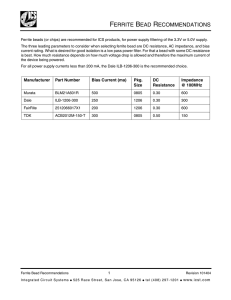

Journal of Mechanical Science and Technology 31 (3) (2017) 1341~1347 www.springerlink.com/content/1738-494x(Print)/1976-3824(Online) DOI 10.1007/s12206-017-0234-x Effect of process parameters on ferrite number in cladding of 317L stainless steel by pulsed MIG welding† R. Prabhu1,* and T. Alwarsamy2 1 Sri Chandrasekharendra Saraswathi Viswa Maha Vidyalaya University, Enathur, Kancheepuram, 631561, Tamil Nadu, India 2 Government College of Technology, Coimbatore-13, Tamil Nadu, India (Manuscript Received May 27, 2015; Revised March 15, 2016; Accepted October 26, 2016) ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- Abstract In the current scenario cladding process are used in many engineering industries to enhance the corrosion resistance surface and wear resistance of the base material in chloride environment. Cladding of stainless steel results in formation of ferrite number content on cladded surface, which deleterious the material properties. The present investigation address the effect of process parameters on ferrite number during austenitic stainless steel 317L cladding by Pulsed Metal inert gas (MIG) welding process. Ferrite number was measured by using Fisher’s ferrite scope. Response surface methodology (RSM) based central composite rotatable design were approached to predict and develop the mathematical model for process parameters such as welding current, welding speed and contact tip to work distance on ferrite number. From the analysis of variance technique it is found that the developed mathematical model was significant. The developed mathematical model is useful to control and determine the ferrite number content in austenitic stainless steel cladding. The direct and interaction effects of input process parameters are presented graphically. Keywords: Ferrite number; Pulse cladding; Prediction; Response surface methodology; Stainless steel ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- 1. Introduction Austenitic stainless steels are widely used in a variety of product forms for architectural consumer and industrial application because of their excellent corrosion and oxidant resistance however these are susceptible to corrosion during welding [1]. Corrosion is a problem which dwindles the steel structure leads to failure. Though it cannot be eradicated it can be reduced to certain extent. Corrosion resistance protective layer is formed over the base metal by a process called weld cladding [2]. The microstructure of austenitic stainless steel shows a delta ferrite phase during cladding generally, delta ferrite phase leads to decremented effect on corrosion resistance [3]. Among fusion welding process pulsed metal inert gas welding has been widely used for cladding austenitic stainless steel due to several advantages like easy to control the process parameters, to produce good bead dimensions, minimising the percentage of dilution, less spatter, fumes and high metal deposition rate [4, 5]. To obtain the better quality welds, it is necessary to have a full control over the relevant process parameters to get the required bead geometry dimensions [6, 7]. * Corresponding author. Tel.: +91 9488458583 E-mail address: prabhu9495@gmail.com † Recommended by Associate Editor Young Whan Park © KSME & Springer 2017 Amos Robert et al. [8] investigated the behaviour of process parameters during stainless steel cladding they concluded that stand of distance is the dominant parameter to decide the bead appearance than with diffusion temperature and welding speed. Palani and Murugan [9] carried out the optimisation study of weld bead geometry for stainless steel cladding deposited by Flux cored arc welding. They found that percentage of dilution increases the pitting corrosion which is initiated by presence of ferrite content during cladding. Rho et al. [10] studied the effects of delta ferrite content on the 304L stainless steel during continuous low-cycle fatigue test with different temperatures. They concluded that the fatigue crack was initiated by delta ferrite on the surface. Sudhakaran et al. [11] investigated the effect of process parameters on ferrite content of 202 grade stainless steel using response surface methodology in gas tungsten arc welding process in that they used Delong diagram and ferrite scope to measure the ferrite number. Lia et al. [12] focused on the formation and microstructural evolution of delta ferrite phase in SAVE12 steel. Further they demonstrated that the formation of delta ferrite was due to the high content of ferrite forming alloy elements. Corrosion resistance of the base material is mainly depends on the chemical composition of filler material during cladding. The more amount of the ferrite number results in poor mate- 1342 R. Prabhu and T. Alwarsamy / Journal of Mechanical Science and Technology 31 (3) (2017) 1341~1347 rial property. Hence it is very important to obtain the optimal number of ferrite number during cladding [13]. In this row Kannan and Murugan [14] predicted the ferrite number of duplex stainless steel cladded metals by using response surface methodology. The mathematical models were developed to predict the delta ferrite content during cladding of austenitic stainless steel and duplex stainless steel using response surface methodology [15, 16]. Vasudevan et al. [17] used Bayesian neural network to develop the mathematical for the prediction of delta ferrite content in stainless steel weld. Rao et al. [18] studied the effect of process parameters on bead geometry during pulsed gas metal arc welding using Taguchi method. Mathematic models were developed using multiple regression analysis and validated the adequacy. Further it was found that predicted models for the responses are within reasonable accuracy. Pal et al. [19] made a study on optimization of process parameters for quality characteristic by using grey-based Taguchi method. It was found that the process parameter has more influence on quality characteristic by ANOVA. Response surface methodology based central composite rotatable design in design expert software technique is mostly used for developing the experimental design matrix. It is the simplest method for developing a mathematical model and correlate relationship between process parameters and response. It is useful to discuss the main effect and interaction effects [2022]. The above literatures clearly show that identifying and selecting the process parameters for the cladding process is challenging one for many research works. However response surface methodology based central composite rotatable design technique was used by various researchers for developing mathematical model and analysing the process parameters. Hence the study related to prediction of ferrite number in Pulsed MIG welding was not that much discussed. There was various attempts have been made to develop the mathematical model for prediction of ferrite number by using nickel and chromium alloy composition. It was found that very few works was discussed about prediction of ferrite number based on process parameters. In this present investigation, the effects of process parameters on ferrite number in Pulsed MIG welding during 317L solid stainless steel wire cladded on structural steel plate IS: 2062 was studied by following approach. By conducting the weld cladding of 317L austenitic stainless steel onto structural steel IS: 2062. Preparing the specimen as per metallurgical procedure and ferrite number was measured by using Fishers ferrite scope. By developing the quadratic polynomial equation and analysing their effects. Table 1. Chemical composition of base material and filler wire (Weight percent). Materials Base material Filler wire C Si Mn P S Cr Ni Cu Mo Fe 0.23 0.31 0.93 0.05 0.02 - - - - 98.46 0.03 0.65 2.5 0.04 0.03 20 15 0.75 4 57 Table 2. Process variables and experimental levels. Process Symbols parameters Levels -1.682 -1 0 +1 +1.682 I 190 200 215 230 240 Welding speed S 170 180 195 210 220 Contact tip to work distance N 17 18 20 21 22 Welding current solid wire of diameter 1.2 mm was used as filler wire and low carbon structural steel IS: 2062 of 20 mm thickness plate was used as base material. The chemical composition of the base material and filler wire are shown in Table 1. 2.2 Experimental methods There are various methods to conduct the experiments such as Taguchi method [19], grey relational analysis, orthogonal array, full factorial design [20], and artificial intelligence [17], face centered composite design and central composite rotatable design [11, 22]. Response surface methodology based central composite rotatable design technique was used to design the experimental matrix to perform the experiments. This design is generally used by maximum number of researchers for obtaining minimum number of experimental runs with good accuracy and developing the second order polynomial regression equation [11, 15]. Based on the literature analysis, the three factors are considered for this present investigation such as welding current (I), welding speed (S) and contact tip to work distance (N). Bead-on-plate type welding were performed with changing the process parameters values and examine the appearance of the bead process parameters levels are selected for this investigation, their upper limits and lower limits of each process parameters are fixed respectively. The upper limits and lower limits of a process parameters was coded as +1.682 and -1.682 respectively, the coded values of the intermediate levels being calculated from the Eq. (1) shown in Table 2 [9]. (1) 2. Experimentation 2.1 Experimental materials In this investigation austenitic stainless steel AISI 317L of where Xi is the required coded value of a variable X, X is any value of the variable from X min to X max, X min is the lower 1343 R. Prabhu and T. Alwarsamy / Journal of Mechanical Science and Technology 31 (3) (2017) 1341~1347 Table 3. Design matrix and ferrite number values. Fig. 1. Typical view of cladded specimen. Fig. 2. Mirror finished specimens for ferrite number measurement. level of the variable, X max is the highest level of the variable the first 8 conditions were derived from factorial experimental design matrix (23 = 8). All the variables at an intermediate level of 0 constitute the 6 center point while, the combination of each process variable between a lower level of −1.682 and a higher level of +1.682 with the other four variables at the intermediate levels constitute the 6 star points totally 20 runs are there [9, 22]. 2.3 Experimental procedure for cladding The deposition was performed as per the design matrix by using Lincoln power wave 455 Pulsed MIG welding machine. A programmable logic controlled manipulator was used to set and control the welding speed uniformly for each run. The contact tip to work distance is also adjusted with help of the manipulator and position of the torch is exactly maintained at 90° throughout the experiments. Base material was prepared as per the required dimensions such as 300 x 200 x 20 mm form structural steel plate IS: 2062. Top surface of the base material was cleaned with steel wire brush and emery sheets to free it from dirt and rust layer. A gas mixture of Argon and Carbon dioxide (95 % and 5 %) are supplied throughout the experiments at the flow rate of 20 lit/min as shielding gas. The base material, filler material and dimensions of the specimen is indicated in Fig 1, weld cladded mirror finished cladded specimens are shown in Fig. 2. 2.4 Experimental procedure for specimen preparation and ferrite number measurement The cladded plates are cross-sectioned at the midpoint to prepare the test specimen, the top surface of the specimens are grounded as flat surface without disturbing the bead geometry Trails Avg FN values Std exp Run exp I 1 3 -1 -1 -1 0.8 0.84 0.81 0.82 0.83 0.82 2 8 1 -1 -1 0.86 0.88 0.87 0.89 0.9 0.88 3 5 -1 1 -1 0.64 0.63 0.52 0.6 0.61 0.6 4 20 1 1 -1 0.57 0.58 0.62 0.61 0.57 0.59 5 6 -1 -1 1 0.56 0.58 0.6 0.61 0.55 0.58 6 7 1 -1 1 0.84 0.8 0.82 0.78 0.81 0.81 7 9 -1 1 1 0.62 0.6 0.59 0.65 0.64 0.62 8 10 1 1 1 0.81 0.84 0.83 0.82 0.85 0.83 9 11 -1.682 0 0 0.73 0.75 0.77 0.74 0.71 0.74 10 4 1.682 0 0 0.97 0.99 0.92 1.04 0.98 0.98 11 2 0 -1.682 0 0.73 0.74 0.75 0.72 0.71 0.73 12 15 0 1.682 0 0.54 0.54 0.52 0.6 0.55 0.55 13 14 0 0 -1.682 0.52 0.54 0.51 0.58 0.55 0.54 14 17 0 0 1.682 0.59 0.6 0.58 0.57 0.61 0.59 15 1 0 0 0 16 13 0 0 17 18 0 0 18 12 0 19 16 20 19 S N 1 2 3 4 5 0.58 0.54 0.52 0.6 0.55 0.56 0 0.5 0.54 0.52 0.6 0.55 0.55 0 0.57 0.59 0.6 0.61 0.55 0.58 0 0 0.6 0.58 0.59 0.55 0.53 0.57 0 0 0 0.57 0.59 0.6 0.61 0.55 0.58 0 0 0 0.58 0.54 0.52 0.6 0.55 0.56 and surface texture [11, 13]. It was then polished with etching solution and made as mirror finish by following metallurgical procedure [12]. Fischer FERRITESCOPE_MP30 were used to measure the ferrite number on cladded specimen [9, 11, 13, 14], measurement ranges from 0.1 to 110 ferrite number or 0.1 to 80 % ferrite in austenitic and duplex stainless steel. A schematic arrangement of ferrite scope and specimen are shown in Fig. 3. Before measuring the ferrite number the instrument has to be calibrated according to existing prepared specimen and ferrite form by comparing with ANSI/AWS A4.2M/A4.2: 1997 [11, 16] standard specimen. The values are measured on the prepared surface of the 20 specimens and in each specimen there are five values are measured along the axis of the deposition and averages of these measured values are tabulated in Table 3. 2.5 Development of mathematical model Ferrite number (Y) of cladded stainless steel is the response function of process parameters such as welding current, welding speed and contact tip to work distance can be expressed by Eq. (2) [20-22]. Y = (I, S, N) where Y : The response function, I : The welding current amps, (2) 1344 R. Prabhu and T. Alwarsamy / Journal of Mechanical Science and Technology 31 (3) (2017) 1341~1347 Table 4. Calculated β coefficients values for ferrite number model. Table 5. ANOVA table for ferrite number. Process parameters Polynominal coefficients Coefficients values Constant β0 47.5088 Source SS DoF MS F value p-value Prob > F I β1 -0.2332 Model 0.33219 9 0.03691 119.279 < 0.0001 Significant S β2 -0.1058 I 0.05847 1 0.05847 188.969 < 0.0001 0.04149 1 0.04149 134.074 < 0.0001 1.5E-08 1 1.5E-08 4.9E-05 0.9946 N Β3 -1.1966 S IxS β12 -5E-05 N IxN β13 0.0022 IS 0.00101 1 0.00101 3.27205 0.1006 0.01901 1 0.01901 61.4419 < 0.0001 0.04061 1 0.04061 131.246 < 0.0001 SxN β23 0.0032 IN IxI β11 0.00048 SN SxS β 22 NxN β 33 2 0.00013 I 0.16591 1 0.16591 536.167 < 0.0001 0.0029 S2 0.01255 1 0.01255 40.5703 < 0.0001 N2 0.00062 1 0.00062 1.98823 0.1889 Residual 0.00309 10 0.00031 Lack of fit 0.00236 5 0.00047 3.21962 0.1126 Pure error 0.00073 5 0.00015 Cor total 0.33528 19 Not significant Eq. (4). Ferrite number = + 47.5088 - 0.2332 * I -0.1058 * S - 1.1966 * N -5E-05* I * S + 0.00217 * I * N + 0.00317 * S* N + 0.00048 * I2 + 0.00013 * S2 + 0.0029 * N2. Fig. 3. Schematic arrangement of ferrite scope and specimen. S : The welding speed mm/min and N : The contact tip to work distance mm. 3.1 Validation of developed mathematical model Relationship between the response and the process variable are unknown. In order to study the main effect and interaction of the process parameters a second order polynomial response surface can be fitted into the following Eq. (3) [21, 22]. k k y = b 0 + å b i xi + å b ii xi2 + åå b ij xi x j + e i =1 i =1 i (4) (3) j i≠j where βo is the free term of the regression equation. The coefficients of β1, β2 and β3 are linear terms. The coefficients of β11, β22 and β33 are the quadratic terms. The coefficients of β12, β13 and β23 are the interaction terms. 2.6 Calculating the coefficients of the models The values of the β coefficients in the second order polynomial equation are calculated by using design expert software and coefficients values are tabulated in Table 4. 3. Development of final mathematical model The final mathematical model in actual variable form are determined by following above procedure and represented as From the above mathematical model, the effects of process parameters on ferrite number were examined. The Eq. (4) it is clear that the positive values of the polynomial coefficients increases and negative values decreases the response. Analysis of variance technique was further used to validate the adequacy of the developed mathematical model. The F-value of 119.28 implies the model is significant at 95 % of confident level. To check the goodness of the fitted model the coefficient of determination R2 and adjusted coefficient of determination R2 are calculated. The value of calculated R2 should lie on 0-1 accordingly R2 is 0.99 it is very closer to 1 indicated that the developed model is good. Adjusted coefficient of determination R2 is 0.98 which is high nearer to coefficient of determination R2 0.9908 agrees that model is adequate it was shown in Table 5. The coefficient of variation and adequate precision ratio are found 2.65 and 33.986, respectively. The coefficient of variation is less than 5 and adequate precision ratio is greater than 4. 3.2 Scatter diagram Further the validity of developed regression models are validated by constructing scatter diagram. A typical scatter diagram for the ferrite number was shown in Fig. 4. The scatter diagram shows that the predicated values and measured R. Prabhu and T. Alwarsamy / Journal of Mechanical Science and Technology 31 (3) (2017) 1341~1347 1345 Table 6. Conformation test parameters. Welding speed Contact tip Predicated Measured to work Error % FN FN distance No Welding current 1 212.55 202.7 19.46 0.53791 0.55138 2.50413 2 207.89 198.02 20.15 0.54783 0.56771 3.62886 3 209.83 201.08 18.91 0.53662 0.53210 0.84231 4 217.53 205.16 18.93 0.53467 0.54961 2.79424 Fig. 5. Effect of welding current on Ferrite number. Fig. 4. Normal probability of residuals for Ferrite number. values of ferrite number are very closer to each other which indicating the developed regression model an almost perfect fit [12, 15, 16]. Fig. 6. Effect of welding speed on Ferrite number. 4. Conformation test The conformation test was conducted to evaluate the developed polynomial equation Eq. (4). The three conformation test run were conducted with different combination of process parameters predicted from software. The ferrite number was measured and differences in predicted and measured values are calculated by using error calculation equation Eq. (5). The values are tabulated in Table 6. % Error = Measured value - Predicted value * 100 . Predicted value (5) 5. Results and discussion RSM based central composite rotatable design was used to develop the mathematical model and predict the effect of process parameters in this investigation. The direct effect and interaction effects of process parameters on ferrite number are presented graphically in Figs. 5-7. 5.1 Effect of welding current on Ferrite number Fig. 5 shows that an increase in welding current decrease the ferrite number up to the mid value of the welding current level, thereafter there is sudden increase in ferrite number. This is mainly attributed to the fact that at higher current level the heat input to the base metal is higher which increases the ferrite number. Fig. 7. Effect of contact tip to work distance on Ferrite number. 5.2 Effect of welding speed on ferrite number In Fig. 6, it is clear that there is continuous decrease in ferrite number along with all the levels of welding speed, hence when welding speed increases the deposition of the filler material also decreases thus results in reducing the ferrite content. 5.3 Effect of contact tip to work distance on ferrite number The direct effect of contact tip to work distance on ferrite number was shown in Fig. 7. It does not affect the response in any levels which shows that it is an insignificant factor for ferrite number measurement.22. 5.4 Interaction effect of welding current and welding speed on ferrite number The interaction effects of welding current and welding 1346 R. Prabhu and T. Alwarsamy / Journal of Mechanical Science and Technology 31 (3) (2017) 1341~1347 considering the contact tip to work distance. 6. Conclusion Fig. 8. 3D Surface plot showing an interaction effect of welding current and welding speed on ferrite number. ·A five-level, three factor design matrix based on central composite rotatable design approach was used for the development of mathematical models to predict the ferrite number for cladding of austenitic stainless steel 317L deposited using pulsed MIG welding process. ·The predicted values using developed model as well as experimental values are closer to each other. ·Welding current and welding speed are the most significant factor in prediction of ferrite number than with the contact tip to work distance. ·The significant factors are identified by ANOVA. The model values are adequate with 95 % of confidence level. ·Ferrite number decreases constantly with the increase in welding speed due to the reduced deposition of filler material over the base metal. However, the ferrite number increases with the increase in welding current. Nomenclature------------------------------------------------------------------------ Fig. 9. 3D Surface plot showing an interaction effects of Welding speed and contact tip to work distance on Ferrite number. speed on ferrite number are shown in Fig. 8. It is clear that at lower level of the welding current with lower level of welding speed the ferrite number was considerably at mid value of the graph. But when the welding current increases there are downstream and rapid upstream in ferrite number was observed. However, when the welding current increases, the melting rate and deposition rate of filler material also increases. The weld pool which gives enough of time for ferrous material to dominate alloying element by diffusion and the ferrous materials occupies top surfaces of the cladded surface to increase ferrite content. On the other hand it was noticed that welding speed also plays an important role to control the ferrite number by increasing their levels. 5.5 Interaction effect of welding speed and contact tip to work distance on ferrite number It is evident that the ferrite number was drastically decreases with increase in welding speed as compared to welding speed (Fig. 9). Because at low levels of welding speed the axial or longitudinal movement of the nozzle is very slow at the same time the contact tip to work distance is also at lower level as it is close to the base material. Hence both the values are at low level, the cushioning effect of the weld zone increases the penetration of the filler material. The increase in penetration causes increases in ferrite number. But when welding speed increases there in no cushioning on the weld zone which drastically decreases the ferrite number without I S N FN SS DoF : Welding current : Welding speed : Contact tip to work distance : Ferrite number : Sum of squares : Degree of freedom References [1] G. Sasikala, S. K. Ray and S. L. Mannan, Kinetics of transformation of delta ferrite during creep in a type 316(N) stainless steel weld metal, Materials and Engineering, A359 (2003) 86-90. [2] T. Kannan and Y. Yoganandh, Effect of process parameters on clad bead geometry and its shape relationships of stainless steel claddings deposited by GMAW, International Journal of Advanced Manufacturing Technology, 47 (2010) 1083-1095. [3] S. H. Kim, H. K. Moon, T. Kang and C. S. Lee, Disssolution kinetics of delta ferrite in AISI 304stainless steel produced by strip casting process, Materials Science and Engineering, A356 (2003) 390-398. [4] K. Pal, S. Bhattacharya and S. K. Pal, Prediction of metal deposition from arc sound and weld temperature signatures in pulsed MIG welding, International Journal of Advanced Manufacturing Technology, 45 (2009) 1113-1130. [5] K. Pal, S. Bhattacharya and S. K. Pal, Multisensorbased monitoring of weld deposition and plate distortion for various torch angles in pulsed MIG welding, International Journal of Advanced Manufacturing Technology, 50 (2010) 543556. [6] P. K. Palani and N. Murugan, A review - Selection of pa- R. Prabhu and T. Alwarsamy / Journal of Mechanical Science and Technology 31 (3) (2017) 1341~1347 rameters of pulsed current gas metal arc welding, Journal of Material Processing Technology, 172 (2006) 1-10. [7] S. C. Juang and Y. S. Tarng, Process parameter selection for optimizing the weld pool geometry in the tungsten inert gas welding of stainless steel, Journal of Material Processing Technology, 122 (2002) 33-37. [8] J. Amos Robert and N. Murugan, Investigations on the influence of surfacing process parameters over bead properties during stainless steel cladding, Materials and Manufacturing Processes, 27 (2012) 69-77. [9] P. K. Palani and N. Murugan, Prediction of delta ferrite content and effect of welding process parameters in claddings by FCAW, Materials and Manufacturing Process, 21 (2006) 431-438. [10] B. S. Rho, H. U. Hong and S. W. Nam, The effect of δferrite on fatigue cracks in 304L steels, International Journal of Fatigue, 22 (2000) 683-690. [11] R. Sudhakaran, V. V. Murugan, P. S. Sivasakthivel and M. Balaji, Modeling and analysis of ferrite number of stainless steel gas tungsten arc welded plates using response surface methodology, International Journal of Advanced Manufacturing Technology, 64 (2013) 1487-1504. [12] S. Lia, Z. Eliniyaza, L. Zhanga, F. Suna, Y. Shenb and A. Shana, Microstructural evolution of delta ferrite in SAVE12 steel under heat treatment and short-term creep, Material Characterization, 73 (2013)144-152. [13] R. Puli and G. D. J. Ram, Corrosion performance of AISI 316L friction surfaced coatings, Corrosion Science, 62 (2012) 95-103. [14] T. Kannan and N. Murugan, Prediction of ferrite number of duplex stainless steel clad metals using RSM, Welding Journal (AWS), 84 (2005) 91s-100s. [15] P. K. Palani and N. Murugan, Optimization of weld bead geometry for stainless steel claddings deposited by FCAW, Journal of Materials Processing Technology, 190 (2007) 291-299. [16] A. Eghlimi, M. Shamanian and K. Raeissi, Dilution and ferrite number prediction in pulsed current cladding of super-duplex stainless steel using RSM, Journal of Materials Engineering and Performance, 22 (2013) 3657- 3664. [17] M. Vasudevan, A. K. Bhaduri, B. Raj and K. P. Rao, Delta ferrite prediction in stainless steel welds using neural net- 1347 work analysis and comparison with other prediction methods, Journal of Material Processing Technology, 142 (2003) 2028. [18] P. S. Rao, O. P. Gupta, S. S. N. Murty and A. K. K. Rao, Effect of process parameters and mathematical model for the prediction of bead geometry in pulsed GMA welding, International Journal of Advanced Manufacturing Technology, 45 (2009) 496-505. [19] S. Pal, S. K. Malviya, S. K. Pal and A. K. Samantaray, Optimization of quality characteristics parameters in a Pulsed MIG weldingprocess using grey-based Taguchi method, International Journal of Advanced Manufacturing Technology, 44 (2009) 1250-1260. [20] J. P. Ganjigatti, D. K. Pratihar and A. R. Choudhury, Modeling of the MIG welding process using statistical approaches, International Journal of Advanced Manufacturing Technology, 35 (2008) 1166-1190. [21] S. Datta, A. Bandyopadhyay and P. K. Pal, Modeling and optimization of features of bead geometry including percentage dilution in submerged arc welding using mixture of fresh flux and fused slag, International Journal of Advanced Manufacturing Technology, 36 (2008) 1080-1090. [22] P. K. Giridharan and N. Murugan, Optimization of pulsed GTA welding process parameters for the welding of AISI 304L stainless steel sheets, International Journal of Advanced Manufacturing Technology, 40 (2009) 478-489. R. Prabhu graduated in Mechanical Engineering from Anna University, Chennai, India in 2005 and received his Masters in Manufacturing Engineering from Anna University, Coimbatore, India in 2009. He is currently an Assistant Professor in the Department of Mechanical Engineering in Sri Chandrasekharendra Saraswathi Viswa Maha Vidyalaya University Kanchipuram, India. His research is in welding of dissimilar metals stainless steel and low carbon steel, corrosion analysis, wear behavior of cladded surface study and currently extending his knowledge by undergoing Ph.D. studies in pulsed MIG welding.