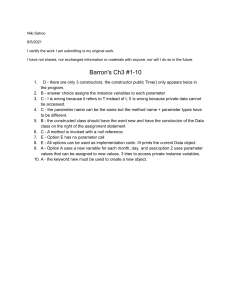

SIMOVERT Master Drives Common Rectifier Operating Instructions

advertisement