fractography,” International Journal of Fatigue, Vol. 31, No. 2, 2009, pp. 300–308. doi:10.1016/j.ijfatigue.2008.08.005 View publication stats [16] Müller, R. P. G., “An Experimental and Analytical Investigation on the Fatigue Behaviour of Fuselage Riveted Lap Joints,” Ph.D. Dissertation, Delft Univ. of Technology, Delft, The Netherlands, 1995. [17] Skorupa, M., Skorupa, A., Machniewicz, T., and Korbel, A., “Effect of Production Variables on the Fatigue Behaviour of Riveted Lap Joints,” International Journal of Fatigue, Vol. 32, No. 7, 2010, pp. 996–1003. doi:10.1016/j.ijfatigue.2009.11.007 [18] Fung, C. P., and Smart, J., “Riveted Single Lap Joints. Part 2: Fatigue Life Prediction,” Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, Vol. 211, No. 2, 1997, pp. 123–128. doi:10.1243/0954410971532550 [19] Yu, H. Q., and Chen, J. D., The Theory of Metal Plastic Processing, China Machine Press, Beijing, 1999, pp. 186–187. [20] Luo, Z. J., The Theory and Technology of Metal Plastic Processing, Northwestern Polytechnical Univ. Press, Xi’an, PRC, 1994, pp. 89–92. [21] Dowling, N. E., Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture and Fatigue, 3rd ed., Prentice–Hall, Upper Saddle River, NJ, 2007, pp. 618–619. [22] Liang, Y. P., Wang, H. Z., and Ren, X. M., “Analytical Solution for Spatial Axisymmetric Problem of a Thick-Wall Cylinder Subjected to Both Ends Average Pressure and Axially Linear Distribution Pressure,” Science in China, Series G: Physics, Mechanics and Astronomy, Vol. 37, No. 5, 2007, pp. 684–688. doi:10.3969/j.issn.1674-7275.2007.05.014 [23] Wu, J. L., Elasticity, China Higher Education Press, Beijing, 2010, pp. 150–153. [24] Xu, B. Y., and Liu, X. S., Application of Elastic and Plastic Mechanics, Tsinghua Univ. Press, Beijing, 1995, pp. 201–202. [25] Yu, H. P., Deng, J. H., Li, C. F., Zhang, T. L., and Sun, L. Q., “Effects of Loading Rate on TA1 Rivet Deformation in Electromagnetic Riveting,” Journal of Harbin Engineering University, Vol. 32, No. 3, 2011, pp. 378–383. doi:10.3969/j.issn.1006-7043.2011.03.020 [26] Yuan, L., Aviation Manufacturing Engineering Handbook: Aircraft Assembly, 2nd ed., Aviation Industry Press, Beijing, 2010, pp. 1301–1302. [27] Skorupa, A., Skorupa, M., Machniewicz, T., and Korbel, A., “Fatigue Crack Location and Fatigue Life for Riveted Lap Joints in Aircraft Fuselage,” International Journal of Fatigue, Vol. 58, Jan. 2014, pp. 209–217. doi:10.1016/j.ijfatigue.2013.01.014 [28] Schijve, J., Fatigue of Structures and Materials, Springer, New York, 2009, p. 66. [29] Cathey, W. H., and Grandt, A. F., “Fracture Mechanics Consideration of Residual Stresses Introduced by Coldworking Fastener Holes,” Journal of Engineering Materials and Technology, Vol. 102, No. 1, 1980, pp. 85–91. doi:10.1115/1.3224790 [30] Clark, G., “Modelling Residual Stresses and Fatigue Crack Growth at Cold-Expanded Fastener Holes,” Fatigue and Fracture of Engineering Materials and Structures, Vol. 14, No. 5, 1991, pp. 579–589. doi:10.1111/j.1460-2695.1991.tb00684.x [31] Ball, D. L., and Lowry, D. R., “Experimental Investigation on the Effects of Cold Expansion of Fastener Holes,” Fatigue and Fracture of Engineering Materials and Structures, Vol. 21, No. 1, 1998, pp. 17–34. doi:10.1046/j.1460-2695.1998.00430.x [32] Marin, J., “Interpretation of Fatigue Strengths for Combined Stresses,” Proceedings of the International Conference on Fatigue of Metals, Inst. of Mechanical Engineers, London, 1956, pp. 184–194. [33] Suresh, S., Fatigue of Materials, Cambridge Univ. Press, Cambridge, England, U.K., 1991, pp. 246–248. [34] “Properties and Selection: Nonferrous Alloys and Special-Purpose Materials,” ASM Handbook, Vol. 2, ASM International, Materials Park, OH, 2009, p. 196.