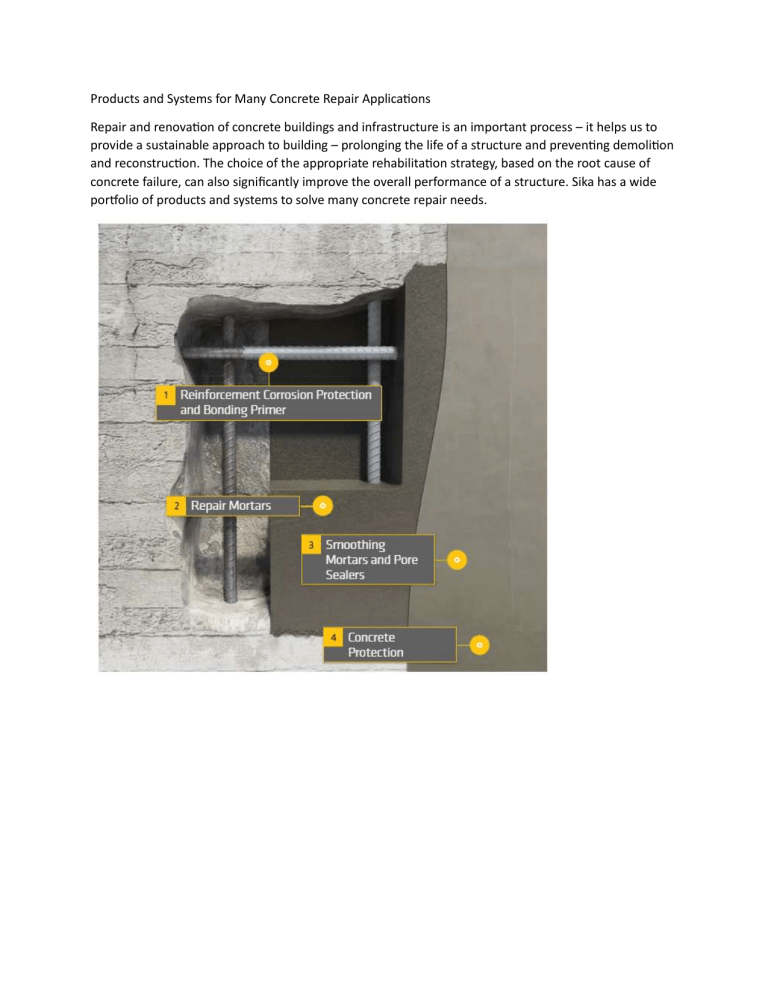

Products and Systems for Many Concrete Repair Applications Repair and renovation of concrete buildings and infrastructure is an important process – it helps us to provide a sustainable approach to building – prolonging the life of a structure and preventing demolition and reconstruction. The choice of the appropriate rehabilitation strategy, based on the root cause of concrete failure, can also significantly improve the overall performance of a structure. Sika has a wide portfolio of products and systems to solve many concrete repair needs. 1. Reinforcement Corrosion Protection and Bonding Primer Corrosion protection and bonding primers are used for bonding concrete repair mortars to existing cementitious or steel substrates and providing additional corrosion protection to reinforcement steel, especially in areas of low concrete cover and in the presence of chlorides. Exposed reinforcement steel bars should be properly prepared and protected with anti-corrosion slurry to further enhance the repair process. Advantages: Ready to mix, easy to apply Adjustable consistency Active corrosion inhibitors for added protection Can be sprayed or manually applied 2. Repair Mortars Repair mortars are specifically designed for restoring or replacing the original profile and function of the damaged concrete. They help to repair concrete defects, improve appearance, restore structural integrity, increase durability and extend the structure’s longevity. Sika concrete repair mortars are suitable for restoration work, repair of spalling and damaged concrete in all types of structures including buildings, bridges, infrastructure and super-structures. Advantages: Easy to mix and apply Pre-bagged for quality, just add water High mechanical properties Can be overcoated with Sika leveling mortars Can be sprayed or manually applied Pure cement-based, cementitious, polymer-modified and epoxy-based repair mortar materials available 3 Smoothing Mortars and Pore Sealers When concrete needs to be coated or levelled, special mortars are necessary to fill the surface pores. Sika pore fillers and leveling mortars are thin layer renders designed to repair minor defects, such as repairing pores and honeycombed concrete. Advantages Easy to mix and apply Pre-bagged for quality, just add water Can be overcoated with Sika protection coatings Can be sprayed or manually applied 4. Concrete Protection The most common causes of steel reinforcement corrosion in concrete are caused by carbonation or chloride ingress with water. Understanding the root cause of steel corrosion determines the most effective repair and protection strategy. Sika provides a full range of products to prevent further corrosion of steel reinforcement by properly protecting the concrete around it. Our corrosion management systems allow flexibility to select the most cost effective, suitable solutions for your project’s needs. Learn more about our concrete protection solutions. The restoration of damaged concrete is one of the most frequent interventions in the existing architectural heritage. Time, the impact of atmospheric agents and mechanical actions contribute to the degradation of buildings. They require a proper and recurrent maintenance. The range of solutions is made up of mortars for restoration, and skim coating. Mortars for restoration are used for the reconstruction of the damaged portions of concrete. There are two kinds of products: a thixotropic consistency, to be applied with a trowel or by machine, for localized or not application ; pourable grout, for greater thicknesses. Pourable mortars can be used for slubs of beams or pillars sections and structural reinforcement of slabs. The mechanical performance of the mortars are further elements of distinction. In fact mortars are classified (according to the UNI EN 1504-3) depending on of their compressive strengths, their adhesion to the substrate and their ability to withstand harsh climatic conditions. Classes range from R1 to R4 and indicate increasing performance. R1 and R2 are strength classes suitable for non-structural application. R3 and R4 are suitable for structural application. The lack of shrinkage is essential for all restoration mortars used in a few centimeter thicknesses, in order to avoid cracks which compromise the works. For this reason mortars known as "non-shrink mortars" for concrete repair are fiber-reinforced with synthetic fibers. Skim coating mortars In addition to the reconstruction of deteriorated concrete portions, it is also necessary to smooth and skim coat the surfaces. It works as a protective layer of concrete. For this they use smoothing mortars, equipped with an ultra-thin granulometry, which are applied in layers of a few millimeters and smoothed with a trowel, thus preparing the artifact to the application of subsequent coatings or finishes. In the case of smoothing mortars mechanical strengths are not fundamental, not being their use of a structural type. For these it is therefore favor of R1 or R2 resistance class mortar. Smoothing mortars with an ultra-thin granulometry are applied in layers of a few millimeters and smoothed with a trowel. In the case of smoothing mortars mechanical strengths are not essential, thay are not used for structural works. For these reasons R1 or R2 classes are the most suitable ones. Last finally known for mortars "all in one". This kind of solutions, thanks to fine particle size, but high mechanical allow through a single product to perform both the reconstruction that skim coating Often they can help you avoid the use of the passivating treatment, thanks to the presence of corrosion inhibitors contained in the formulation. https://www.uk.weber/blog/choosing-right-products/how-choose-right-patch-repair-mortar https://www.chemcosystems.com/tech_faqs.php Unimix SF Unimix UW Unimix RM Skim up to 10 mm Joint up to 50 mm Joint up to 100 mm U-Fix AC 40 Epoxy Putty Fine Epoxy Putty Medium Up t0 3 mm Up to 10 mm Up to 15 mm